Reciprocating type coring method and device for rock stratum sampling

A coring device and reciprocating technology, applied in the direction of extracting undisturbed cores, earthwork drilling, etc., can solve the problems of reduced coring accuracy, low coring efficiency, and reduced coring quality, so as to improve the quality of coring and improve Effect of improving coring efficiency and coring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A reciprocating coring method for rock formation sampling, specifically comprising the following steps:

[0018] 1) Drill the hollow drill pipe with the coring chamber fixed at the front end according to the predetermined drilling path. When the drilling depth reaches the coring length, stop drilling and the core enters the coring chamber;

[0019] 2) The hollow drill pipe is fixed, and the coring chamber is taken out along the inner hole of the hollow drill pipe, and then the core is taken out of the core chamber;

[0020] 3) Push the coring chamber into the front end of the hollow drill pipe along the inner hole of the hollow drill pipe and fix it, and then drill and coring according to the predetermined drilling path again;

[0021] 4) Repeat step 1) to step 3) until the total drilling depth reaches the predetermined depth.

Embodiment 2

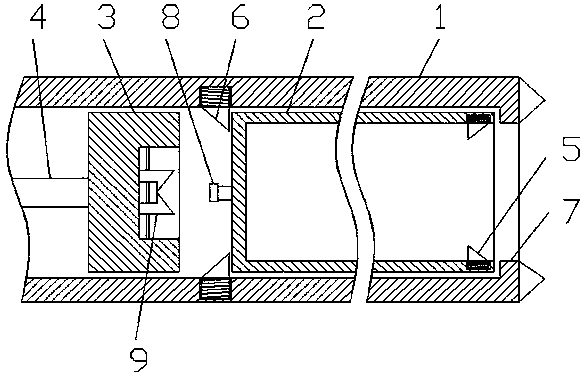

[0023] like figure 1 As shown, a reciprocating coring device for rock formation sampling includes a hollow drill rod 1, a coring bin 2 and a coring rod 4; the coring bin 2 is a cylinder with an open end, and the outer diameter of the cylinder is the same as the hollow The inner diameter of the drill pipe 1 matches; the front end of the inner wall of the hollow drill pipe 1 is provided with a front limit 7 for fixing the coring chamber 2 and a rear limit 6 for the coring chamber, and a front limit 7 for the coring chamber. In order to fix the limit, the limit 6 behind the coring chamber is a one-way limit set along the rear; the coring rod 4 is a hard drill rod, and the front end of the coring rod 4 is provided with a detachable connector 3, The connecting head 3 is used to drive the rear limiter 6 of the coring chamber and is connected with the coring chamber 2 .

[0024] The front end of the inner side wall of the coring chamber 2 is provided with a core limiter 5, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com