Hydraulic rock core lifting device for exploratory boring

A core and hydraulic technology, applied in the field of core clamping devices, can solve the problems of low construction efficiency, affecting the stability of the hole wall, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

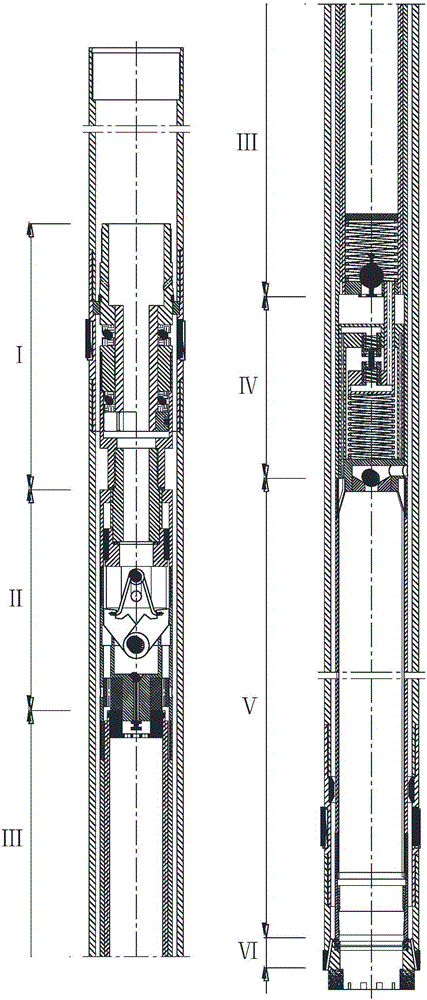

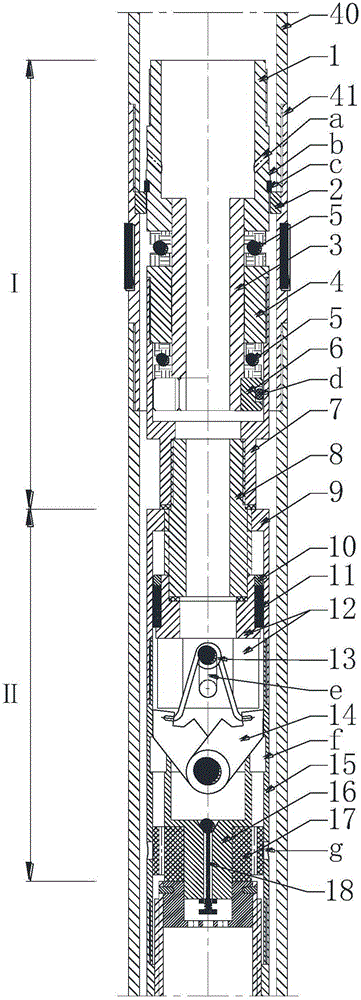

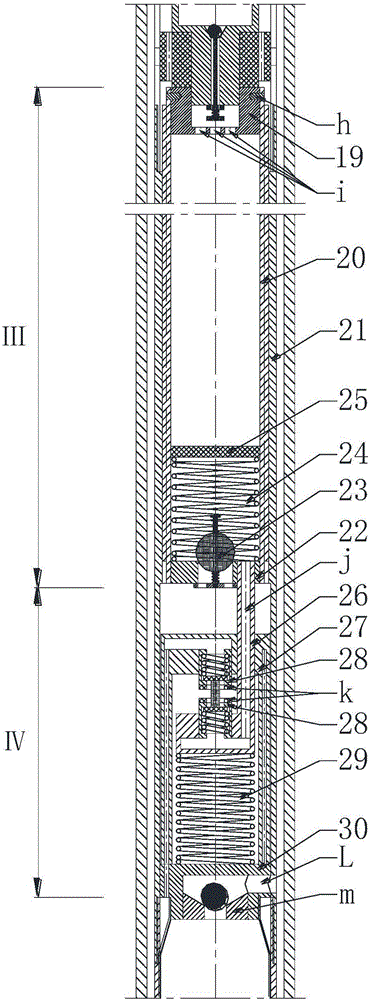

[0047] In this embodiment, the hydraulic core clamping device for drilling, such as figure 1 and Figure 4As shown, the hydraulic core clamping device for drilling is characterized in that it includes a water-separating mechanism I, a diversion limit mechanism II, a pressure storage mechanism III, a lifting and injection pressure mechanism IV, a hydraulic core mechanism V, and a side spray drill bit. The transfer mechanism Ⅵ and the sealing system, the diversion limit mechanism Ⅱ is connected to the water separation mechanism Ⅰ, the pressure storage mechanism Ⅲ is connected to the flow diversion limit mechanism Ⅱ, the lifting and injection pressure mechanism Ⅳ is connected to the pressure storage mechanism Ⅲ, and the hydraulic clamping mechanism Ⅴ Docking lifting injection pressure mechanism Ⅳ, side injection drill head transfer mechanism Ⅵ docking hydraulic clamping mechanism Ⅴ;

[0048] The hydraulic clamp mechanism V includes a bottom bearing platform 30, a hydraulic membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com