Concrete drilling and coring machine

A technology for drilling coring and concrete, which is applied in earthwork drilling, drilling equipment, and undisturbed core extraction devices, etc. It can solve the problems of affecting the drilling effect, the stability of the drilling coring machine, affecting the efficiency of coring, and the cumbersome process of coring and other issues to achieve the effect of improving work stability, reducing labor intensity and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

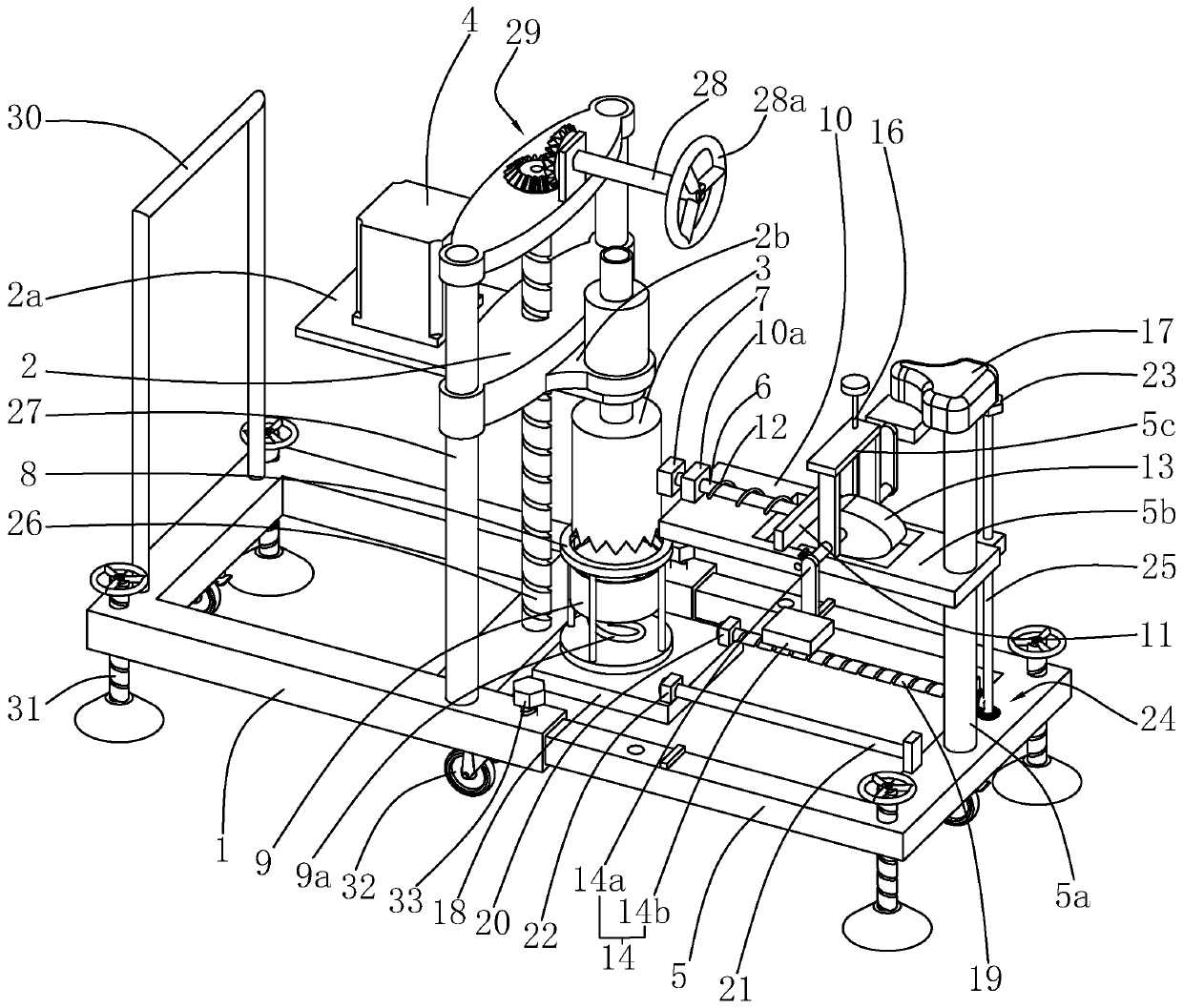

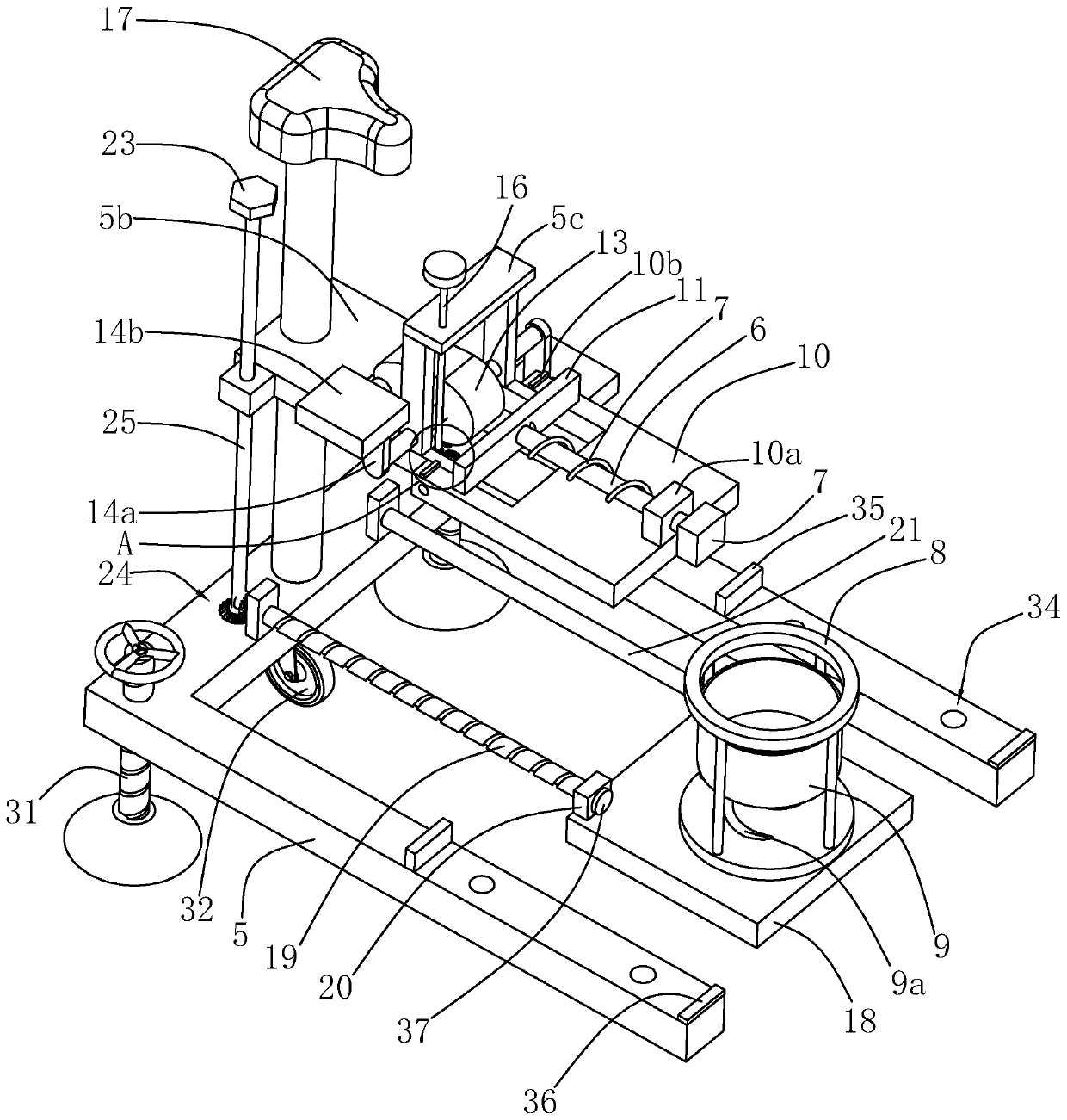

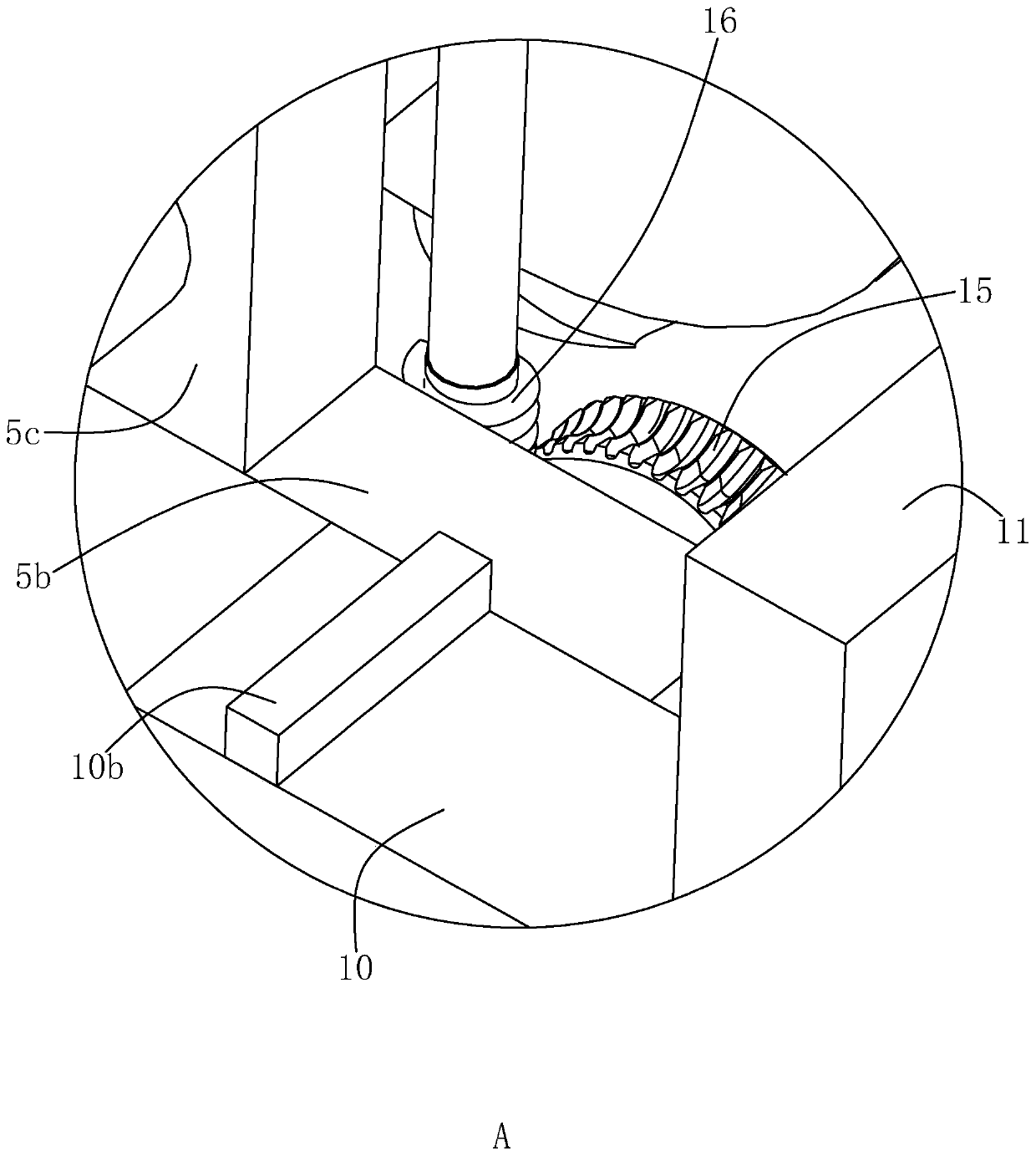

[0035] refer to figure 1 , is a concrete drilling and coring machine disclosed by the present invention, comprising a frame 1, a lifting frame 2, a coring bit 3, a sliding frame 5, a counterweight mechanism and a coring mechanism, wherein the frame 1 is similar to a rectangular frame shape, and the two sides of the width direction of the upper end surface of the frame 1 are fixedly installed with two cylindrical elevating slide bars 27 along the vertical direction; the elevating frame 2 is located above the frame 1, and the elevating frame 2 slides along the vertical direction Move and install between two lifting slide bars 27, meanwhile, frame 1 is equipped with a lifting mechanism for driving lifting frame 2 to move vertically, specifically, lifting mechanism includes lifting screw rod 26 and driving shaft 28.

[0036] Wherein, the lifting screw rod 26 rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com