Drilling and coring device for early-age concrete

A concrete and early-age technology, which is applied in the field of drilling and coring devices for early-age concrete, can solve the problems of low success rate, broken cores, missing corners, and slow one-way coring efficiency, etc. Effect of large chip removal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

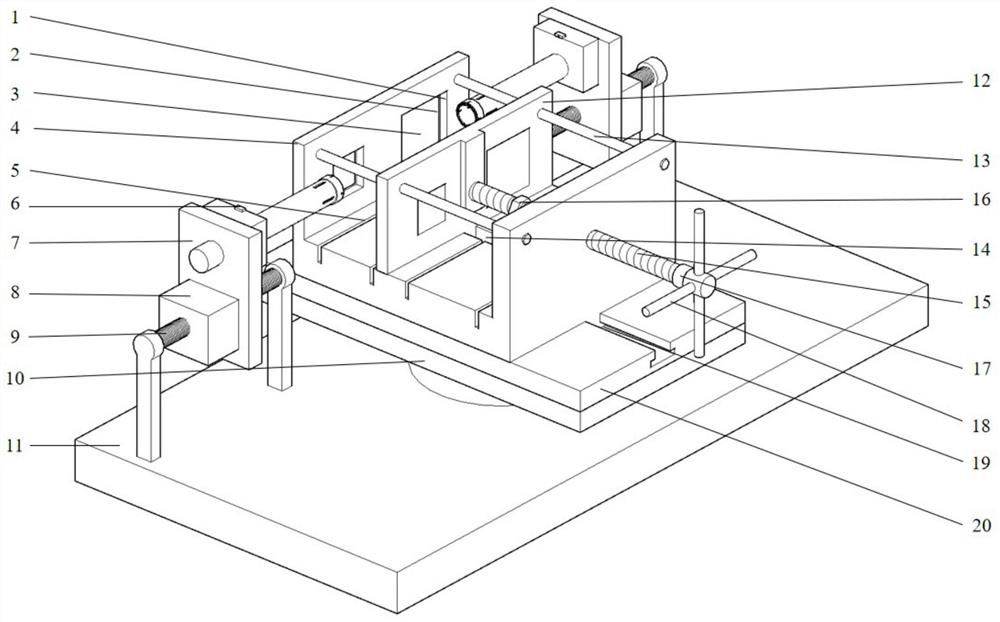

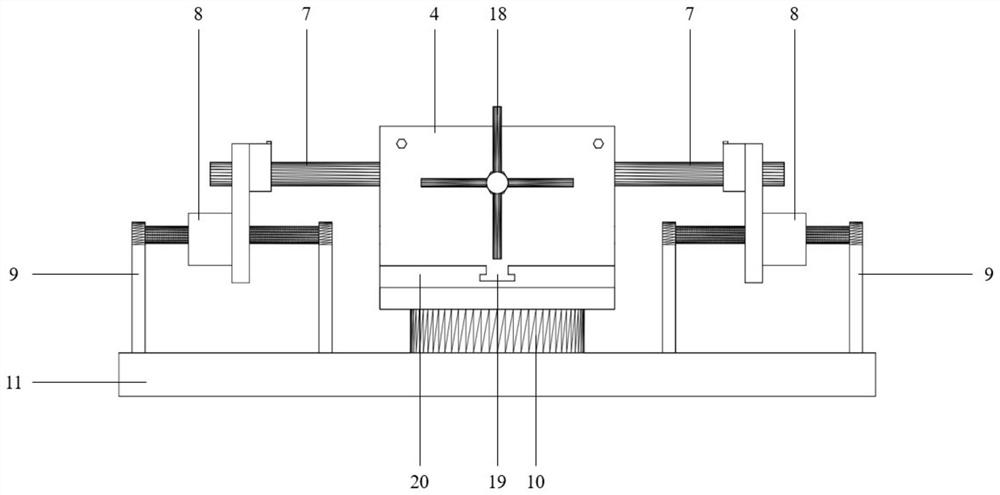

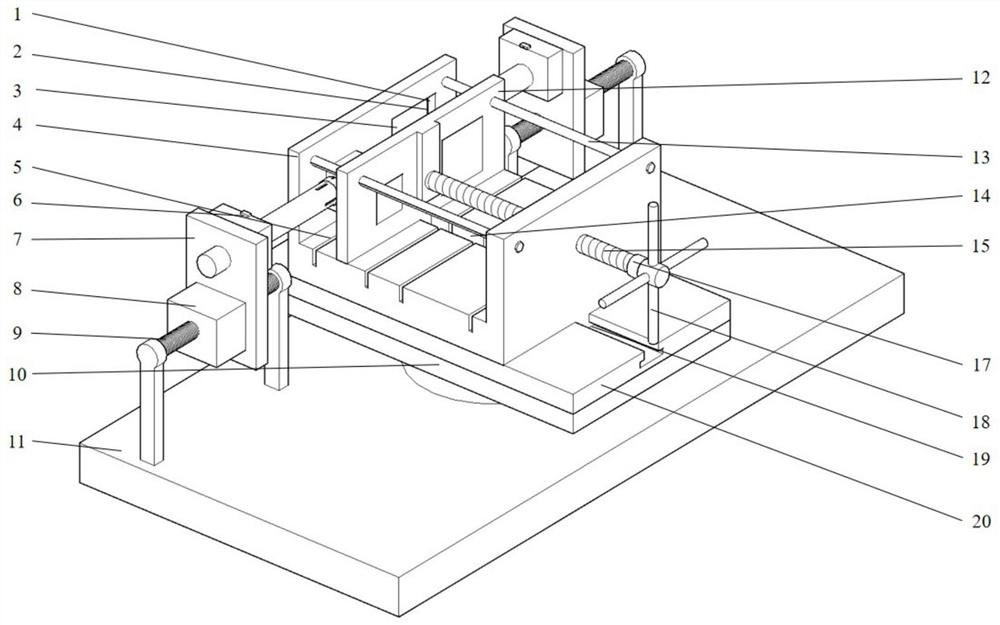

Embodiment 1

[0031] Such as figure 1 A drilling core device for early concrete is a positioning recess 1, a measuring probe fixing groove 2, a fixed support 4, a drain groove 5, a core drill device 7, a motor 8, a thread The fixing assembly 9, the hydraulic jack 10, the base 11, the moving fixing plate 12, the auxiliary positioning rod 13, the slide 14, the propulsion screw 15, nut 16, electronic torque measuring meter 17, torque measuring handle 18, T-shaped body 19, T-shaped The slot plate 20 is composed, the fixed support 4, the movable fixing plate 12, the auxiliary positioning rod 13 is connected to each other, and the nut 16 is connected to the propulsion screw 15, the propulsion screw 15 is used to connect the moving fixing plate. 12, fixed support 4 and electronic torque measuring meter 17, the electronic torque measuring meter 17 is connected to the torque measuring handle 18, the propulsion screw 15, nut 16, electronic torque measuring meter 17, torque measuring handle 18 interconnec...

Embodiment 2

[0039] Such as figure 1 A drilling core device for early concrete is a positioning recess 1, a measuring probe fixing groove 2, a fixed support 4, a drain groove 5, a core drill device 7, a motor 8, a thread The fixing assembly 9, the hydraulic jack 10, the base 11, the moving fixing plate 12, the auxiliary positioning rod 13, the slide 14, the propulsion screw 15, nut 16, electronic torque measuring meter 17, torque measuring handle 18, T-shaped body 19, T-shaped The slot plate 20 is composed, the fixed support 4, the movable fixing plate 12, the auxiliary positioning rod 13 is connected to each other, and the nut 16 is connected to the propulsion screw 15, the propulsion screw 15 is used to connect the moving fixing plate. 12, fixed support 4 and electronic torque measuring meter 17, the electronic torque measuring meter 17 is connected to the torque measuring handle 18, the propulsion screw 15, nut 16, electronic torque measuring meter 17, torque measuring handle 18 interconnec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com