A Composite Drill Bit Suitable for Difficult-Drilling Formation

A compound drill bit and drill bit technology, which is applied in the direction of drill bit, earthwork drilling, drilling equipment, etc., can solve the problems of drilling efficiency limitation, bit drilling efficiency limitation, unsatisfactory service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

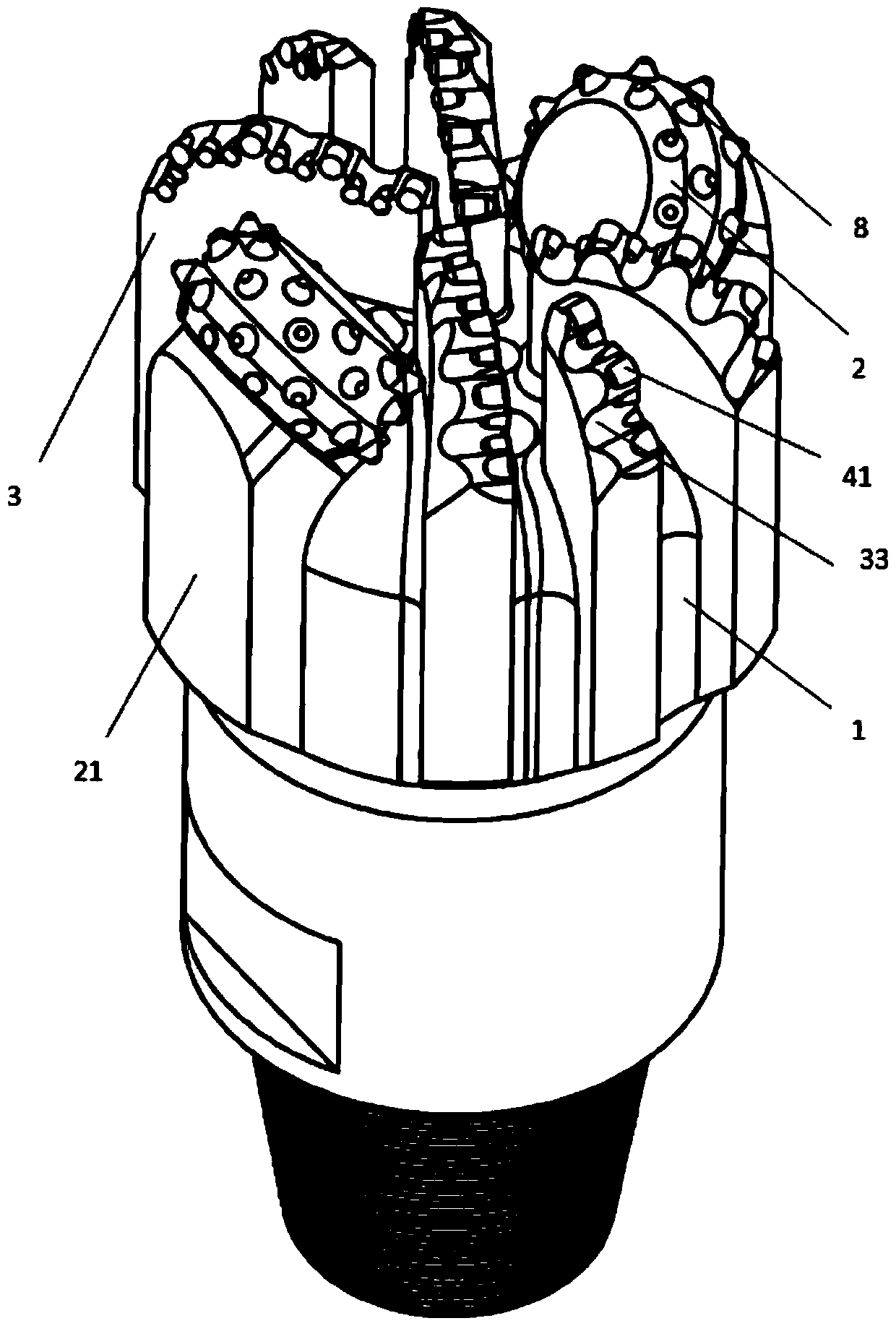

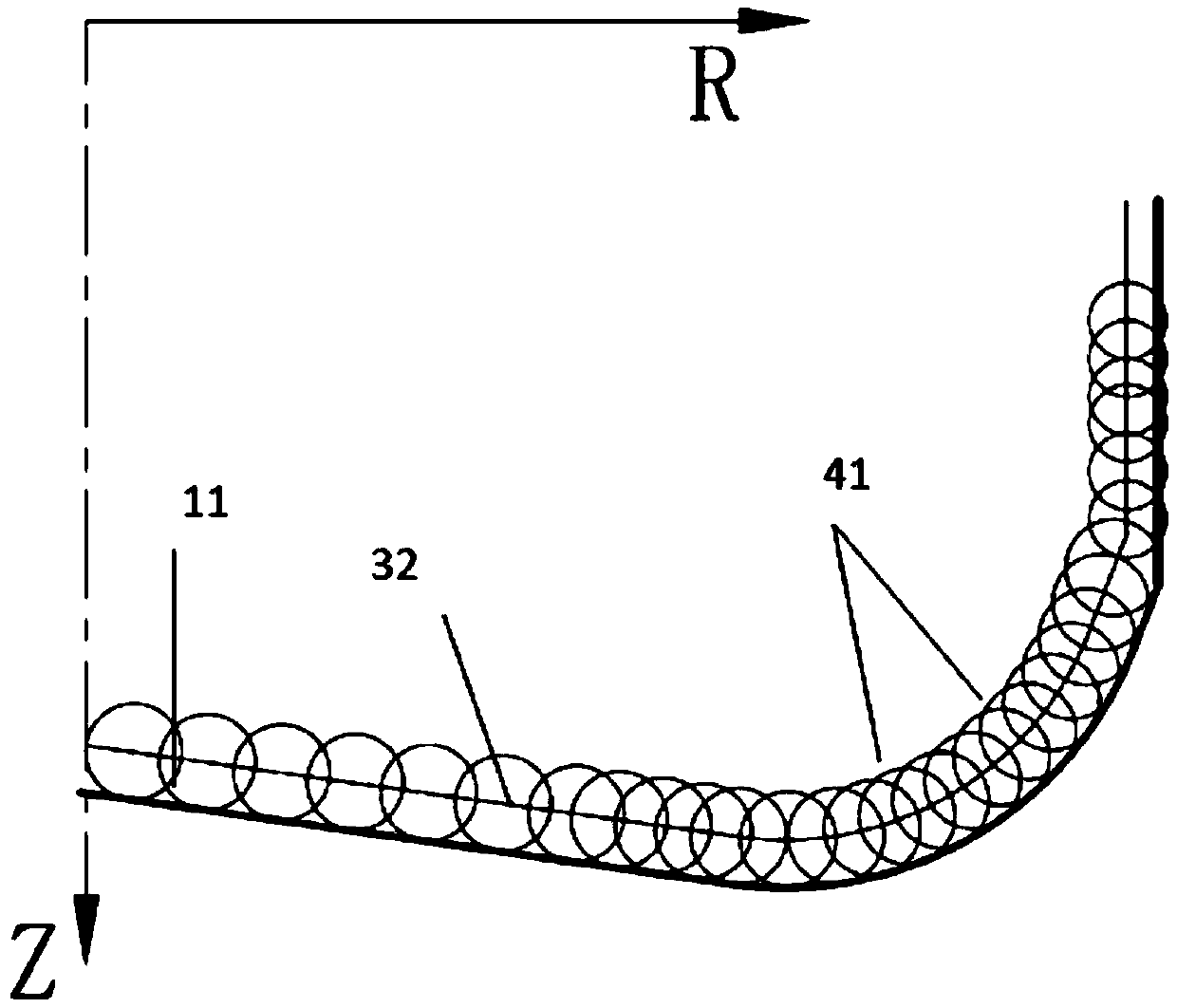

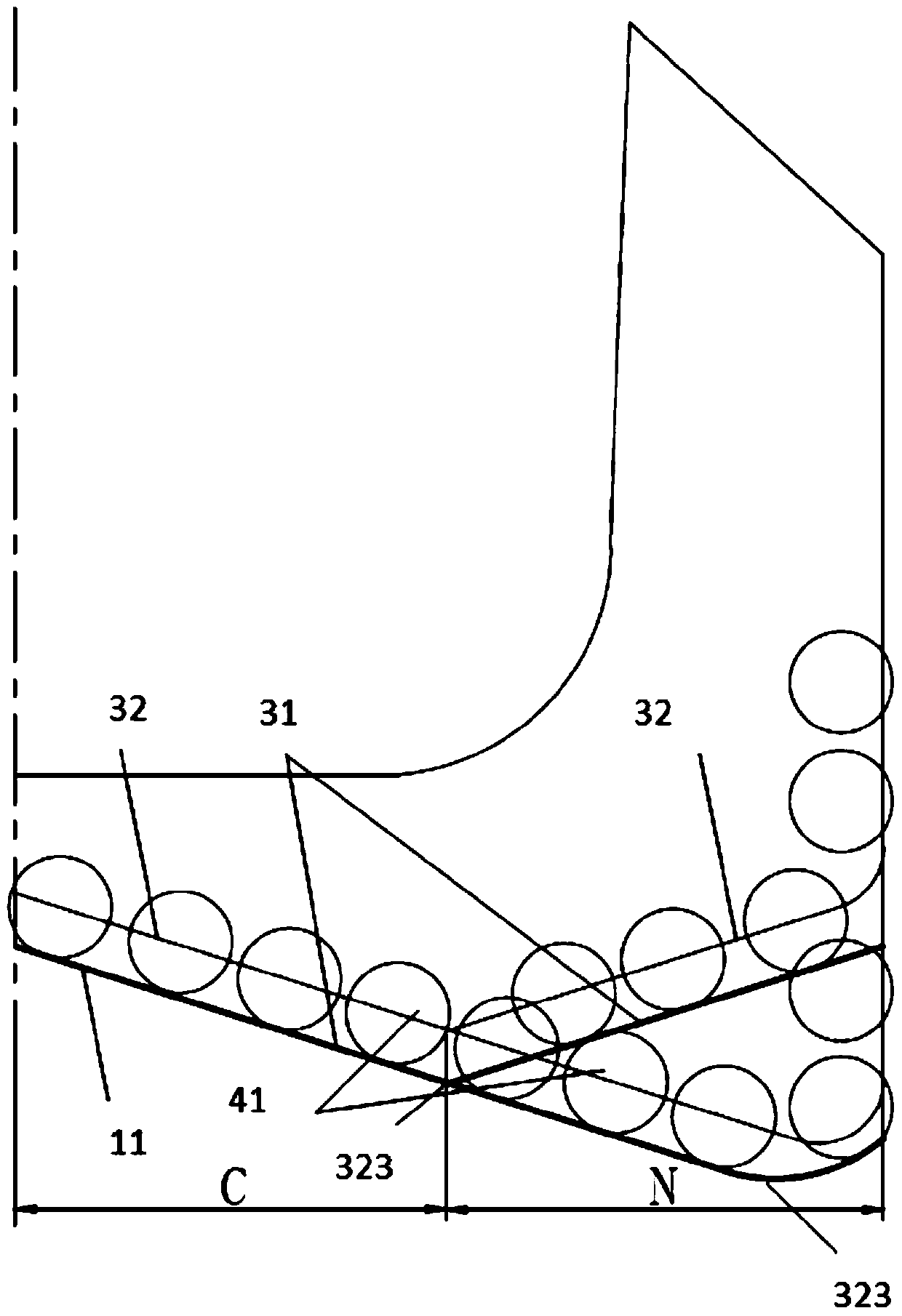

[0108] Such as figure 1 , 11 , 12, 13, and 14, a long-life drill bit with asynchronous cutting principle, including a drill body 1, a knife wing 3 solidified relative to the drill body 1, a cone 2 that is rotatably connected to the drill body 1, and arranged on The water eye or nozzle 61 on the drill body 1 has a tooth palm 21 on the drill body 1, and the cone 2 is installed on the tooth palm 21 to form a rotational connection with the tooth palm 21. The tooth 8 is arranged on the cone 2, and the blade 3 is provided with a plurality of first groups of cutting teeth 41, and the tooth surface 33 of the blade 3 is provided with dimples for fixing the first group of cutting teeth 41, and water holes or nozzles 61 are arranged in the flow channel between the blades. The body outline 32 of at least one blade 3 (may include the front blade body outline and the rear blade body outline) and the body outline 32 of at least one other blade 3 have at least one Non-coincident areas, and...

Embodiment 2

[0115] Such as Figure 15 As shown, the present embodiment is basically the same as the first embodiment, the difference is that the cutting teeth 8 on the cone 2 are wide inserts, such as Figure 16 shown. In this embodiment, the cone 2 crushes and splits the rock in a manner similar to static pressure, and the ring gear on it rolls out a circle of almost continuous broken pits on the rock at the bottom of the well, so that the fixed The bottom scraping surface of the cutting teeth becomes uneven, so that the fixed cutting teeth can naturally eat into the rock and scrape and break the rock. With the mutual cooperation of the two sets of cutting structures, the rock-breaking efficiency of the drill bit in hard formations can be significantly improved.

Embodiment 3

[0117] Such as Figure 17 As shown, the present embodiment is basically the same as the first embodiment, the difference is that the cone 2 is a disc cone, that is, the teeth 8 on the cone are in the shape of a continuous disk knife, compared with the second embodiment, it is based on The rock is broken in the way of complete static pressure, and a continuous broken groove is formed at the bottom of the well. It can significantly reduce the longitudinal vibration of the drill bit during the rock breaking process, and at the same time reduce the stick-slip phenomenon under special conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com