Patents

Literature

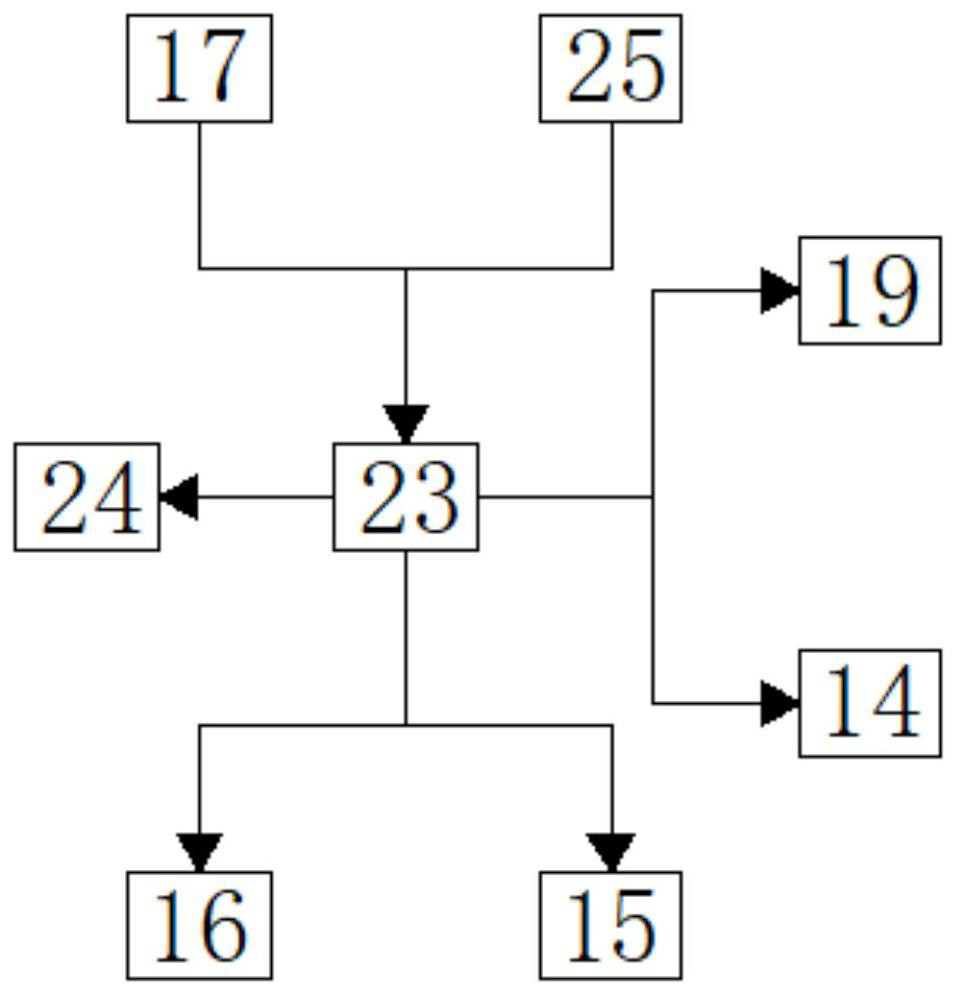

35results about How to "Reduce thermal wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

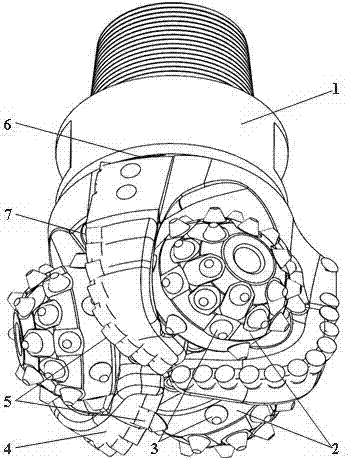

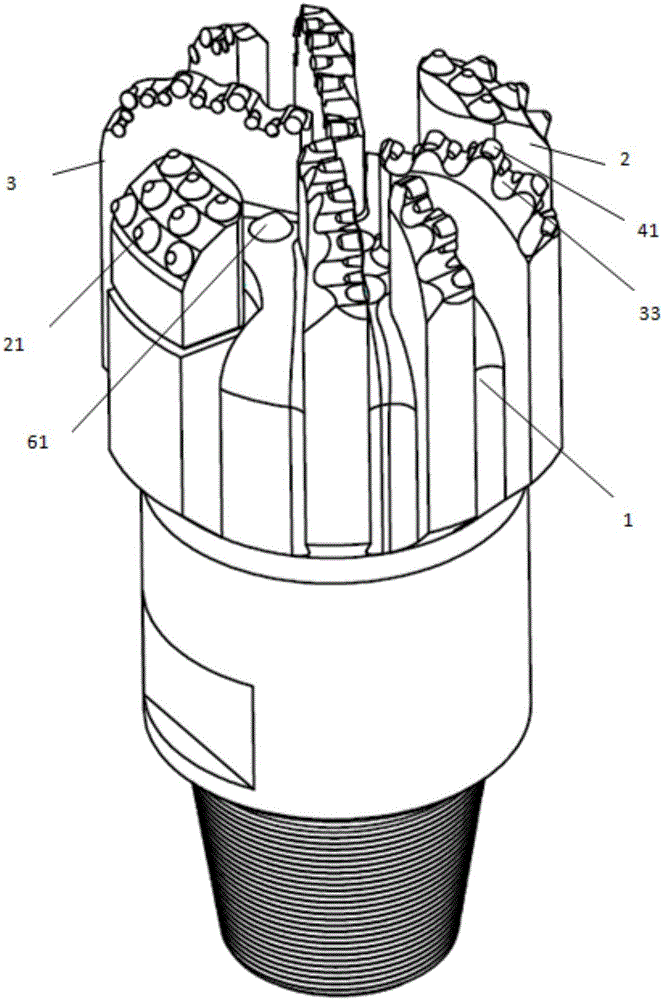

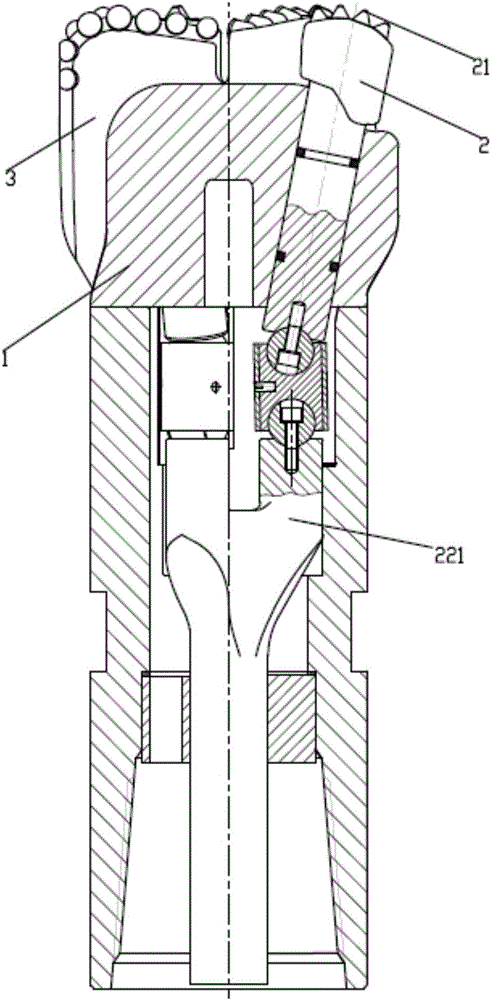

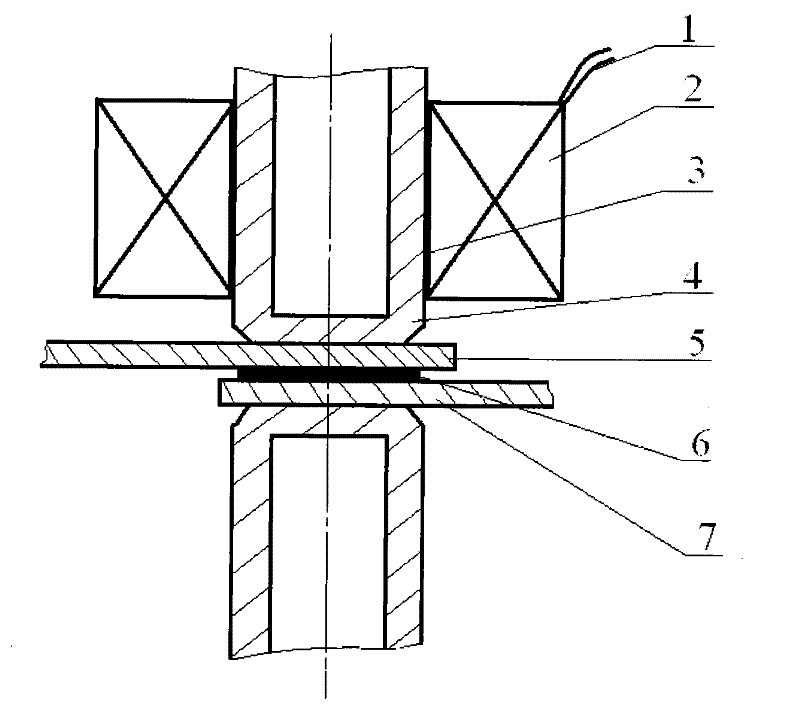

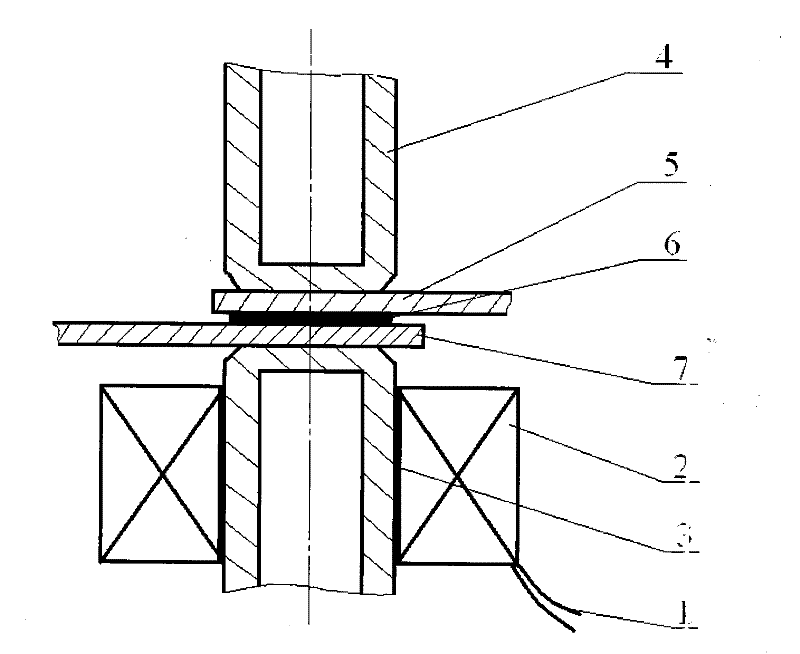

Compound bit formed by PDC (polycrystalline diamond compact) bits and rotary cutting bit

InactiveCN102392605AExtended service lifeIncrease cutting forceConstructionsHigh ratePolycrystalline diamond

The invention discloses a compound bit formed by PDC (polycrystalline diamond compact) bits and a rotary cutting bit. The compound bit comprises a main body (1), rotary cutting bit cones (2), rotary cutting bit cutting teeth (3), PDC blades (4), PDC cutting teeth (5), oil storage sacs (6) and nozzles (7), wherein the main body (1) comprises a cone journal, centralizing blocks, high-pressure slurry channels and a connection screw thread. The compound bit is characterized in that a compound bit cutting unit comprises the rotary cutting bit and a PDC bit cutting unit. The compound bit has the following beneficial effects: the PDC bits complete drilling the central part of the borehole in the drilling process; the linear velocity of the periphery of the borehole is high in the drilling process and the rotary cutting bit and the PDC bit cutting unit complete drilling the periphery of the borehole; and the rotary cutting bit in the compound bit shocks, crushes and cuts the rocks by way of rotary cutting, has high central rock breaking efficiency, high rate of penetration and better dynamic performance, is uniform in wear, simultaneously improves the bit bearing structure, ensures to prolong the service life of the bit while improving the rock breaking efficiency, improves the cutting capability of the compound bit and ensures good gauge protection effect.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

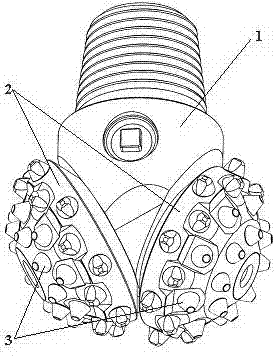

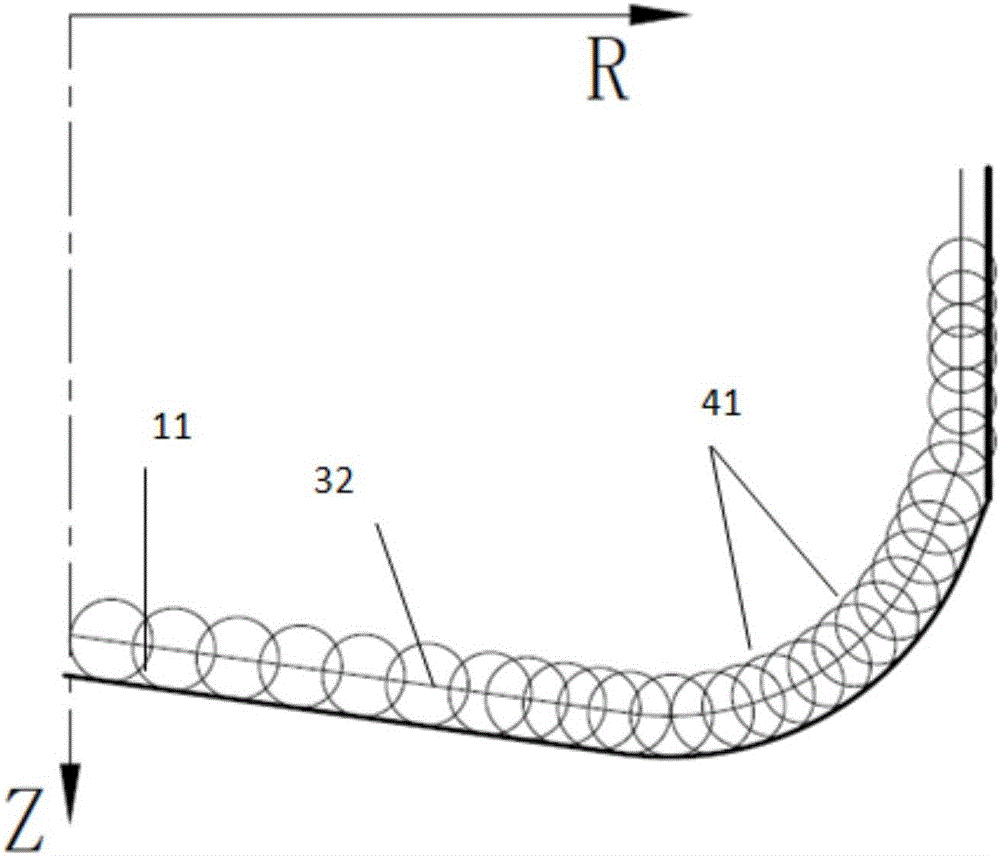

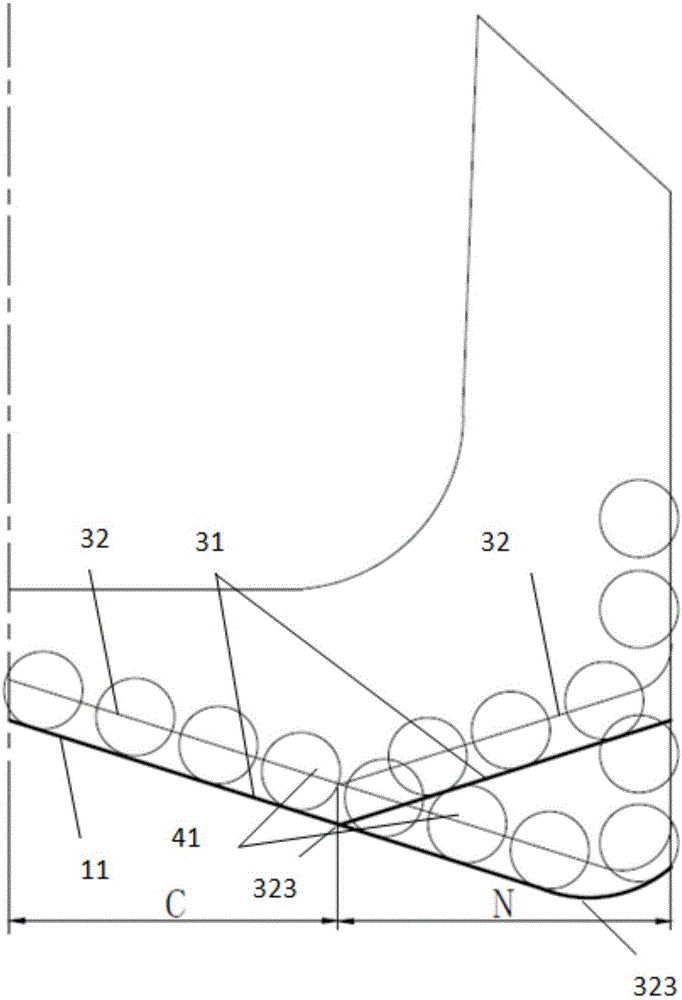

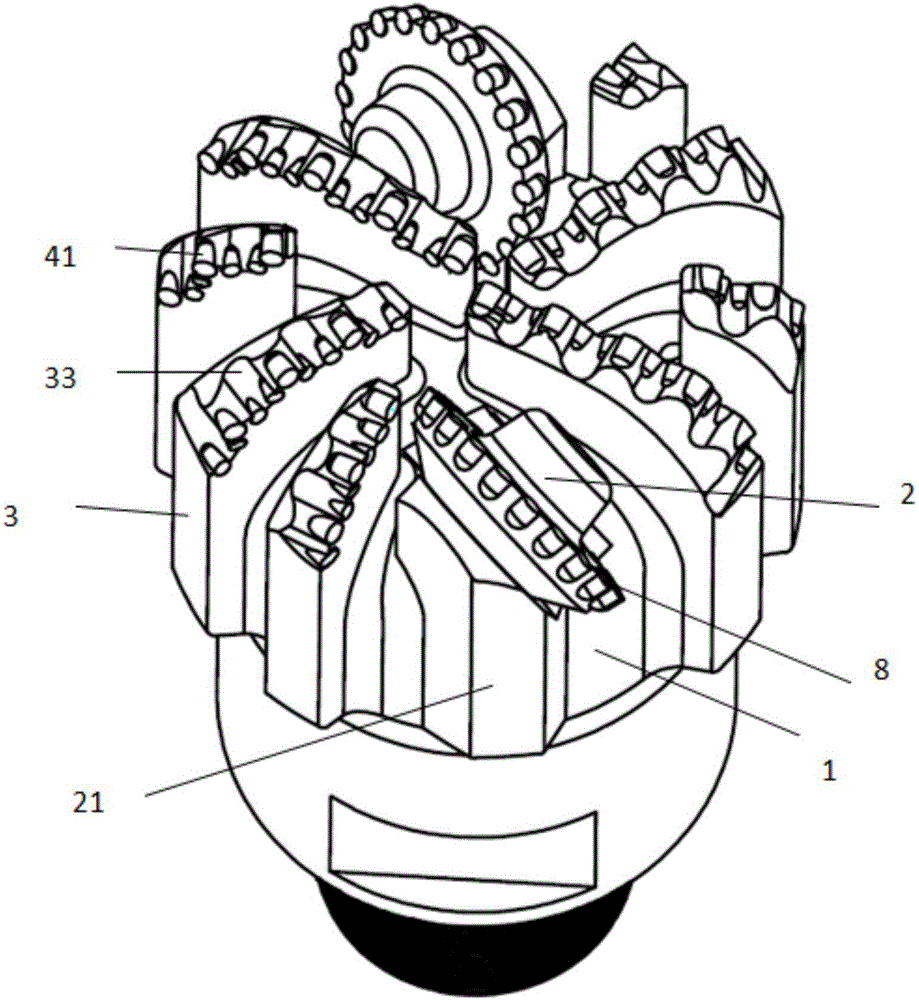

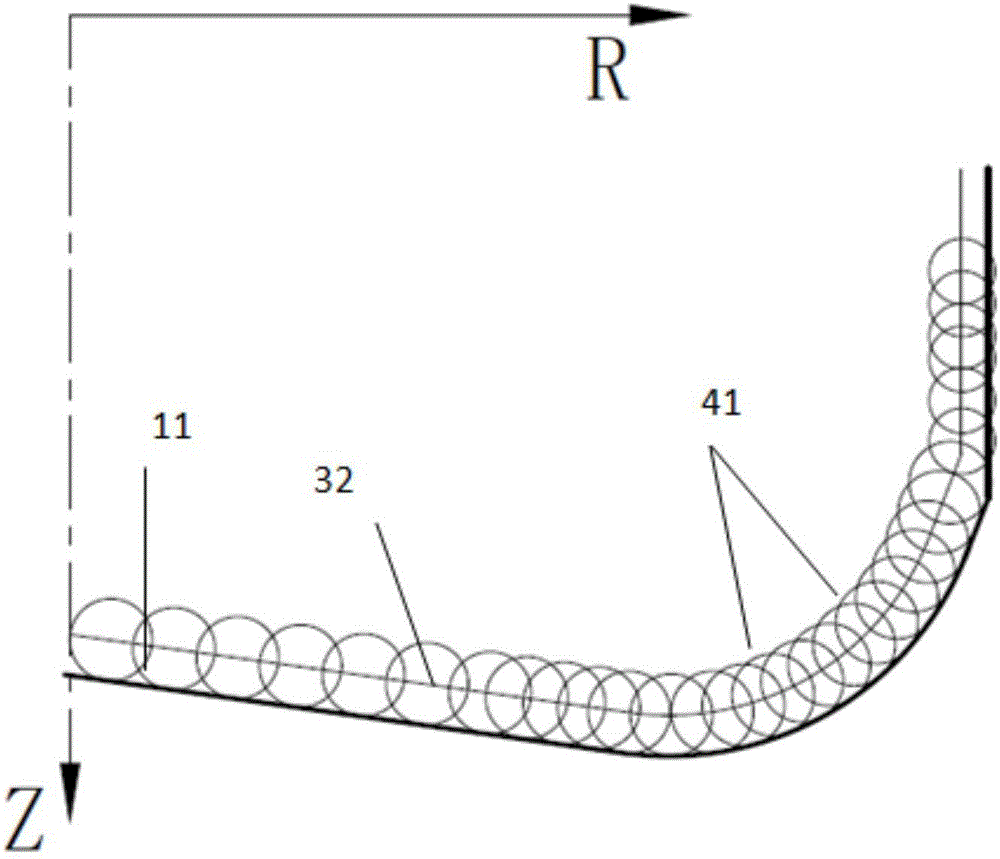

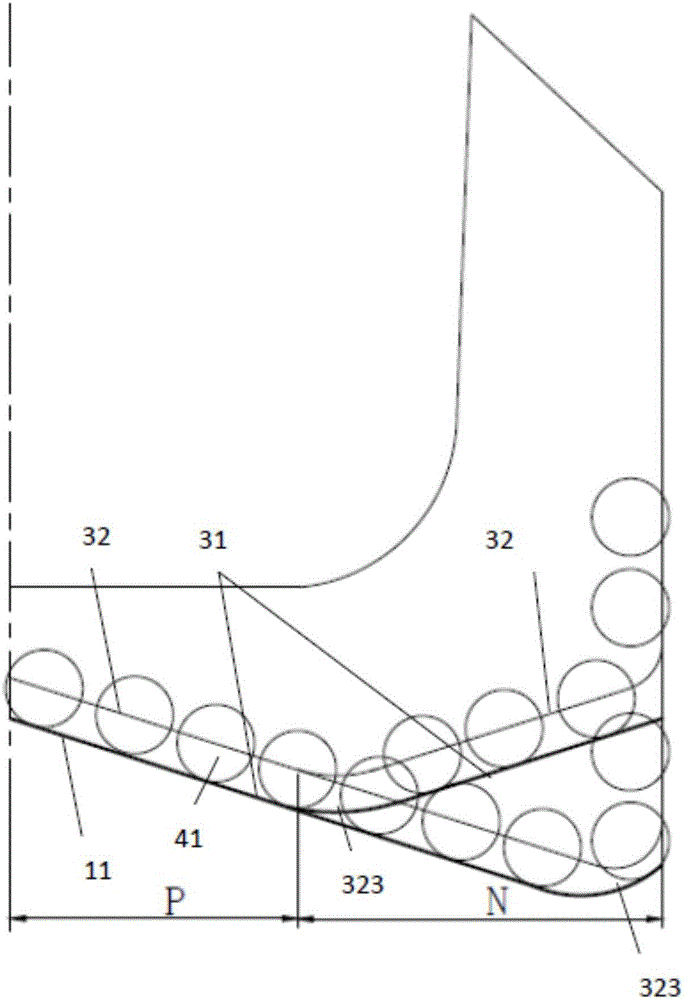

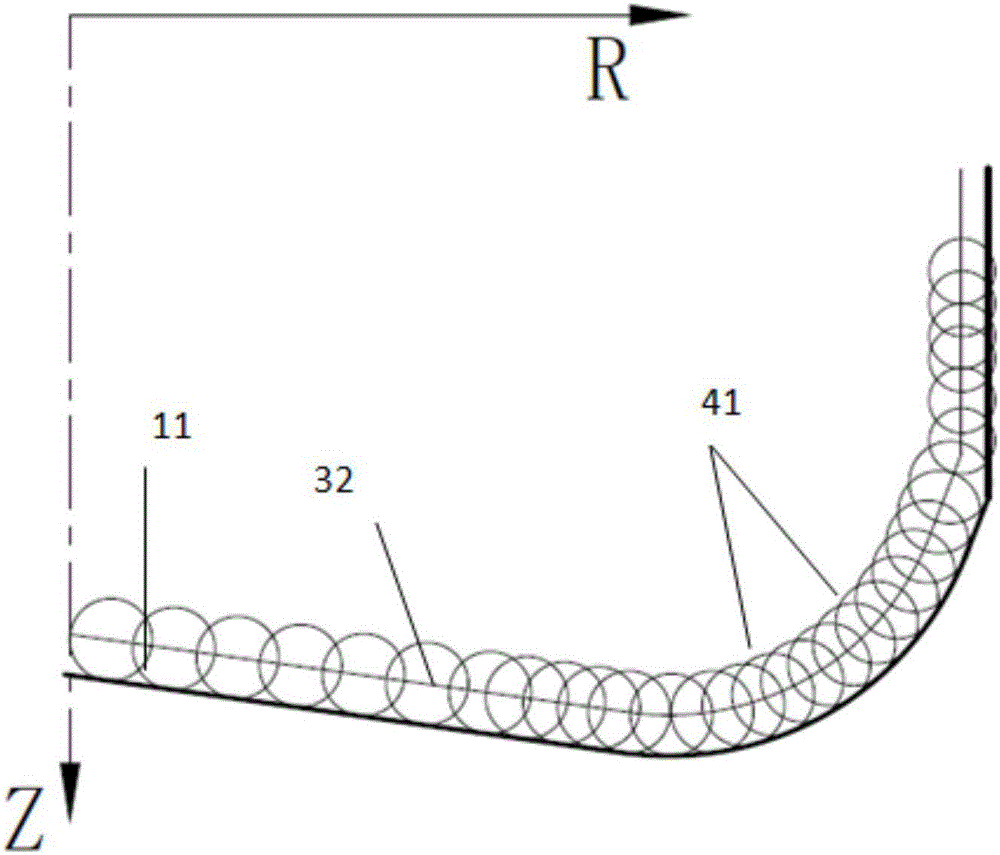

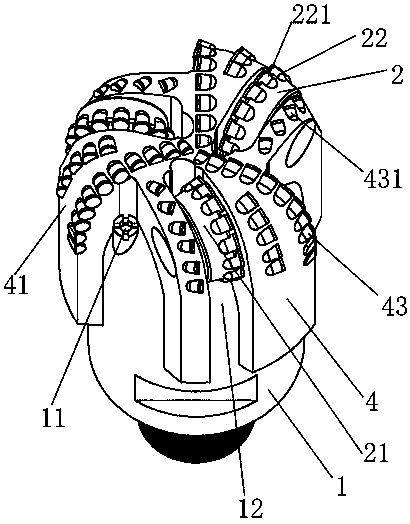

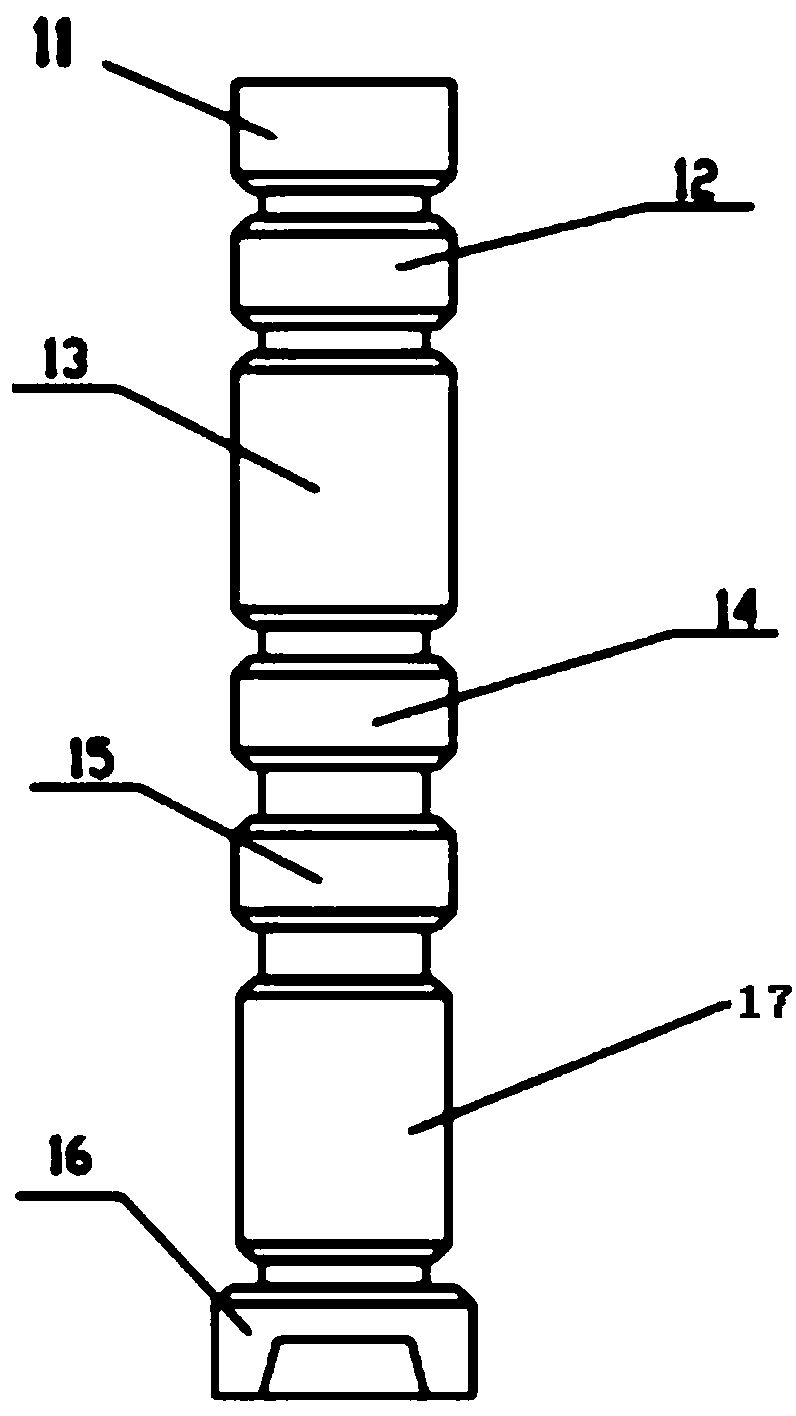

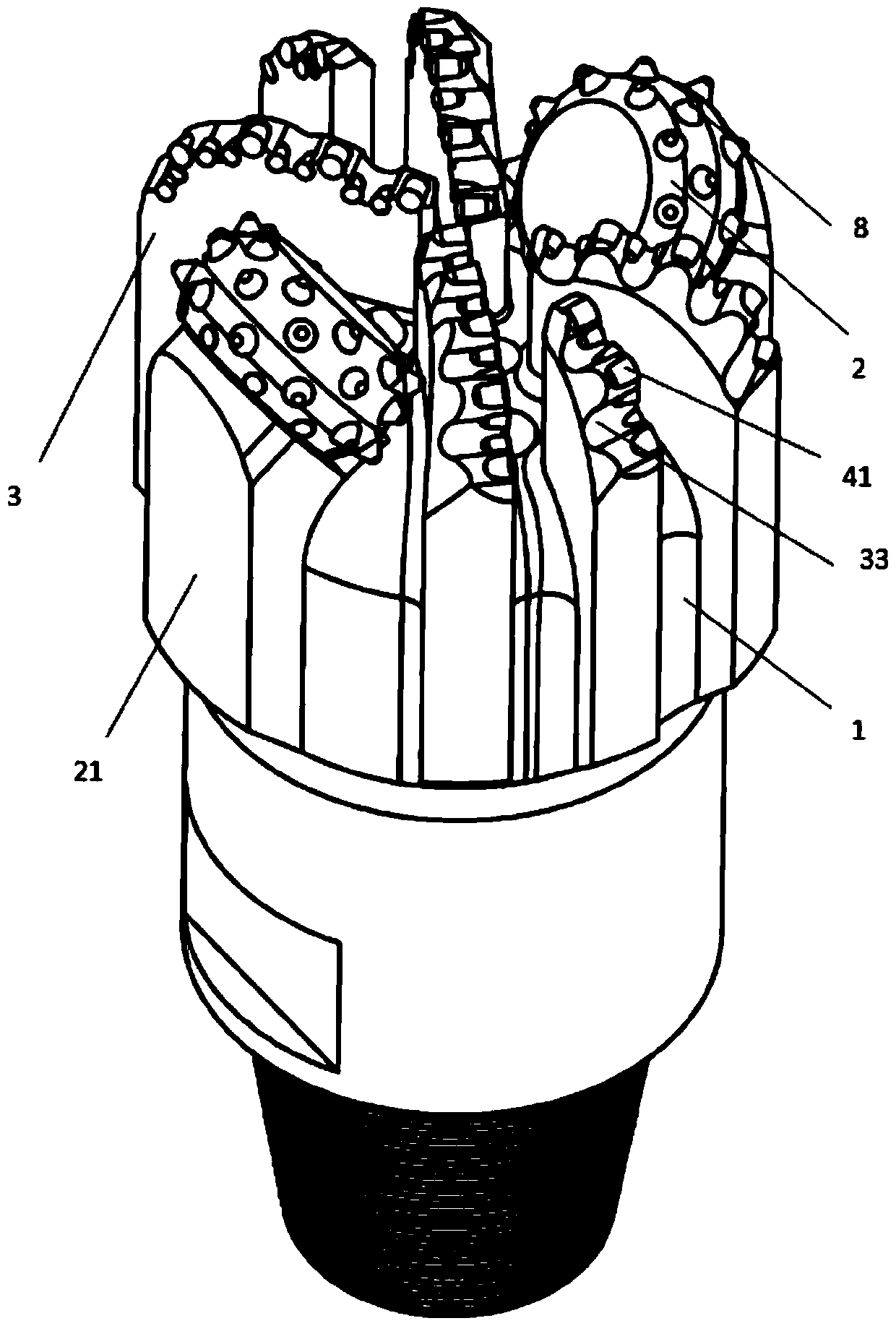

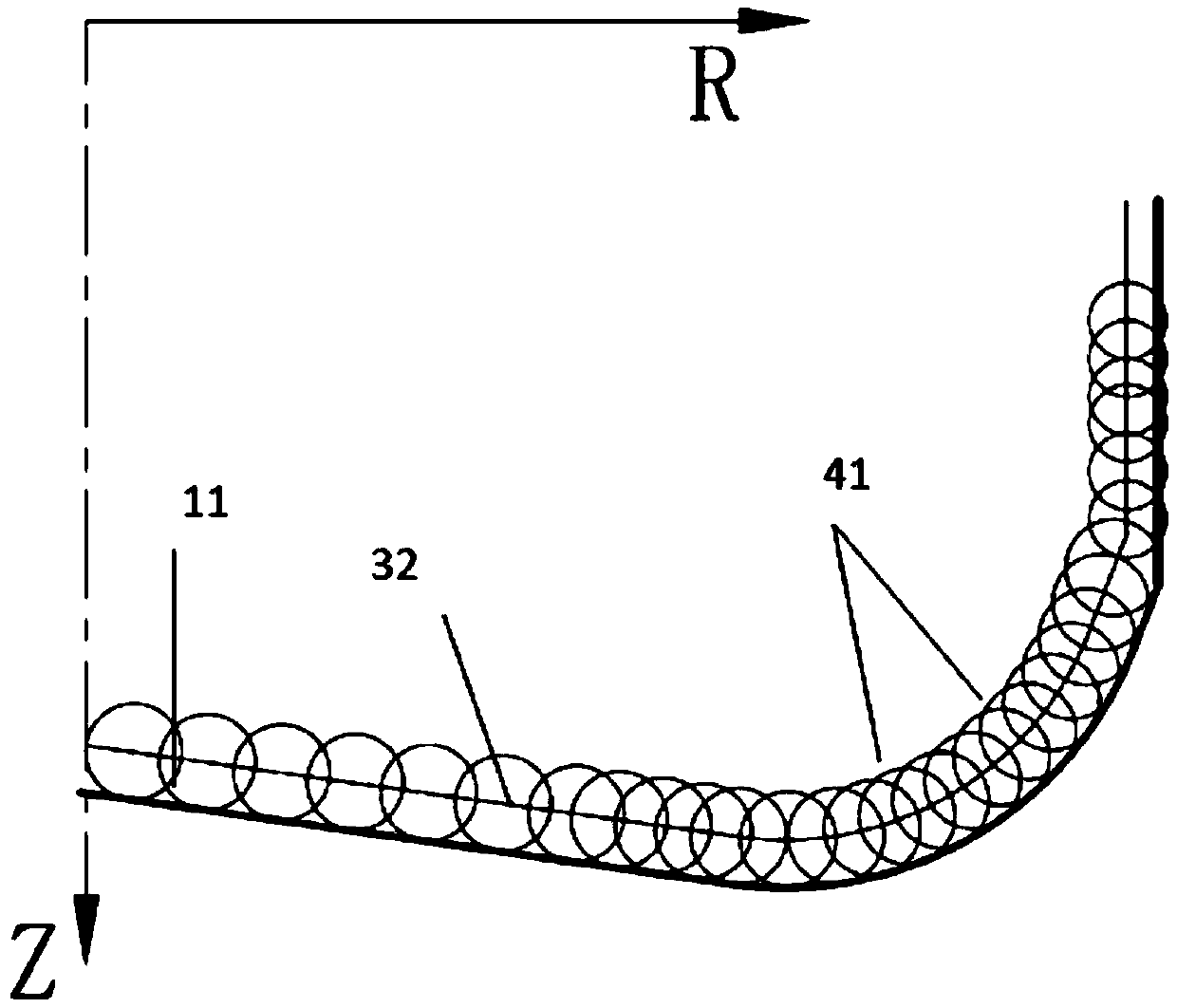

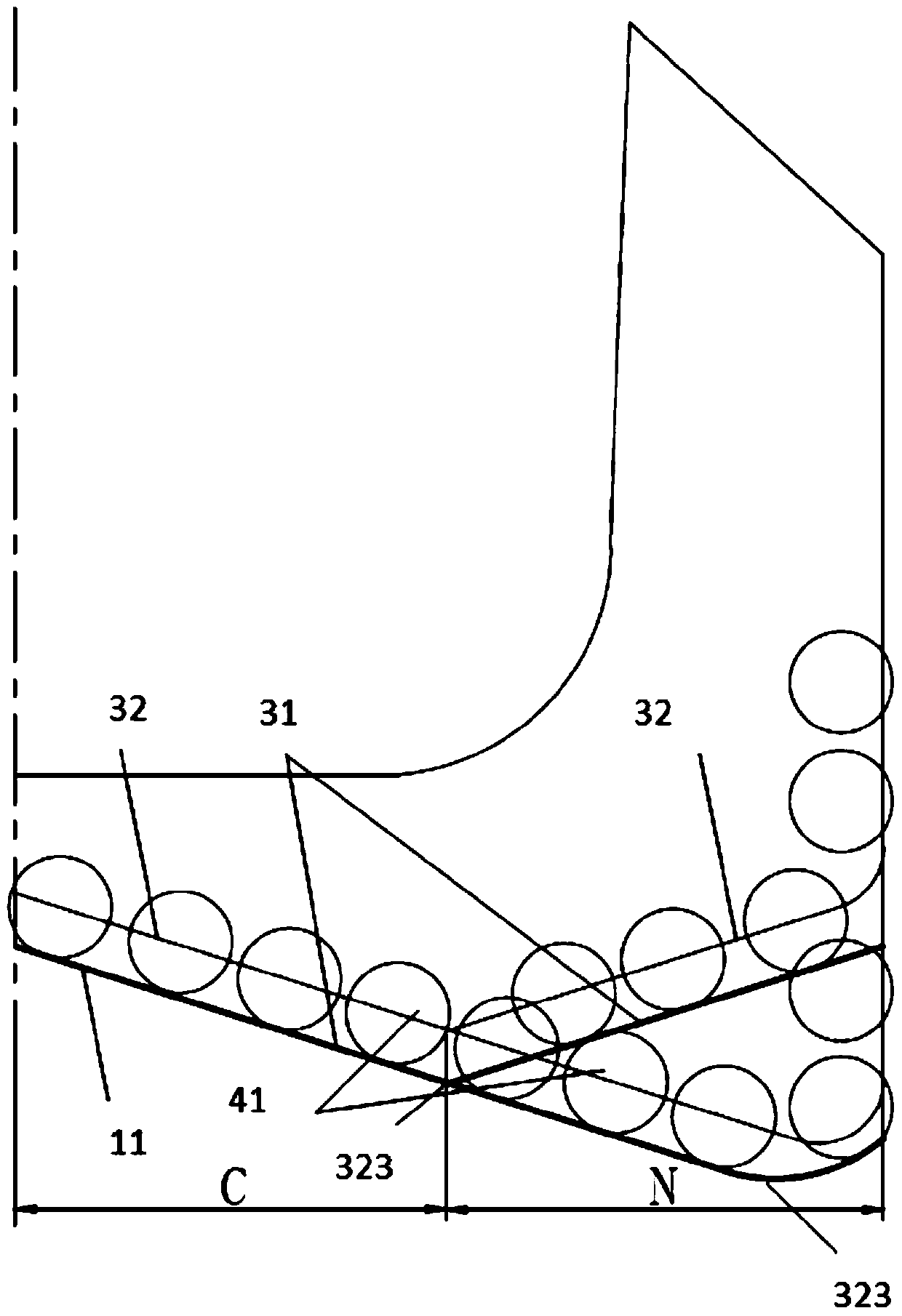

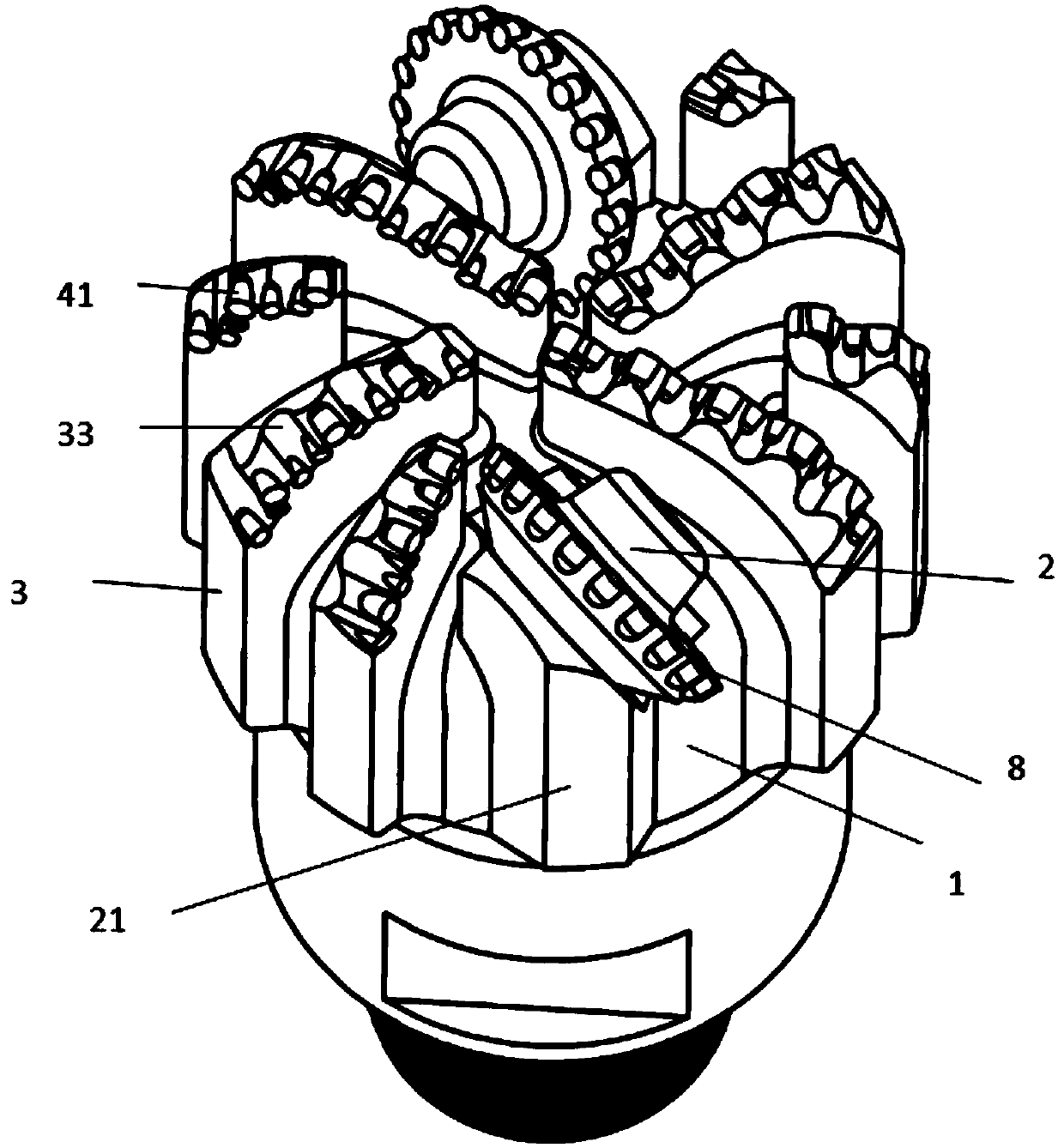

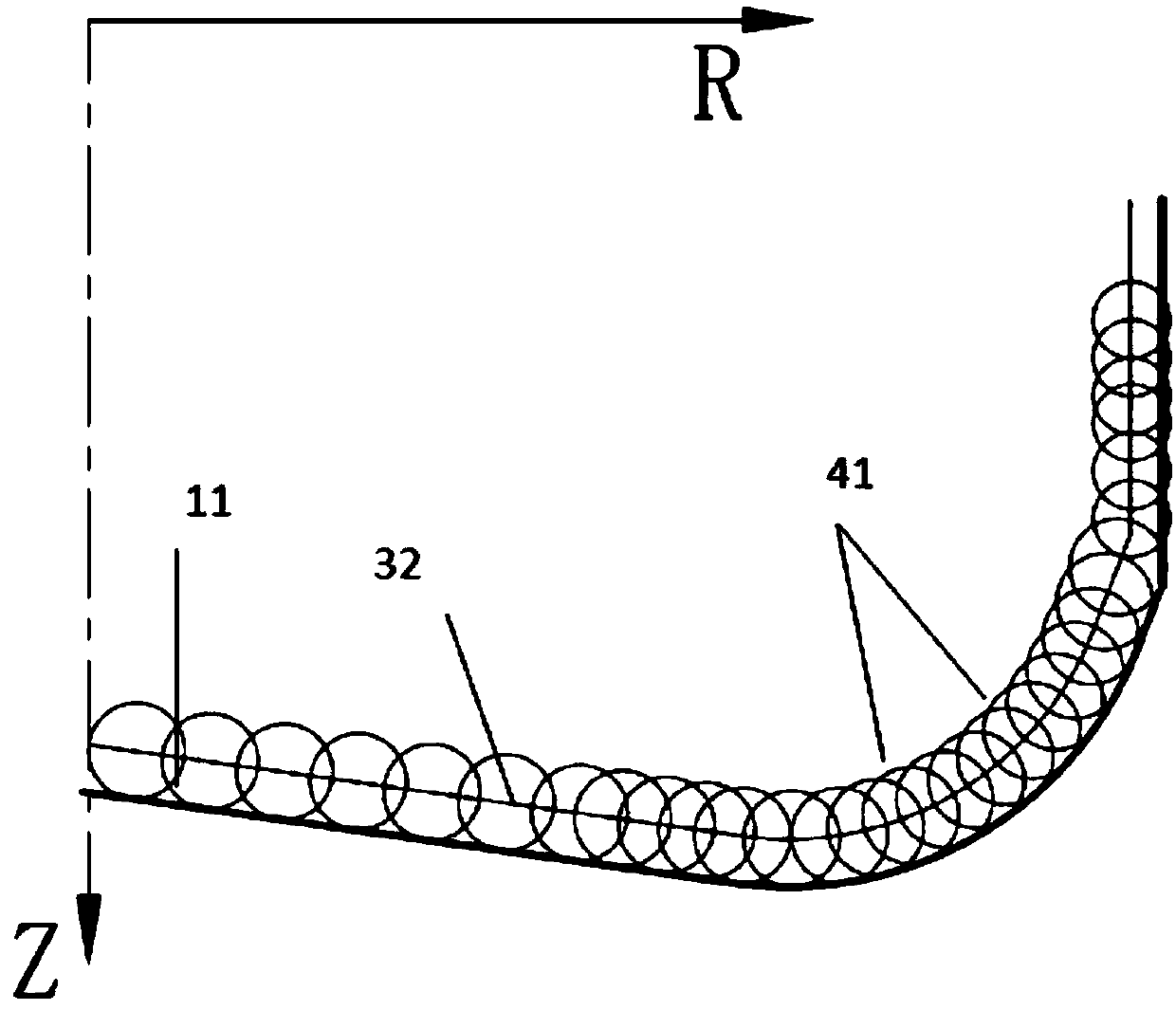

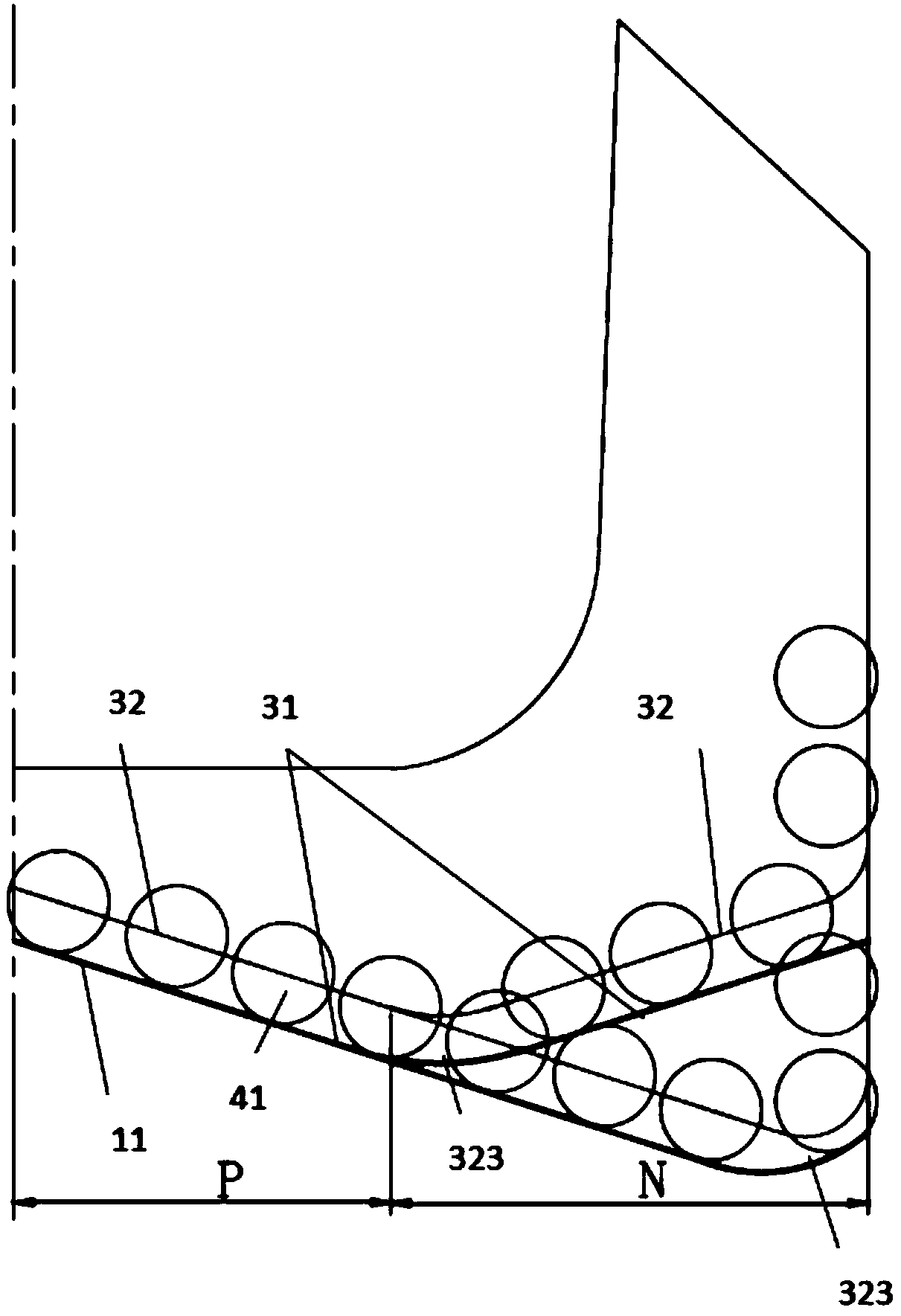

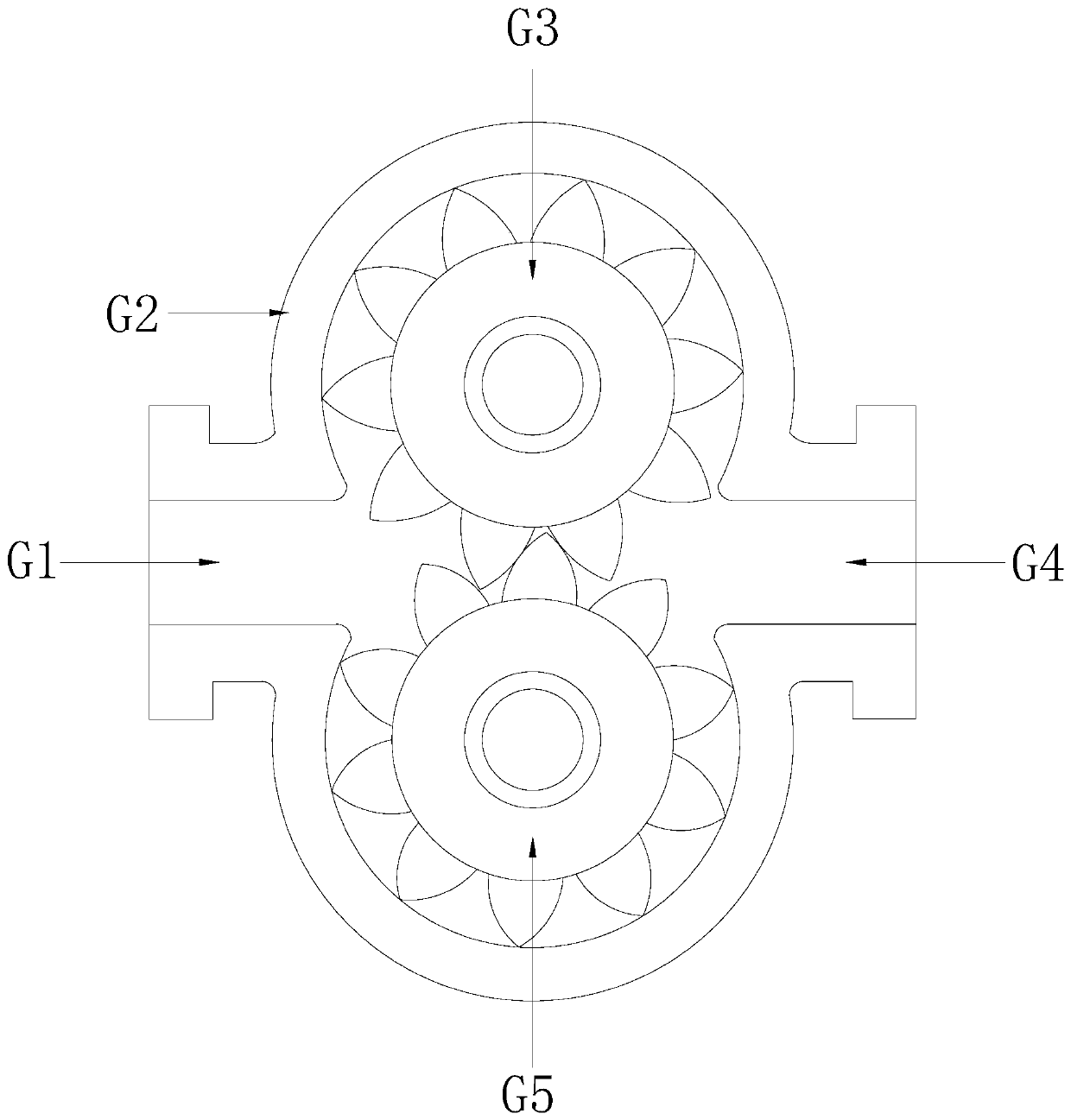

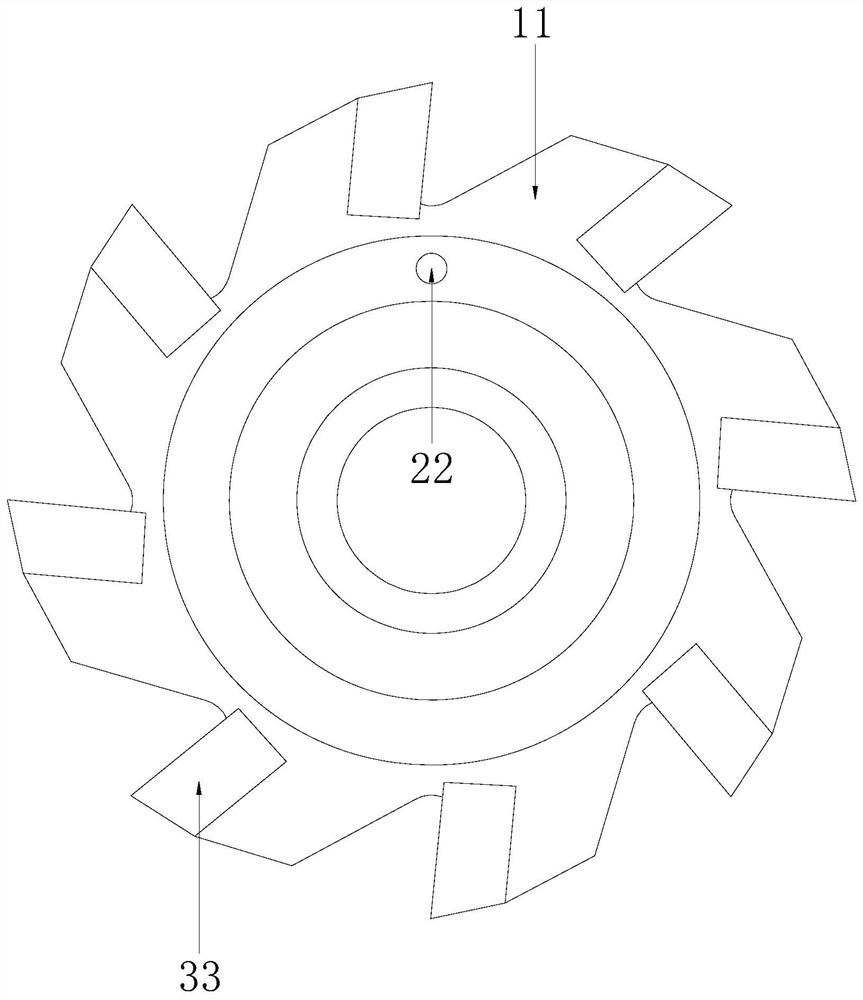

Composite drill bit suitable for stratum difficult to drill

ActiveCN106437525AAdjust the tooth densityIncreased axial wear volumeDrill bitsConstructionsDrill bitPetroleum engineering

The invention discloses a composite drill bit suitable for a stratum difficult to drill. The composite drill bit suitable for the stratum difficult to drill comprises a drill bit body, cutter wings which are fixedly connected with the drill bit body, tooth wheels which are rotatably connected with the drill bit body, and water holes or nozzles which are arranged on the drill bit body. A plurality of first sets of cutting teeth are arranged on each cutter wing. Pits are formed in the sides, provided with the teeth, of the cutter wings and used for fixing the first sets of cutting teeth. The tooth wheels are rotatably connected with the drill bit body through tooth palms. Teeth are mounted on the tooth wheels. In the common coverage area of the body contour line of at least one cutter wing and the body contour line of at least another cutter wing, at least one non-overlapping area and at least one overlapping point or overlapping area exist. Through the structure characteristic, the drill bit can operate in an asynchronous cutting mode, the longitudinal abrasion length of the drill bit can be increased, and the service life of the drill bit can be prolonged; and the drill bit is in a high-specific-pressure drilling state in the whole drilling process, the capacity to intrude into rocks of the drill bit is improved, the drilling speed of the drill bit in the stratum difficult to drill is increased accordingly, and the service life of the drill bit in the stratum difficult to drill is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV +1

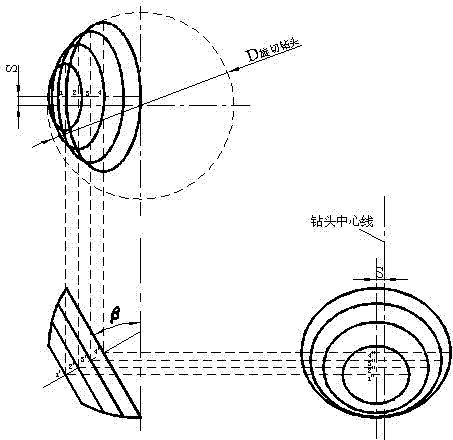

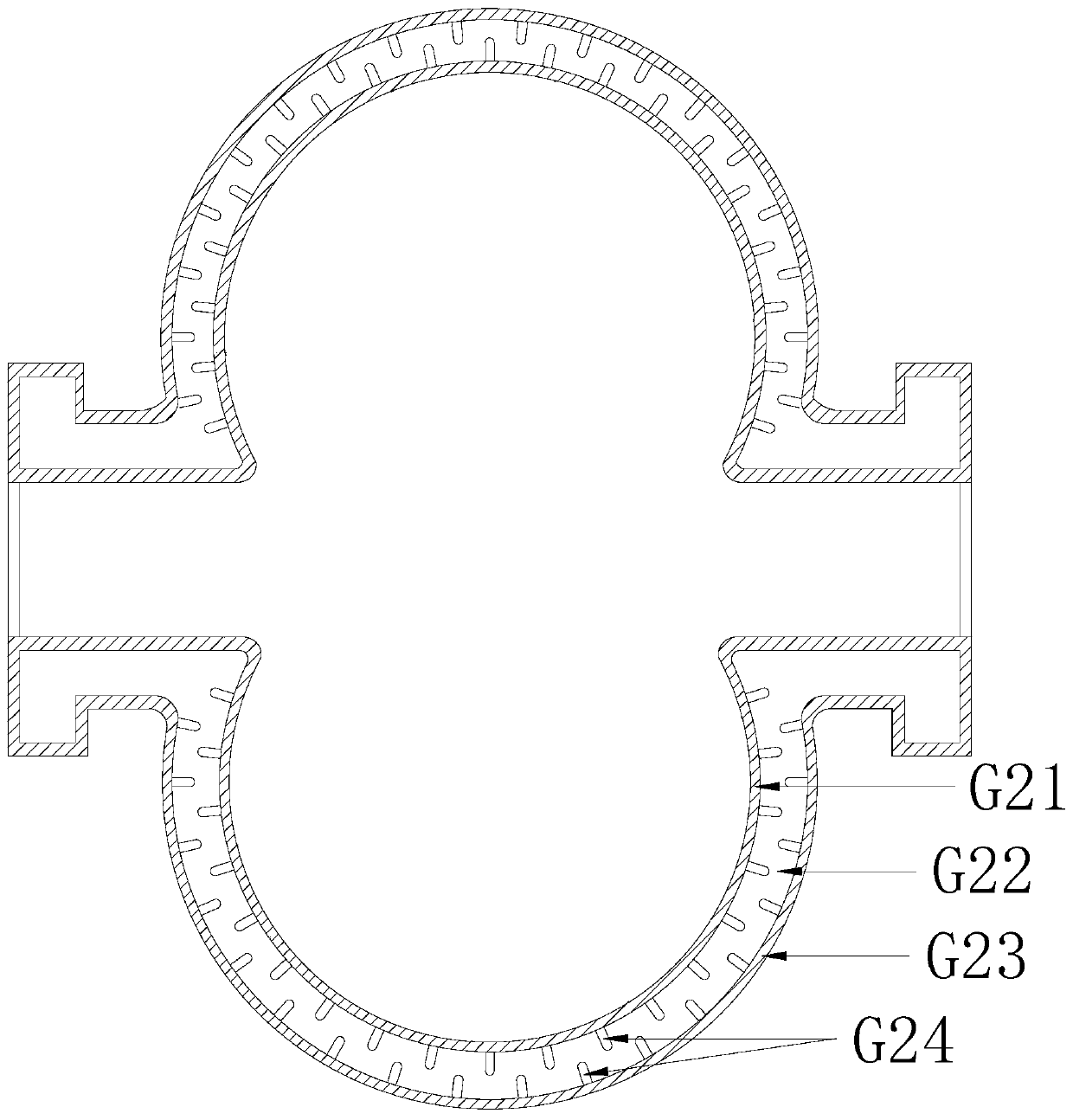

Disc cutter type multiple drill bit suitable for hard-to-drill stratum

The invention discloses a disc cutter type multiple drill bit suitable for a hard-to-drill stratum. The disc cutter type multiple drill bit comprises a drill bit body, a plurality of cutter wings extending to the drill bit body, a disc cutter rotatably connected relatively to the drill bit body, and a water hole or a nozzle formed in the drill bit body; a plurality of first groups of cutting teeth are formed in the cutter wings, a slot is formed in the tooth surface of the cutter wing to fix the first group of cutting teeth, the disc cutter comprises a disc cutter body and disc cutter teeth arranged on the disc cutter body, the contour line of a body of at least one cutter wing and the contour line of a body of at least another cutter wing have at least one mismatched area in the common coverage area and at least one matched point or matched area. The structural feature enables the drill bit to work in an asynchronous cutting manner, so that the longitudinal abrasion length of the drill bit is increased, the service life of the drill bit is prolonged, in addition, the drill bit is kept in a high specific pressure drilling state in the whole drilling process, and the capability of the drill bit drilling in a rock is strengthened. Therefore, and the drilling speed and the service life of the drill bit in the hard-to-drill stratum are increased and prolonged.

Owner:SOUTHWEST PETROLEUM UNIV +1

Punching composite drill bit suitable for difficult-to-drill stratums

ActiveCN106089087AAdjust the tooth densityEffective intakeDrill bitsConstructionsPunchingBody contour

The invention discloses a punching composite drill bit suitable for difficult-to-drill stratums. The drill bit comprises a drill bit body, blades and water holes or nozzles arranged in the drill bit body, wherein each blade is provided with a plurality of first cutting teeth, the tooth arranging face of each blade is provided with sockets for fixing the first cutting teeth, the drill bit body is further provided with punching structures and an impact force transmission mechanism, the punching structures are provided with punching teeth, and the body contour line of at least one blade and the body contour line of at least another blade are provided with at least one non-overlap area and at least one overlap point or area in a joint covering area. By the structure, the drill bit can work in an asynchronous cutting manner, the longitudinal abrasion length of the drill bit can be increased, the service life of the drill bit can be prolonged, the drill bit can be allowed to be in a high-specific-pressure drilling state during the whole drilling process, the rock drilling ability of the drill bit is enhanced, the drilling speed of the drill bit in the difficult-to-drill stratums is increased, and the service life of the drill bit in the difficult-to-drill stratums is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV +1

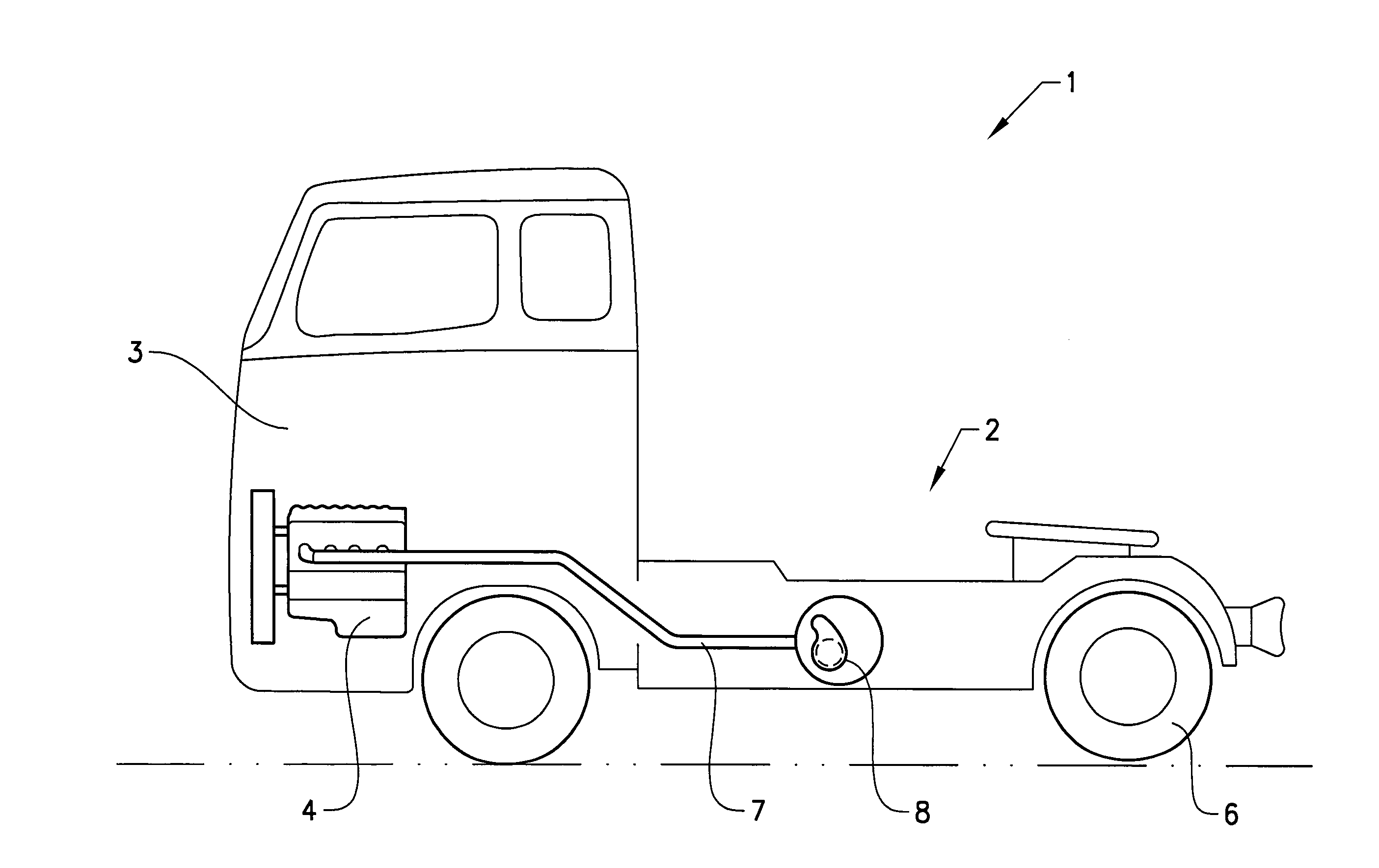

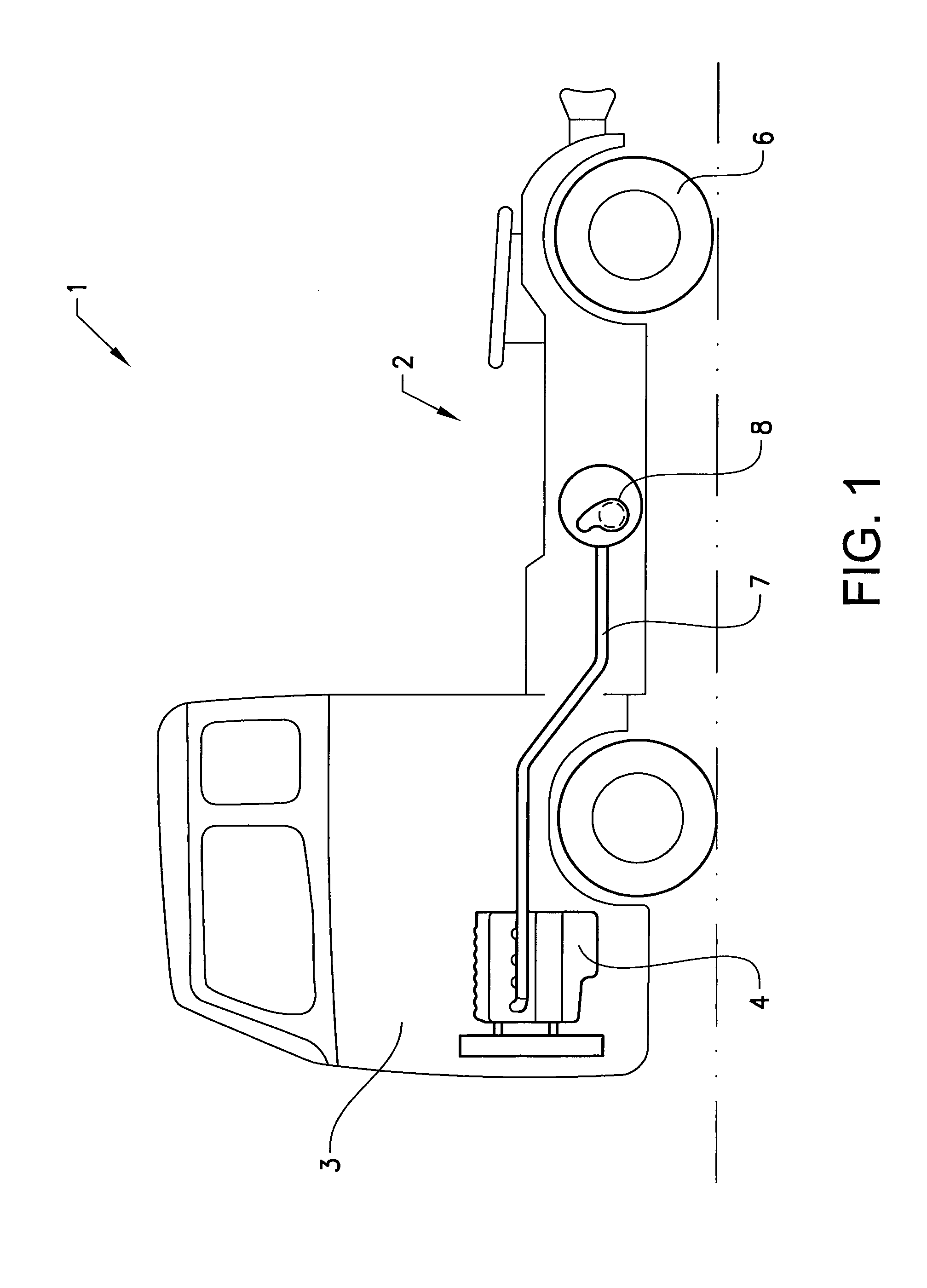

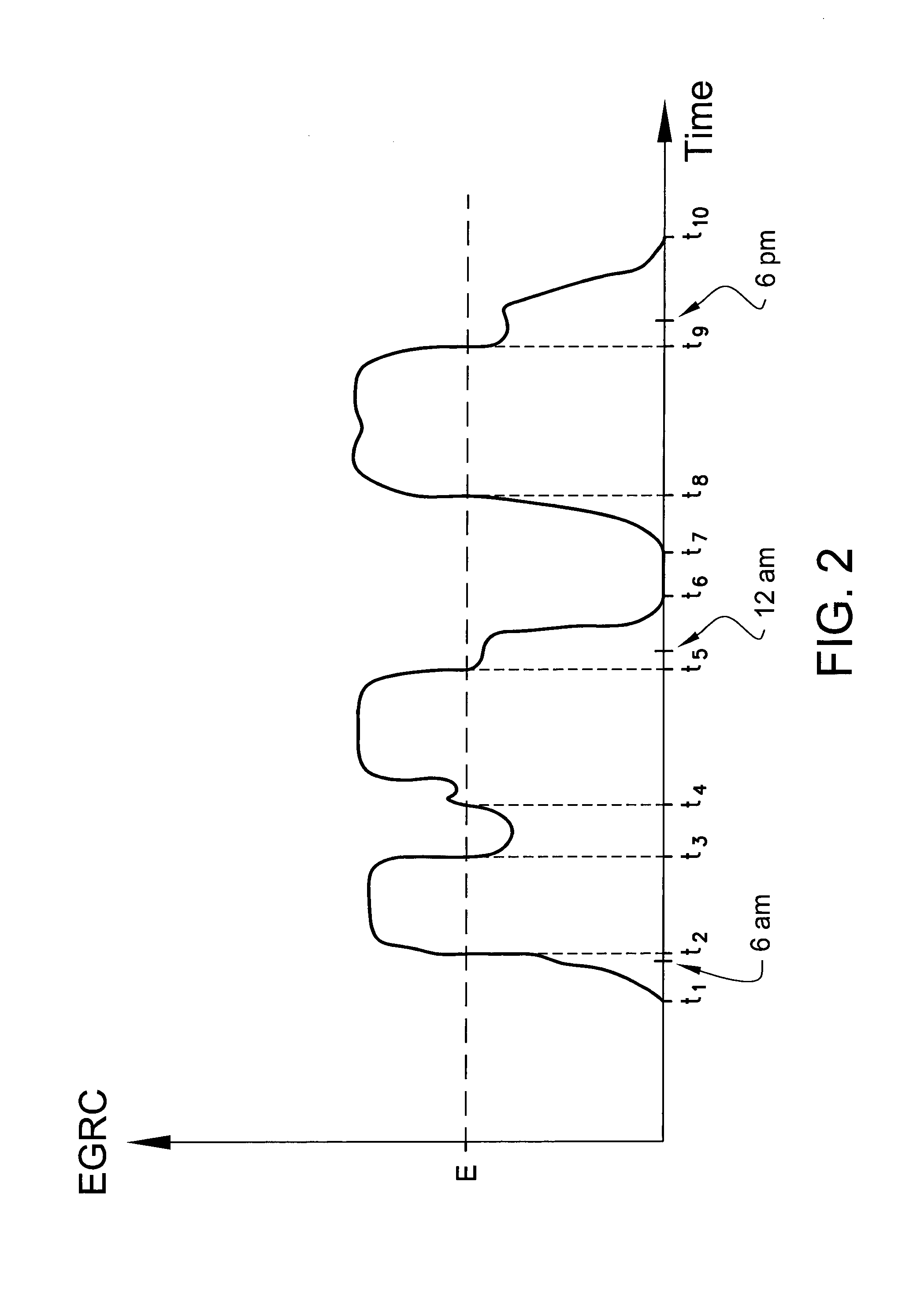

Method for timing a regeneration process

ActiveUS20160131011A1Extension of timeIncrease success rateVehicle testingElectrical controlRegenerative processExhaust fumes

A method for timing of a regeneration process of an exhaust gas system of a vehicle engine includes collecting, during operation of the vehicle, data on an exhaust gas regeneration capability as a function of time, establishing, from the collected data, a statistical probability function for the exhaust gas regeneration capability as a function of time, and identifying, from the probability function, one or several time periods that statistically are suitable and / or unsuitable for carrying out a regeneration process. A method for regeneration of an exhaust gas system of a vehicle engine is also provided.

Owner:VOLVO LASTVAGNAR AB

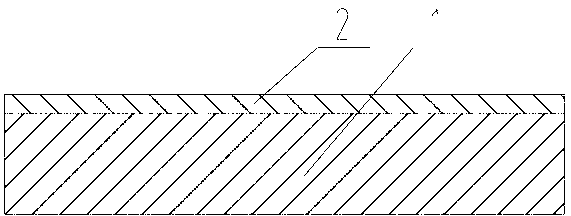

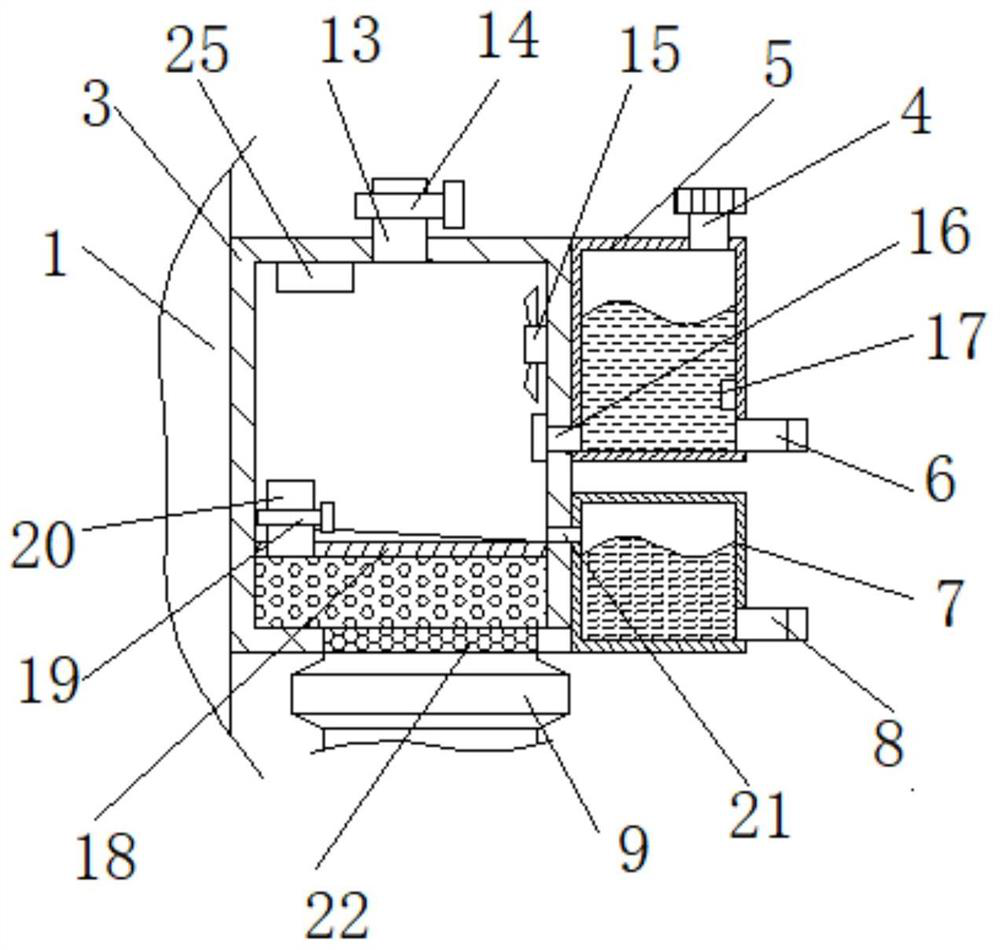

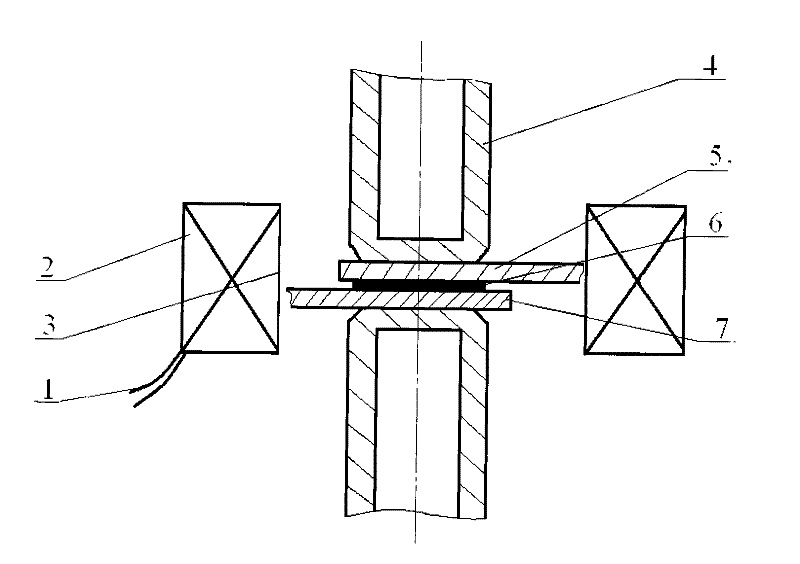

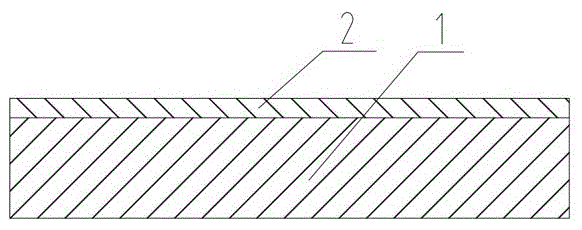

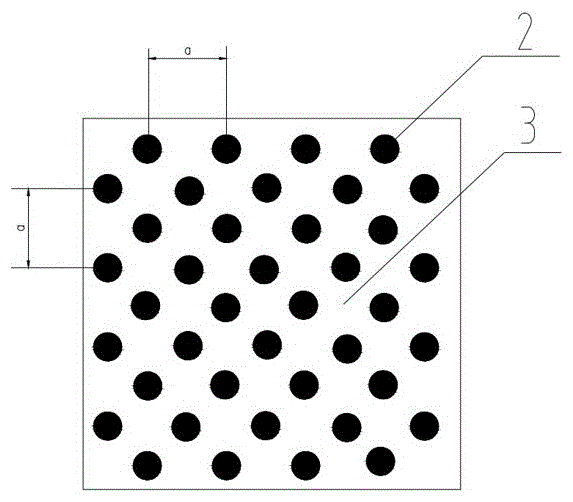

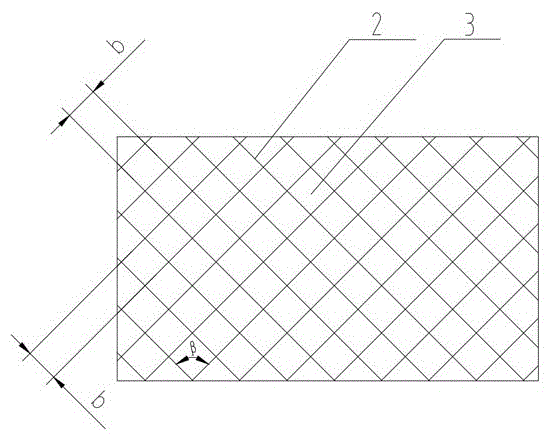

Brake pad with bionic structure and preparation method thereof

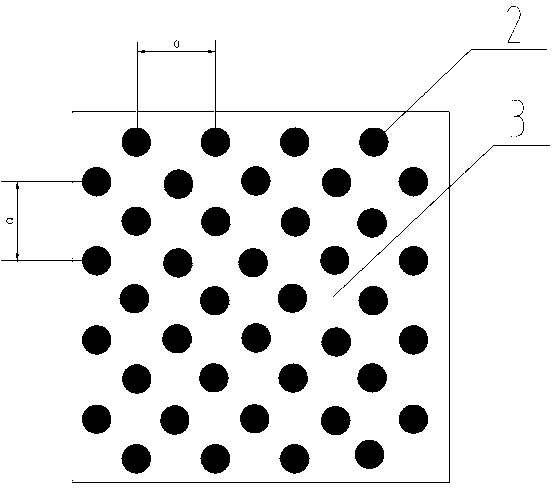

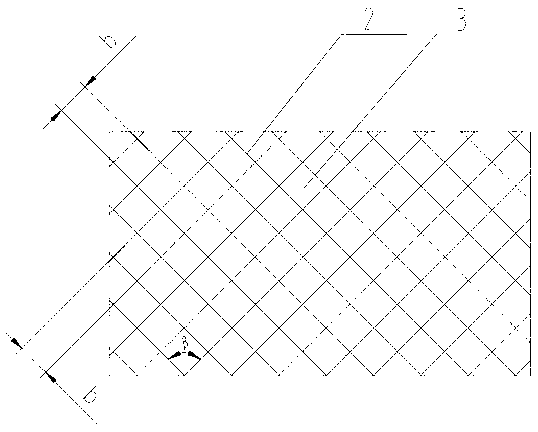

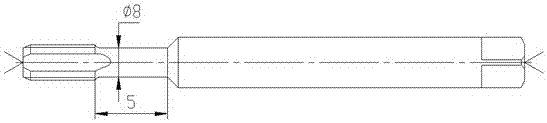

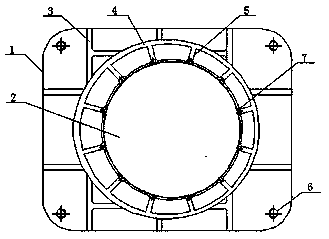

InactiveCN102853012ASmall change in coefficient of frictionReduce thermal wearFriction liningEngineeringBrake pad

The invention relates to the field of brake pads, especially to a brake pad with a bionic structure and a preparation method thereof. The brake pad comprises a brake pad substrate (1). A bionic reinforced framework (2) is arranged on one surface of the brake pad substrate (1); and compacted wear-resistant materials (3) are arranged in a gap of the bionic reinforced framework (2). The brake pad has the advantages of less friction coefficient variation, less thermal wear, higher reliability and longer service life at the high temperature.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Cutting Fluids in the Processing of Superhard Materials

Owner:GUIZHOU HONGLIN MACHINERY

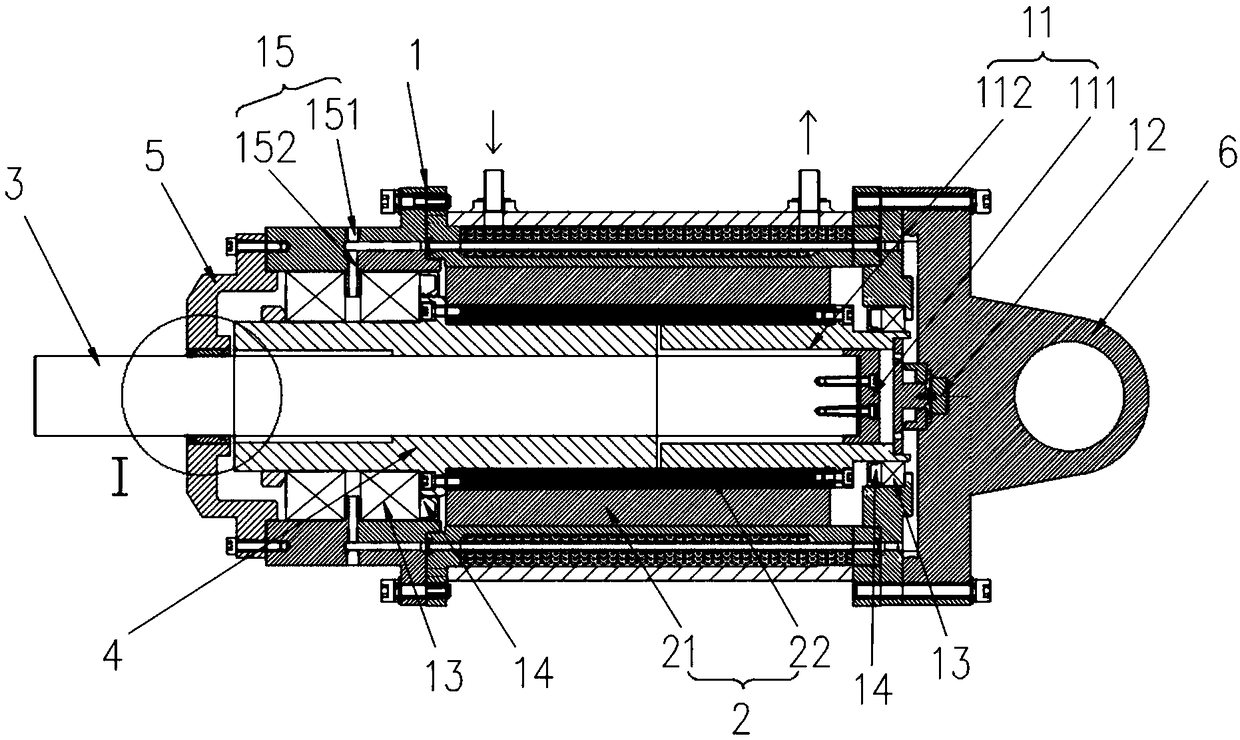

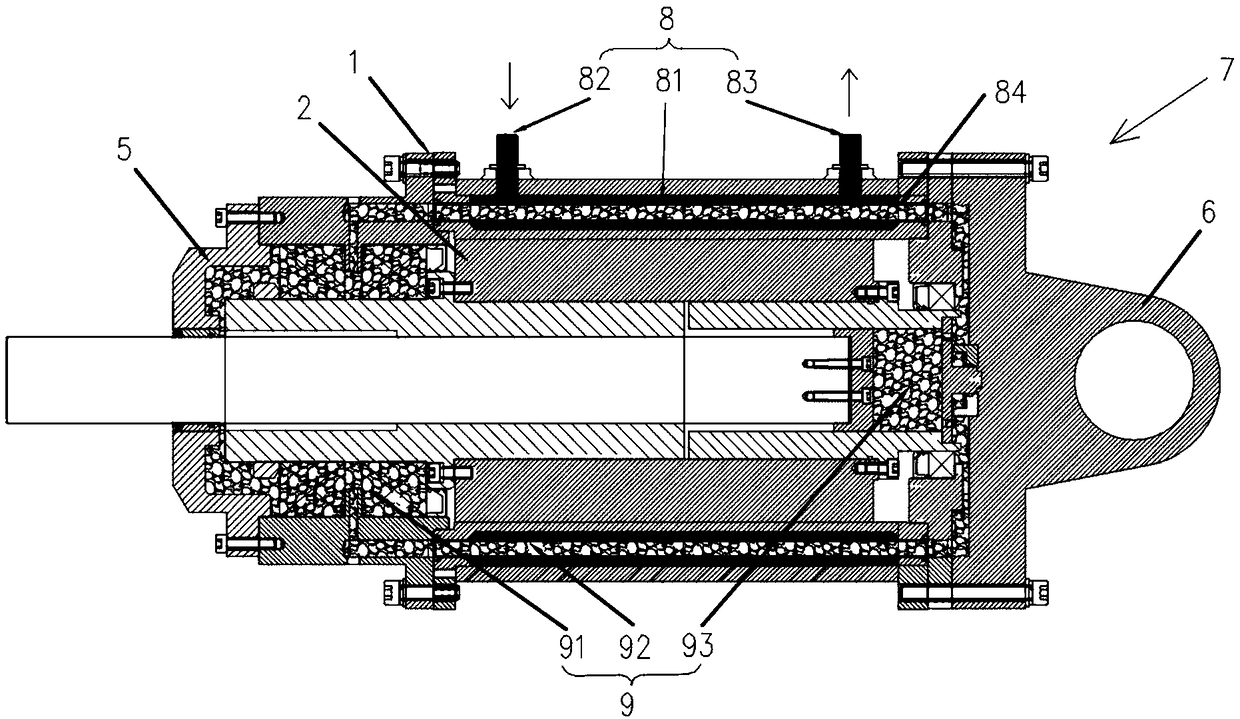

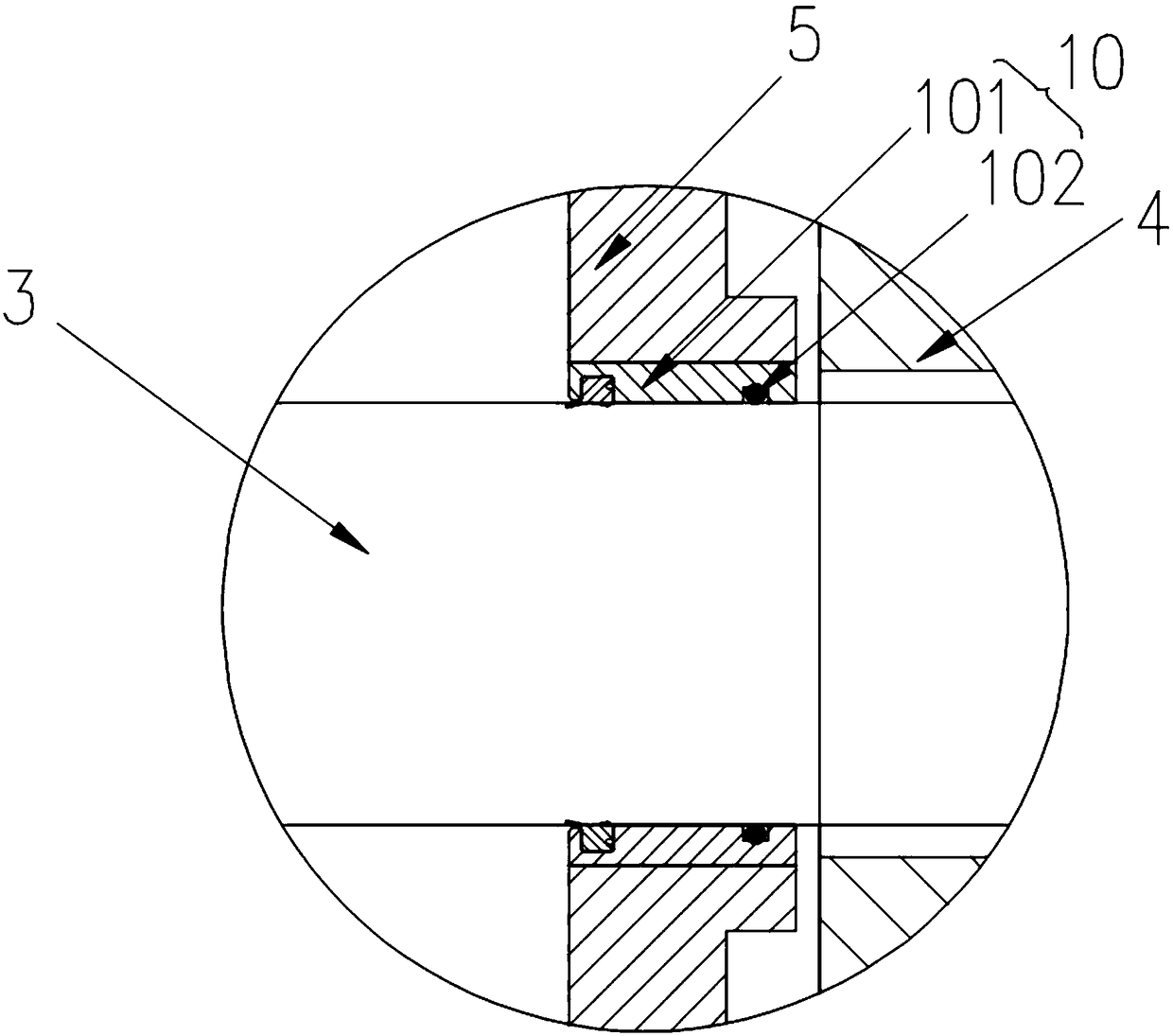

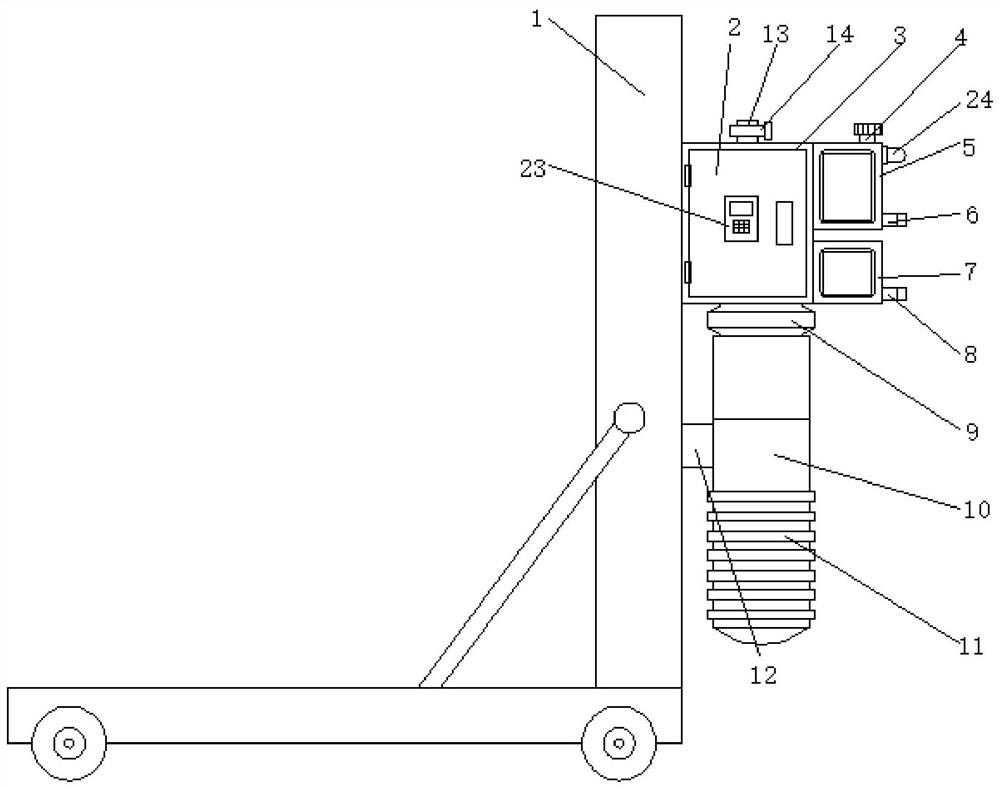

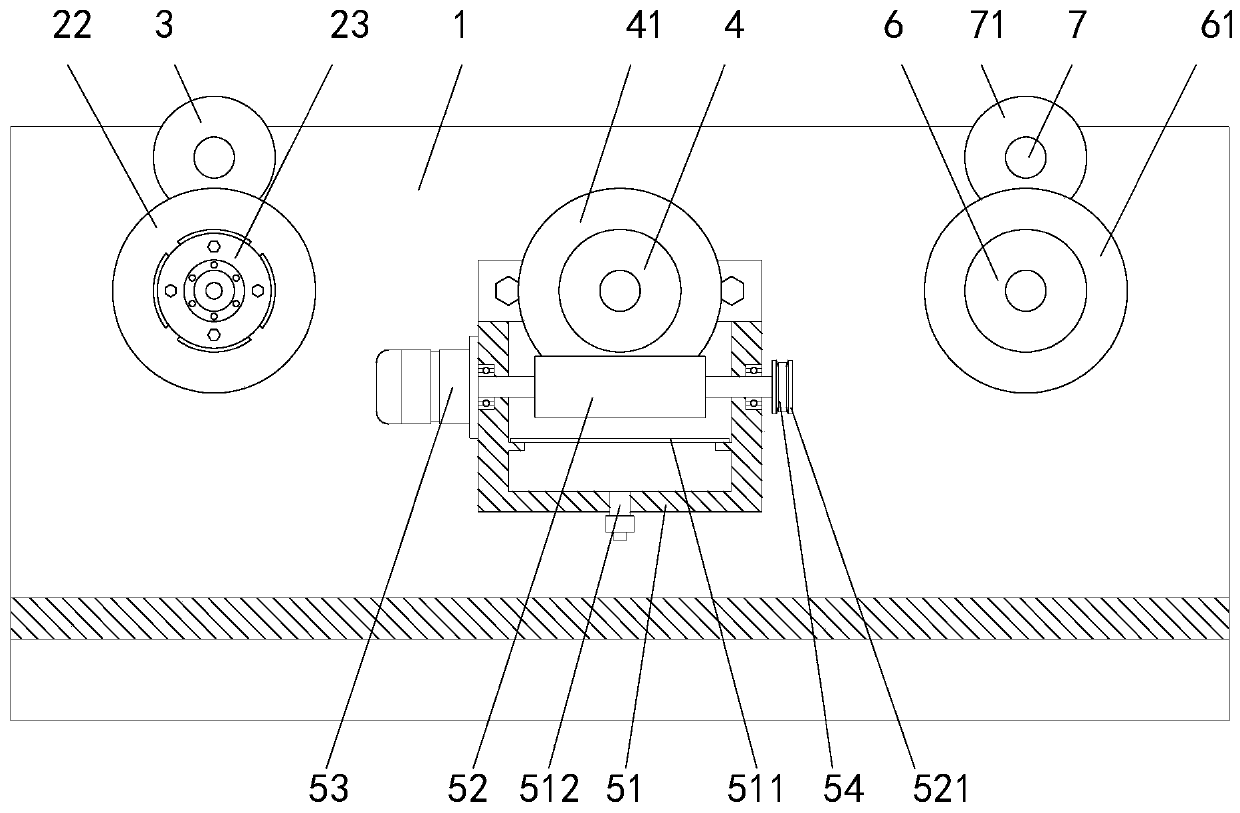

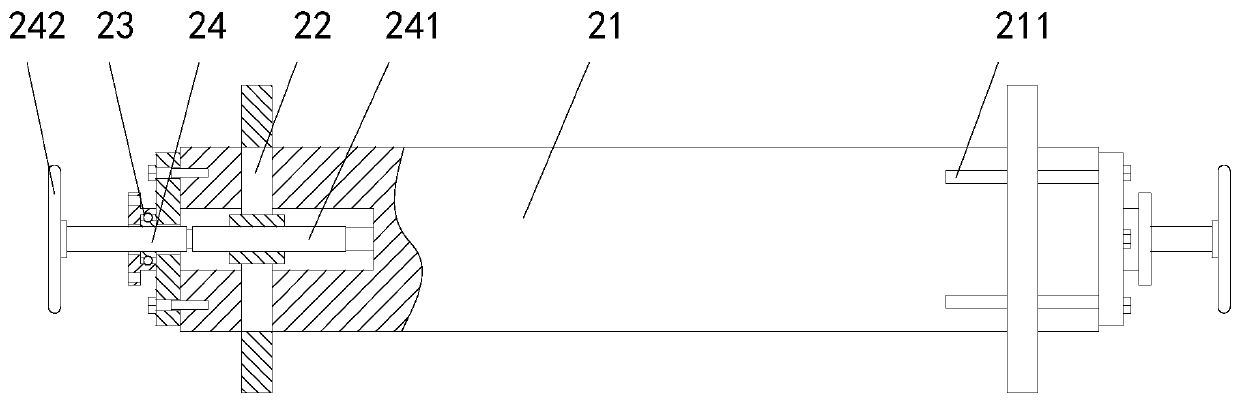

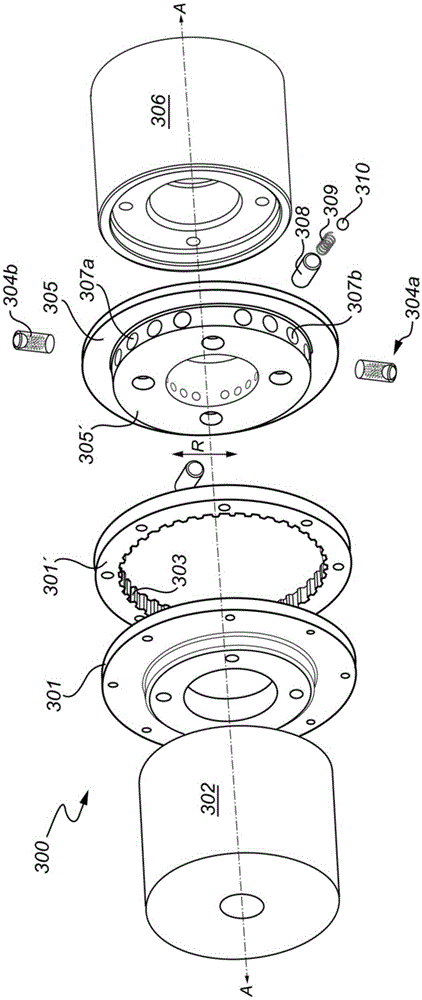

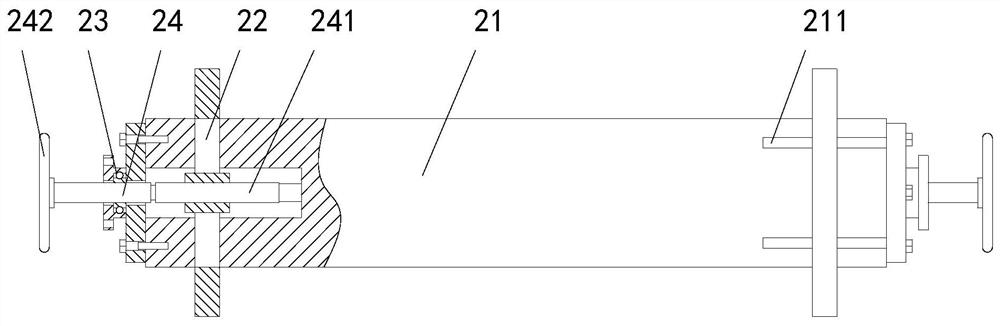

Electric cylinder with circulation cooling channel

ActiveCN108869680AAchieve coolingAchieve lubricationGearingMechanical energy handlingCooling channelTelescopic cylinder

The invention discloses an electric cylinder with a circulation cooling channel, and belongs to the field of driving machines. The electric cylinder comprises a machine case, a motor, a lead screw, alead screw nut which are mounted in the machine case, and a front end cover and a rear end cover which are used for sealing the two ends of the machine case. The electric cylinder further comprises acooling mechanism, wherein the cooling mechanism is provided with a lubricating oil circulation channel; the lubricating oil circulation channel comprises a first oil storage area formed by the frontend cover and the gap between the machine case and the motor, a second oil storage area formed in the machine case, and a third oil storage area formed by the rear end cover and the gap between the machine case and the motor, wherein the first oil storage area is communicated with the second oil storage area, and the second oil storage area is communicated with the third oil storage area. The cooling mechanism is utilized to transfer the heat in the electric cylinder out of the machine case through circulation flowing in the lubricating oil circulation channel, the double effects of cooling and lubricating of the electric cylinder are achieved, thermal abrasion is reduced, the stability of the electric cylinder is improved, and the service life of the electric cylinder is prolonged.

Owner:厦门微控科技有限公司

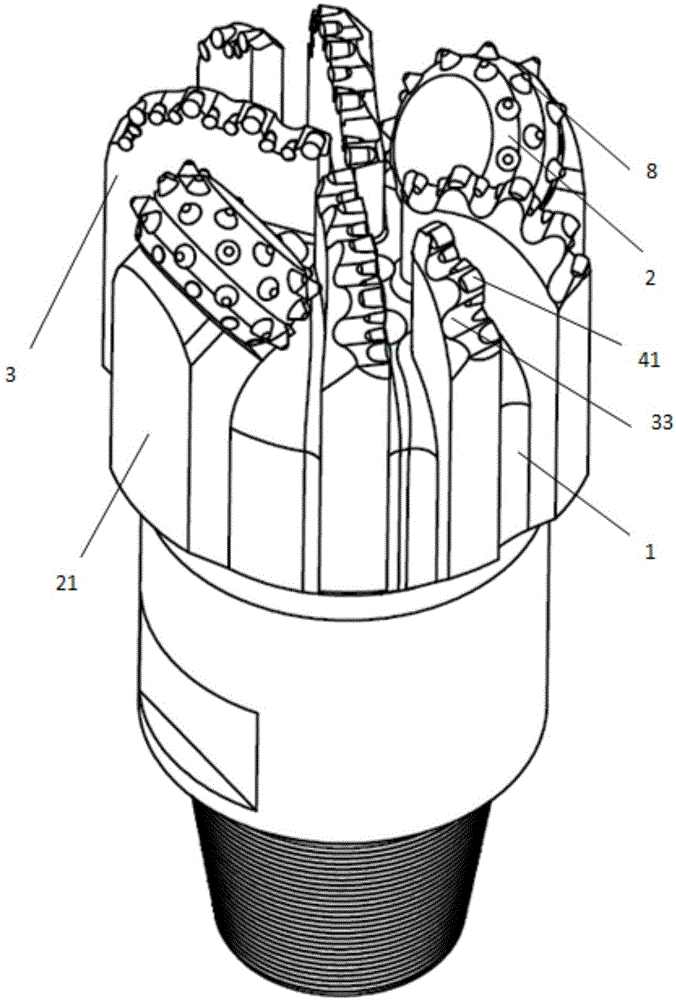

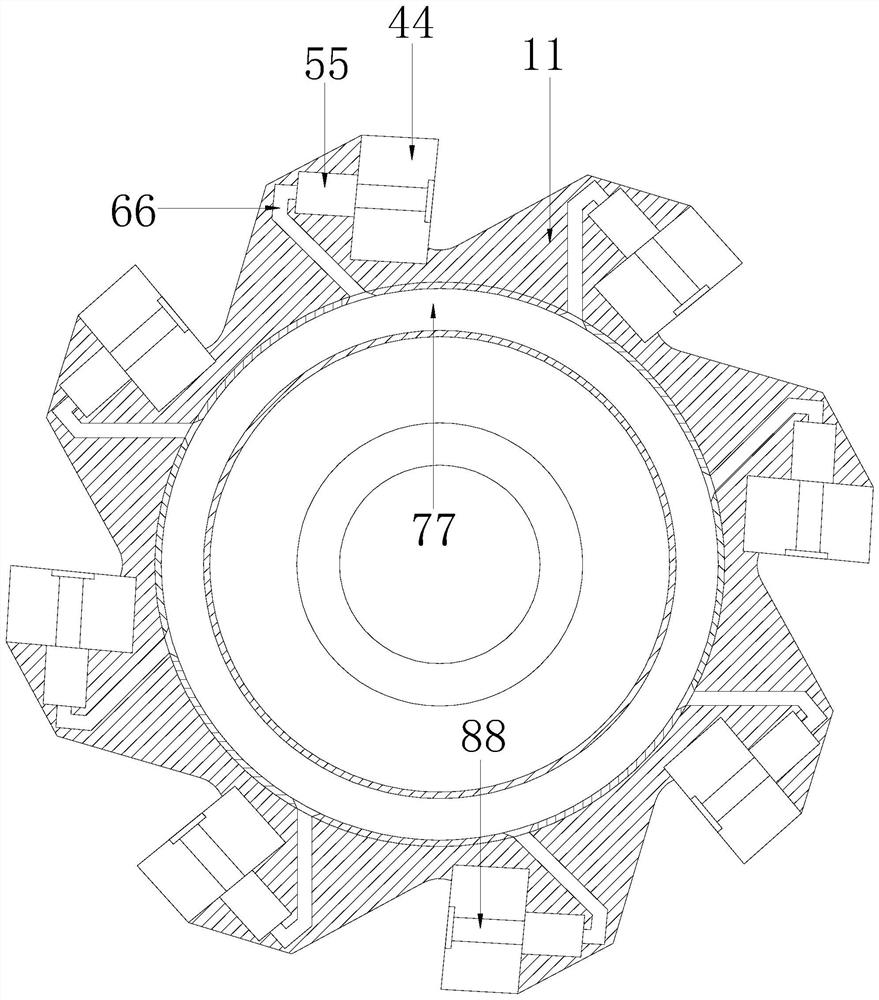

Composite cutting diamond drill bit

PendingCN108868625AAvoid or reduce competence phenomenaExtended service lifeDrill bitsConstructionsSpray nozzleDisc cutter

The invention relates to a composite cutting diamond drill bit. The drill bit comprises a drill bit body, fixing blades, disc cutters, water channel grooves and water passages or spray nozzles. The fixing blades extend from the drill bit body and are fixedly connected with the drill bit body, the water channel grooves are located among the fixing blades, blade cutting elements are arranged on thefixing blades, and one or more disc cutter cutting units are arranged on the drill bit body, wherein each disc cutter cutting unit is composed of a disc cutter, disc cutter cutting teeth on the disc cutter and a disc cutter shaft; the disc cutters are installed on the disc cutter shafts or are integrated with the disc cutter shafts, and the deviation angle alpha of the disc cutters is larger thanor equal to 20 degrees and smaller than or equal to 90 degrees. The composite cutting diamond drill bit is characterized in that one or more disc cutters are arranged on one fixing blade or in the water channel groove between every two fixing blades, the two sides of each disc cutter cutting unit are supported on supporting bodies respectively and rotatably connected with the supporting bodies, the service life of disc cutter bearings can be effectively prolonged, the safety performance of the disc cutter cutting units during use is improved, the rock breaking efficiency of the drill bit is effectively improved, and the service life of the drill bit is effectively prolonged.

Owner:SOUTHWEST PETROLEUM UNIV +1

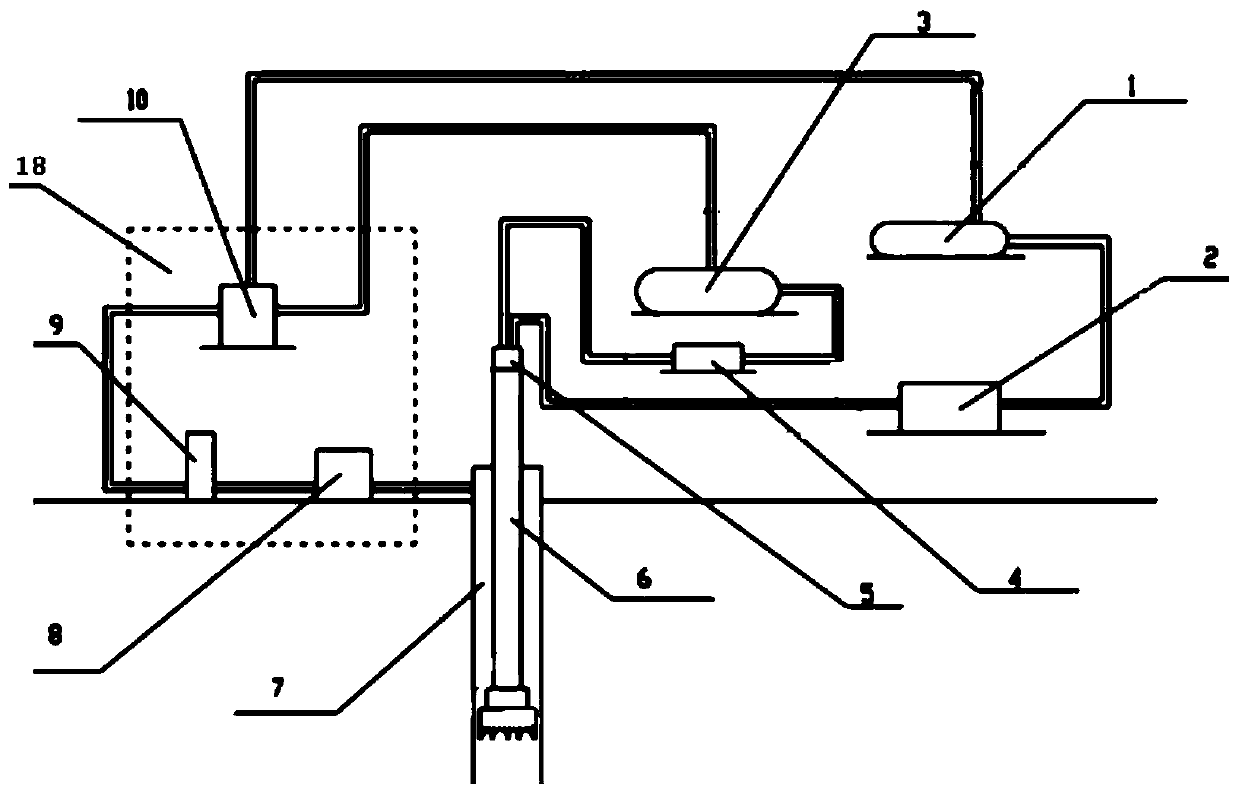

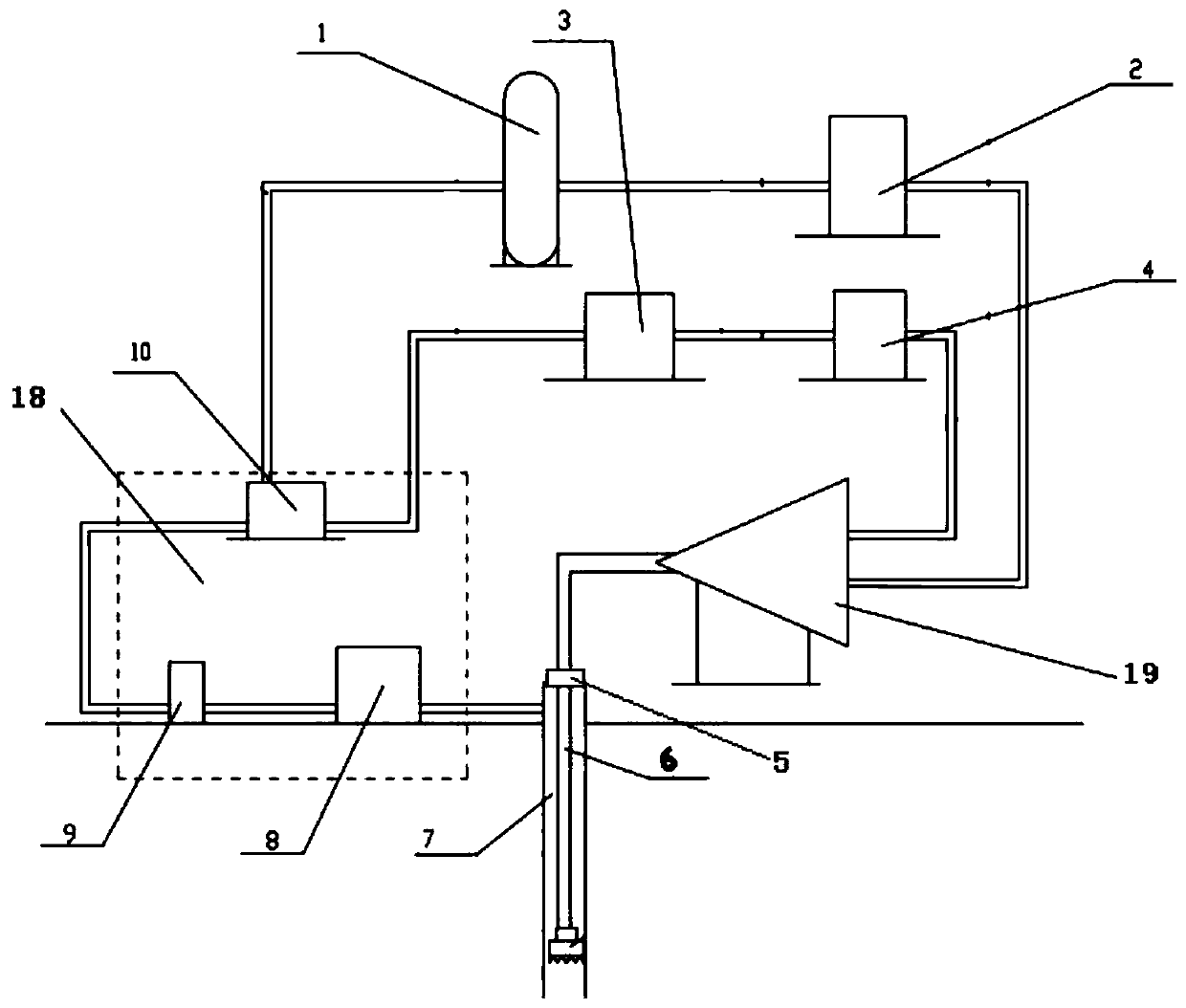

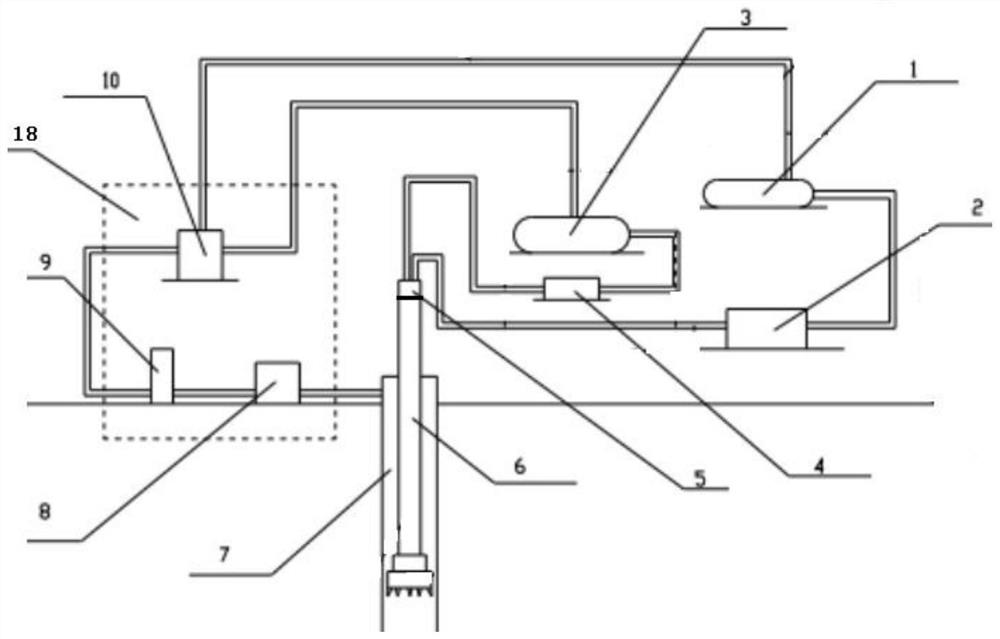

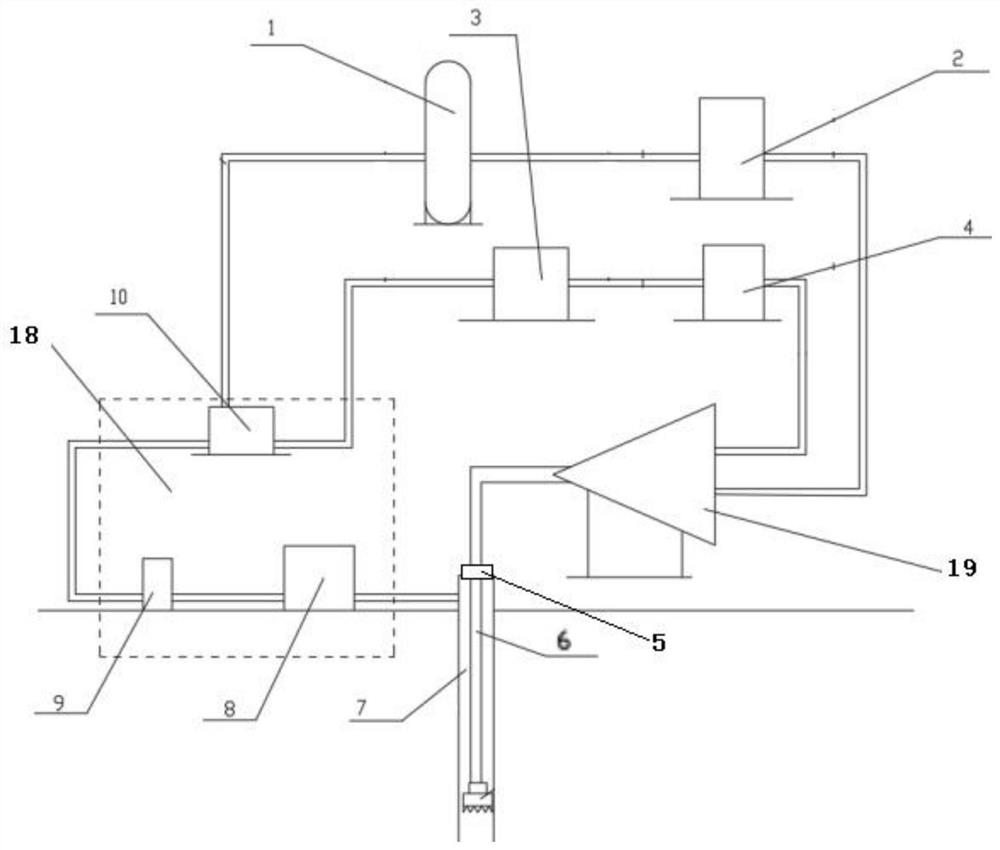

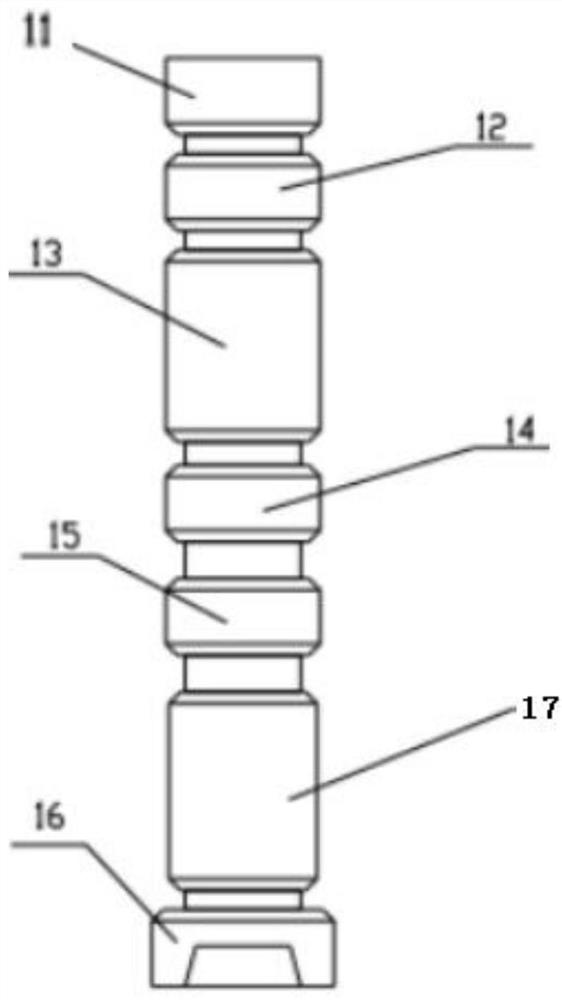

Dual-wall screw well drilling system based on gas-liquid two-phase drive

InactiveCN110344752AReduce thermal wearImprove continuous operation abilityConstructionsLiquid/gas jet drillingDirectional wellUniversal joint

A dual-wall screw well drilling system based on gas-liquid two-phase drive comprises a ground system, a well opening device and a downhole drilling tool assembly. The ground system comprises a gas storage and collection tank and a liquid storage and collection tank, wherein the gas storage and collection tank and the liquid storage and collection tank communicate with the well opening device through an air compressor and a liquid high-pressure pump correspondingly and then are connected with a gas-liquid two-phase flow recovery device. The gas-liquid two-phase flow recovery device comprises asand recover, a back-pressure valve and a ground gas-liquid separation device. The downhole drilling tool assembly comprises a dual arm drilling rod I connected with the well opening device. The lowerportion of the dual arm drilling rod I is sequentially connected with a short joint, a dual-wall screw motor, a universal joint, a downhole gas-liquid separation device I, a dual arm drill rod II anda drill bit. According to the dual-wall screw well drilling system, the problem that an air screw is prone to being damaged under a well can be reduced, the rock breaking efficiency can be improved,and therefore safe, rapid and economical well drilling can be achieved on a horizontal well and a directional well.

Owner:SOUTHWEST PETROLEUM UNIV

Pile hammer and pile driving device with pile hammer

InactiveCN112982401AEasy dischargeEasy to observeCombination devicesBulkheads/pilesNitrogen oxidesStructural engineering

The invention discloses a pile hammer and a pile driving device with the pile hammer. The pile hammer comprises a pile driving device body, wherein a filter box is fixedly connected to the top of the right side of the pile driving device body, and a diesel pile hammer is arranged at the bottom of the right side of the pile driving device body. According to the pile hammer and the pile driving device with the pile hammer, the pile driving device body, a box door, the filter box, a liquid inlet pipe, a first box body, a first liquid outlet valve, a second box body, a second liquid outlet valve, an exhaust fan, the diesel pile hammer, cooling fins, a sliding block, a second air outlet pipe, a second electromagnetic valve, a fan, an atomizing nozzle, a water level sensor, a partition plate, a first electromagnetic valve, a first air outlet pipe, a communicating pipe, a dustproof filter screen, a controller, an audible and visual alarm and a nitric oxide gas sensor are arranged and used in cooperation, and therefore the problem that due to the fact that an existing pile hammer and an existing pile driving device with the pile hammer usually do not have the function of efficiently filtering and removing nitric oxide, large pollution is prone to being caused to the atmosphere is solved.

Owner:上海三航奔腾海洋工程有限公司

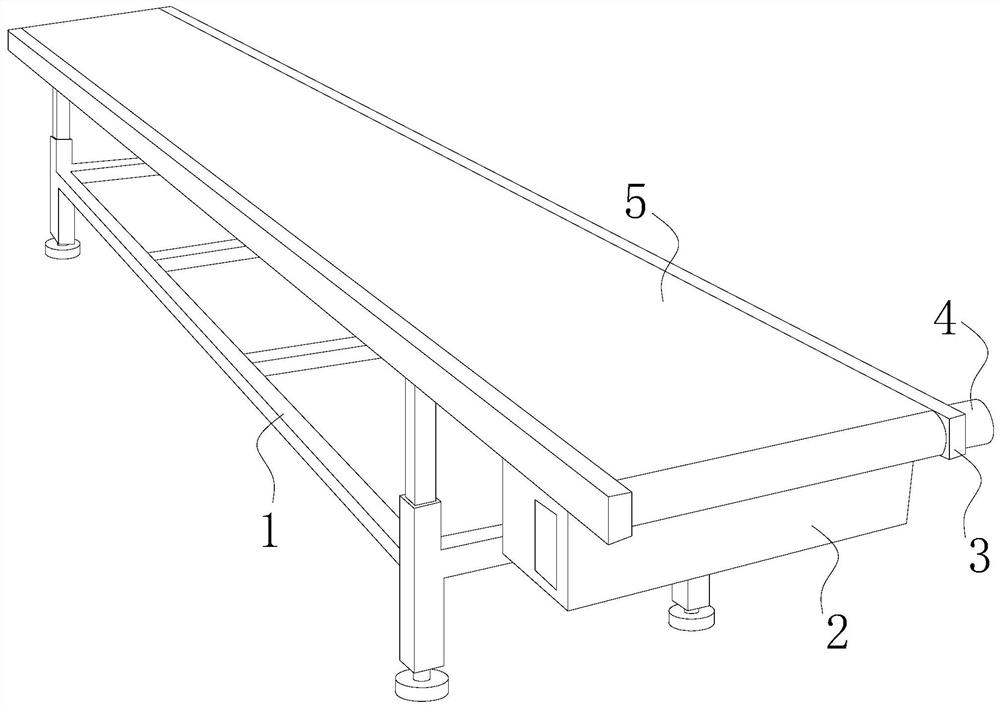

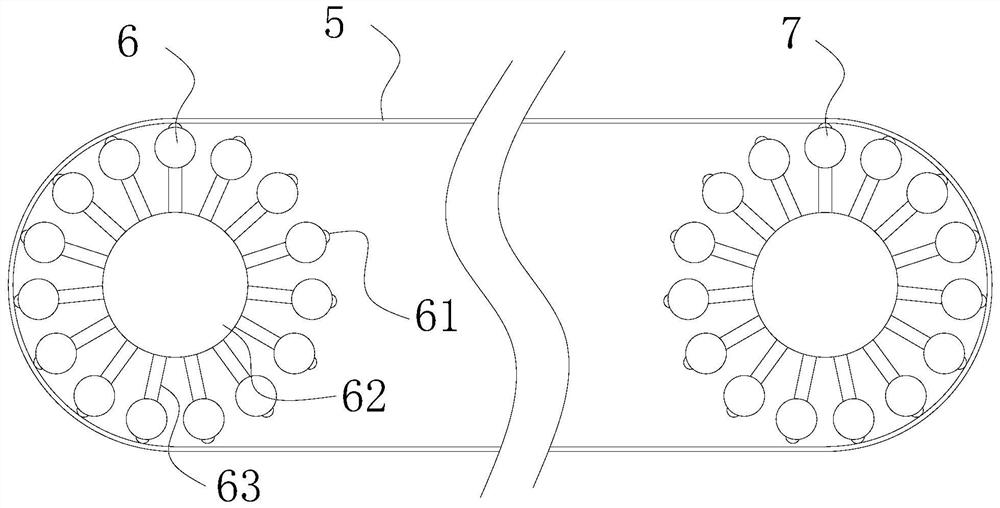

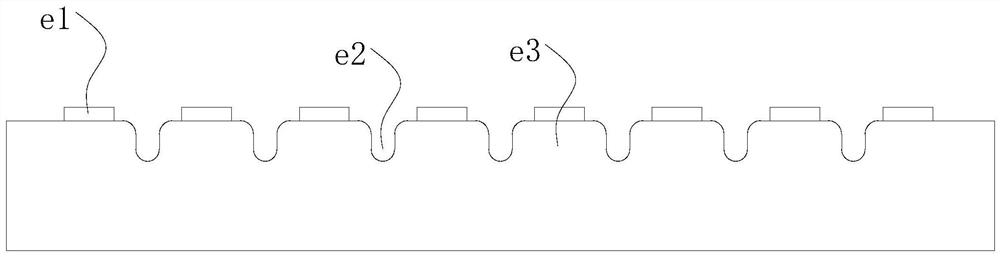

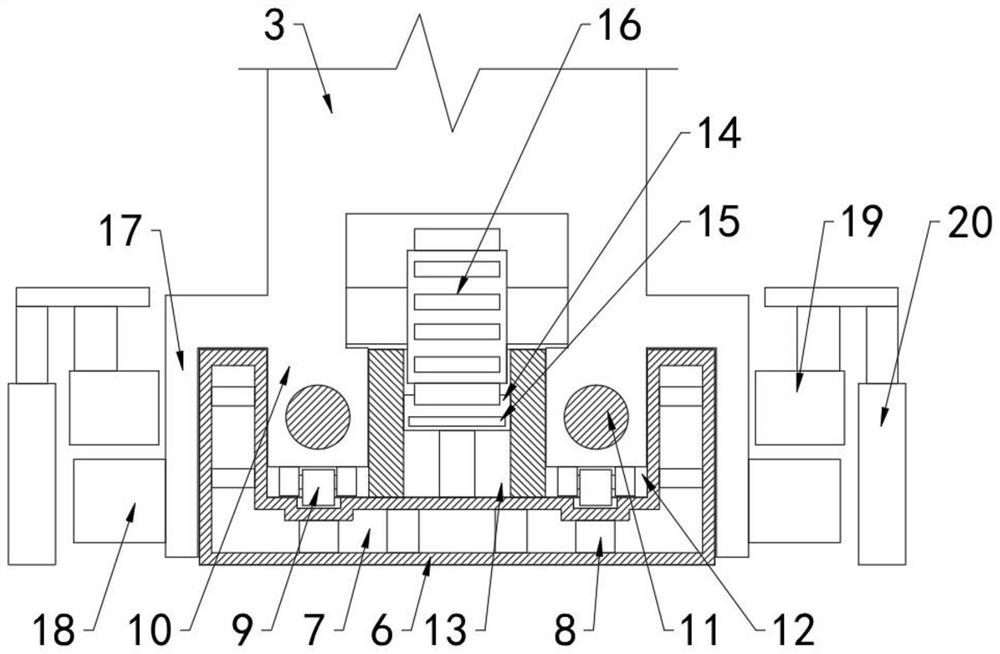

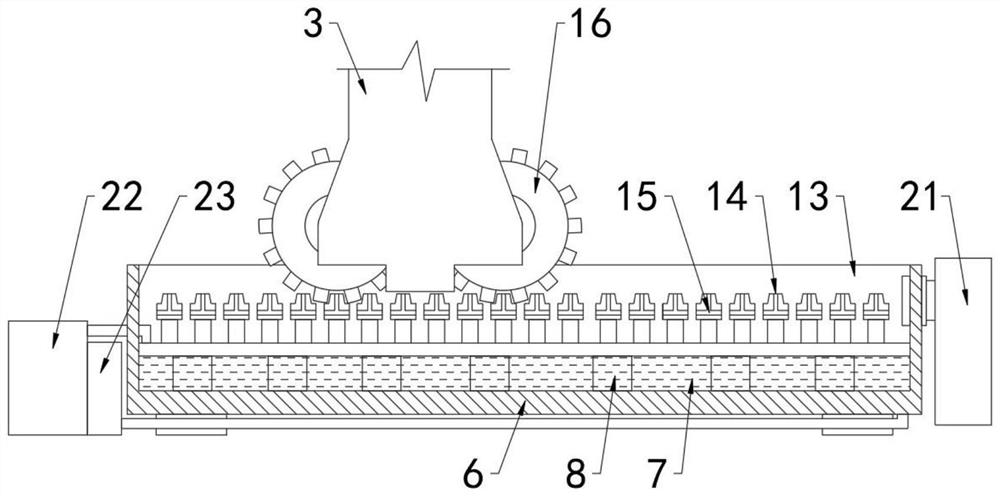

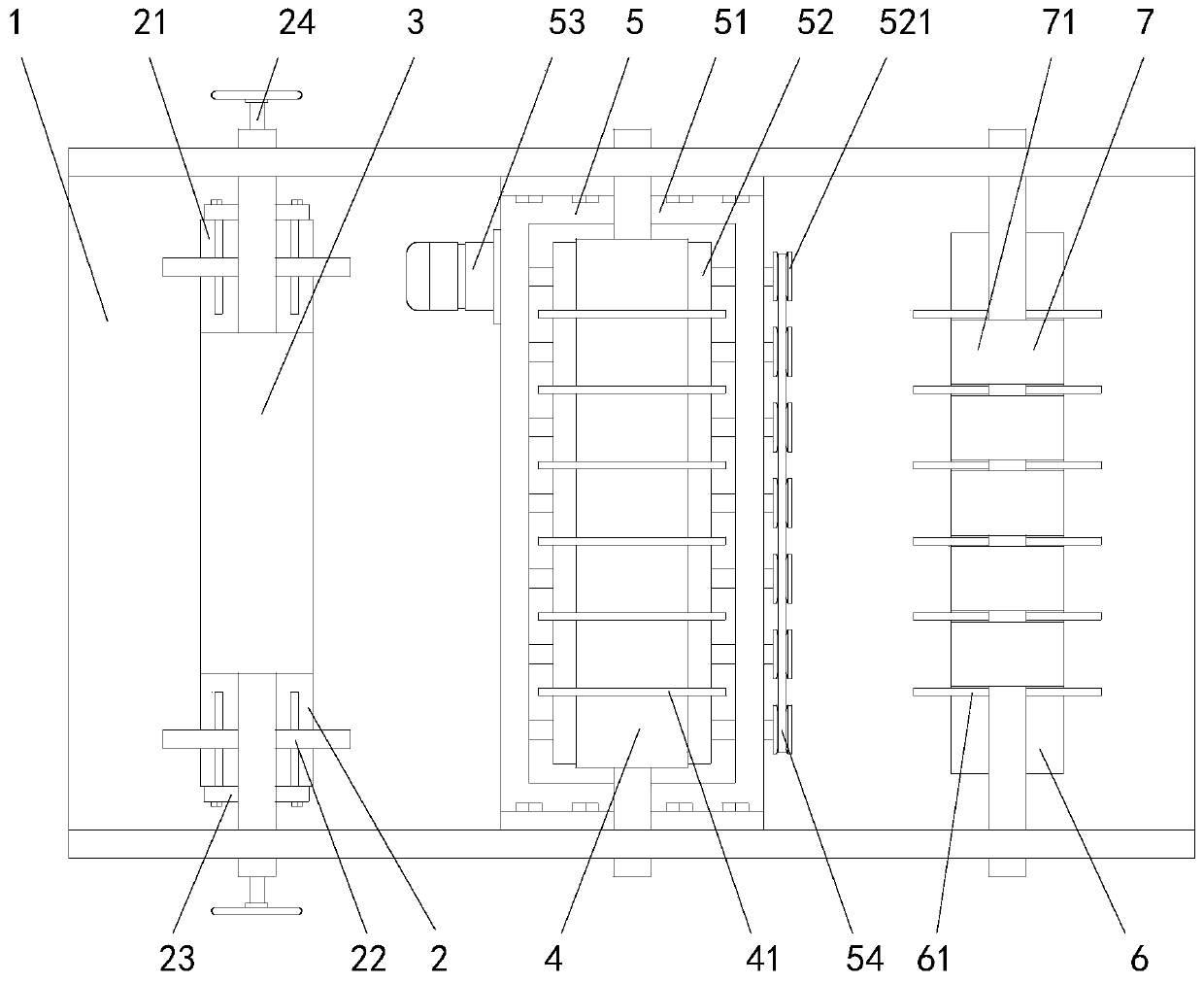

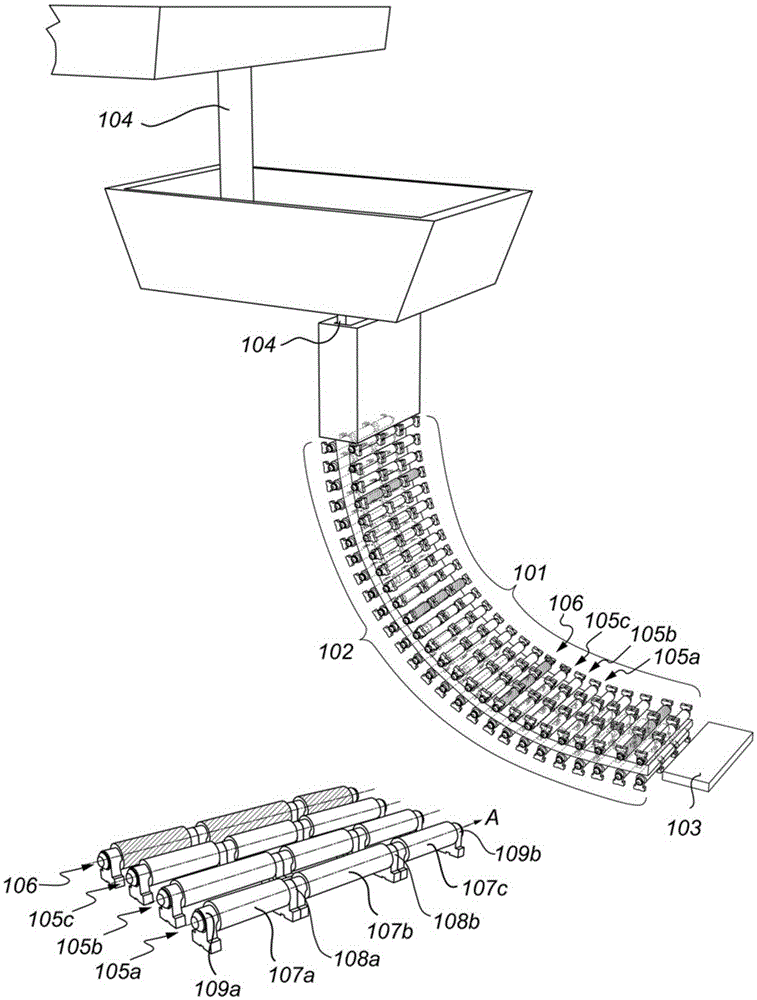

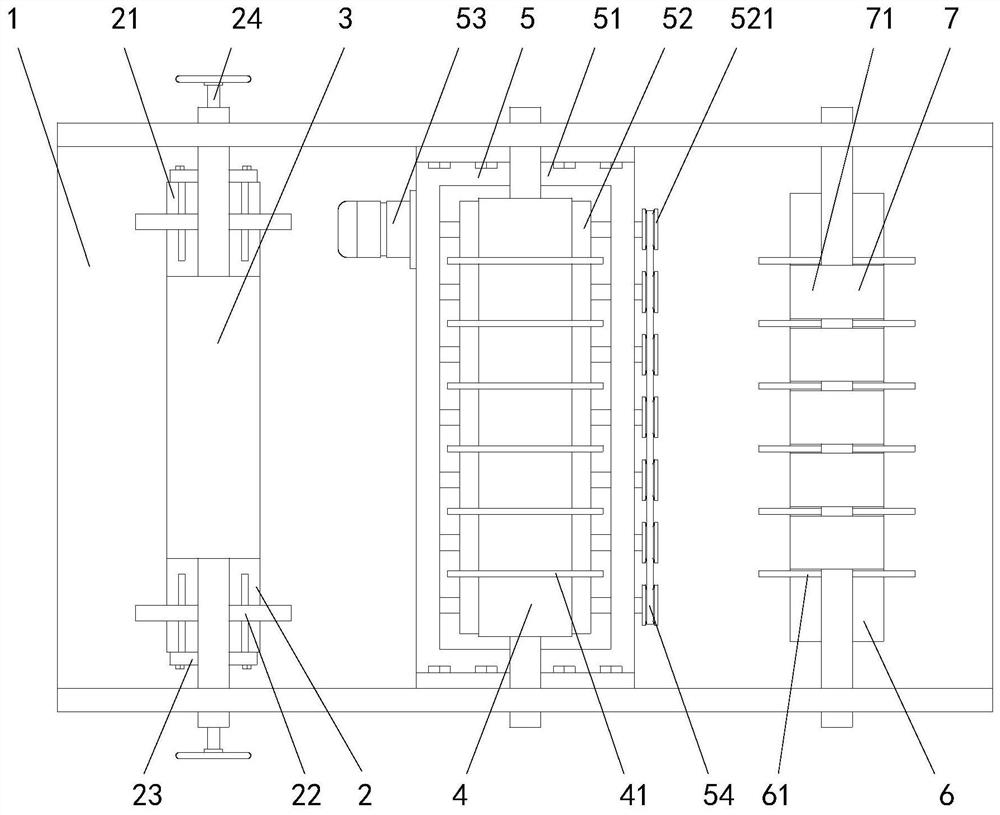

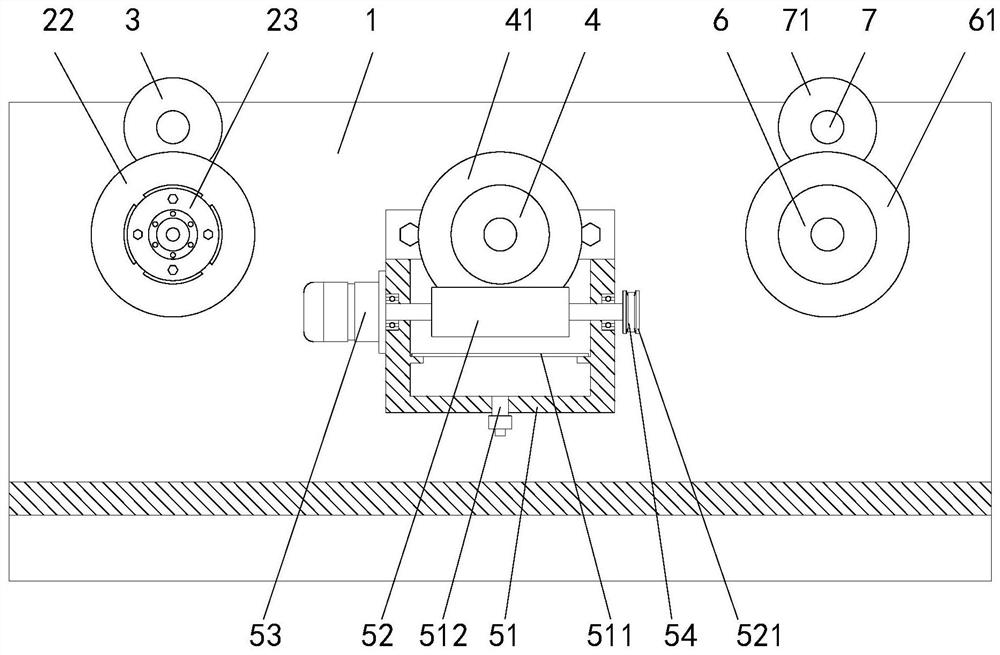

Belt assembly line

InactiveCN112158524AImprove cooling effectReduce thermal wearConveyorsRollersElectric machineryEngineering

The invention discloses a belt assembly line. The belt assembly line structurally comprises a supporting frame, a control box, limiting protection plates, a motor, a belt, a first roller and a secondroller, wherein the supporting frame is connected with the limiting protection plates, the number of the limiting protection plates is two, the belt is arranged between the two limiting protection plates, one end of the belt movably matches with the first roller, the other end of the belt matches with the second roller. Compared with the prior art, the belt assembly line has the beneficial effectsthat a novel roller is formed by combining a branch roller, a center shaft and a connecting plate and is greatly different from a traditional cylindrical roller, so that the belt is in linear contactwith the novel roller, the area contact of the traditional roller and the belt are abandoned, the contact area of the roller and the belt can be greatly reduced, the heat friction area can be reduced, the heat abrasion degree of the belt can be reduced, air circulation is facilitated through a formed ventilation channel and a formed heat dissipation channel, heat dissipation of the belt is betterfacilitated, a transverse column is detachably installed, only the transverse column need to be replaced, and the cost is reduced.

Owner:徐小林

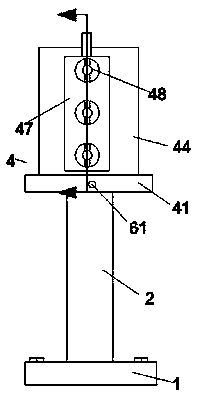

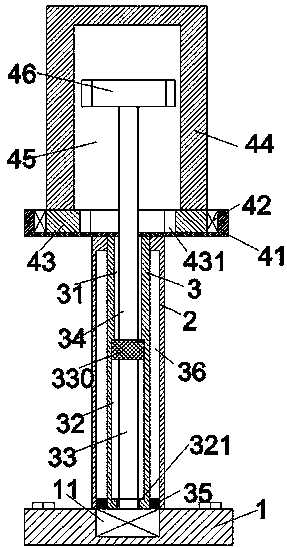

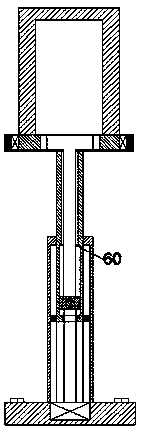

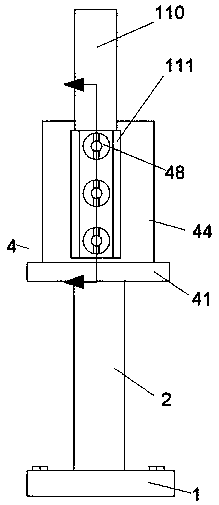

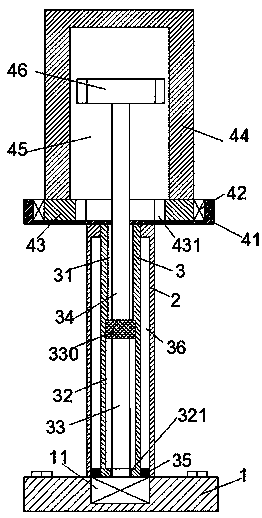

Novel cooling device of machining center

InactiveCN108202270AEasy to transportImprove ease of transportationMaintainance and safety accessoriesButt jointEngineering

The invention discloses a novel cooling device of a machining center. The novel cooling device of the machining center comprises an installation base, a vertical rod and a rotation mechanism. The vertical rod is fixedly arranged on the top of the installation base. The rotation mechanism is arranged above the vertical rod. A through movement groove with an upward cut is formed in the vertical rod.A vertical supporting rod which can carry out vertical sliding connection is installed in the through movement groove. A supporting rod bottom groove and a slot are formed in the vertical supportingrod, the cut of the supporting rod bottom groove is upward, and the slot is located below the supporting rod bottom groove. A first rotary column is arranged in the slot. A spiral block used in cooperation with the slot in a spiral fit manner is arranged on the top of the first rotary column. A second rotary column is arranged in the supporting rod bottom groove in an upward stretch manner. A rotary shell is arranged on the top of the second rotary column. A spray structure is further installed on the shell. The spray structure penetrates through a fixing metal piece and is in butt joint fit with a rotary liquid inlet pipe. A sealing pressure part, a pressure withstand rotary platform, a liquid sealing ring and a connecting block are arranged on the part, with the outlet, of the liquid inlet pipe. A retainer ring, a limiting rotary platform and a rotary platform fixing part are arranged on the part, with the inlet, of the liquid inlet pipe.

Owner:梅金琪

Double-wall screw drilling system based on gas-liquid two-phase drive

InactiveCN110344752BReduce thermal wearImprove continuous operation abilityConstructionsLiquid/gas jet drillingHorizontal wellsDirectional well

A dual-wall screw well drilling system based on gas-liquid two-phase drive comprises a ground system, a well opening device and a downhole drilling tool assembly. The ground system comprises a gas storage and collection tank and a liquid storage and collection tank, wherein the gas storage and collection tank and the liquid storage and collection tank communicate with the well opening device through an air compressor and a liquid high-pressure pump correspondingly and then are connected with a gas-liquid two-phase flow recovery device. The gas-liquid two-phase flow recovery device comprises asand recover, a back-pressure valve and a ground gas-liquid separation device. The downhole drilling tool assembly comprises a dual arm drilling rod I connected with the well opening device. The lowerportion of the dual arm drilling rod I is sequentially connected with a short joint, a dual-wall screw motor, a universal joint, a downhole gas-liquid separation device I, a dual arm drill rod II anda drill bit. According to the dual-wall screw well drilling system, the problem that an air screw is prone to being damaged under a well can be reduced, the rock breaking efficiency can be improved,and therefore safe, rapid and economical well drilling can be achieved on a horizontal well and a directional well.

Owner:SOUTHWEST PETROLEUM UNIV

A Composite Drill Bit Suitable for Difficult-Drilling Formation

ActiveCN106437525BAdjust the tooth densityIncreased axial wear volumeDrill bitsConstructionsPetroleum engineering

The invention discloses a composite drill bit suitable for a stratum difficult to drill. The composite drill bit suitable for the stratum difficult to drill comprises a drill bit body, cutter wings which are fixedly connected with the drill bit body, tooth wheels which are rotatably connected with the drill bit body, and water holes or nozzles which are arranged on the drill bit body. A plurality of first sets of cutting teeth are arranged on each cutter wing. Pits are formed in the sides, provided with the teeth, of the cutter wings and used for fixing the first sets of cutting teeth. The tooth wheels are rotatably connected with the drill bit body through tooth palms. Teeth are mounted on the tooth wheels. In the common coverage area of the body contour line of at least one cutter wing and the body contour line of at least another cutter wing, at least one non-overlapping area and at least one overlapping point or overlapping area exist. Through the structure characteristic, the drill bit can operate in an asynchronous cutting mode, the longitudinal abrasion length of the drill bit can be increased, and the service life of the drill bit can be prolonged; and the drill bit is in a high-specific-pressure drilling state in the whole drilling process, the capacity to intrude into rocks of the drill bit is improved, the drilling speed of the drill bit in the stratum difficult to drill is increased accordingly, and the service life of the drill bit in the stratum difficult to drill is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV +1

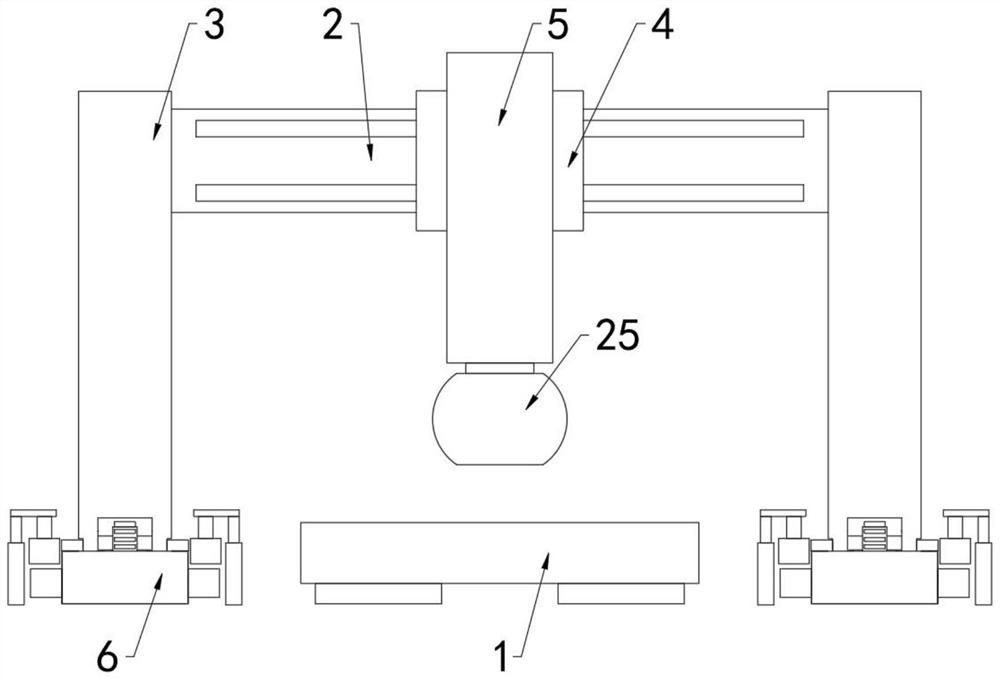

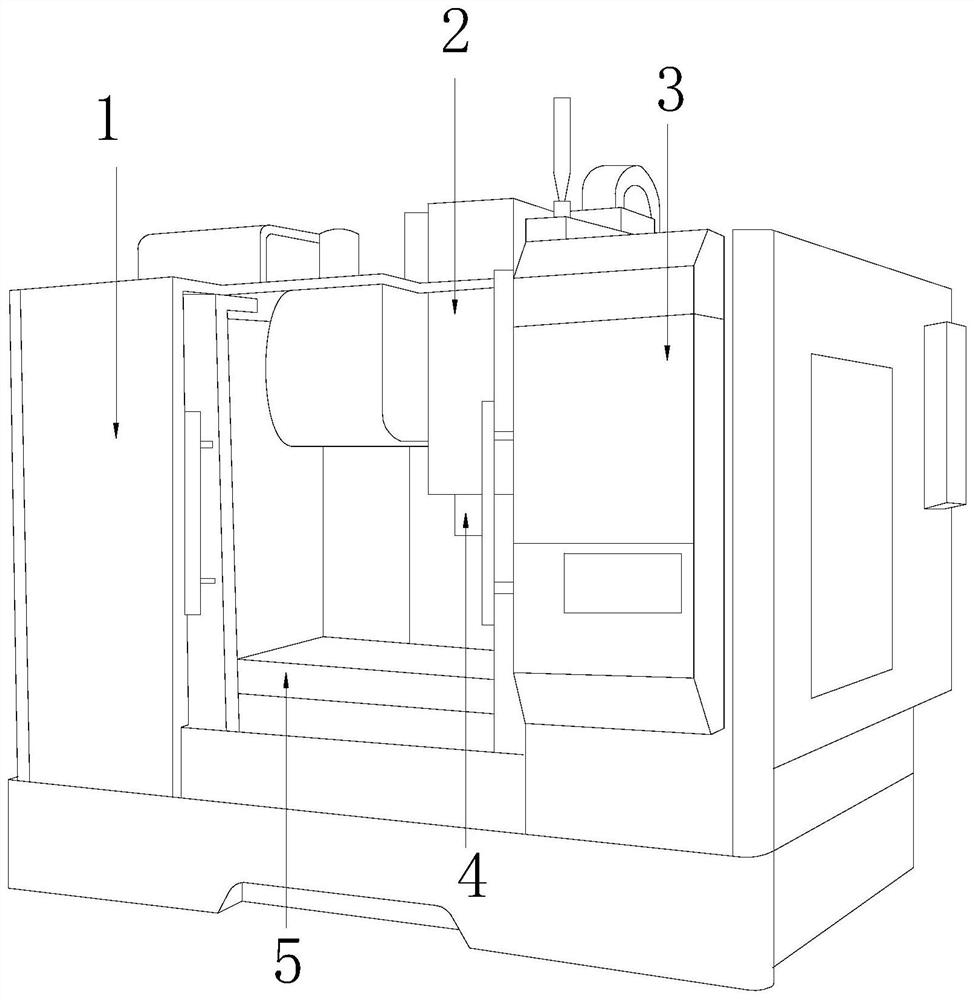

Ultrahigh-speed movable column type gantry machining center

PendingCN113909924AReduce thermal wearExtended service lifeLarge fixed membersMaintainance and safety accessoriesUltra high speedEngineering

The invention relates to the technical field of gantry machining centers, in particular to an ultrahigh-speed movable column type gantry machining center, and solves the problem that the moving accuracy of a stand column of an ultrahigh-speed gantry machining center needs to be improved in the prior art. The ultrahigh-speed movable column type gantry machining center comprises a workbench, a cross beam arranged above the workbench, a ram arranged on the cross beam, a sliding column installed on the ram and a machining cutting die installed at the bottom end of the sliding column, and further comprises two sets of fixing bases symmetrically arranged, and two moving grooves are symmetrically formed in the tops of the fixing bases. According to the ultrahigh-speed movable column type gantry machining center, when a stand column stopping command is started, speed stopping plates rapidly move downwards till positioning toothed plates connected with outer side plates are vertically connected in an inserted mode so as to limit inertial motion of stand columns, braking of inertial motion of the ultrahigh-speed movable column type gantry machining center is achieved through the up-and-down insertion meshing mode of teeth, and therefore the stability and the accuracy of high-speed movement of the loaded stand columns are realized.

Owner:CHANGZHOU TRANSCEND CNC MACHINE TOOL

High heat-resistant 4Cr3Mo3W4VNb hot work die steel

InactiveCN110318002AExtended service lifeReduce manufacturing costProcess efficiency improvementHeat resistanceMetallurgy

The invention discloses high heat-resistant 4Cr3Mo3W4VNb hot work die steel which is prepared from the following components including, by weight, 0.1%-0.3% of C, 0.2%-0.6% of Mn, 0.4%-0.6% of Si, 2.0%-2.5% of Cr, 1.2%-1.8% of Mo, 1.0%-1.5% of Nb, 0.8%-1.2% of W, 0.8%-1.2% of V and the balance Fe. The high heat-resistant 4Cr3Mo3W4VNb hot work die steel disclosed by the invention is long in servicelife and particularly small in heat wear.

Owner:湖北长怡特殊材料科技有限公司

Automatic sheet longitudinal shearing unit guide roller

ActiveCN110587019APrevent oxidationPrevent discolorationShearing machine accessoriesCooling effectCopper

The invention relates to an automatic sheet longitudinal shearing unit guide roller which comprises a roller frame, a feeding guide roller assembly, a feeding guide pressure roller located over the feeding guide roller assembly, a longitudinal shearing roller, an anti-oxidation coating mechanism located under the longitudinal shearing roller, a partition conveying roller and a leveling pressure roller located over the partition conveying roller. By means of the automatic sheet longitudinal shearing unit guide roller, the anti-oxidation coating mechanism is arranged so that oxidation and discoloration of a copper strip shearing place can be effectively prevented, and burrs and scratch marks generated by copper scales and other pollutants at the copper strip shearing place can be avoided; and a cotton brush roller has a cooling effect on a disc knife, so that the thermal wear of the disc knife is reduced, and the service life of the disc knife is prolonged.

Owner:绍兴市上虞运鑫模具加工有限公司

A Disc Cutter Composite Drill Bit Suitable for Difficult-Drilling Formation

Owner:SOUTHWEST PETROLEUM UNIV +1

Method and device for performing electric magnetization resistance welding-braze welding compounding on dissimilar materials

InactiveCN101844260BSpeed up the flowReduce temperature gradientSoldering apparatusMetal working apparatusMagnetizationMetallic materials

The invention discloses a method and a device for performing electric magnetization resistance welding-braze welding compounding on dissimilar materials by assistance of an applied magnetic field. In the process of performing resistance welding-braze welding on the dissimilar metal material, a liquid solder is subjected to auxiliary electromagnetic stirring and ordered control, and the molten liquid solder is subjected to the reinforced booster action of electromagnetic stirring and electric magnetization by using an external applied alternating magnetic field which is generated by a magnet exciting coil in a welding area so as to promote directional flow of the liquid solder, and rupture of membranes, wetting, spreading and diffusion of the liquid solder on the surface of the metal material with a higher melting point, promote the liquid solder and a base metal which is molten by the metal material with a lower melting point to be mixed fully, promote interdiffusion of elements and compositions between the solder and the base metal and alloying between the two, improve uniformity of compositions of a soldered seam, reduce the weld defects, optimize the texture and the performanceof the soldered seam, and improve the resistance soldered joint; and the device has the advantages of simple structure, flexible application, lower cost, good effect, and easy implementation.

Owner:CHONGQING UNIV

Brake pad with bionic structure and preparation method thereof

InactiveCN102853012BSmall change in coefficient of frictionReduce thermal wearFriction liningWear resistantEngineering

The invention relates to the field of brake pads, especially to a brake pad with a bionic structure and a preparation method thereof. The brake pad comprises a brake pad substrate (1). A bionic reinforced framework (2) is arranged on one surface of the brake pad substrate (1); and compacted wear-resistant materials (3) are arranged in a gap of the bionic reinforced framework (2). The brake pad has the advantages of less friction coefficient variation, less thermal wear, higher reliability and longer service life at the high temperature.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Hot forging die for cutting sheet

InactiveCN109794573ASimple structureReduce thermal wear andForging/hammering/pressing machinesLubricationForging

The invention discloses a hot forging die for a cutting sheet. The hot forging die comprises a forging die, a hot forging containing cavity, an oil passage and an oil groove, the forging die is provided with the hot forging containing cavity matched with a rotor punching piece, a plurality of transverse oil passages and longitudinal oil passages are formed in the forging die, the plurality of transverse oil passages and longitudinal oil passages are connected in a staggered way to form the oil passage, the annular oil groove is arranged in the forging die, the oil groove is arranged around thehot forging containing core and communicated with the oil passages, a plurality of oil groove branches are arranged between the oil groove and the hot forging containing core, and a plurality of cooling holes are formed in the forging die. The hot forging die has the advantages that the structure is simple, through the mutual cooperation of the oil passage and the oil groove, the lubricating oilto pass through and flow in the hot forging containing cavity, the degree of hot wear and crack damage of the forging die is reduced, the lubrication and cooling effects are obvious, the service lifeof the mold is effectively prolonged, the product precision is ensured, and the cost is low.

Owner:江苏德克精密工具有限公司

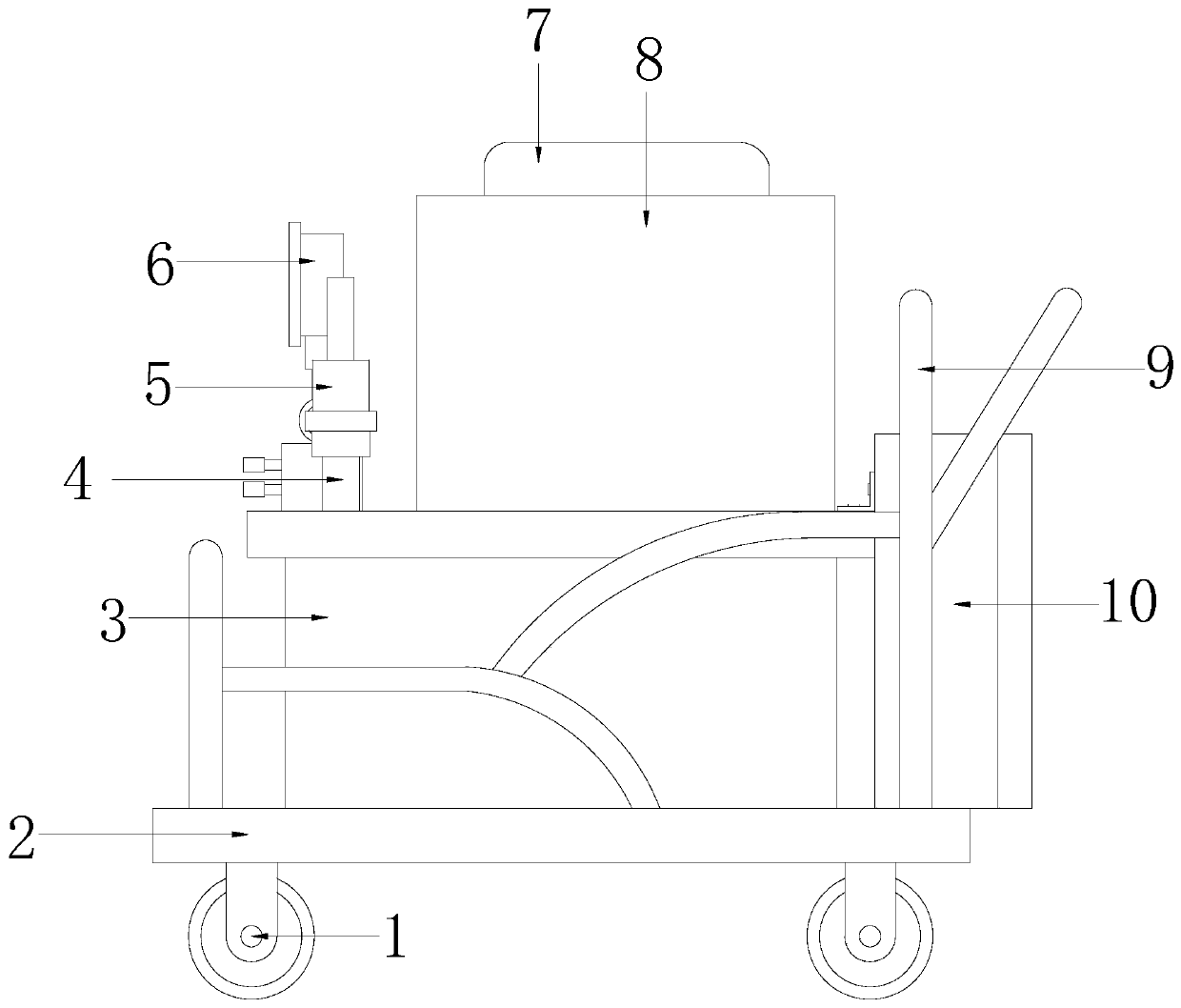

Ring groove type rivet machine

InactiveCN111331068AAvoid overheating damageReduce wearRotary piston pumpsRotary piston liquid enginesGear pumpDamping function

The present invention discloses a ring groove type rivet machine. The ring groove type rivet machine structurally comprises full-braking castors, a base, a machine body, a rivet gun, a novel gear pump, a pressure gauge, an efficient energy-saving motor, a damping device, a pushing frame and a hydraulic tank, wherein the top of the base is provided with the pushing frame by welding. Compared with the prior art, the machine has the beneficial effects that the machine has a cooling function and can cool a pump body, so that the pump body is prevented from being damaged due to overheat; gear blocks are sleeved with rubber sleeve strips, so that the machine has the protective effect on the gear blocks, the situation that the whole driving wheel is scrapped as the gear blocks are in direct contact to be worn is avoided, and oil leakage caused by gaps can be avoided; after the rubber sleeve strips are worn, only the rubber sleeve strips need to be replaced, so that the repair cost can be reduced and the repair efficiency is improved; by arranging the damping device, the machine has the functions of absorbing sound and reducing noise, the noise generated by the motor can be absorbed, noisepollution is avoided, the machine also has the damping function, vibration force generated by the motor in operation can be reduced, and equipment is prevented from being damaged due to resonance shaking.

Owner:郑玉林

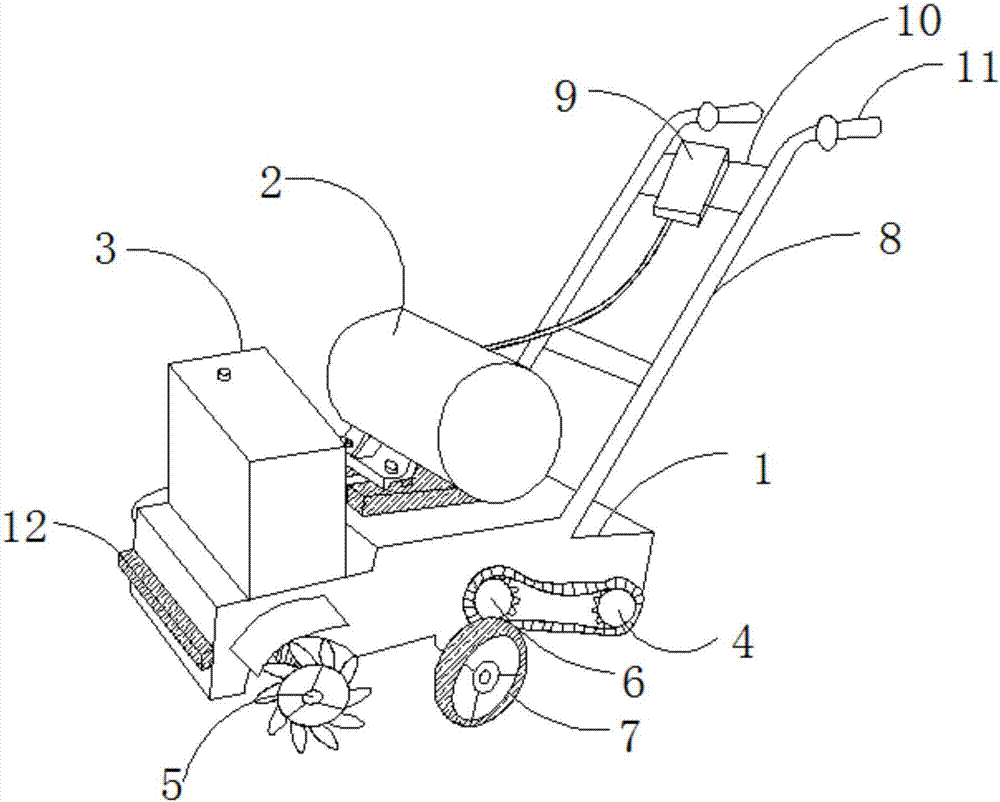

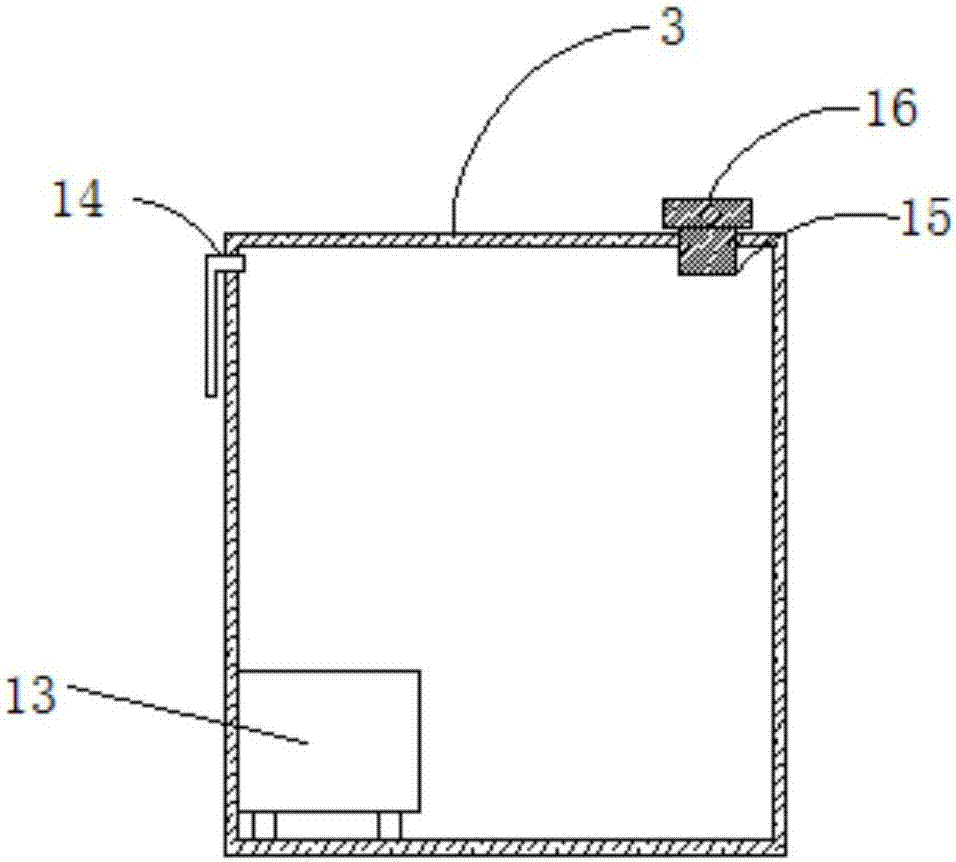

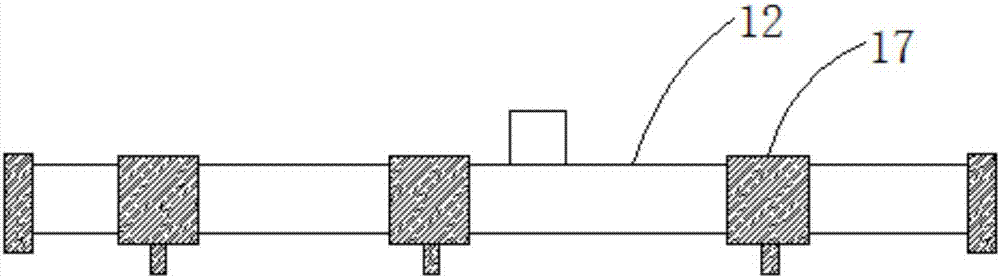

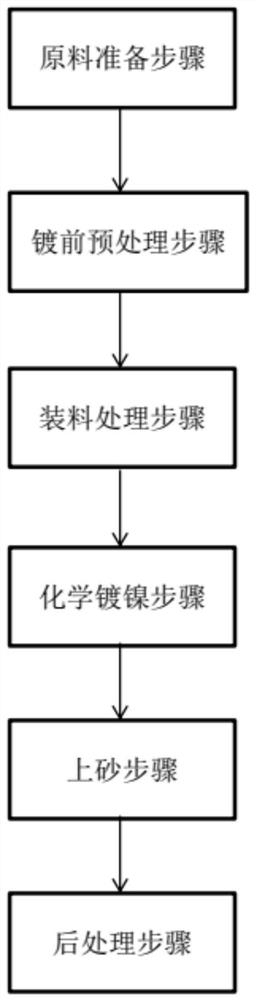

Novel building deslagging device

The invention discloses a novel building deslagging device, which comprises a rack, an electromotor and a water tank. Walking wheels are arranged in middle positions of two sides of the bottom part of the rack; a front deslagging rolling shaft is arranged at one side, close to the lower part of the water tank, of each walking wheel; a rear deslagging rolling shaft is arranged at the other side, close to the lower part of a pushing hand, of each walking wheel; a horizontal water spray pipe is fixedly arranged at the front end of the rack; a transmission rolling shaft is arranged under the electromotor, and is rotataby connected with the electromotor through a gear hobbing; one end of the transmission rolling shaft is connected with each front deslagging rolling shaft through a transmission chain; the other end of the transmission rolling shaft is connected with each rear deslagging rolling shaft through a transmission chain. The novel building deslagging device provided by the invention is mainly used for cleaning concrete residues remained by a building, and spraying water for moistening the concrete residues while cleaning, prevents dust from being raised during a deslagging process, is beneficial for reducing the abrasion of a deslagging gear, and also plays a role in cooling the deslagging gear at the same time.

Owner:WUXI JIAN AUTOMATION TECH CO LTD

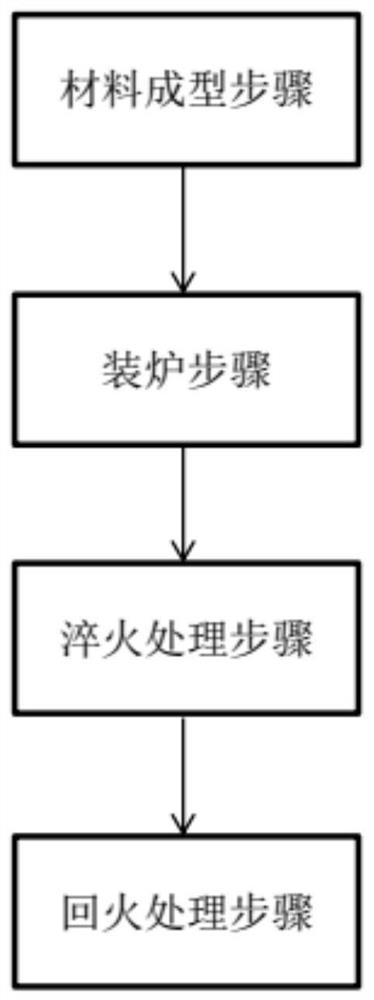

Heat treatment process for self-tightening nut and self-tightening gasket

ActiveCN112522492AImprove hardenabilityUniform mechanical propertiesFurnace typesHeat treatment furnacesTemperingIndustrial engineering

The invention discloses a heat treatment process for a self-tightening nut and a self-tightening gasket. The heat treatment process comprises the following steps of 2.1, material forming; 2.2, charging; 2.3, quenching treatment; and 2.4, tempering treatment. The heat treatment process of the self-tightening nut and the self-tightening gasket has the advantages of high temperature resistance, wearresistance and high hardenability.

Owner:ZHEJIANG ZIJINWANG MACHINARY CO LTD

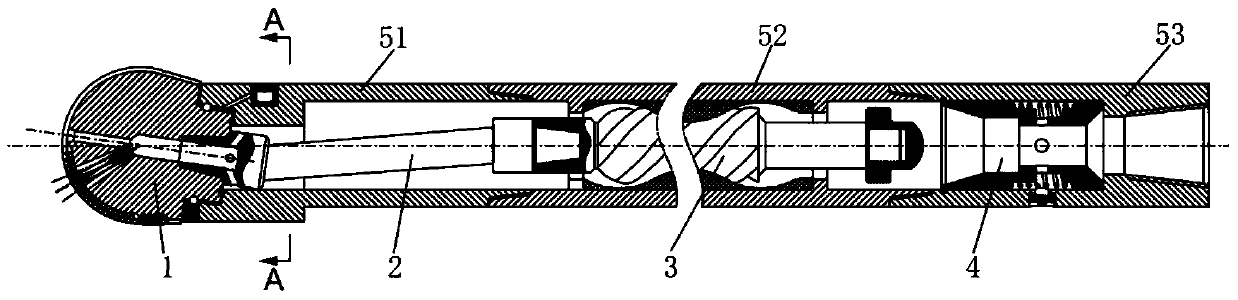

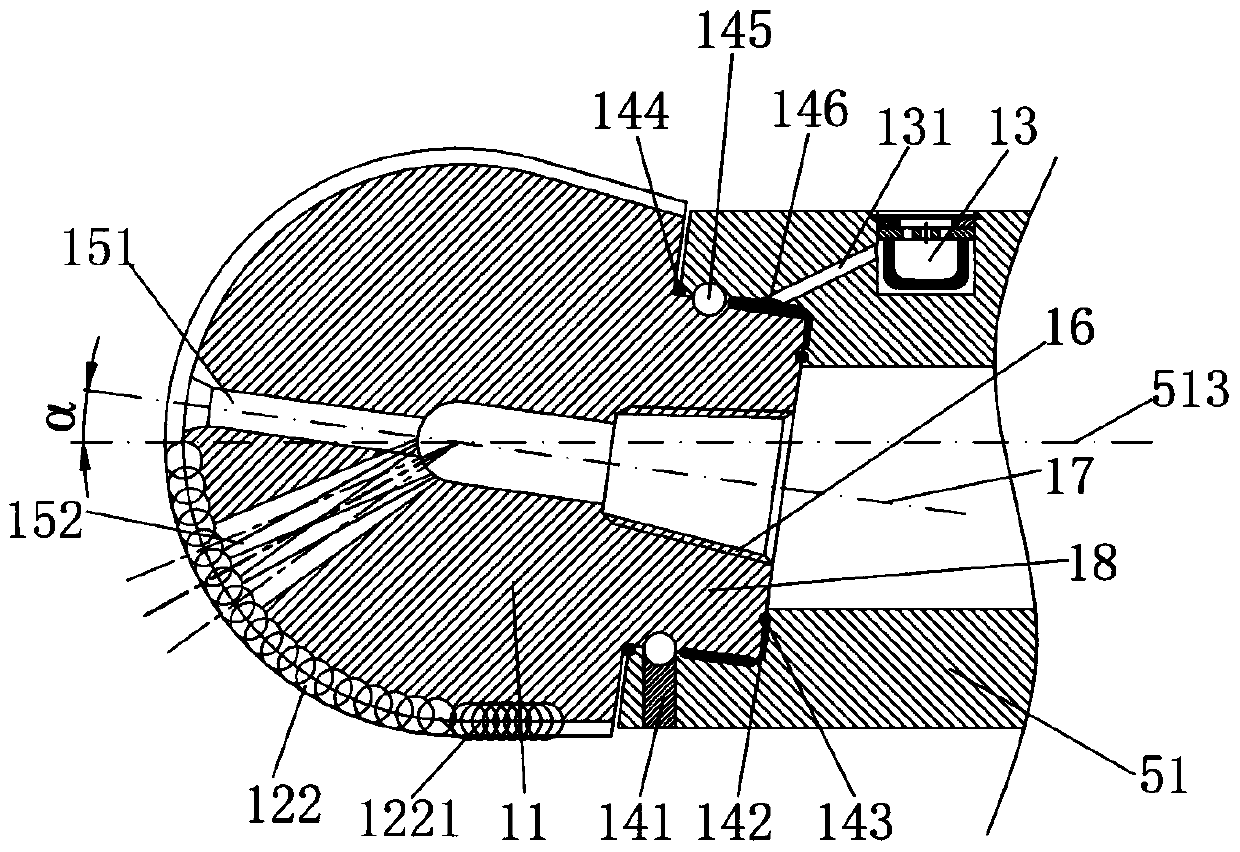

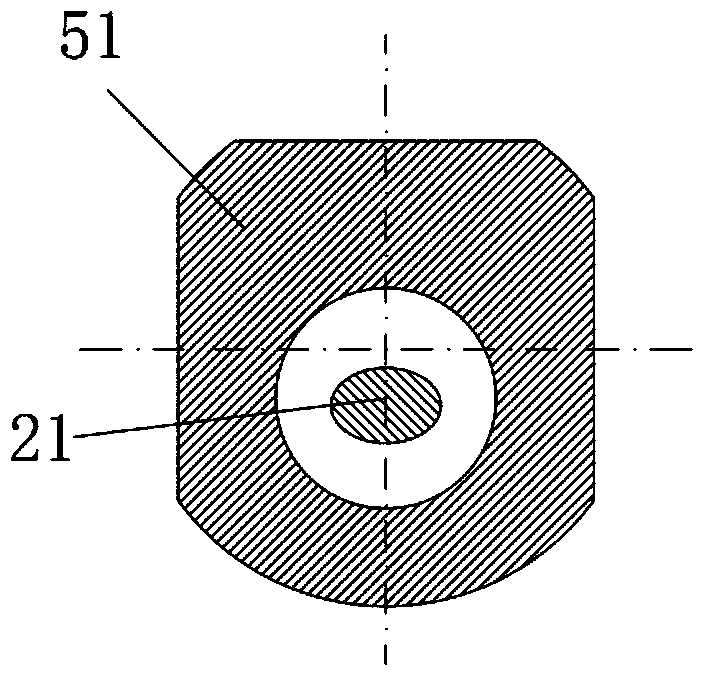

An Alternating Trajectory Cutting Rock Breaking Tool

ActiveCN105507809BImprove eating abilityMovement regularity is stableDrill bitsConstructionsCross cutWell drilling

The invention discloses a rock breaking tool capable of achieving cutting in an alternate trajectory. The rock breaking tool comprises a drill assembly and an outer shell group, wherein a cardan shaft assembly, a screw motor assembly and a bypass valve assembly are arranged in the outer shell group; the drill assembly is installed at the lower end of a lower shell to form rotary connection and is fixedly connected with the cardan shaft assembly by a screw; cutting teeth are fixed on a drill body. The rock breaking tool is characterized in that the axial tilt alpha is formed between the axis of rotation of the drill body and the axis of rotation of the outer shell group, so that revolution of the outer shell group is combined with rotation of the drill body, thus achieving cutting motion of the cutting teeth in the alternate trajectory; the cardan shaft assembly is directly connected with the drill body fixedly. The rock breaking tool has the beneficial effects that stable and reliable cutting motion of the cutting teeth in the alternate trajectory can be achieved, so that the penetration capacity of a drill on hard rocks can be obviously improved and then the rock breaking efficiency can be improved; meanwhile, a drill-screw drill composition structure is simplified, thus improving the well drilling safety and reducing the costs of well drilling tools.

Owner:SOUTHWEST PETROLEUM UNIV

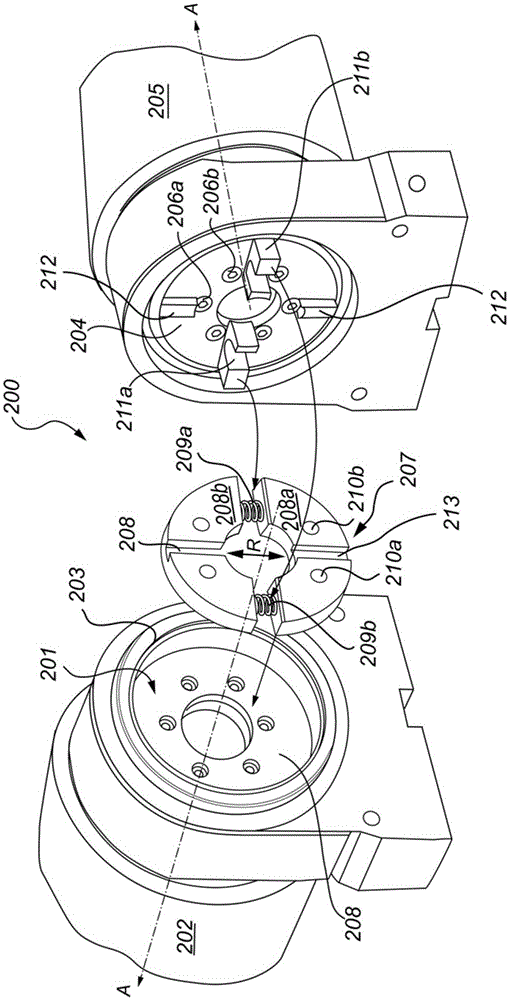

Coupling arrangement for an idler roll line

ActiveCN105715634AExtended service lifeReduce stressSlip couplingSecuring devicesCouplingContinuous caster

The present invention relates to a coupling arrangement for an idler roll line in a continuous caster. The coupling arrangement comprises at least a first component adapted to be arranged in connection with a first roll body of the idler roll line and a second component adapted to be arranged in connection with a second roll body of the idler roll line. The first component and the second component, respectively, are rotatably moveable about a central axis. The coupling arrangement is switchable between a locking state, allowing for synchronized rotational motion of the first component and the second component about the central axis, and a releasing state, allowing for relative rotational motion between the first component and the second component about the central axis. The present invention also relates to an idler roll line comprising the coupling arrangement. The coupling arrangement allows for improved service life and reduced down-time.

Owner:AB SKF

Numerical control milling machine

InactiveCN111975059AAchieve fixationImprove stabilityMilling machinesMaintainance and safety accessoriesNumerical controlMilling cutter

The invention discloses a numerical control milling machine. The numerical control milling machine structurally comprises a machine body, a spindle box, a controller, a milling cutter head and a workbench. The controller is mounted outside the machine body and connected with the spindle box. The milling cutter head is mounted at the bottom of the spindle box. The workbench connected with the machine body is arranged below the milling cutter head. Compared with the prior art, the numerical control milling machine has the beneficial effects that the same thing is that milling cutters are fixed through bolts, and the different thing is that the bolts can also be clamped and fixed; the bolts are internally provided with clamping grooves and grooves, pistons are pushed to drive clamping blocksto clamp and fix the clamping grooves with injected cooling fluid as power, and the bolts are effectively prevented from getting loose due to the fact that the installation and rotating direction of bolt bodies is the same as the rotating direction of the milling cutter head and can also be protected against cracking due to the fact that the installation and rotating direction of the bolt bodies is opposite to the rotating direction of the milling cutter head; the stability of the milling cutters is further improved, and the machining precision of the milling cutters can be improved. Moreover,the cooling fluid can cool a cutter head body and the milling cutters to reduce the thermal wear degree of the milling cutters.

Owner:曾群英

A guide roller of automatic plate slitting unit

ActiveCN110587019BPrevent oxidationPrevent discolorationShearing machine accessoriesCircular discEngineering

The invention relates to a guide roller of an automatic plate slitting unit, which includes a roller frame, a feeding guide roller assembly, a feeding guide pressure roller located directly above the feeding guide roller assembly, a slitting roller, and a roller located directly below the slitting roller. Anti-oxidation brushing mechanism, separating conveying rollers and leveling rollers located directly above the separating conveying rollers; the set of guide rollers provided by the present invention can effectively prevent oxidation and discoloration of copper strip shears through the anti-oxidation brushing mechanism provided , to avoid the copper shavings and other pollutants produced by the shearing to cause burrs and scratches on the copper strip shearing. At the same time, the cotton brush roller has a cooling effect on the disc knife, thereby reducing the thermal wear of the disc knife and improving the disc. knife life.

Owner:绍兴市上虞运鑫模具加工有限公司

Improved cooling device for machining center

InactiveCN108202267AEasy to transportImprove ease of transportationMaintainance and safety accessoriesMechanical engineering

The invention discloses an improved cooling device for a machining center. The improved cooling device for the machining center comprises an installation base, a vertical rod and a rotation mechanism.The vertical rod is fixedly arranged on the top of the installation base. The rotation mechanism is arranged above the vertical rod. A through movement groove with an upward cut is formed in the vertical rod. A vertical supporting rod which can carry out vertical sliding connection is installed in the through movement groove. A supporting rod bottom groove and a slot are formed in the vertical supporting rod, the cut of the supporting rod bottom groove is upward, and the slot is located below the supporting rod bottom groove. A first rotary column is arranged in the slot. A spiral block usedin cooperation with the slot in a spiral manner is arranged on the top of the first rotary column. A second rotary column is arranged in the supporting rod bottom groove in an upward stretch manner. Arotary shell is arranged on the top of the second rotary column. A spray structure is further installed on the shell. The spray structure penetrates through a fixing metal piece and is in butt jointfit with a rotary liquid inlet pipe. A sealing pressure part, a pressure withstand rotary platform, a liquid sealing ring and a connecting block are arranged on the part, with an outlet, of the liquidinlet pipe. A retainer ring, a limiting rotary platform and a rotary platform fixing part are arranged on the part, with an inlet, of the liquid inlet pipe.

Owner:梅金琪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com