Numerical control milling machine

A technology of CNC milling machine and milling cutter disc, applied in the field of CNC machine tools, can solve the problems of bolts, milling cutter cracking, excessive rotation of bolts, unfavorable milling cutter processing, etc., to improve the stability, reduce thermal wear, and improve machining accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

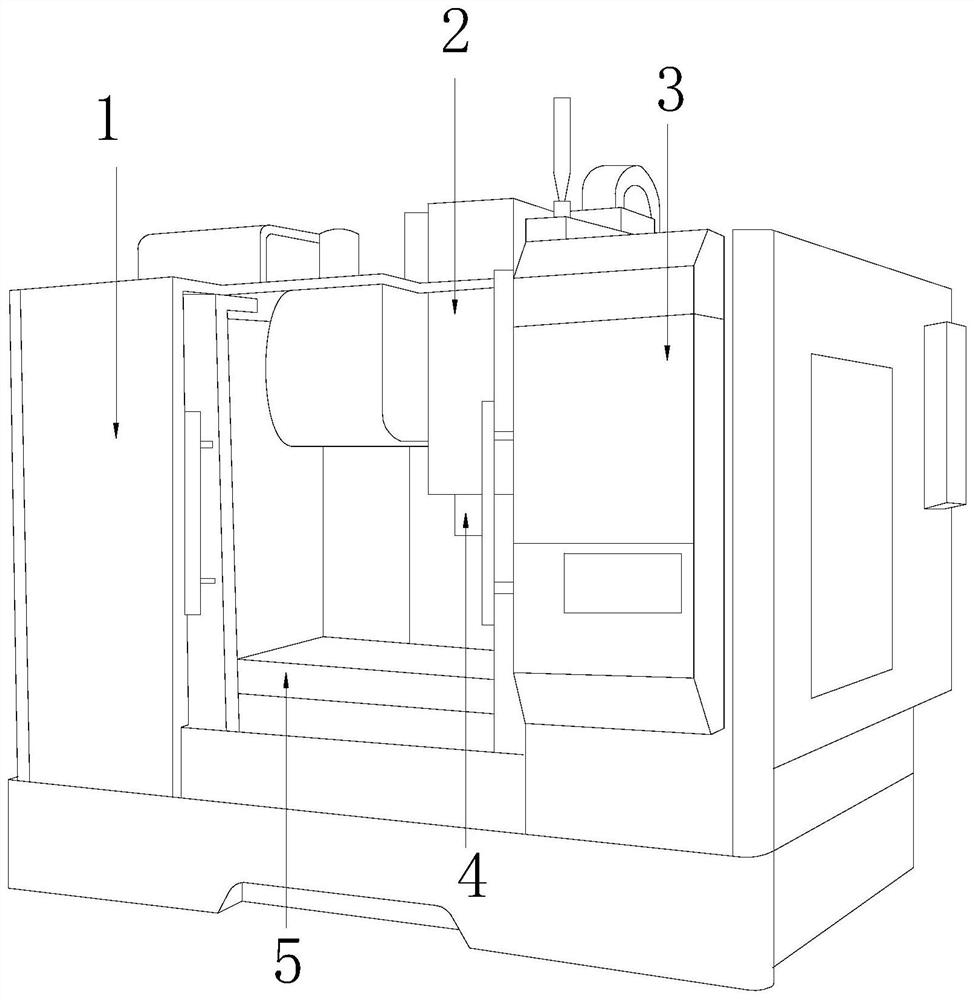

[0033] see Figure 1-10 , the present invention provides a technical scheme of a numerically controlled milling machine: its structure includes a body 1, a spindle box 2, a controller 3, a milling cutter head 4, and a workbench 5, and the body 1 is equipped with a controller 3, and the controller 3 Connected with the spindle box 2, the bottom of the spindle box 2 is equipped with a milling cutter disc 4, and a workbench 5 connected with the machine body 1 is arranged below the milling cutter disc 4.

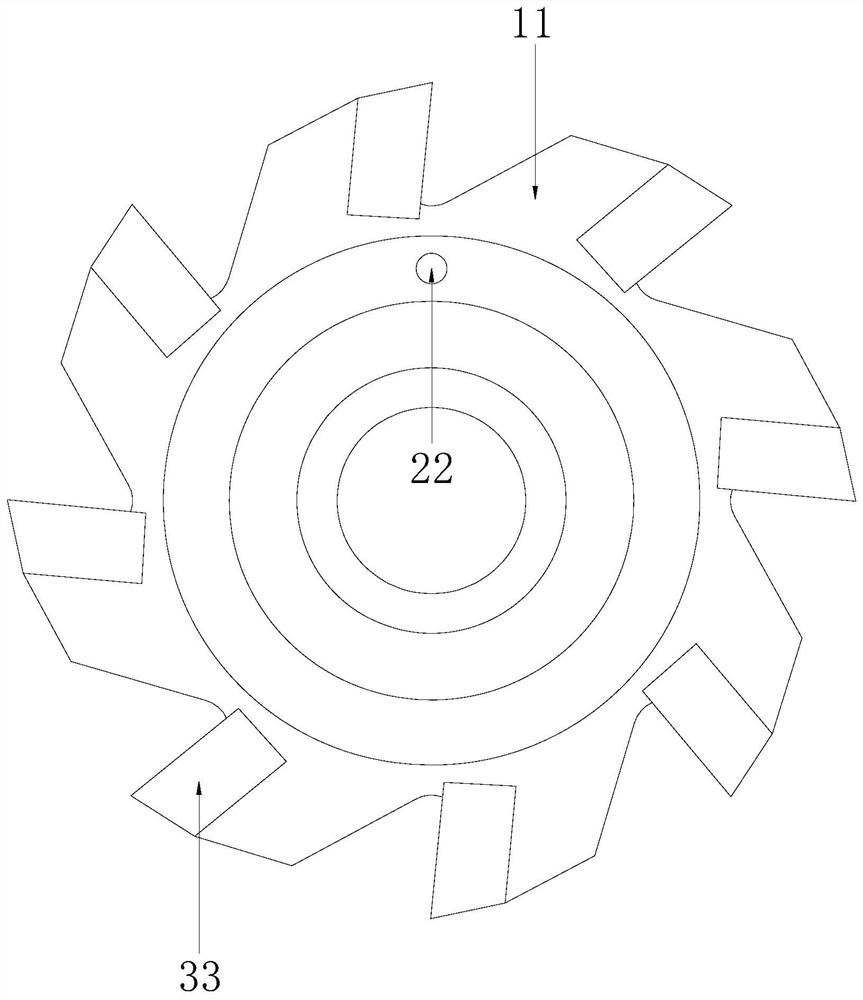

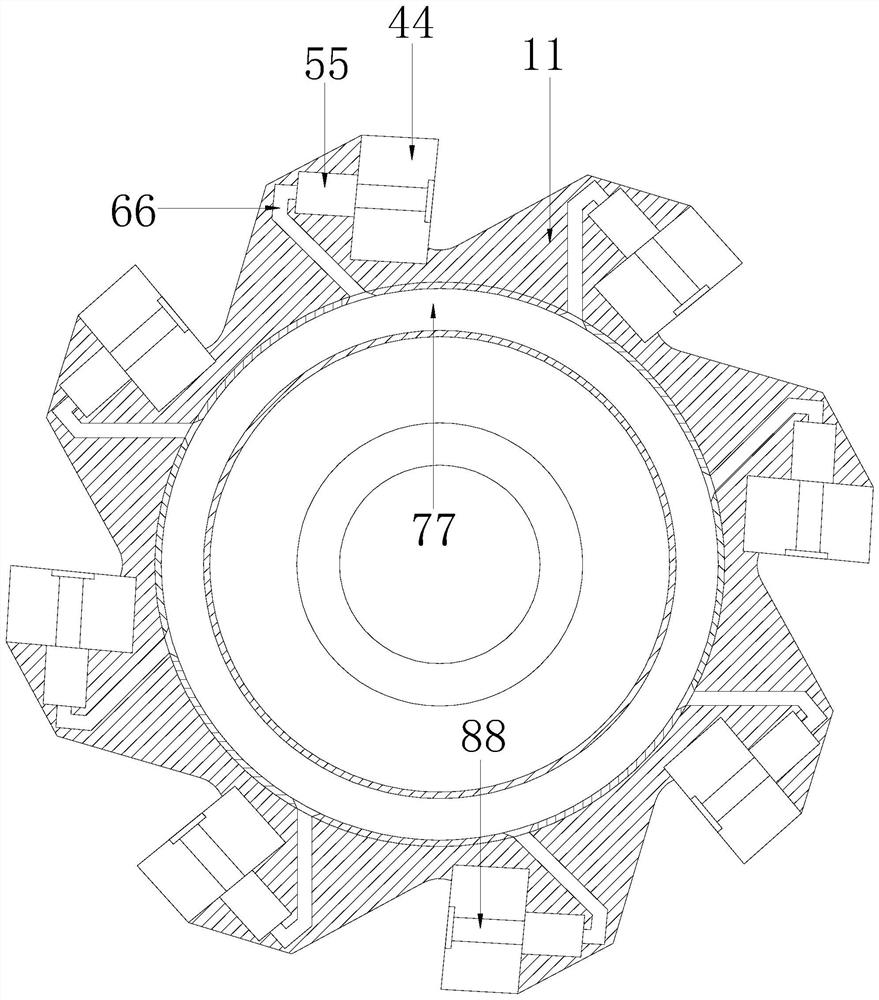

[0034] The milling cutter disc 4 includes a disc body 11, a liquid injection head 22, a milling cutter 33, a sipe 44, a limit clamping block 55, a runner 66, an annular cavity 77, and a bolt 88. Eight parts of the disc body 11 The equally divided positions are all provided with sipes 44, and the slits 44 are all placed with milling cutters 33, and the milling cutters 33 are connected with the limit clamping block 55 through bolts 88, and the limit clamping block 55 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com