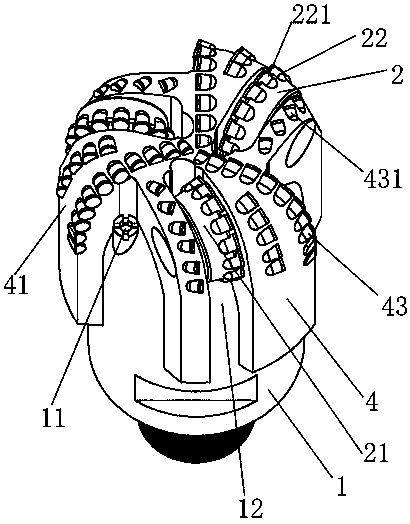

Composite cutting diamond drill bit

A diamond drill bit and compound cutting technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems affecting the service life of the drill bit and the service life of the bearing system, and achieve a compact structure of the drill bit, improve service life and safety performance, The effect of increasing the tooth space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] specific implementation plan

[0112] The following non-limiting examples serve to illustrate the invention

[0113] Basic example

[0114] A composite cutting diamond drill bit, comprising a drill body 1, a fixed blade 4 extending from the drill body or fixedly connected to the drill body, a disc cutter 21, a water channel groove 12 between the fixed blades, and water holes or nozzles 11. The fixed blade 4 is provided with a blade cutting element 43, and the drill body has at least one disk cutter cutting unit 2 composed of the disk cutter 21, the disk cutter cutting teeth 22 and the disk cutter shaft 23, The disc cutter 21 is installed on the disc cutter shaft 23, or integrated with the disc cutter shaft 23, and the offset angle range of the disc cutter 21 is 20°≤|α|≤90°, and it is characterized in that: at least one disc cutter 21 is arranged on a fixed blade 4 or in the water channel groove 12 between two fixed blades, the two sides of the disc cutter cutting unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com