Coupling arrangement for an idler roll line

A technology of connecting device and guiding device, which is applied in the field of continuous casting of steel, can solve problems such as slab influence, roll line breakage, wear, etc., and achieve the effects of improving service life, reducing width, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will now be described more fully with reference to the accompanying drawings, in which presently preferred embodiments of the invention are shown. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein; rather, these embodiments are provided for thoroughness and completeness, and will fully convey the teachings of those skilled in the art scope of the invention.

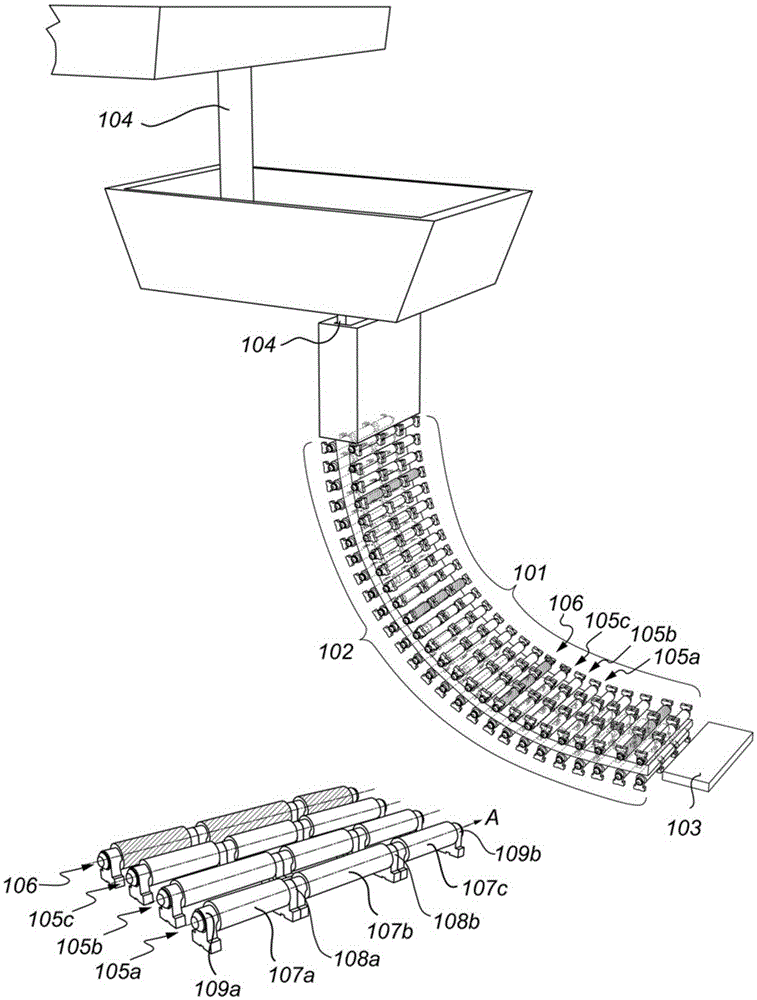

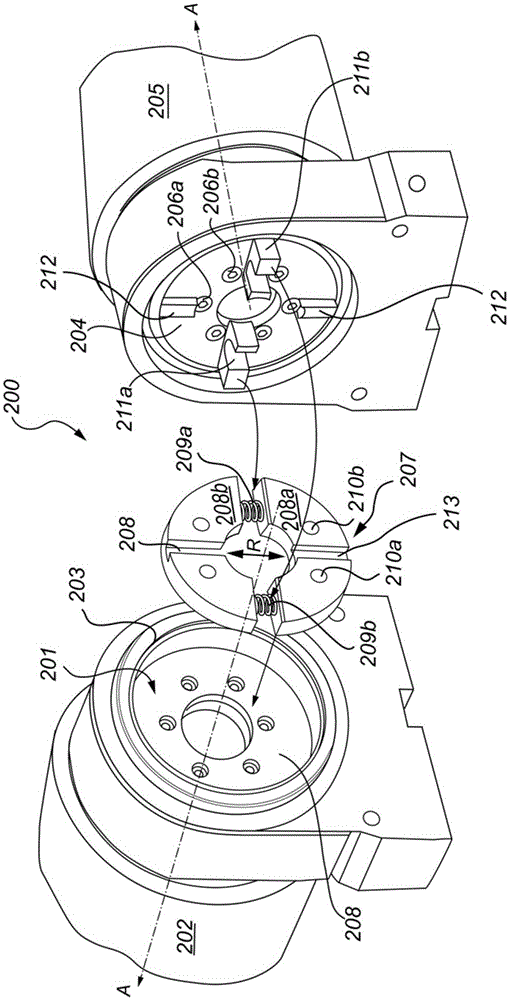

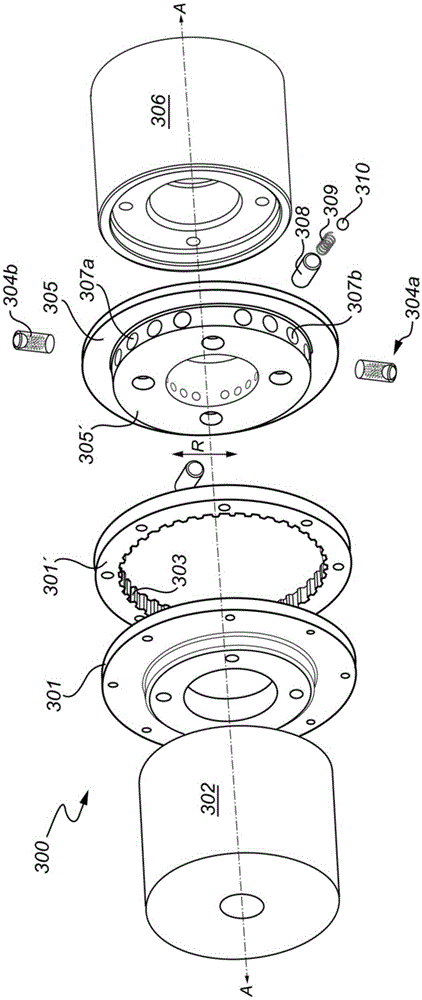

[0065] The invention relates to a coupling device for an idler roll line in a continuous casting machine. The coupling device comprises at least a first part adapted to be arranged in connection with a first roller body of the idler line; and a second part adapted to be arranged in connection with a second roller body of the idler line. The first part and the second part are respectively rotatably movable about the central axis. The coupling device is switchable between a locked state allowing synchronou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com