Brake pad with bionic structure and preparation method thereof

A technology of brake pads and one side, which is applied in the field of brake pads to achieve good braking, less R&D funds and R&D time, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

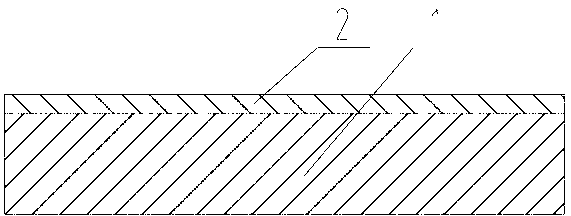

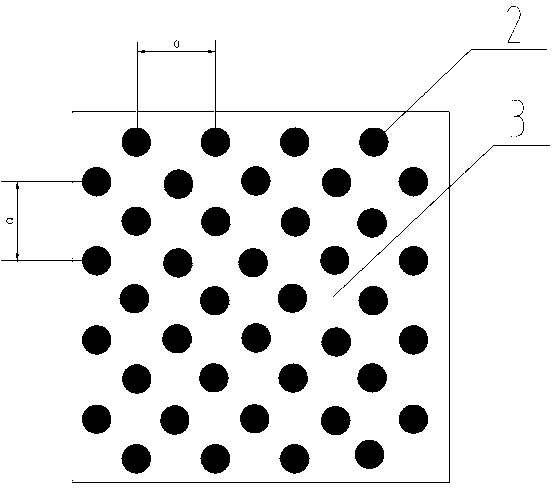

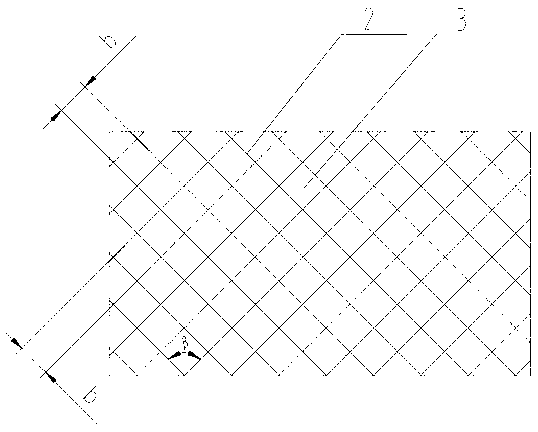

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing a brake pad with a bionic structure, comprising the following steps,

[0037] (1) Design and manufacture the bionic reinforced skeleton according to the bionic coupling distance;

[0038] (2) Weld or inlay the bionic reinforced skeleton on the brake pad substrate;

[0039] (3) Pre-treat the surface of the brake pad substrate and the bionic reinforced skeleton;

[0040] (4) Fill the gaps of the bionic reinforced skeleton with wear-resistant materials and compact and solidify them.

[0041] The embedding on the brake pad substrate means that a plurality of grooves are provided on the brake pad substrate for embedding the bionic reinforced skeleton, and then the whole bionic reinforced skeleton is embedded into these grooves.

[0042] The pretreatment of the surface of the brake pad base and the bionic reinforced skeleton includes the following steps,

[0043] (1) Texturize the surface of the brake pad substrate and bionic reinforced skeleton or p...

specific Embodiment 1

[0050] Specific embodiment 1: A crank press brake pad, according to the working conditions and usage requirements of the crank press, a plant leaf vein-shaped bionic reinforced skeleton is selected, and the distance between two adjacent side veins of the plant leaf vein-shaped bionic reinforced skeleton The volume ratio between the bionic reinforced skeleton and the filled wear-resistant material is 1 / 8, the height of the bionic reinforced skeleton is 3mm, the brake pad substrate material is cold-rolled steel plate, and the bionic reinforced skeleton material is carbon structural steel. The reinforced frame is fixed on the brake pad substrate by welding. After the brake pad base plate and the bionic reinforced skeleton are welded and fixed, the surface is roughened, and then the surface is polished with sandpaper. First, use 7% NaOH solution to remove oil, then use 70°C hot water to rinse, and then use 20% h 2 S0 4Pickling to remove scale, then rinsing with hot water at 70°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com