Ring groove type rivet machine

A technology of riveting machine and ring groove, which is applied in the direction of rotary piston machinery, mechanical equipment, machine/engine, etc. It can solve the problems of large vibration force, waste, high requirements for materials and processing accuracy, and achieve the purpose of preventing direct meshing contact and reducing maintenance cost, the effect of avoiding friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

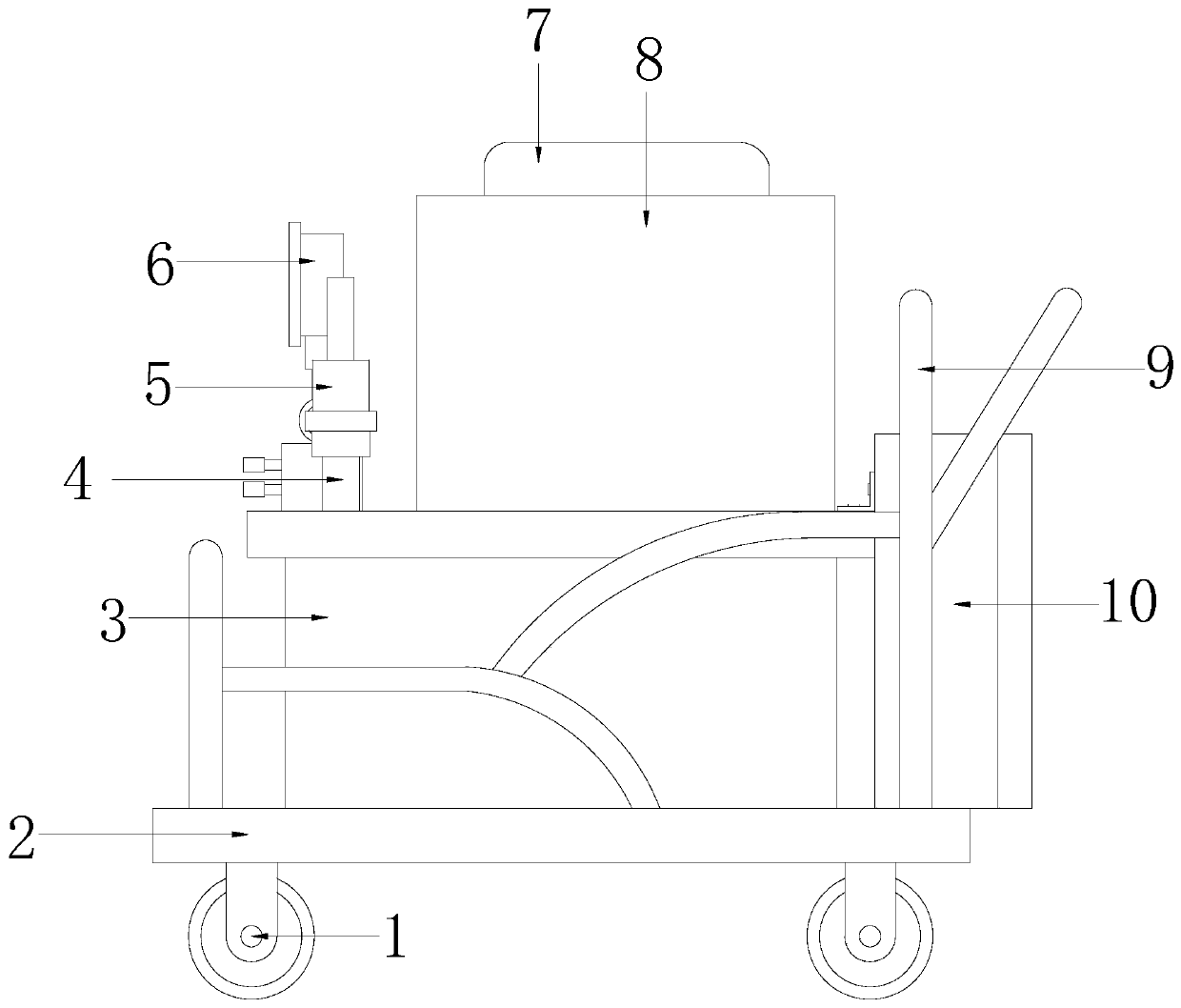

[0036] see figure 1 , the present invention provides a technical scheme of a ring groove type rivet machine: its structure includes a full brake caster 1, a base 2, a body 3, a rivet gun 4, a new gear pump 5, a pressure gauge 6, a high-efficiency energy-saving motor 7, a Vibration device 8, push frame 9, hydraulic tank 10, push frame 9 is welded on the top of the base 2, all four directions of the bottom of the base 2 are mechanically connected with full brake casters 1, and the body 3 is installed on the base 2, The body 3 is vertically connected to the high-efficiency energy-saving motor 7, the high-efficiency energy-saving motor 7 is equipped with a shock absorber 8, the shock absorber 8 is connected to the body 3, and one side of the high-efficiency energy-saving motor 7 is provided with a hydraulic tank 10. A pressure gauge 6 and a rivet gun 4 are provided on the other side, and the rivet gun 4 is connected to the new gear pump 5;

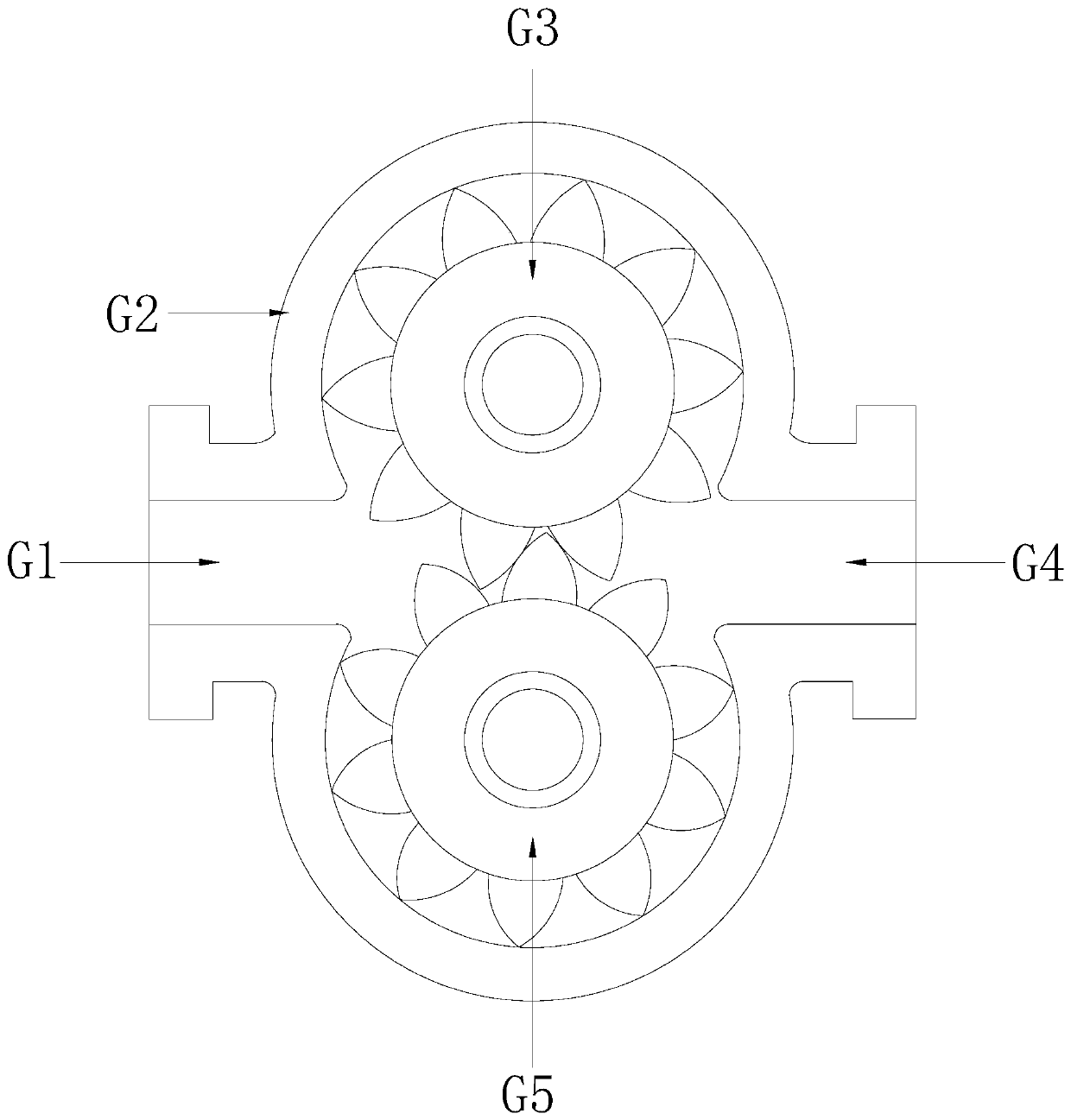

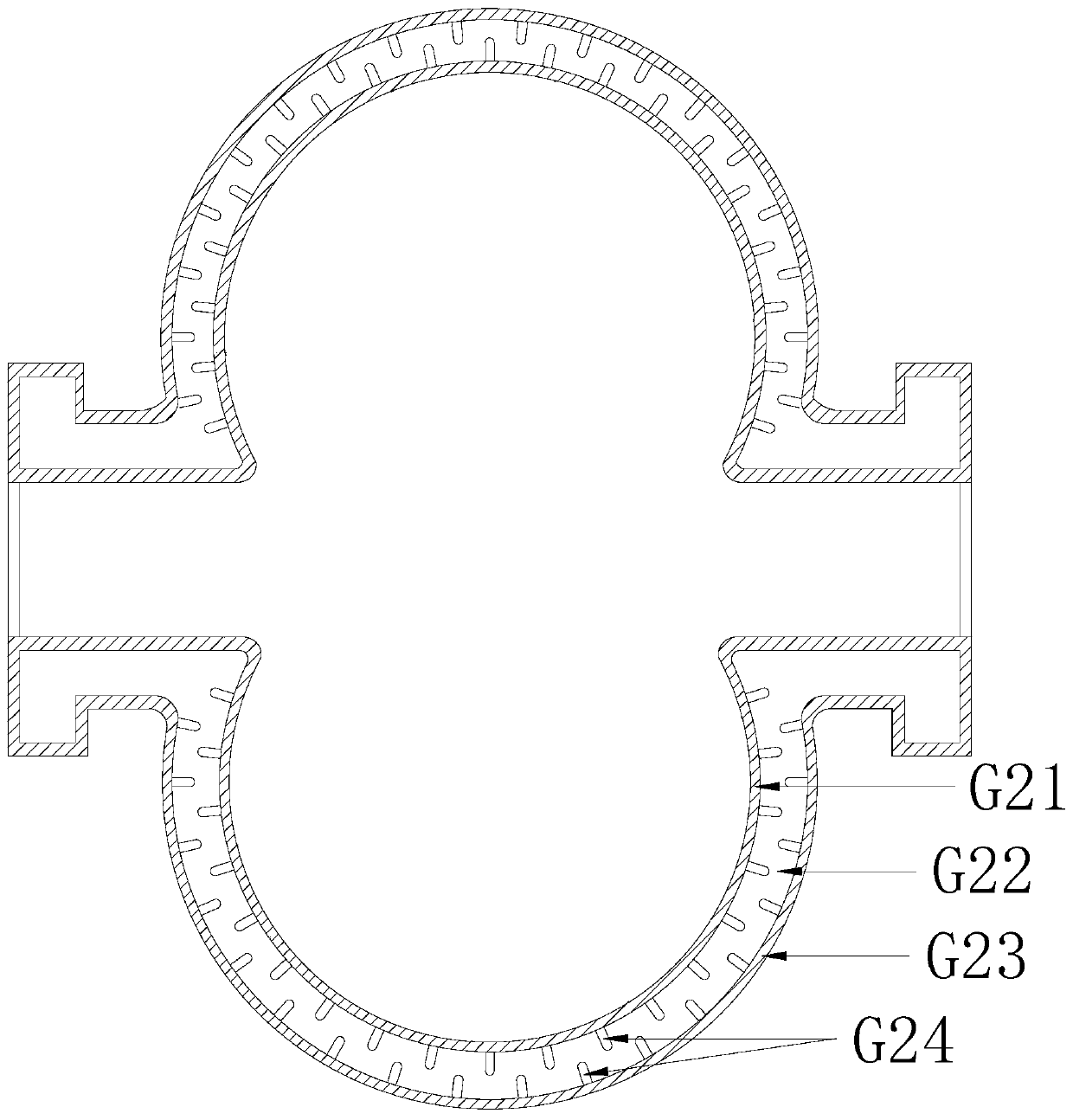

[0037] see figure 2 The new gear pu...

Embodiment 2

[0043] see Figure 1-7 , the present invention provides a technical scheme of a ring groove type rivet machine: its structure includes a full brake caster 1, a base 2, a body 3, a rivet gun 4, a new gear pump 5, a pressure gauge 6, a high-efficiency energy-saving motor 7, a Shock device 8, push frame 9, hydraulic tank 10, the push frame 9 is welded on the top of the base 2, the four directions of the bottom of the base 2 are mechanically connected with full brake casters 1, and the body 3 is installed on the base 2, The body 3 is vertically connected to the high-efficiency energy-saving motor 7, the high-efficiency energy-saving motor 7 is equipped with a shock absorber 8, the shock absorber 8 is connected to the body 3, and one side of the high-efficiency energy-saving motor 7 is provided with a hydraulic tank 10. A pressure gauge 6 and a rivet gun 4 are provided on the other side, and the rivet gun 4 is connected to the new gear pump 5;

[0044] The new gear pump 5 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com