Heat treatment process for self-tightening nut and self-tightening gasket

A technology of self-tightening nuts and gaskets, which is applied in the field of manufacturing, can solve the problems of complex installation process, low service life of high-temperature fasteners, and frequent maintenance, and achieve low maintenance costs, extended practical life, and the effect of overcoming fastening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

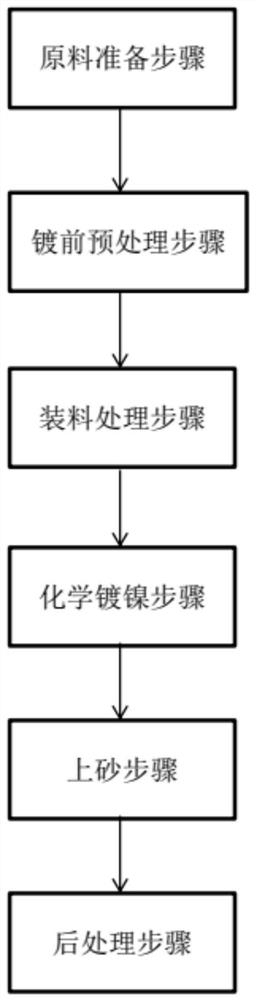

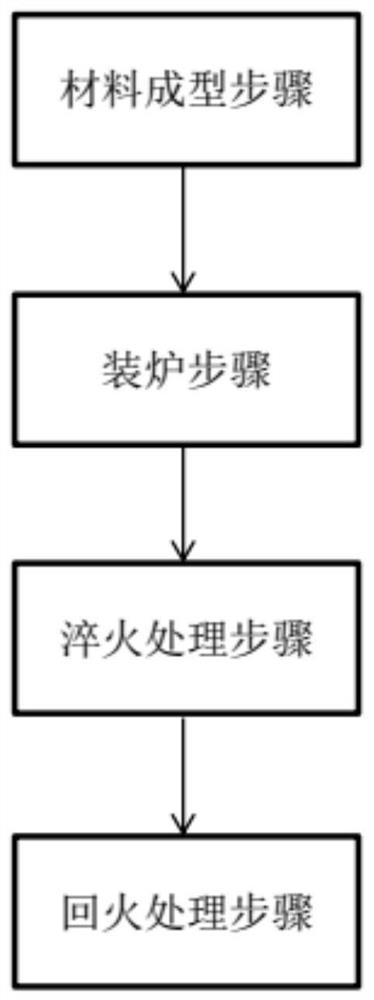

[0033] As shown in the figure, a heat treatment process for self-tightening nuts and self-tightening washers specifically includes the following steps:

[0034]2.1) Material forming steps: select high-temperature resistant alloy steel, and control the carbon and carbide content in it, control the carbon quality at 0.3% to 0.5%, and add a small amount of chromium, molybdenum, vanadium, nickel, manganese, silicon, and add A small amount of molybdenum or tungsten forms a new heat-resistant alloy material; the new heat-resistant alloy material forms a self-tightening nut or a self-tightening washer after cold heading. The metals chromium, molybdenum, vanadium, nickel, manganese, and silicon are added, and a small amount of molybdenum or tungsten is added, and the total amount of added metals is controlled within 1% of the overall mass. Generally, the elements to be added can be added at a mass ratio of 1:1, that is, 1g of chromium, molybdenum, vanadium, nickel, manganese, and sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com