Cutting Fluids in the Processing of Superhard Materials

A technology of processing and superhard materials, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of shortened tool life and cutting tool immobility, and achieve the effects of shortened tool life, reduced fluidity, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

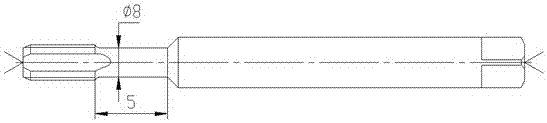

Image

Examples

Embodiment 1

[0011] Embodiment 1 of the present invention: a cutting fluid in the processing of superhard materials, which is prepared by mixing the following components: molybdenum disulfide, tartaric acid, chlorinated paraffin, oleic acid, sodium petroleum sulfonate , and transformer oil and / or soybean oil.

[0012] When the cutting fluid is prepared, the above components are calculated by weight: molybdenum disulfide 15-20kg, tartaric acid 10-15kg, chlorinated paraffin 10-15kg, oleic acid 5-6kg, petroleum sodium sulfonate 10-15kg, And transformer oil and / or soybean oil 15-20kg.

[0013] The cutting fluid also includes: 2-5 kg of carbon tetrachloride.

[0014] The cutting fluid also includes: 2-5 kg of petroleum lead sulfate.

Embodiment 2

[0015] Embodiment 2 of the present invention: a cutting fluid in the processing of superhard materials, which is prepared from the following components: molybdenum disulfide, tartaric acid, chlorinated paraffin, oleic acid, sodium petroleum sulfonate, and transformer oil and / or soybean oil.

[0016] When the cutting fluid is prepared, the above components are calculated by weight: 15kg of molybdenum disulfide, 10kg of tartaric acid, 10kg of chlorinated paraffin, 5kg of oleic acid, 10kg of sodium petroleum sulfonate, and 15kg of transformer oil and / or soybean oil.

[0017] Also included in this cutting fluid: carbon tetrachloride 2kg.

[0018] The cutting fluid also includes: 2kg of petroleum lead sulfate.

[0019] The cutting fluid prepared by this embodiment has better cooling and lubricating effect than ordinary cutting fluid when processing superhard materials.

Embodiment 3

[0020] Embodiment 3 of the present invention: a cutting fluid in the processing of superhard materials, which is prepared from the following components: molybdenum disulfide, tartaric acid, chlorinated paraffin, oleic acid, sodium petroleum sulfonate, and transformer oil and / or soybean oil.

[0021] When the cutting fluid was prepared, the above components were calculated by weight: 18kg of molybdenum disulfide, 13kg of tartaric acid, 13kg of chlorinated paraffin, 5kg of oleic acid, 13kg of sodium petroleum sulfonate, and 18kg of transformer oil and / or soybean oil.

[0022] The cutting fluid also includes: 3.5 kg of carbon tetrachloride.

[0023] The cutting fluid also includes: 3.5 kg of petroleum lead sulfate.

[0024] Compared with the cutting fluid prepared in Example 2, the cutting fluid prepared in this example has better cooling and lubricating effects when processing superhard materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com