A Punching Composite Drill Bit Suitable for Difficult-Drilling Formation

A composite drill bit and formation technology, which is applied to drill bits, earth-moving drilling, drilling equipment, etc., can solve the problems of strong impact load of cutting teeth, low rock breaking efficiency of drill bits, and difficulty of cutting teeth invading rocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

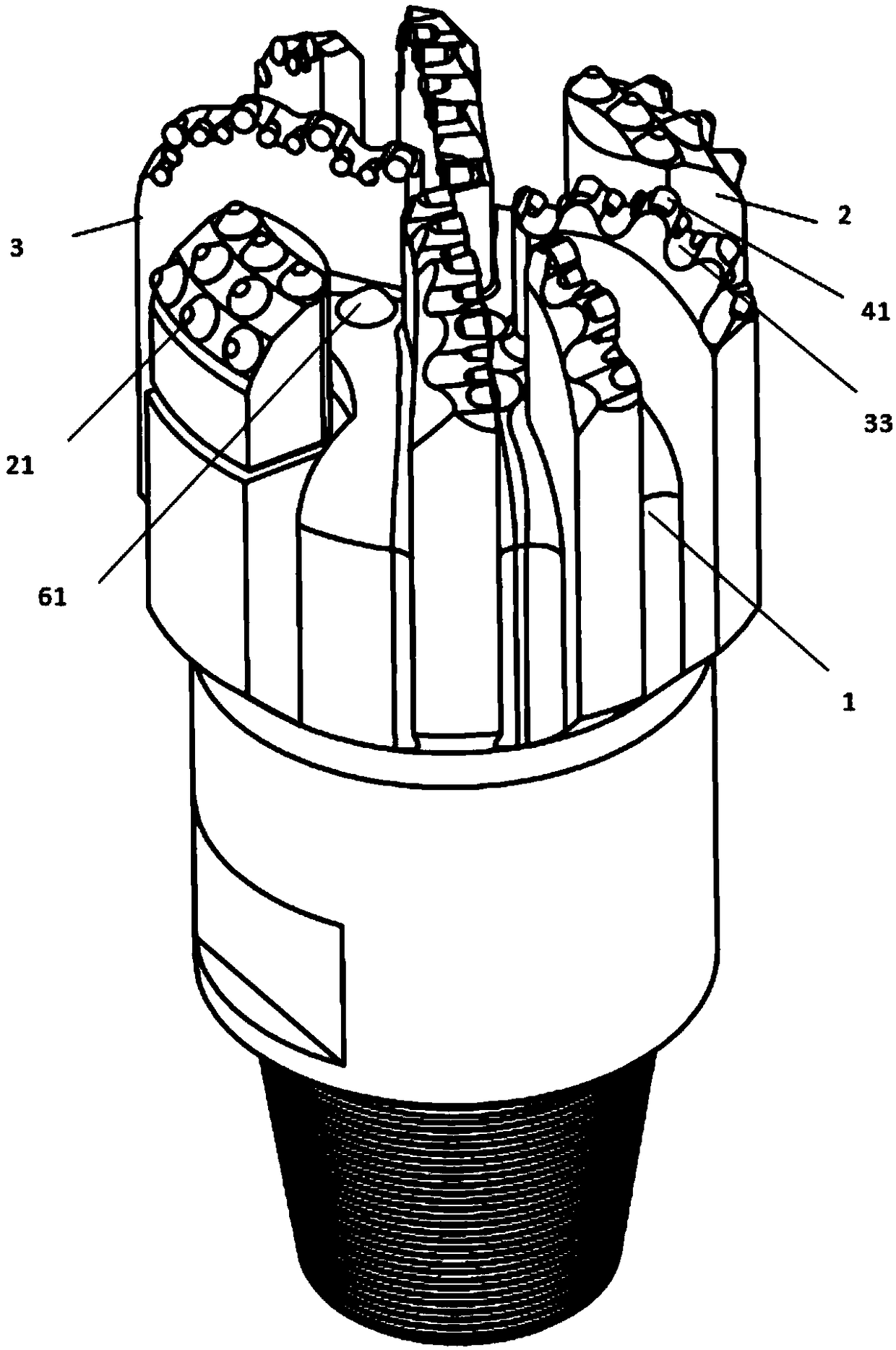

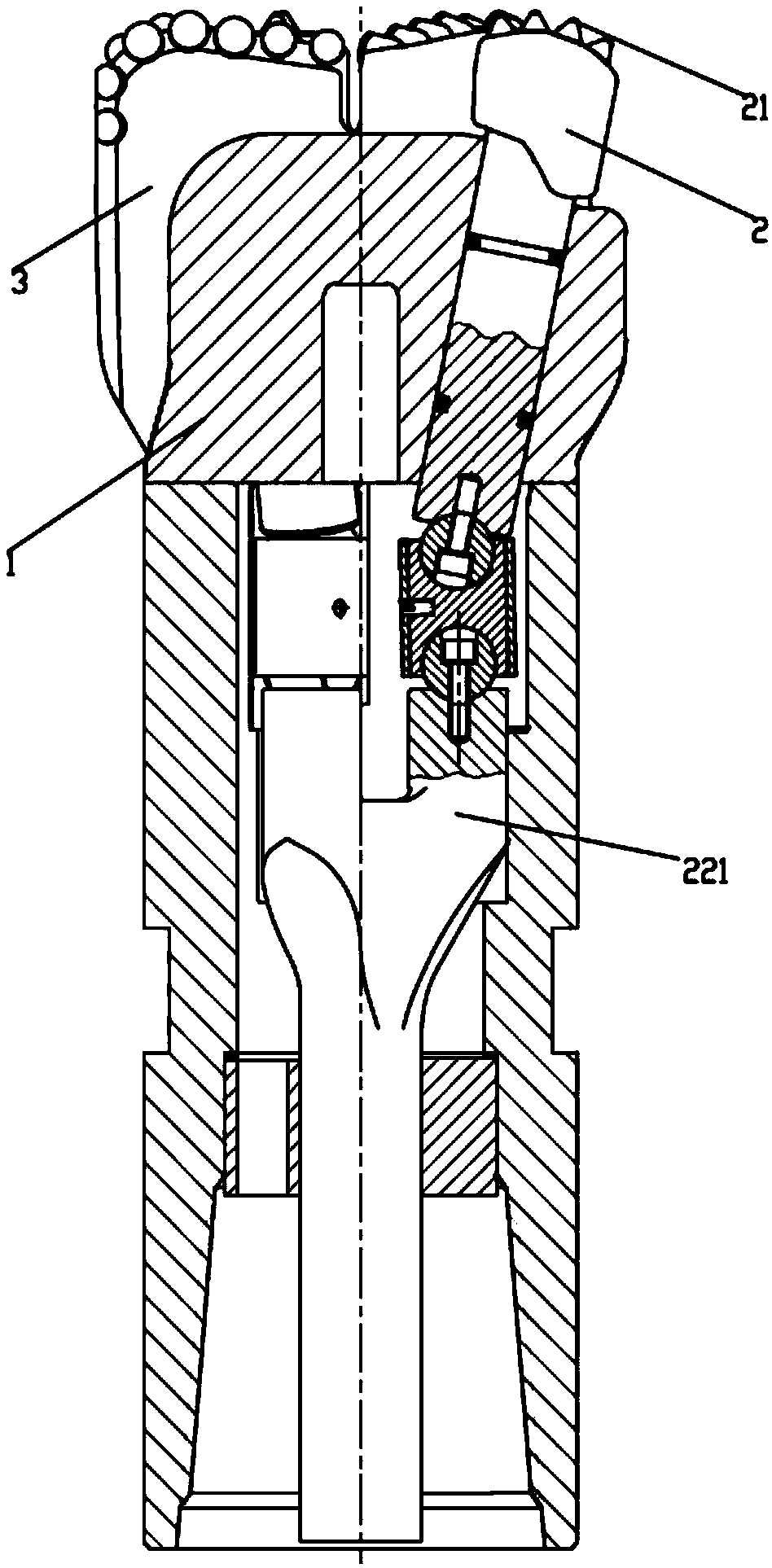

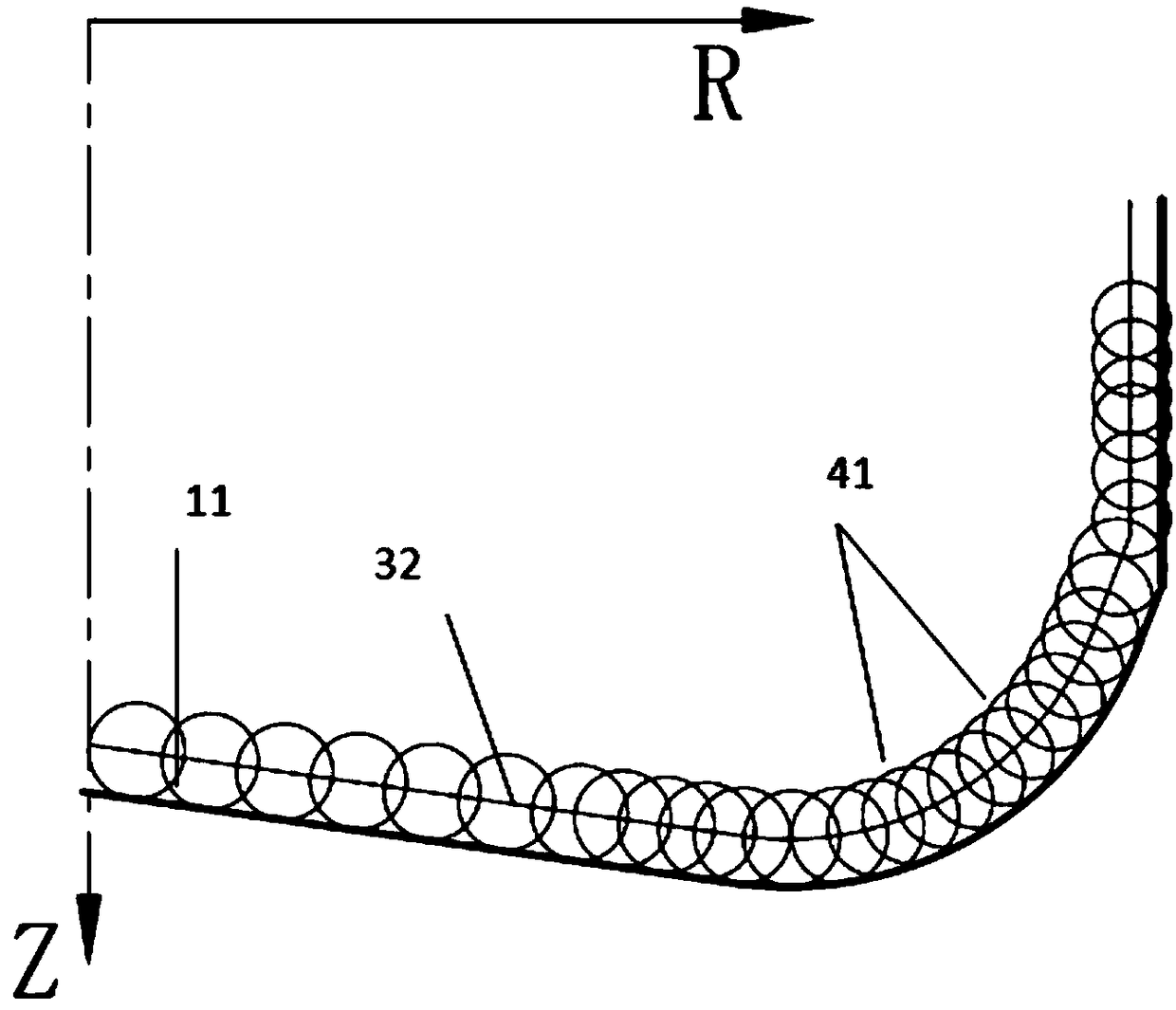

[0101] like figure 1 , 2, 12, 13, and 14, a punching compound drill bit with asynchronous cutting principle, including a drill body 1, a knife wing 3 consolidated relative to the drill body 1, and a water eye or nozzle 61 arranged on the drill body 1 , the blade 3 is provided with several first groups of cutting teeth 41, the tooth surface 33 of the blade 3 is provided with dimples for fixing the first group of cutting teeth 41, and the drill body 1 has an impact force transmission structure 221 and an impact cutting mechanism. Structure 2, impact cutting teeth 21 are arranged on the impact cutting structure, water eyes or nozzles 61 are arranged in the flow channel between the blades, and at least one body contour line 32 of the blade 3 (may include the body contour of the front blade) line and the rear blade body contour line) and the body contour line 32 of at least one other blade 3 have at least one non-overlapping area, and at least one overlapping point or overlapping...

Embodiment 2

[0107] like Figure 15-18 As shown, this embodiment is basically the same as Embodiment 1, the difference is that a second set of cutting teeth is arranged on the blade 3 . In the present invention, the first group of cutting teeth 41 arranged on the raised portion 321 are the cutting teeth that are first in contact with the formation and are also the first to be worn out. Arranging the inner insert 42a on the raised portion 321 can further increase the wearable volume of the cutting teeth, thereby prolonging the life of the drill bit, as Figure 17 as shown in b. In addition, another form of second group of cutting teeth (built-in table insert 42b) can also be arranged on the blade, and the built-in table insert 42b is arranged in the hollow groove 5, such as Figure 17 as shown in a. Wherein, empty groove 5 can be such as Figure 18 (a) through the through grooves on the front and rear sides of the blade, also can be as follows Figure 18 (b) The groove recessed into th...

Embodiment 3

[0109] like Figure 19 As shown, this embodiment is basically the same as Embodiments 1 and 2, the difference is that the body contour lines 32 of at least two blades are curves with local protrusions 321, and the non-overlapping areas of the curves are distributed on the drill bit. The inner radial two-thirds of the area. The curve is a multi-peak curve with a plurality of convex parts 321, and the teeth are arranged along the outline 32 of the blade body to form a multi-stage cutting structure in the core area. For composite drill bits, under complex drilling conditions, the core area is relatively weak, which is likely to cause early failure of the cutting teeth, and then cause the failure of the drill bit. The invention can well enhance the cutting ability and service life of the core area, effectively avoid the phenomenon of core circumcision or core out failure, and prolong the service life of the drill bit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com