Reactor core water injection evaluation method for nuclear power plant equipped with reactor core catcher

A technology of core capture and evaluation method, which is applied in the field of core water injection evaluation of nuclear power plants, can solve problems such as changes, and achieve the effects of avoiding steam explosions, improving severe accident management, and improving monitoring and status diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

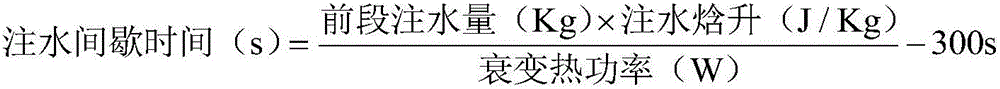

[0092] A pressurized water reactor nuclear power plant is equipped with a crucible-type core trap specially for severe accidents. The power plant has arranged a large number of passive hydrogen recombiners in the containment for the threat of hydrogen in severe accidents. Therefore, the threat of hydrogen is not the main serious accident of the plant. The threat of accidents, the negative impact of hydrogen generation will not be considered in the analysis of core water injection countermeasures.

[0093] Similar to the scene of the Fukushima accident, after the tsunami, the entire plant was powered off, and the special safety facilities could not be activated. After the power outage, the power plant stopped unnecessary power consumption such as lighting, and the battery power was maintained for a long time. The main control room can still grasp the key points. Instrument monitoring data. After the core is exposed, it is monitored that the core outlet temperature exceeds 650°C...

Embodiment 2

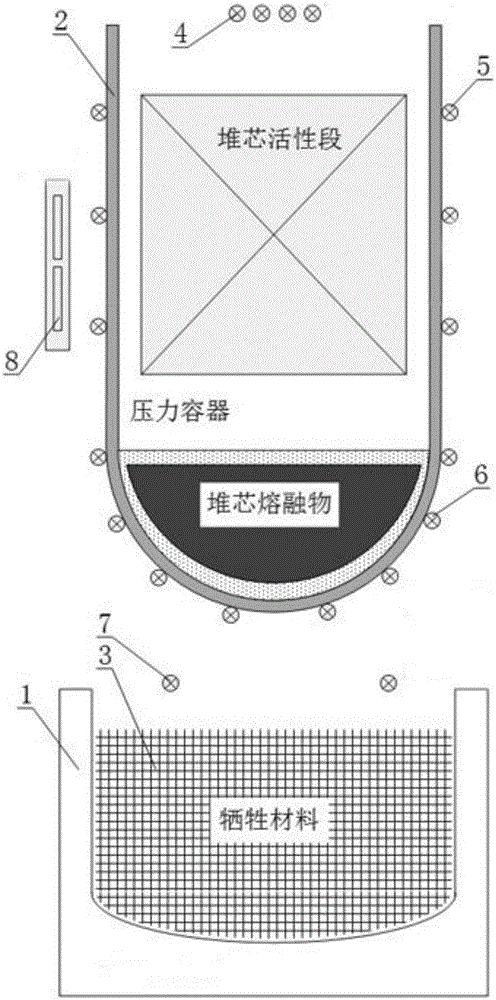

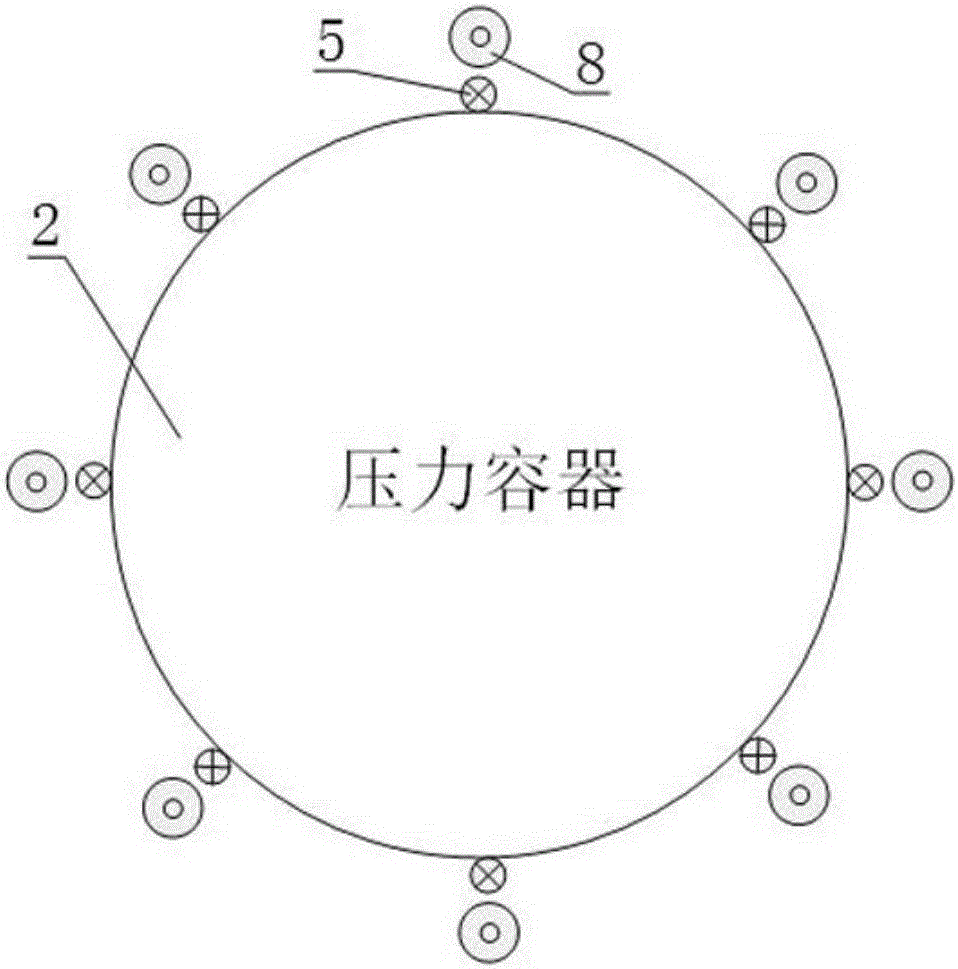

[0106] The configuration of the power plant is roughly the same as that of Example 1. On the basis of Example 1, the design of the power plant has been improved for monitoring the temperature outside the pressure vessel. Several high-range thermocouples are installed in the insulation layer close to the outer wall of the pressure vessel. These thermocouples Evenly distributed at different angles in the circumferential direction of the pressure vessel, and thermocouples are arranged vertically from the height of the active section of the core to the bottom of the lower head, such as figure 1 , figure 2 shown. In terms of signal transmission, a temperature signal transmission channel is added on the basis of the original external nuclear test signal channel, and finally the main control room can monitor the temperature of the outer wall of the pressure vessel.

[0107] After the earthquake, a large breach accident occurred, the double ends of the main pipeline were sheared and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com