Large-scale passive pressurized water reactor nuclear power plant reactor core catcher with melt expansion room

A core trapping and expansion chamber technology, applied in the field of passive cooling design, can solve the problems of radioactive material release, failure, IVR success probability reduction, etc., achieve high reliability, enhance the ability to mitigate severe accidents, and heat transfer The effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

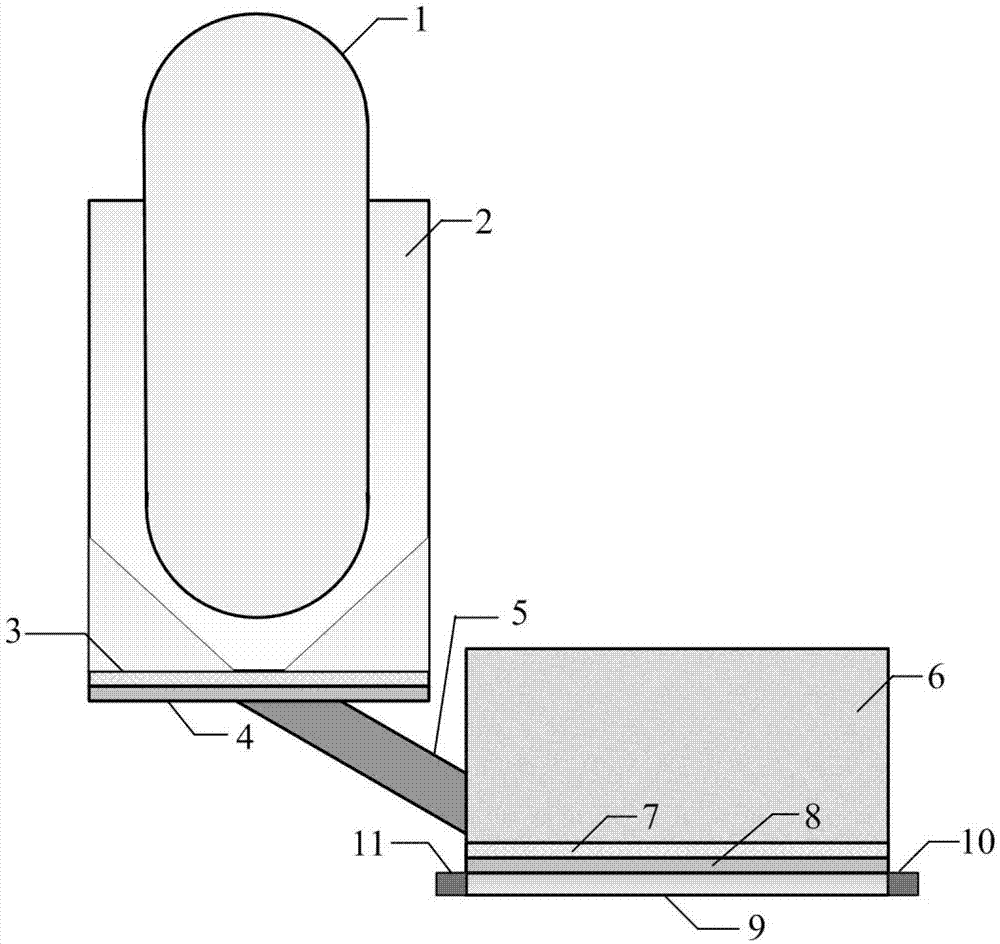

[0012] A large passive pressurized water reactor nuclear power plant core catcher with a melt expansion chamber according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 As shown, a large passive pressurized water reactor nuclear power plant core catcher with a melt expansion chamber according to the present invention mainly includes a reactor cavity 2, a melt release channel 5, a melt expansion chamber 6 and the outside of the expansion chamber Cooling channel 9.

[0014] The reactor cavity 2 covers the middle and lower part of the reactor pressure vessel 1, the lower part of the reactor cavity 2 is the reactor cavity concrete bottom plate 3, and the lower part of the reactor cavity concrete bottom plate 3 is the reactor cavity refractory layer 4. The refractory layer 4 of the stack cavity has a thickness of 0.1m-0.5m (for example: 0.1m, 0.3m or 0.5m), and is made of ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com