Light stabilizer and preparation method and application thereof

A light stabilizer and solvent technology, applied in the field of light stabilizer and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

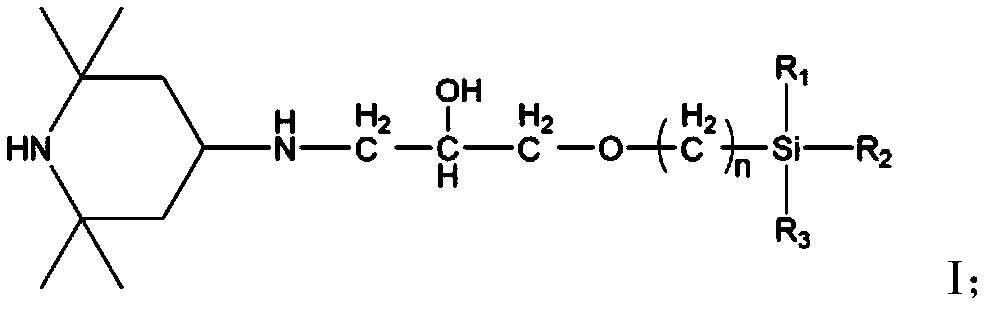

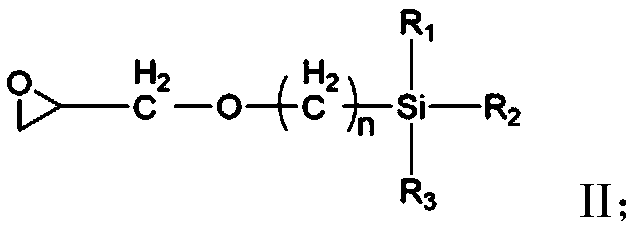

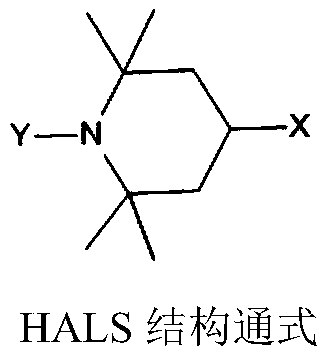

[0039] Preparation of Light Stabilizer A1:

[0040] In a four-necked flask equipped with a thermometer, add II, 105g of 1,1,6,6-tetramethylpiperidinamine, 53g of 3-(2,3-epoxypropoxy)propyltrimethoxysilane, Dissolve it in 350g of toluene solvent, install a condenser, start the stirrer, and raise the temperature to 65°C for 4 hours in a water bath. After the ring-opening addition reaction, the organic solvent and unreacted small molecule intermediates were distilled off under reduced pressure to obtain the target product with a yield of 94%. According to infrared characterization, the obtained product is at 910cm -1 The characteristic peak of the epoxy group at around 3300cm disappears, while at 3300cm -1 There are obvious alcoholic hydroxyl peaks at the left and right.

Embodiment 2

[0042] Preparation of Light Stabilizer A2:

[0043] In a four-necked flask equipped with a thermometer, add II, 150g of 1,1,6,6-tetramethylpiperidinamine, 120g of 3-(2,3-epoxypropoxy)propyltriethoxysilane , dissolved in 350g of ethanol solvent, fitted with a condenser, started the agitator, and heated to 25°C for 6 hours in a water bath. After the ring-opening addition reaction, the organic solvent and unreacted small molecule intermediates were distilled off under reduced pressure to obtain the target product with a yield of 96%.

Embodiment 3

[0045] The preparation of light stabilizer A3:

[0046] In a four-necked flask equipped with a thermometer, add 150g of II, 1,1,6,6-tetramethylpiperidinamine, 3-(2,3-epoxypropoxy)propyldimethoxymethyl 150g of silane was dissolved in 600g of petroleum ether solvent, a condenser was installed, the stirrer was started, and the temperature was raised to 90°C for 9 hours in a water bath. After the ring-opening addition reaction, the organic solvent and unreacted small molecule intermediates were distilled off under reduced pressure to obtain the target product with a yield of 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com