A kind of organic luminescent material and its application on oled

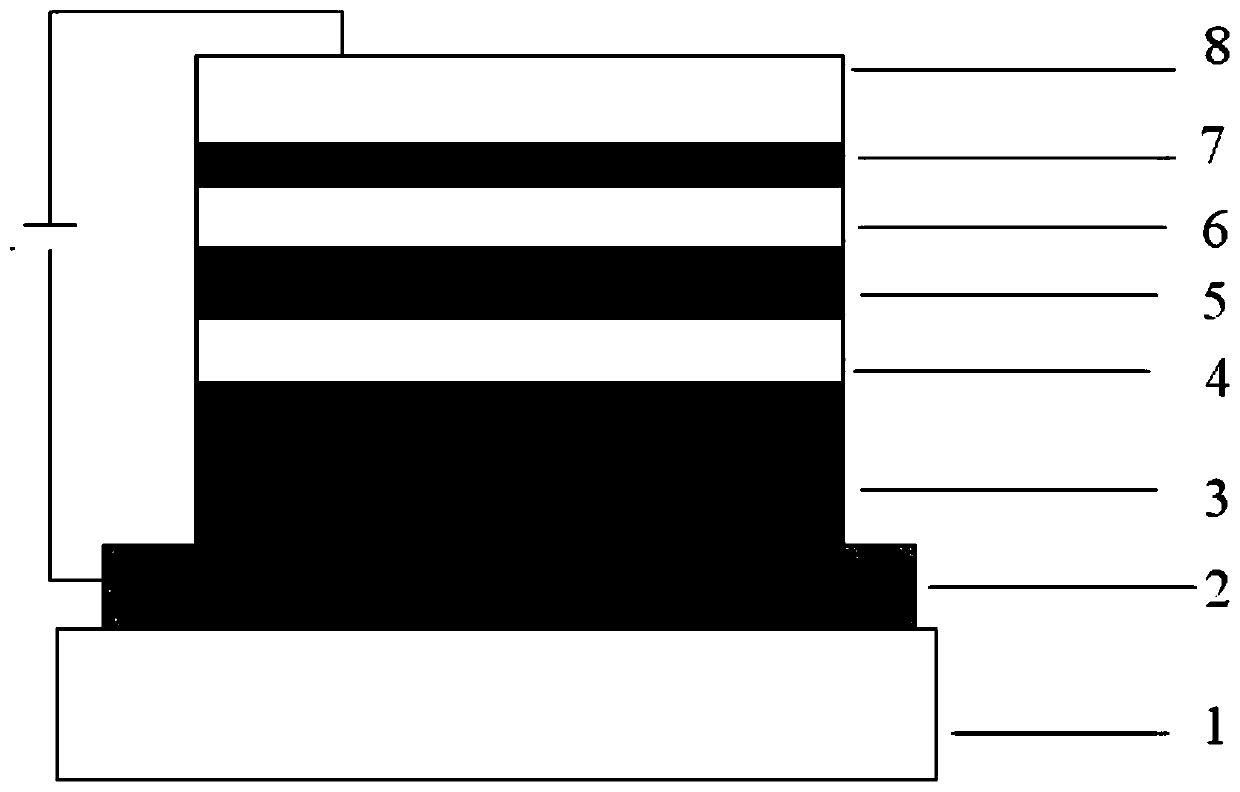

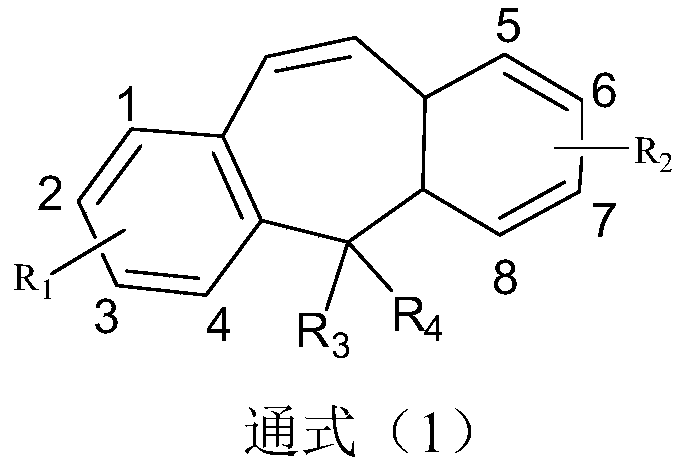

An organic and electroluminescent technology, applied in the field of semiconductors, can solve the problems of insufficient efficiency, lifespan, difficult to achieve full-color RGB, very different, etc., to achieve the effect of improving color purity, good industrialization prospects, and inhibiting the degree of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

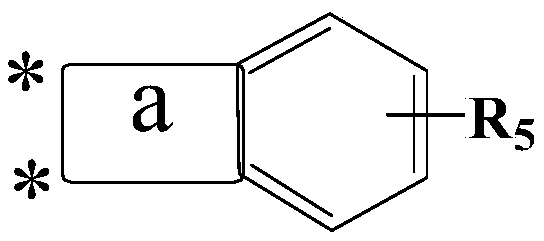

Method used

Image

Examples

Embodiment 1

[0057] Example 1 (Compound 04)

[0058] The concrete synthetic route of this compound is provided now:

[0059]

[0060] 250ml four-necked bottle, under the protection of nitrogen, add 0.01mol intermediate A, 0.025mol diphenylamine, 0.03mol sodium tert-butoxide, 1×10 -4 mol Pd 2 (dba) 3 , 1×10 -4 mol tri-tert-butylphosphine, 150ml toluene, heated to reflux for 20 hours, the reaction was complete; naturally cooled, filtered, the filtrate was rotary evaporated, passed through a silica gel column, beaten with a mixed solvent of toluene:ethanol=1:3 (volume ratio), and recrystallized White solid, purity (HPLC) 98.3%, yield 62.2%.

[0061] Elemental analysis structure (molecular formula C 53 h 38 N 2 o 2 ): Theoretical value C,86.62; H,5.21; N,3.81; O,4.35 Test value: C,86.67; H,5.16; N,3.80; O,4.37

Embodiment 2

[0062] Example 2 (Compound 08)

[0063] The concrete synthetic route of this compound is provided now:

[0064]

[0065] In a 250ml four-neck flask, under nitrogen protection, add 0.01mol of intermediate A, 0.011mol of bis(4-tert-butylphenyl)amine, 0.03mol of sodium tert-butoxide, 1×10 -4 mol Pd 2 (dba) 3 , 1×10 -4 mol tri-tert-butylphosphine, 150ml toluene, heated to reflux for 20 hours, the reaction was complete; naturally cooled, filtered, the filtrate was rotary evaporated, passed through a silica gel column, beaten with a mixed solvent of toluene:ethanol=1:2 (volume ratio), and recrystallized White solid, purity (HPLC) 98.6%, yield 54.1%.

[0066] Elemental analysis structure (molecular formula C 62 h 55 NO): Theoretical value C,89.71; H,6.68; N,1.69; O,1.93 Test value: C,89.68; H,6.71; N,1.71; O,1.92

Embodiment 3

[0067] Example 3 (compound 14)

[0068] The concrete synthetic route of this compound is provided now:

[0069]

[0070] In a 250ml four-neck flask, under nitrogen protection, add 0.01mol of intermediate A, 0.025mol of bis(3,4-dimethylphenyl)amine, 0.03mol of sodium tert-butoxide, 1×10 -4 mol Pd 2 (dba) 3 , 1×10 -4 mol tri-tert-butylphosphine, 150ml toluene, heated to reflux for 20 hours, the reaction was complete; naturally cooled, filtered, the filtrate was rotary evaporated, passed through a silica gel column, beaten with a mixed solvent of toluene:ethanol=1:2.5 (volume ratio), and recrystallized White solid, purity (HPLC) 98.3%, yield 57.8%.

[0071] Elemental analysis structure (molecular formula C 71 h 56 N 2 o 2 ): Theoretical value C,87.98; H,5.82; N,2.89; O,3.30 Test value: C,87.89; H,5.84; N,2.80; O,3.47

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com