High-temperature-resistant low-compression-deformation flame-retardant thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer, low-compression technology, applied in the production of bulk chemicals, etc., can solve the problems of low temperature resistance, hydrolysis resistance, and poor resistance to chemical media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

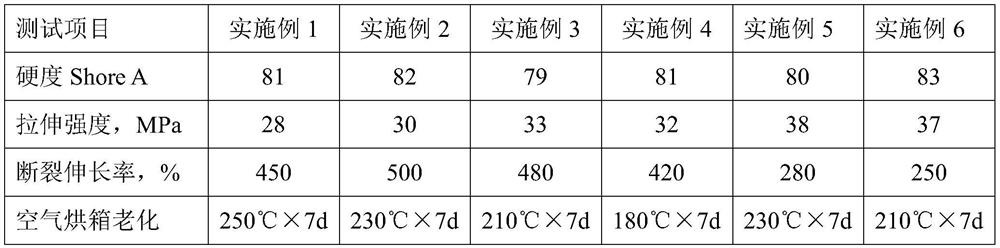

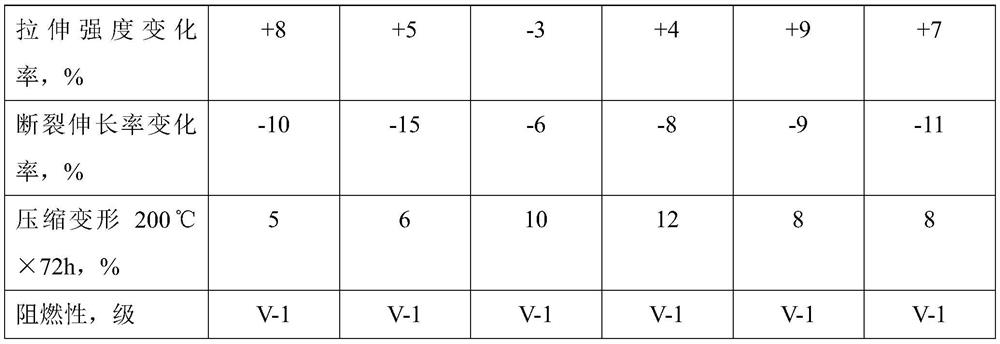

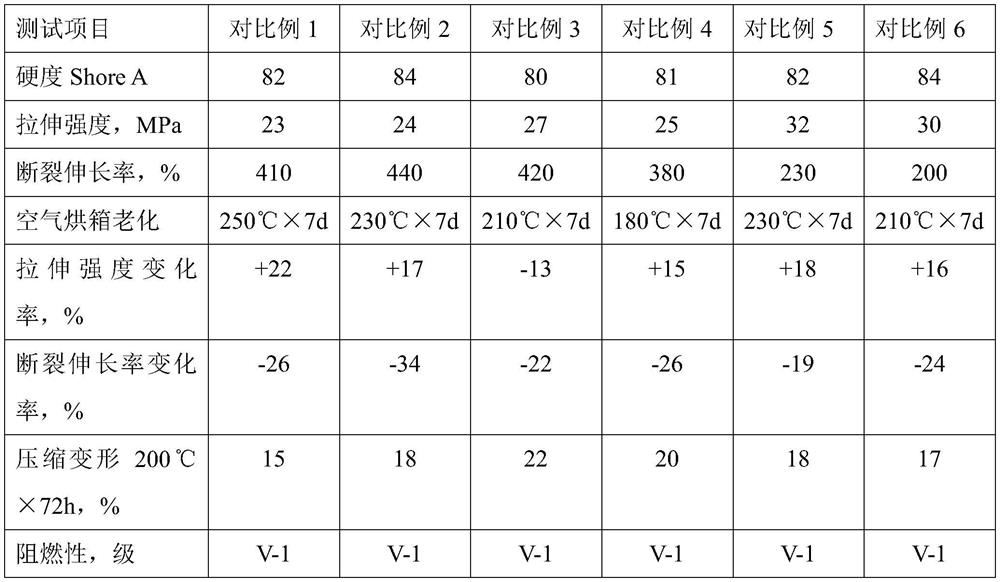

Examples

Embodiment 1

[0031] A flame-retardant thermoplastic elastomer with high temperature resistance and low compression deformation, comprising the following raw materials in parts by mass: 30 parts of PFA resin, 55 parts of flame-retardant fluororubber premix, 1.5 parts of bisphenol AF, and 1 part of trimethallyl isocyanate , 10 parts of fluorosilicone oil, 0.5 parts of hindered phenol antioxidant, 0.5 part of thioester antioxidant;

[0032] The preparation method of the flame-retardant fluororubber premix is as follows: in parts by mass, 40 parts of vinylidene fluoride-tetrafluoroethylene-hexafluoropropylene ternary rubber and 15 parts of fluorine-containing silane coupling agent modified inorganic flame retardant are first Put it into an internal mixer, knead at 75°C for 400s, then put it in a high-pressure container, and feed it with supercritical CO 2 Treat for 4.5 hours under the conditions of 12MPa and 130°C, and release the pressure quickly.

[0033] The preparation method of the flu...

Embodiment 2

[0037] A flame-retardant thermoplastic elastomer with high temperature resistance and low compression deformation, comprising the following raw materials in parts by mass: 20 parts of FEP resin, 67 parts of flame-retardant fluororubber premix, 2 parts of ethylenediamine carbamate, cyanuric acid 5 parts of triallyl ester, 10 parts of Brazilian wax, 0.5 part of hindered phenol antioxidant, 0.5 part of thioester antioxidant;

[0038] The preparation method of the flame-retardant fluororubber premix is as follows: in parts by mass, 40 parts of vinylidene fluoride-hexafluoropropylene binary rubber and 27 parts of fluorine-containing silane coupling agent modified inorganic flame retardant are first added to the internal mixer , kneaded at 78°C for 500s, then placed in a high-pressure vessel, and fed supercritical CO 2 Treat for 6 hours under the conditions of 15MPa and 150°C, and quickly release the pressure to get it;

[0039] The preparation method of the fluorine-containing sil...

Embodiment 3

[0043] A flame-retardant thermoplastic elastomer with high temperature resistance and low compression deformation, including the following raw materials in parts by mass: 30 parts of ECTFE resin, 55 parts of flame-retardant fluororubber premix, 2,5-dimethyl-2,5-bis-hexyl 2 parts of alkane, 4.5 parts of triallyl isocyanurate, 5 parts of Brazilian wax, 0.5 parts of hindered phenol antioxidant, 1.5 parts of thioester antioxidant;

[0044] The preparation method of the flame-retardant fluororubber premix is as follows: in parts by mass, add 40 parts of tetrafluoroethylene-propylene binary fluororubber and 15 parts of fluorine-containing silane coupling agent modified inorganic flame retardant into the internal mixer , kneaded at 80°C for 450s, then placed in a high-pressure container, and fed supercritical CO 2 Treat for 4 hours under the conditions of 10MPa and 120°C, and quickly release the pressure to get it;

[0045] The preparation method of the fluorine-containing silane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com