Organic electroluminescence compound and application thereof

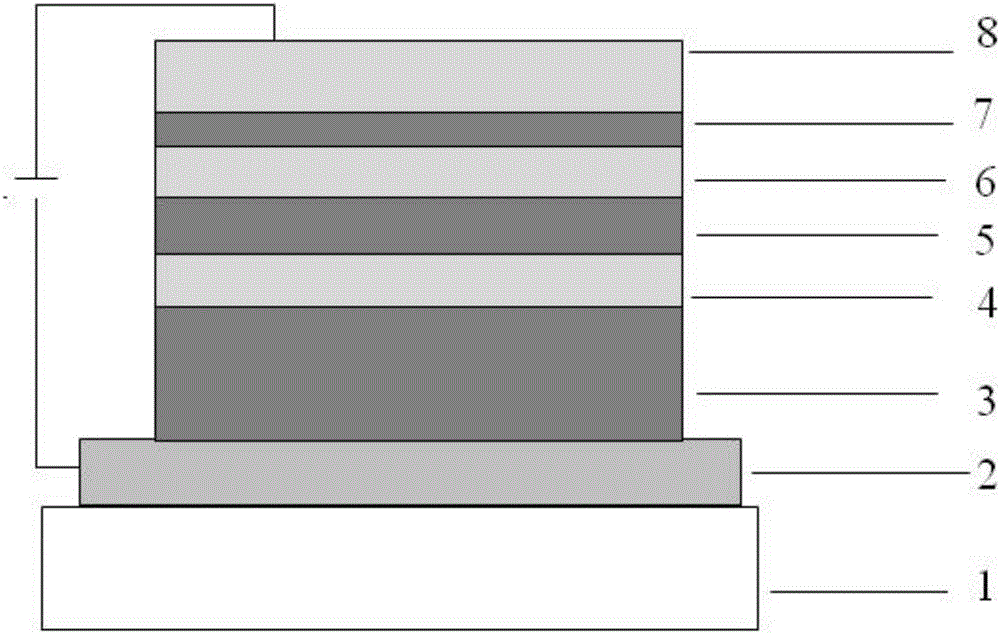

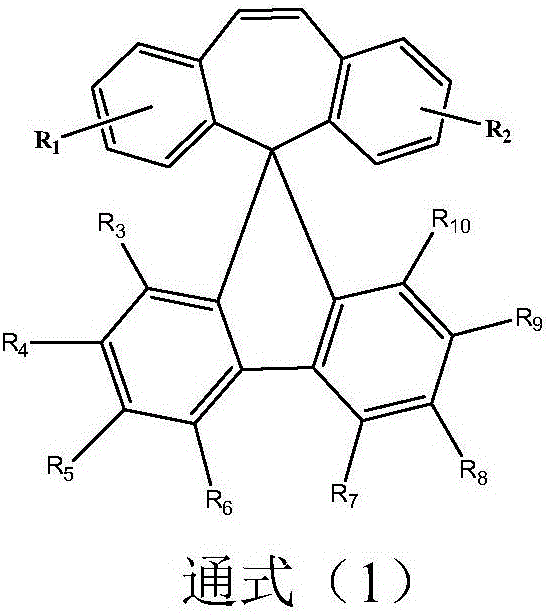

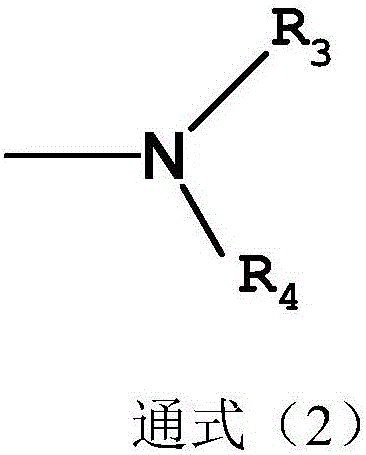

A technology of electroluminescent devices and compounds, applied in the field of semiconductors, can solve problems such as insufficient efficiency, insufficient life, difficulty in achieving full-color RGB, and great differences, and achieve the effects of improving color purity, good industrialization prospects, and inhibiting the degree of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1 (compound 01)

[0047]

[0048] The concrete synthetic route of this compound is provided now:

[0049]

[0050] In a 250ml four-neck flask, under nitrogen protection, add 5.0 grams (0.01M) of intermediate A, 4.62 grams (0.025M) of bis(3,4-dimethylphenyl)amine, 1.15 grams (0.012M) of tert-butanol Sodium, 0.1 gram of palladium acetate, 0.05 gram of CXA (n-butyl bis(1-adamantyl) phosphine), 200ml of toluene, heated to reflux for 12 hours, the reaction was complete; naturally cooled, filtered, and the filtrate was rotary evaporated, passed through a silica gel column, and used Toluene:ethanol=3:1 (volume ratio) mixed solvent was beaten, and 5.88 g of white solid was obtained after recrystallization, the purity (HPLC) was 99.0%, and the yield was 74.6%.

[0051] Elemental analysis structure (molecular formula C 59 h 52 N 2 ): theoretical value C, 89.81; H, 6.64; N, 3.55;

[0052] Test values: C, 89.60; H, 6.70; N, 5.70.

Embodiment 2

[0053] Example 2 (compound 03)

[0054]

[0055] The concrete synthetic route of this compound is provided now:

[0056]

[0057] In a 250ml four-neck flask, under nitrogen protection, add 5.0 grams (0.01M) of intermediate A, 7.53 grams (0.025M) of intermediate a, 1.15 grams (0.012M) of sodium tert-butoxide, 0.1 grams of palladium acetate, and 0.05 grams of CXA (N-butyl bis (1-adamantyl) phosphine), 200ml toluene, refluxed 20 hours, reaction is complete; Natural cooling, filtration, filtrate rotary steaming, pass silica gel column, with toluene: ethanol=3:1 (volume ratio ) mixed solvent for beating, and after recrystallization, 6.59 grams of white solid were obtained, the purity (HPLC) was 98.4%, and the yield was 70.0%.

[0058] Elemental analysis structure (molecular formula C 69 h 52 N 2 o 2 ): theoretical value C, 88.05; H, 5.57; N, 2.98; O, 3.40;

[0059] Test values: C, 87.9; H, 5.70; N, 3.05; O, 3.35.

Embodiment 3

[0060] Example 3 (compound 06)

[0061] The concrete synthetic route of this compound is provided now:

[0062]

[0063] In a 250ml four-neck flask, under nitrogen protection, add 5.0 grams (0.01M) of intermediate A, 6.85 grams (0.025M) of intermediate b, 1.15 grams (0.012M) of sodium tert-butoxide, 0.1 grams of palladium acetate, and 0.05 grams of CXA (N-butyl bis (1-adamantyl) phosphine), 200ml toluene, 16 hours of heating and reflux, reaction is complete; Natural cooling, filtration, filtrate rotary steaming, pass through silica gel column, with toluene: ethanol=3:1 (volume ratio ) mixed solvent for beating, and after recrystallization, 6.07 grams of white solid were obtained, the purity (HPLC) was 98.8%, and the yield was 68.5%.

[0064] Elemental analysis structure (molecular formula C65H50N4): theoretical value C, 88; H, 5.68; N, 6.32;

[0065] Test values: C, 87.8; H, 5.90; N, 6.30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com