Large-scale infrared focal plane structure with thermal stress unloading capacity

A thermal stress unloading, infrared focal plane technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems affecting the life and reliability of focal plane devices, detector material damage, affecting imaging quality, etc., to reduce material Risk of damage, reduced thermal stress, increased effect of damping properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

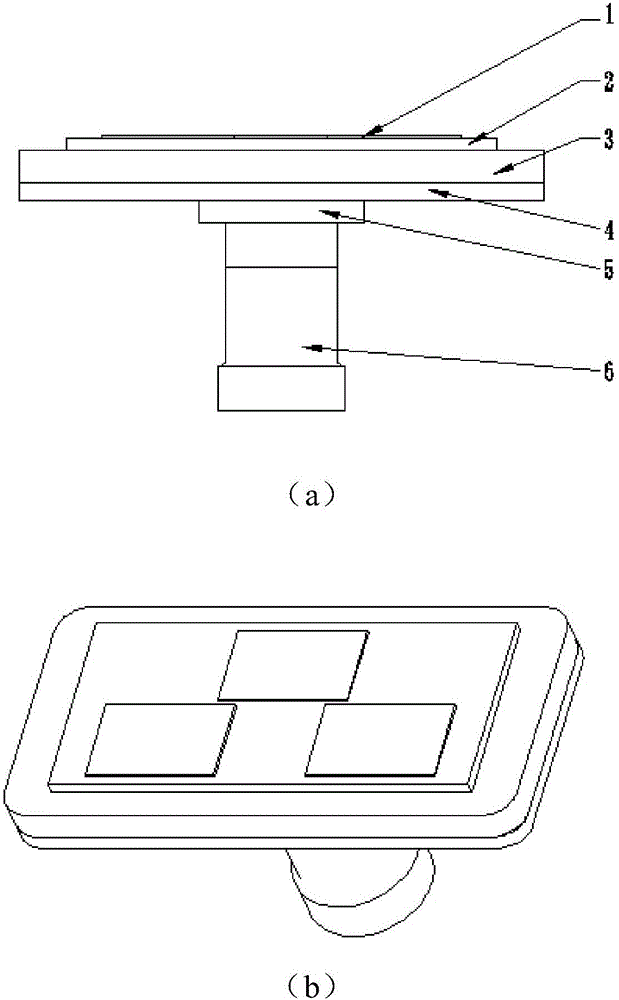

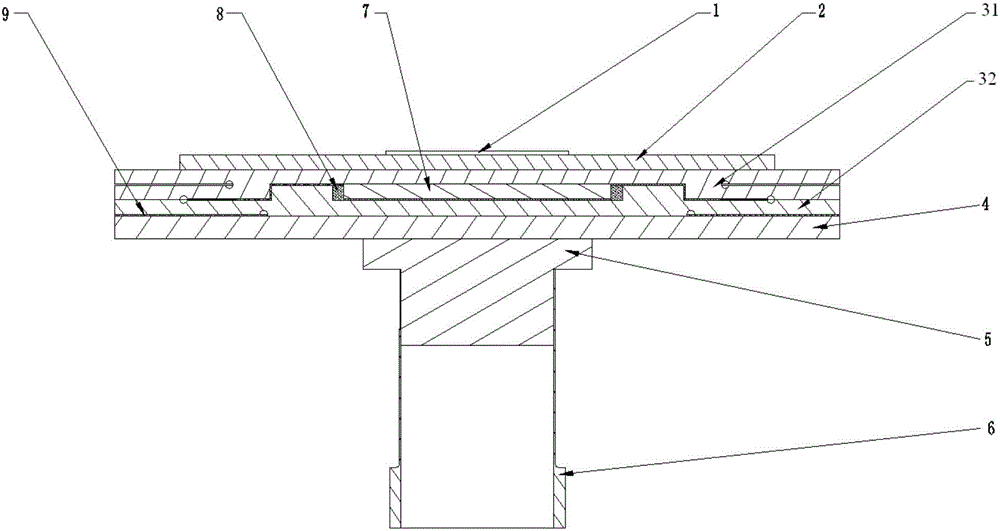

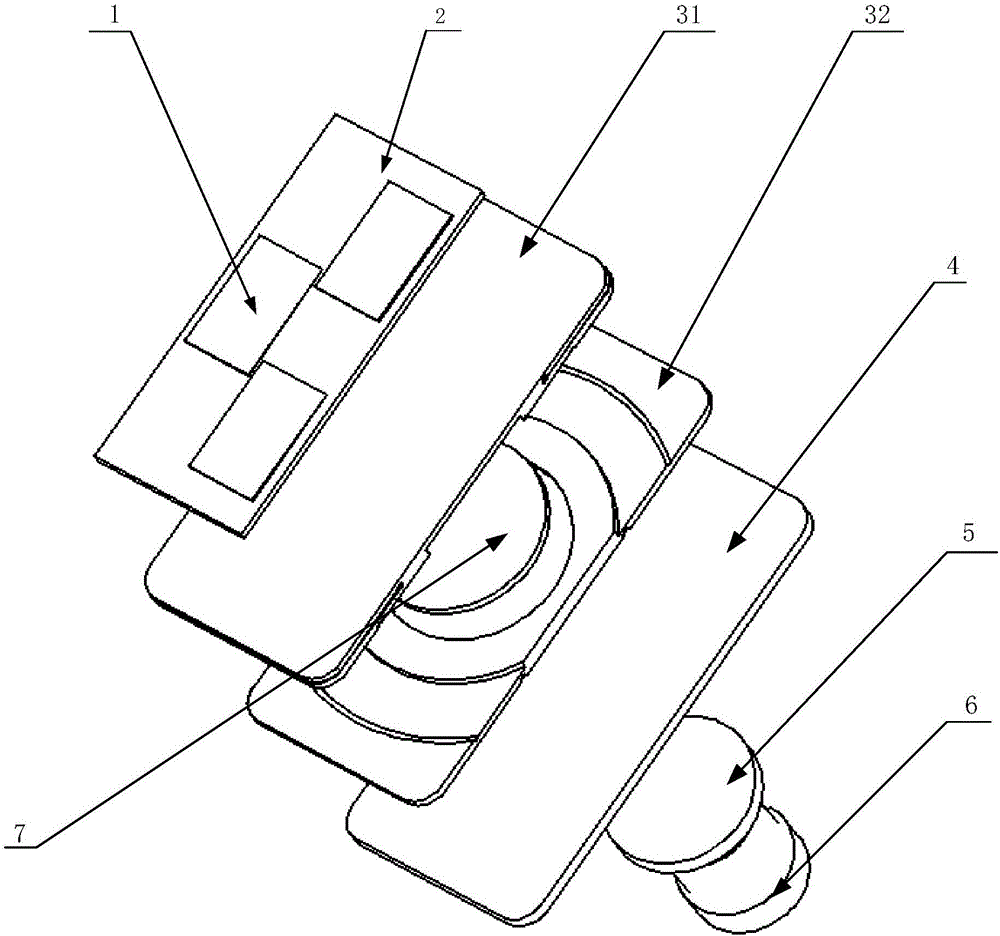

[0027] Such as figure 2 , image 3 As shown, a large infrared focal plane structure with thermal stress unloading capability, including detector chip 1, sapphire 2, first transition substrate 31 (Invar), second transition substrate 32 (Invar), cold plate 4, gem compensation sheet 7, metal rubber or copper wool 8 and indium foil 9; the detector chip 1 is installed on the sapphire 2; one side of the first transition plate 31 is a plane, and an annular groove is opened in the middle of the other side, and the sapphire 2 is glued on the One side of transition substrate 31 is flat; one side of second transition substrate 32 is flat, and the middle part of the other side has an annular protruding structure. The protruding structure is docked with the annular groove on the first transition plate 31 to form a cavity. Installed in the cavity and pasted on the first transition substrate 31 ; the second transition substrate 32 is installed on the cold plate 4 . The cold plate 4 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com