Patents

Literature

47results about How to "Guaranteed coplanarity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

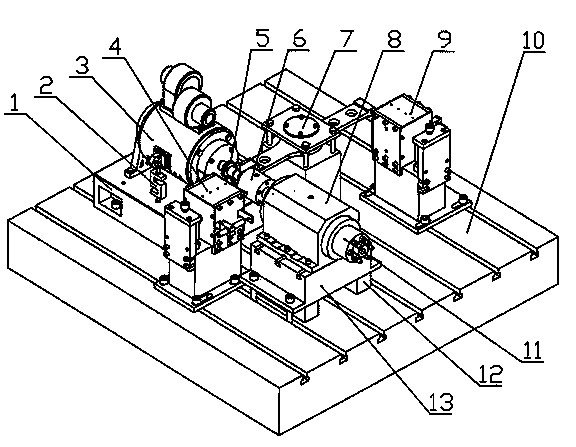

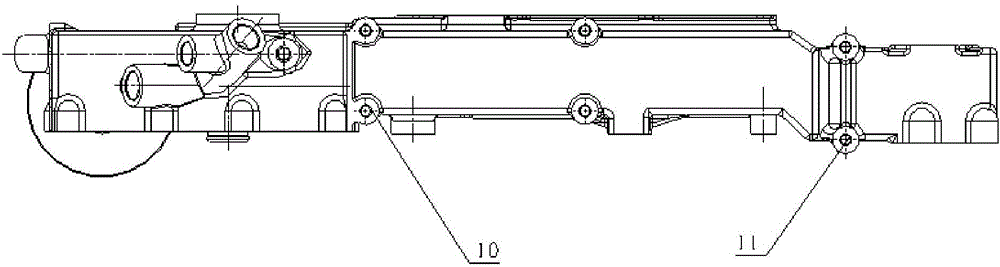

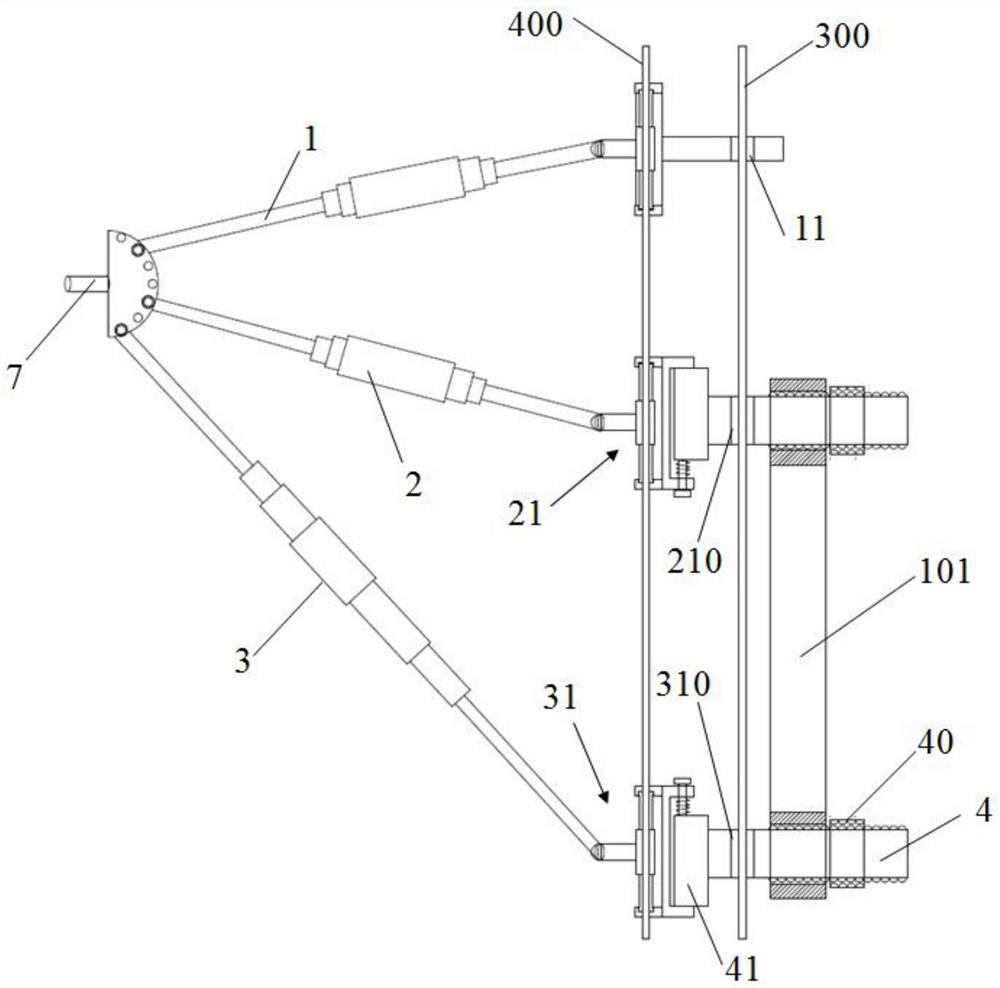

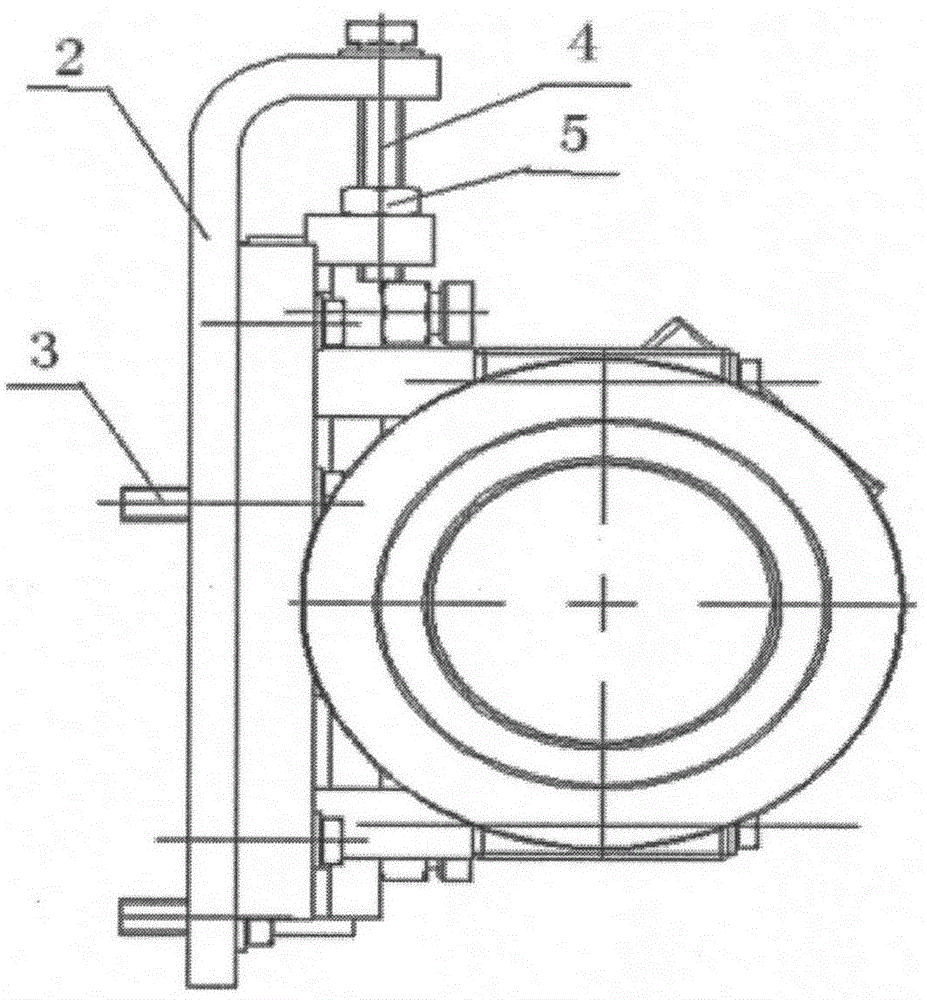

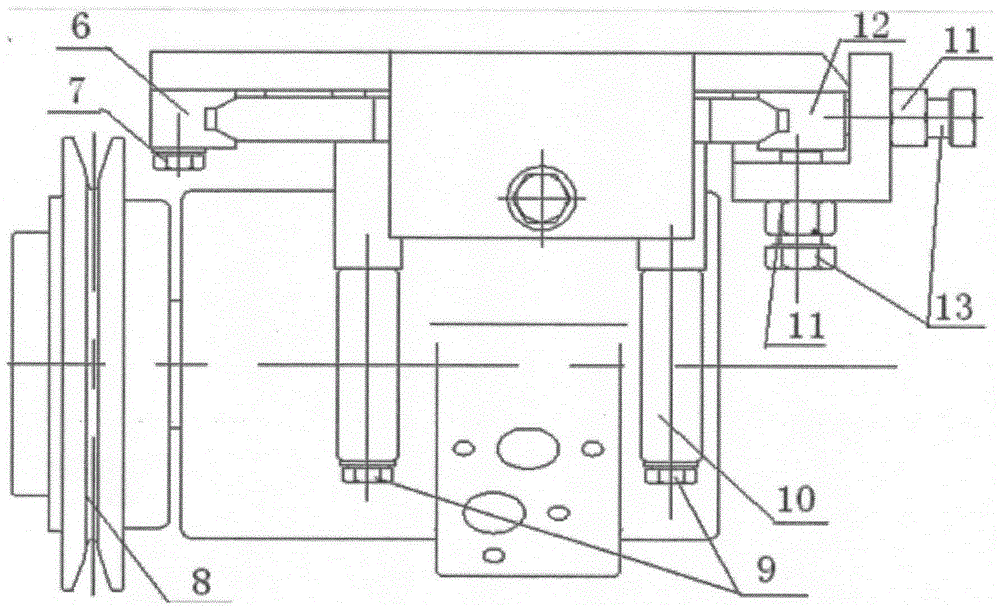

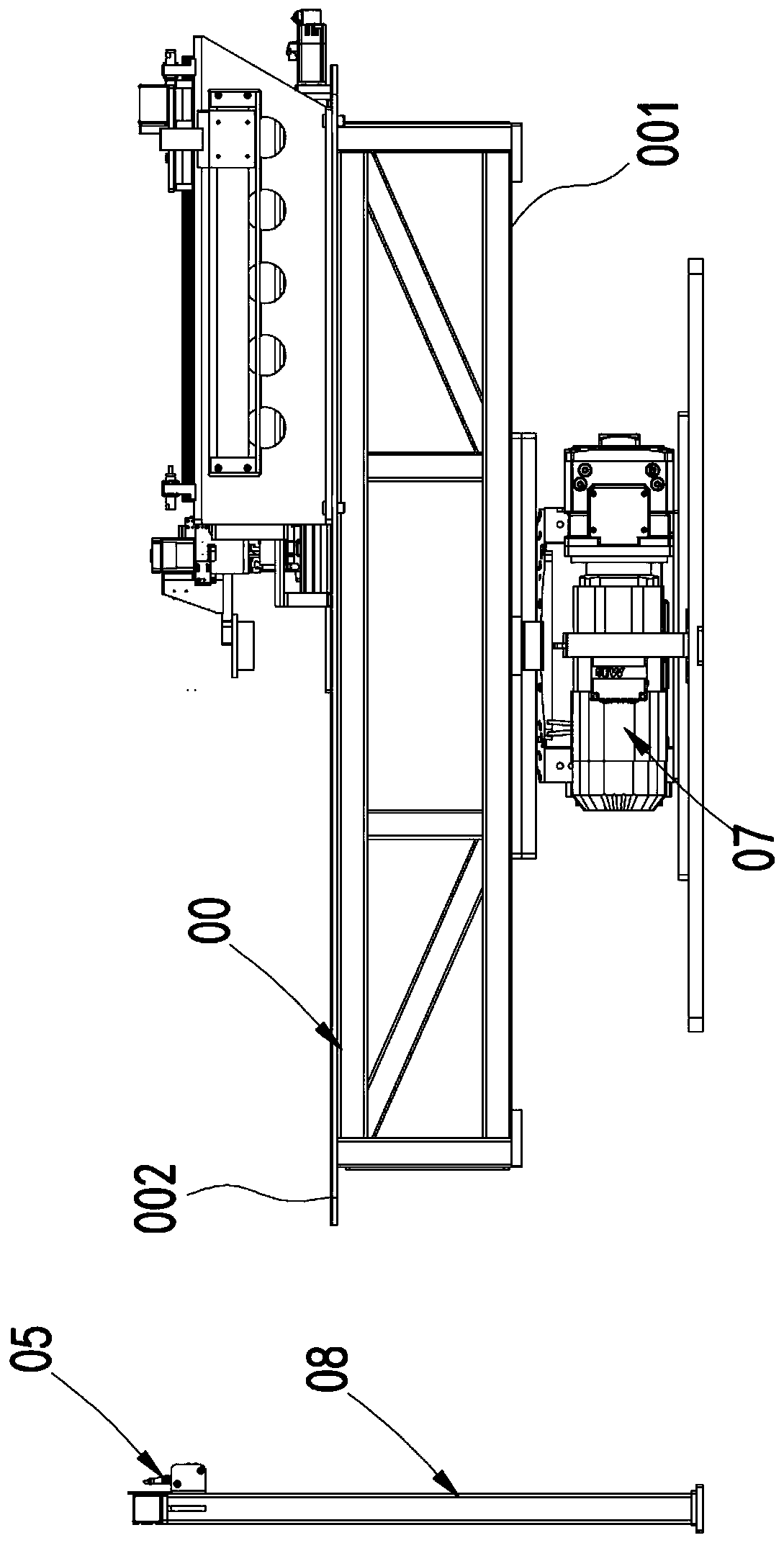

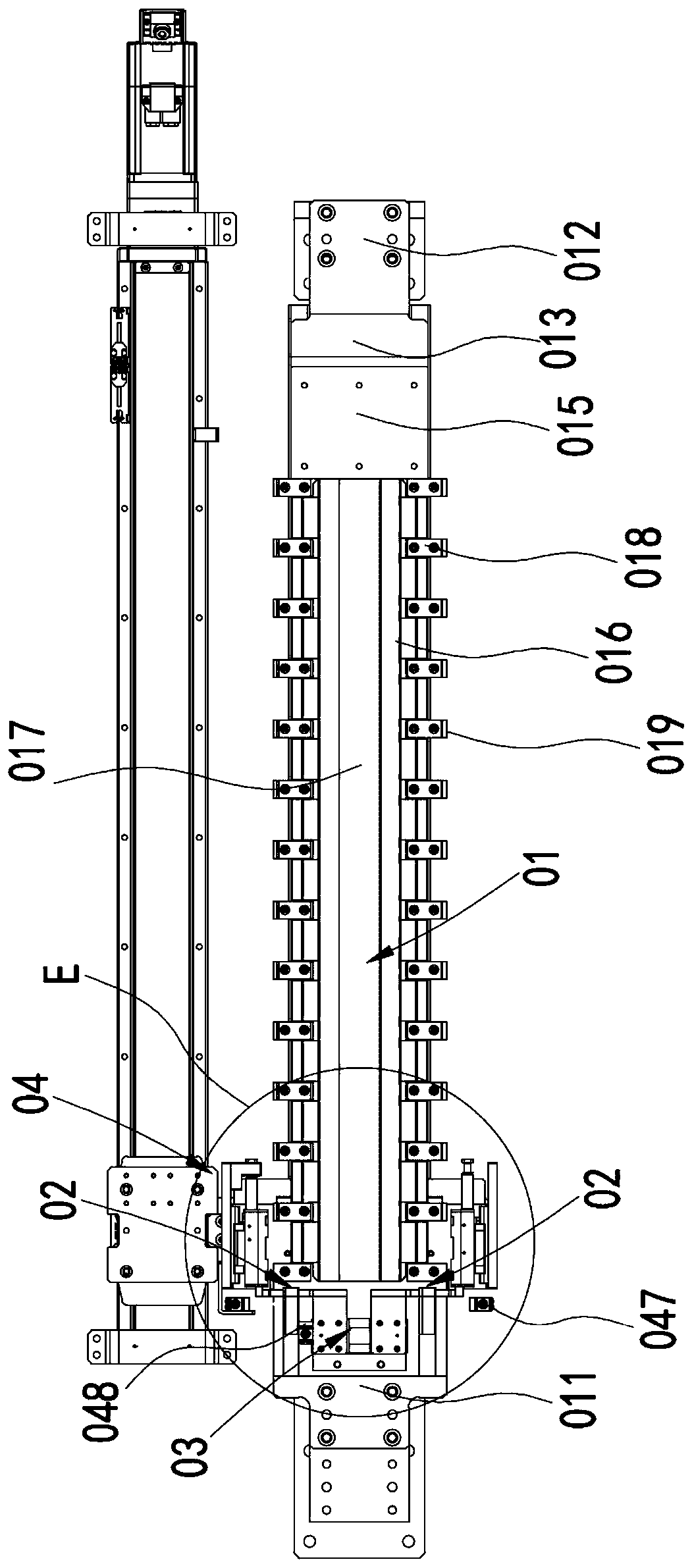

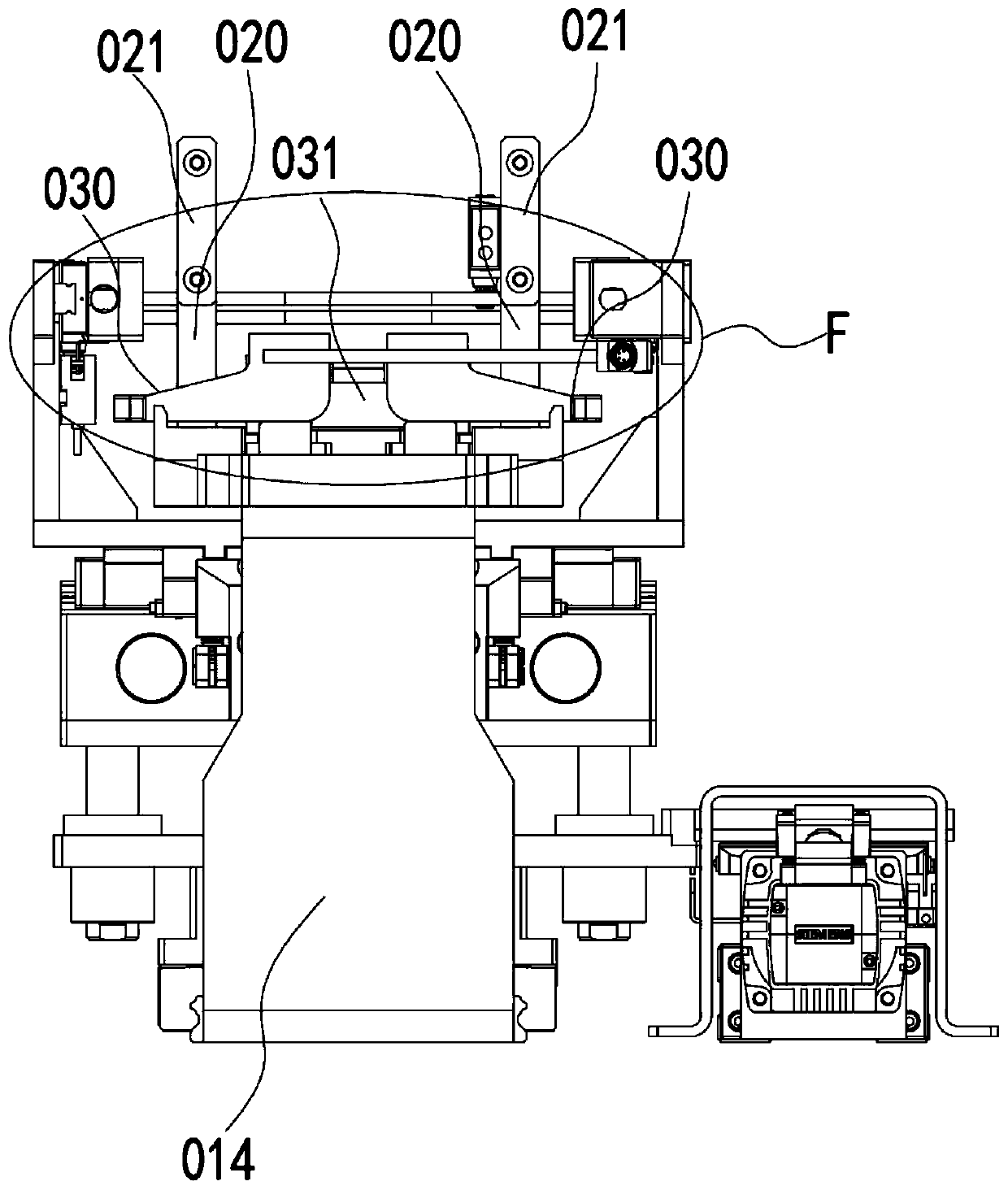

Contact-type reliability test bed capable of conducting mixed loading on electric main shaft

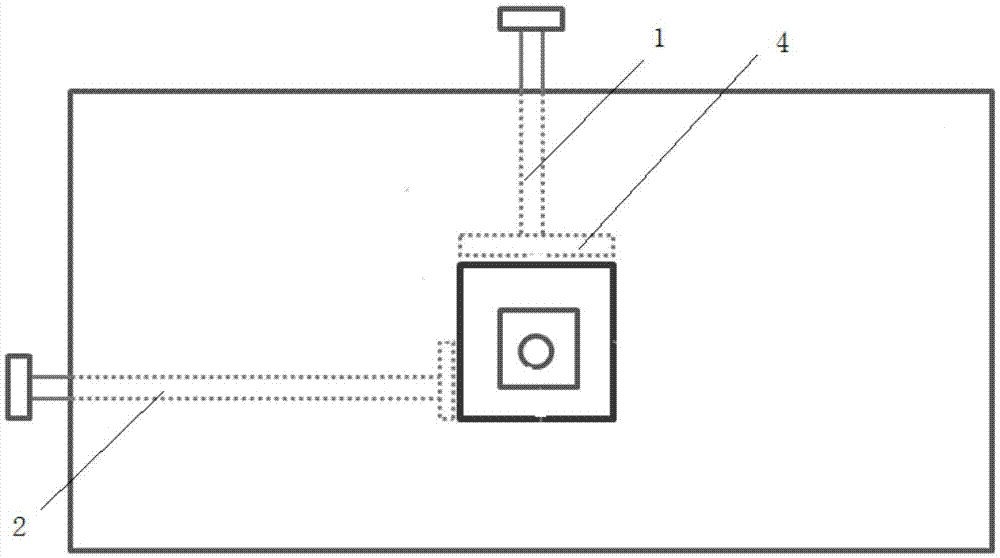

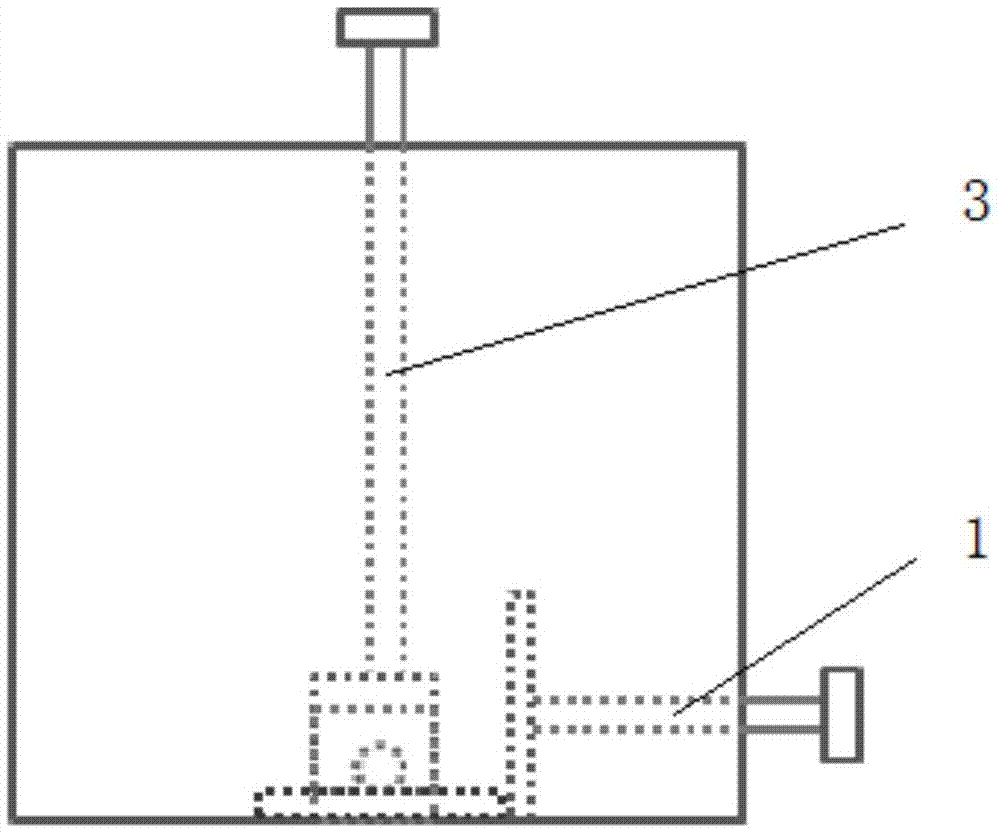

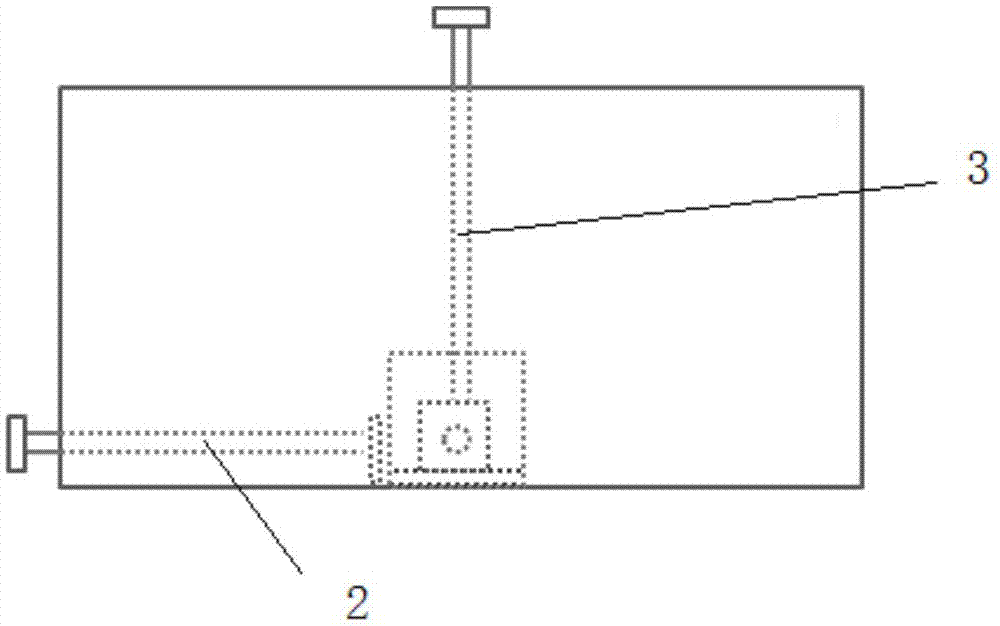

The invention discloses a contact-type reliability test bed capable of conducting mixed loading on an electric main shaft. The test bed is composed of the electric main shaft, a connecting shaft unit, a torque loading device, a radial force electromagnetic loading device, an axial force electromagnetic loading device and a swing arm device. The test bed can load an axial force, a radial force and a torque on the electric main shaft at the same time, control the magnitudes of the three forces in a coordinate mode to simulate cutting forces in different magnitudes and different directions, really and reliably simulate the cutting forces of the electric shaft in practical working conditions, and provide a test foundation for reliability acceleration tests of the electric shaft.

Owner:JILIN UNIV

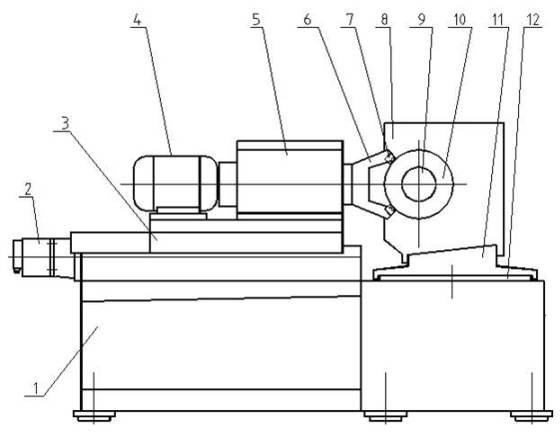

New Spherical Surface Grinding Machine Tool and Its Grinding Method

InactiveCN102275114AGuaranteed coplanarityImprove productivityGrinding drivesSpherical surface grinding machinesSpherical shapedServomotor

The invention discloses a novel spherical surface grinding machine tool and a grinding method thereof. The novel spherical surface grinding method comprises the following steps: 1) Workpiece installation: the workpiece is installed on the mandrel, and the workpiece has a spherical shape to be processed. On the surface, the headstock and tailstock of the machine tool withstand the two ends of the mandrel, and the longitudinal drive mechanism drives the machine table, headstock and tailstock to move left and right along the Y-axis direction of the machine tool, so that the spherical center of the workpiece is located on the axis of the sand table ; Start the machine tool servo motor 1 to drive the saddle to move along the X-axis direction of the machine tool, and make the sand disc buckle cover on the surface to be processed on the workpiece; 2) spherical grinding: start the motor to make the sand disc rotate at a high speed around the machine tool X axis Start the frequency conversion motor and drive the mandrel and the workpiece to rotate around the Y-axis of the machine tool at a low speed under the action of the deceleration device. Under the action of the turntable mechanism, the worktable, headstock, tailstock and workpiece all revolve around the Z-axis Reciprocating rotation, and the saddle is driven forward by the servo motor 1.

Owner:CMCU ENG

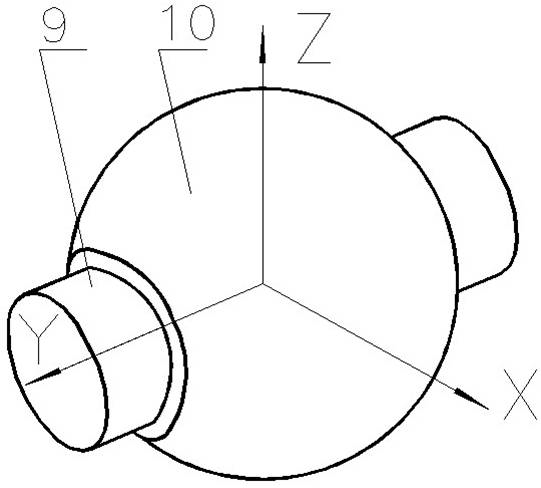

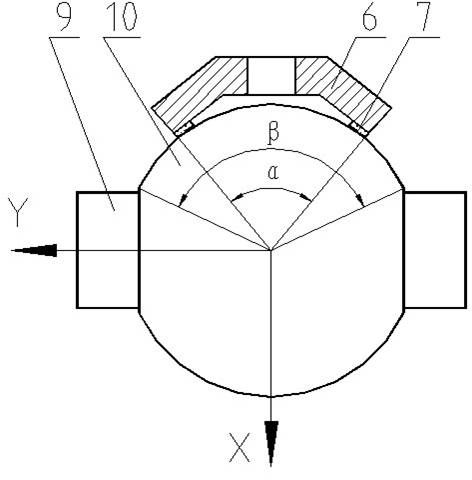

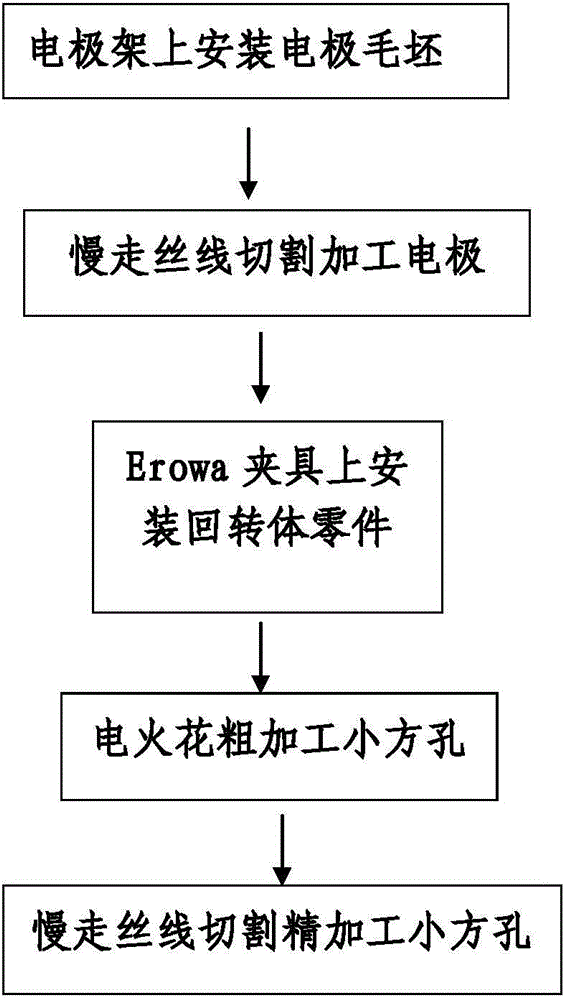

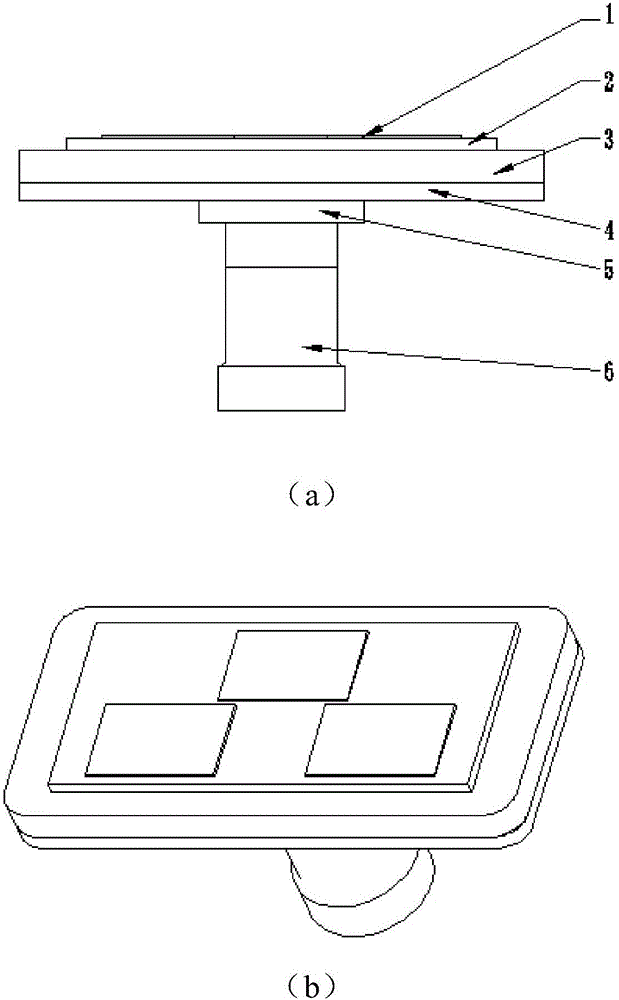

Machining method for radial high-precision small square holes of rotary part

ActiveCN105643032ASimple processReduce manufacturing costElectrical-based machining electrodesOther manufacturing equipments/toolsElectric dischargeWire cutting

The invention discloses a machining method for radial high-precision small square holes of a rotary part. The machining range is 0.3-3.0 mm, the machining thickness is less than 1.5 mm, the root Rmax is 0.08, and the radial coplanarity degree of the opposite holes is within 0.01 mm. According to the machining method for the radial high-precision small square holes of the rotary part, on the basis of machining the small square holes through traditional electric spark forming, the small square holes are machined roughly on an electric discharge machining machine tool through an EROWA fixture and a homemade electrode stand to reserve margins for finish machining; by using the characteristics and advantages of machining the workpiece through the EROWA fixture and slow speed wire cutting, slow speed wire cutting is added into the finish machining process for the small square holes, accordingly, the purpose that the radial coplanarity degree of the opposite holes is within 0.01 mm is achieved, and the small square holes are regular in shape. Compared with a traditional machining method, the machining method for the radial high-precision small square holes of the rotary part is high in efficiency and stable in quality, and the qualified rate reaches 99% or higher.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

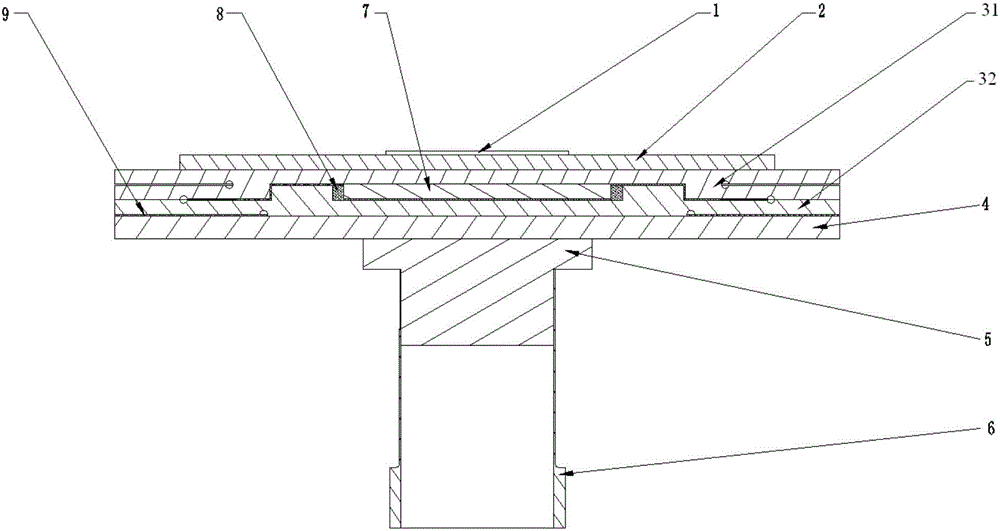

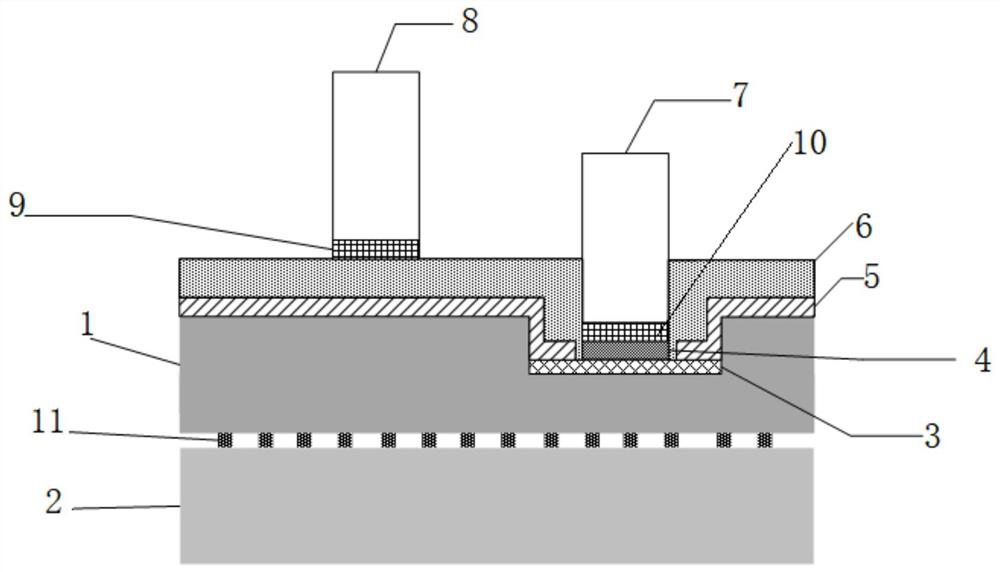

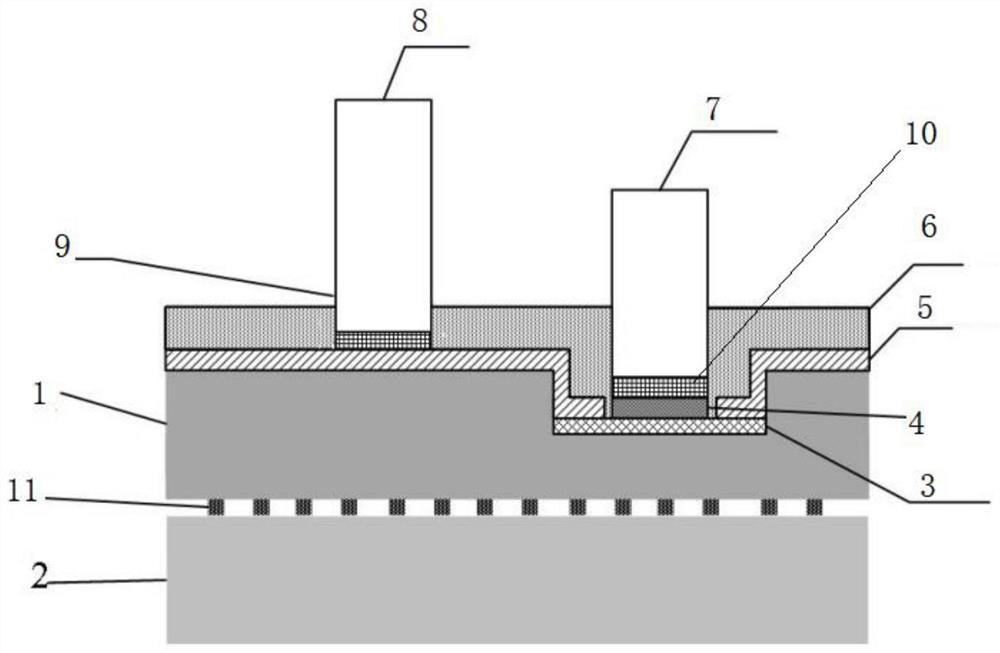

Large-scale infrared focal plane structure with thermal stress unloading capacity

ActiveCN106549067AReduce thermal stressReduce risk of sabotageSemiconductor devicesConvex structureThermal deformation

The invention relates to a large-scale infrared focal plane structure with thermal stress unloading capacity, which comprises a detector chip (1) and the like. The detector chip (1) is mounted on sapphire (2); one lateral surface of a first transitional substrate (31) is a plane, a ring-shaped groove is formed at the middle part of the other lateral surface of the first transitional substrate (31), and the sapphire (2) is adhered to the side of the plane of the first transitional substrate (31); one lateral surface of a second transitional substrate (32) is a plane, a ring-shaped convex structure is formed at the middle part of the other lateral surface of the second transitional substrate (32), the convex structure is abutted with the ring-shaped groove of the first transitional substrate (31) to form a cavity, and a sapphire compensation sheet (7) is mounted in the cavity and is adhered to the first transitional substrate (31); and the second transitional substrate (32) is mounted on a cold plate (4). According to the invention, by the stress unloading structure, a thermal stress and thermal deformation which are generated due to mismatching of thermal expansion coefficients of laminated materials are adsorbed, so that the thermal stress and thermal deformation of a large-scale infrared focal plane are effectively reduced, and reliability of a large-scale infrared focal plane device is improved.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

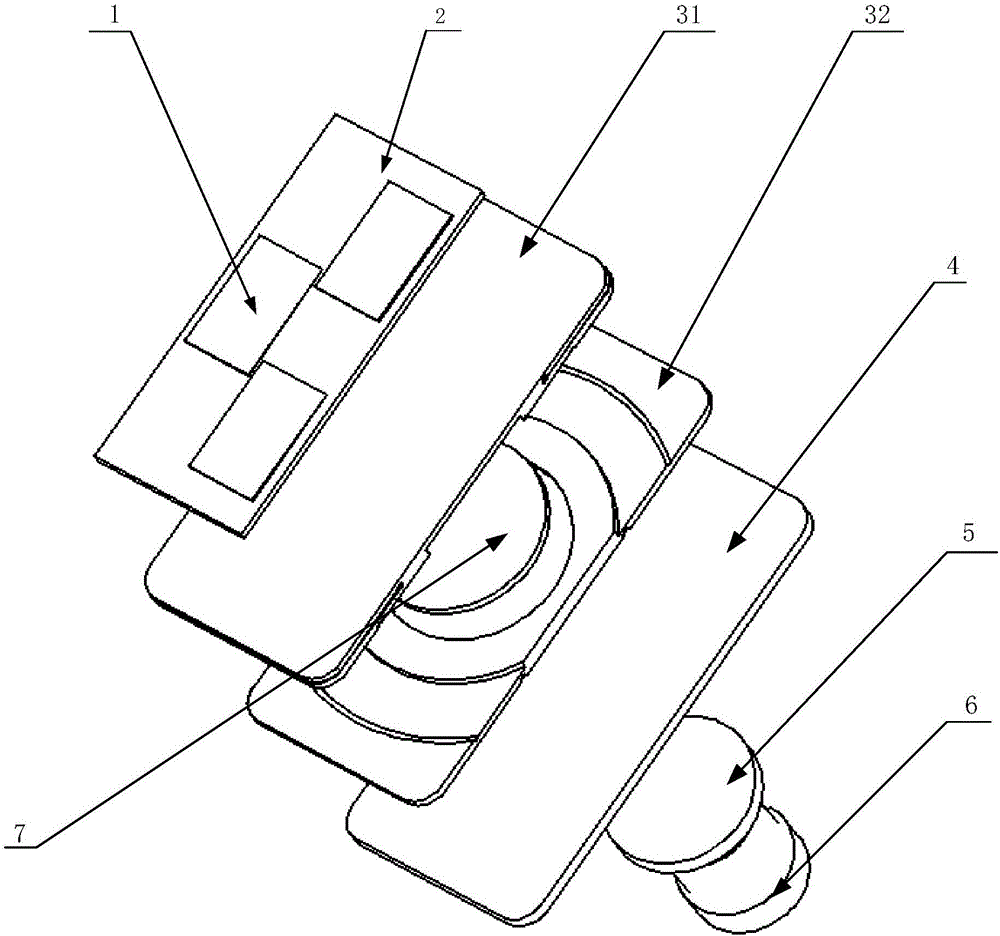

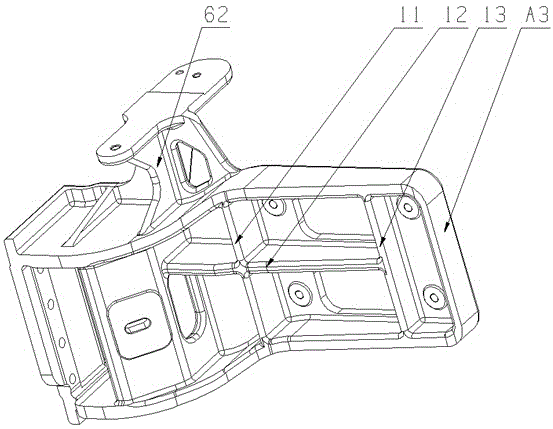

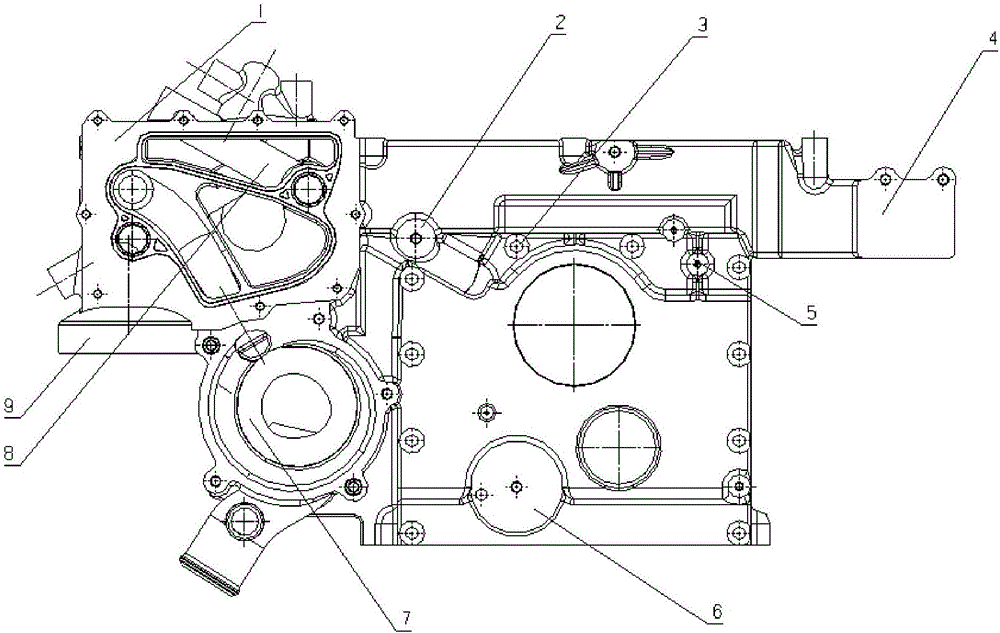

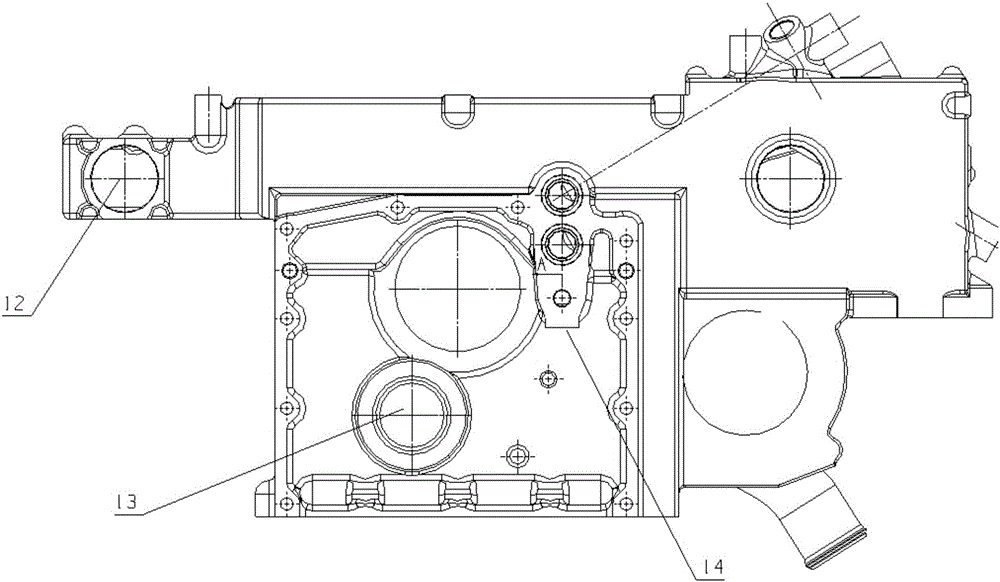

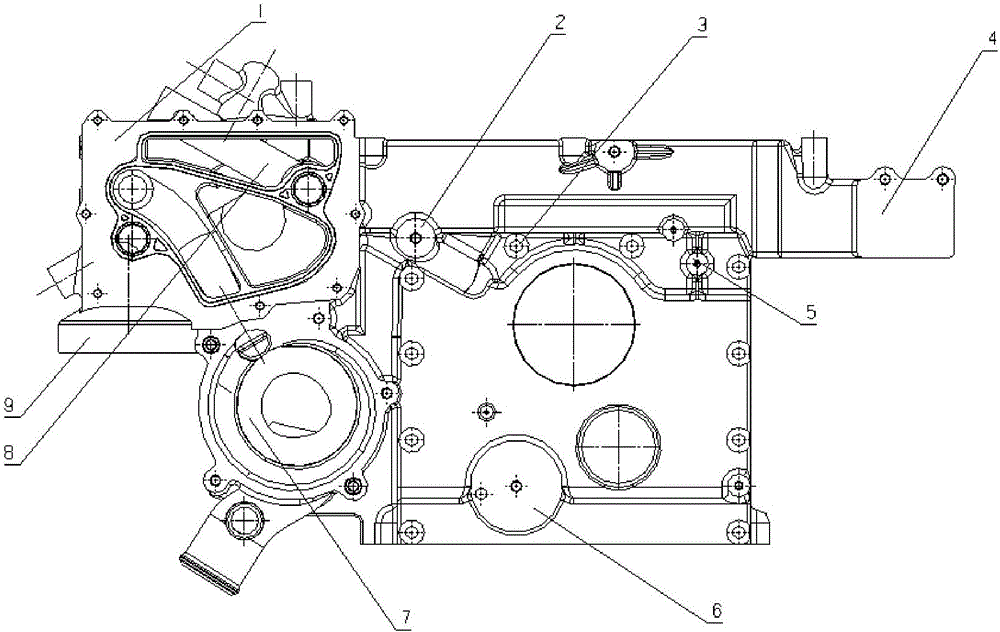

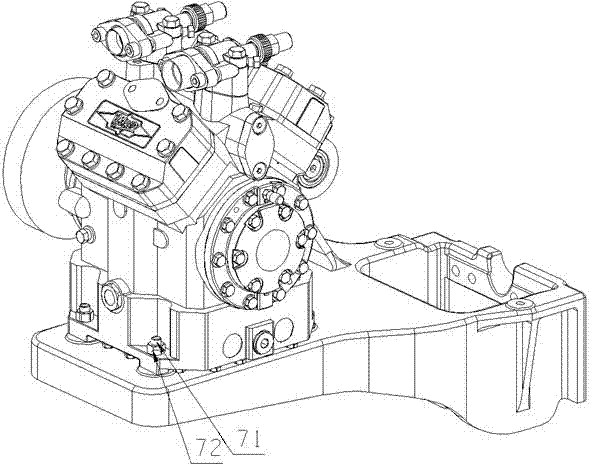

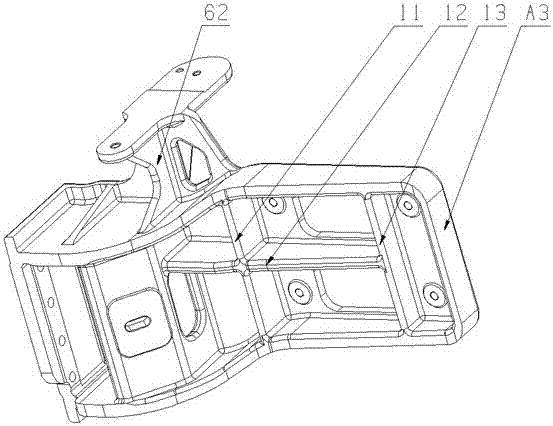

Integrated multifunctional air conditioner compressor holder

ActiveCN105332896AVibration syncReduce vibrationPositive displacement pump componentsPiston pumpsEngineeringEngine mount

The invention discloses an integrated multifunctional air conditioner compressor holder. The integrated multifunctional air conditioner compressor holder is characterized in that an engine front suspension holder body and an air conditioner compressor holder body are integrated; an engine mounting board is provided with eight engine mounting holes and connected with an engine; the holder is provided with a front suspension cushion mounting hole connected with a whole vehicle connecting suspension cushion; the air conditioner compressor supporting face of the holder is used for supporting an air conditioner compressor, and a tensioning wheel for tensioning an air conditioner compressor belt and an idle wheel are mounted on the other mounting face perpendicular to the air conditioner compressor supporting face. According to the integrated multifunctional air conditioner compressor holder, the air conditioner compressor holder body and the engine front suspension holder body are integrated, and therefore the air conditioner compressor and the engine can vibrate synchronously, vibration of a whole vehicle is reduced, and the comfort level of the whole vehicle is improved; meanwhile, the coplanarity of the air conditioner compressor belt is easily ensured, and the transmission reliability is high.

Owner:GUANGXI YUCHAI MASCH CO LTD

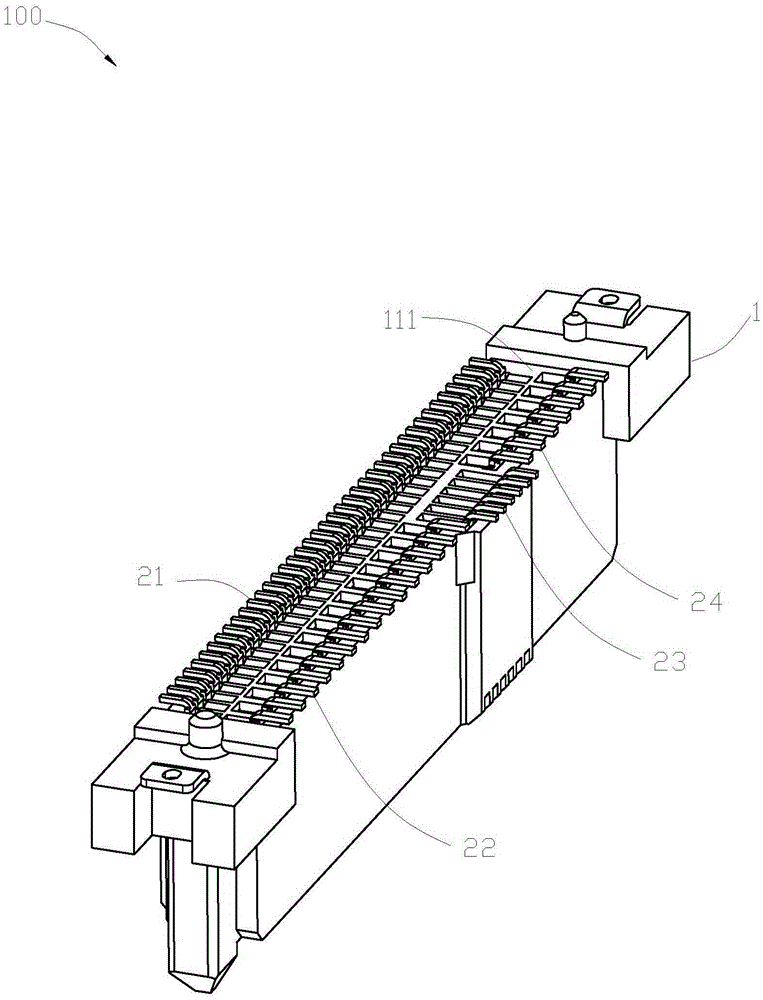

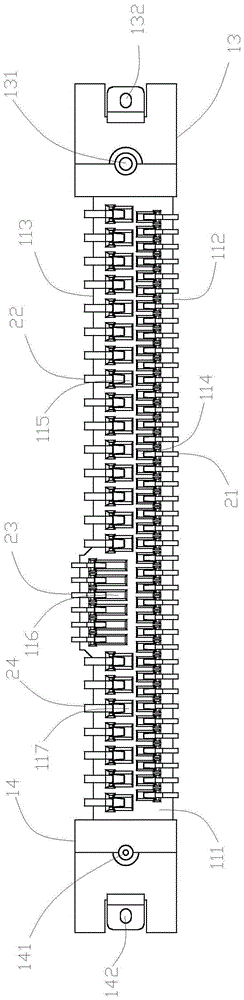

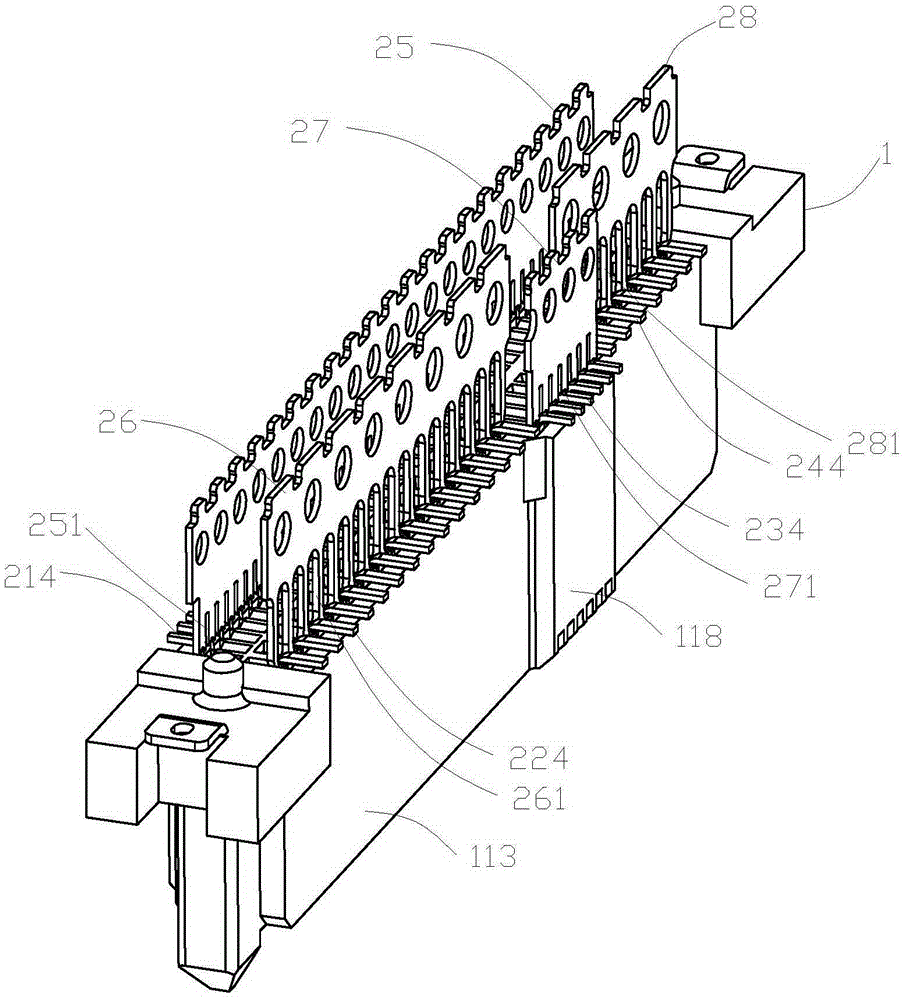

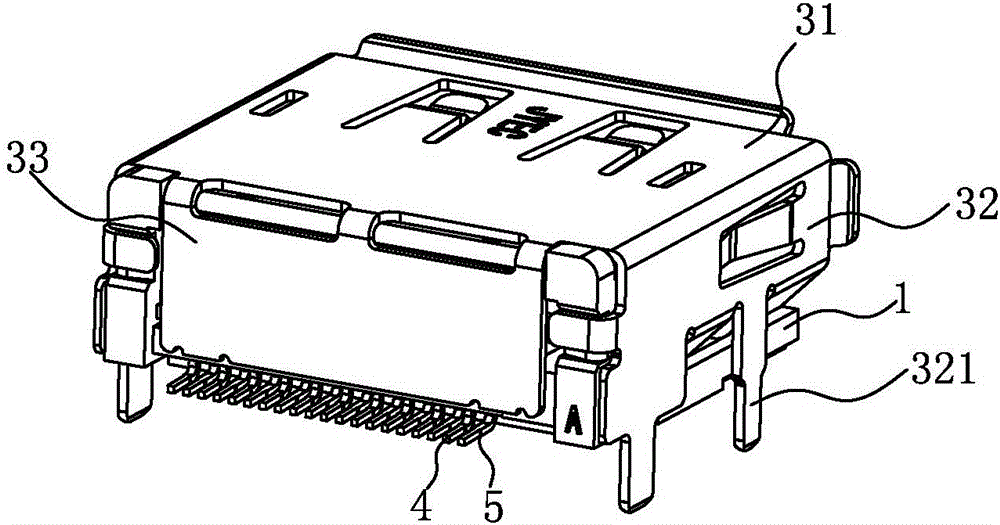

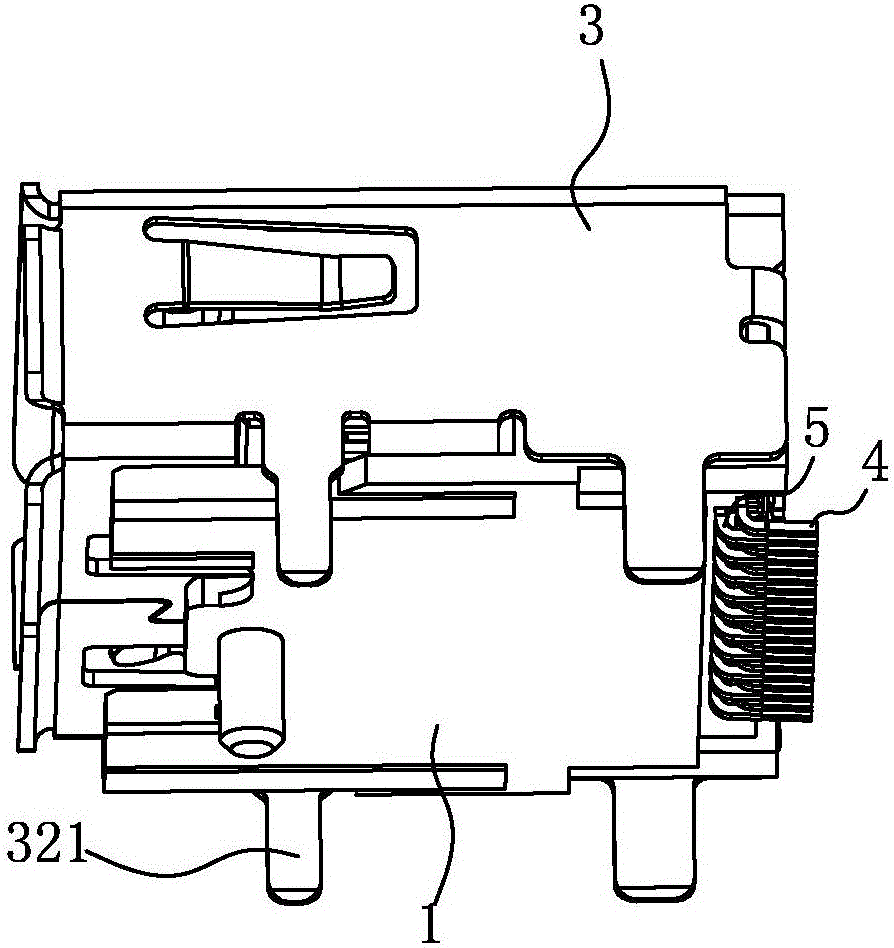

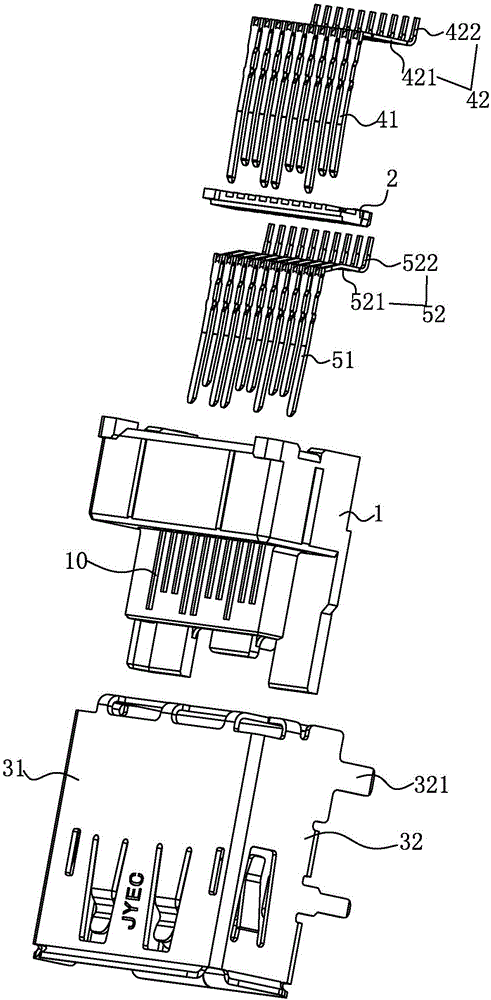

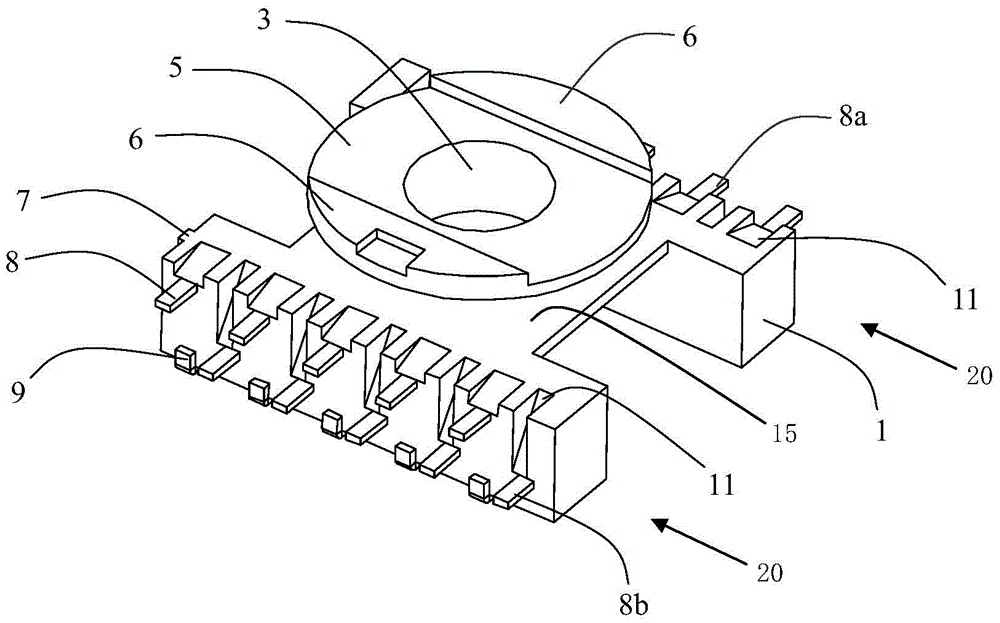

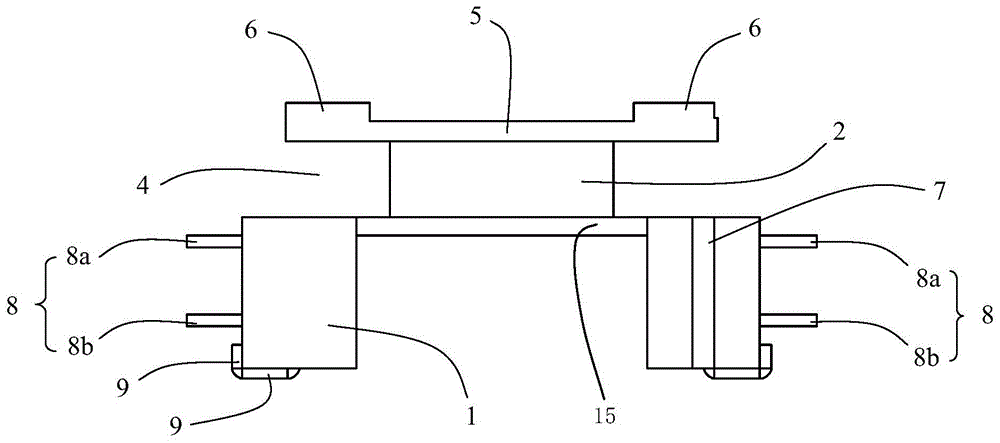

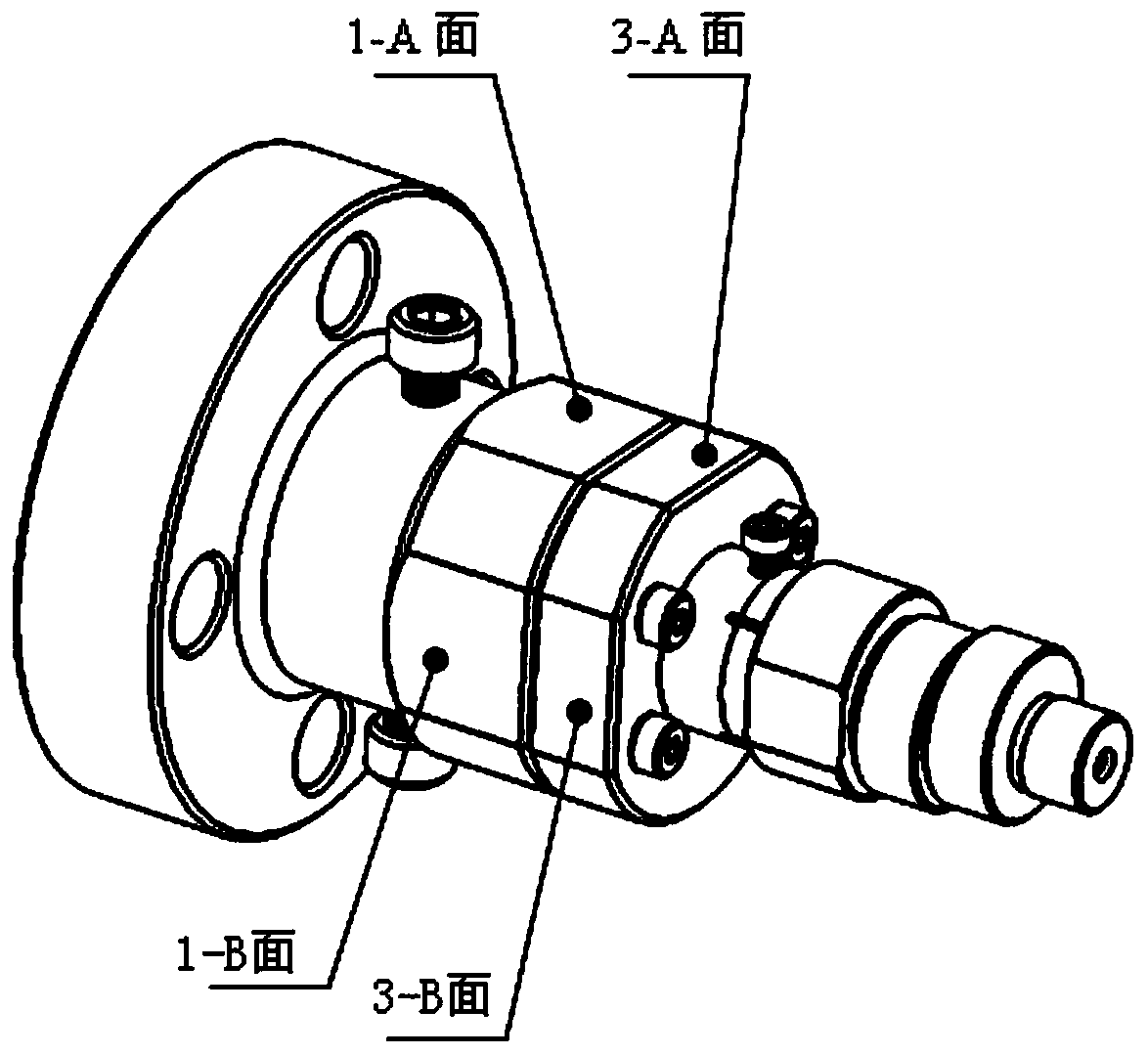

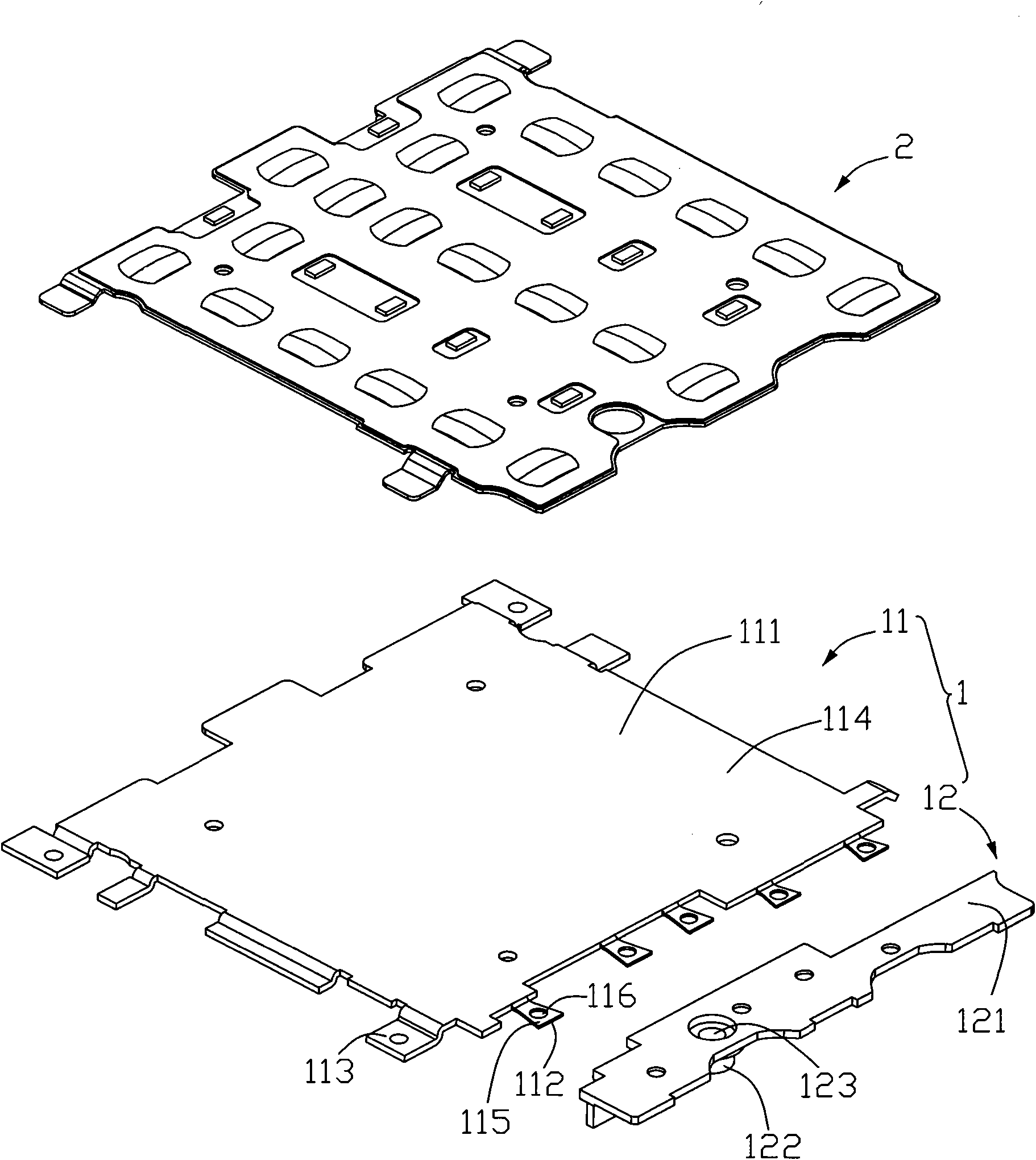

Electrical connector and manufacturing method thereof

InactiveCN106611907AGuaranteed coplanarityCoplanarity effectContact member assembly/disassemblySecuring/insulating coupling contact membersEngineeringElectrical connector

The invention provides an electrical connector and a manufacturing method thereof. The electrical connector comprises a plastic body and a number of first terminals which are integrally connected with the same side edge of a first tape body. A number of first terminal blanking holes are formed in the first tape body. Each first terminal is provided with a first fixing part, a first contact part which is connected with one end, which is away from the first tape body, of the first fixing part, first shoulder parts and a first weld leg located between the first shoulder parts. A number of first weld legs are integrally torn and formed by the corresponding first terminal blanking holes. The first terminals are arranged on the plastic body through the matching of a jig and the first tape body, and then the first tape body is removed. According to the electrical connector provided by the invention, the coplanarity of the terminal weld legs can be improved and ensured, and the corresponding manufacturing and installation process of the electrical connector is improved.

Owner:ALLTOP ELECTRONICS SU ZHOU +1

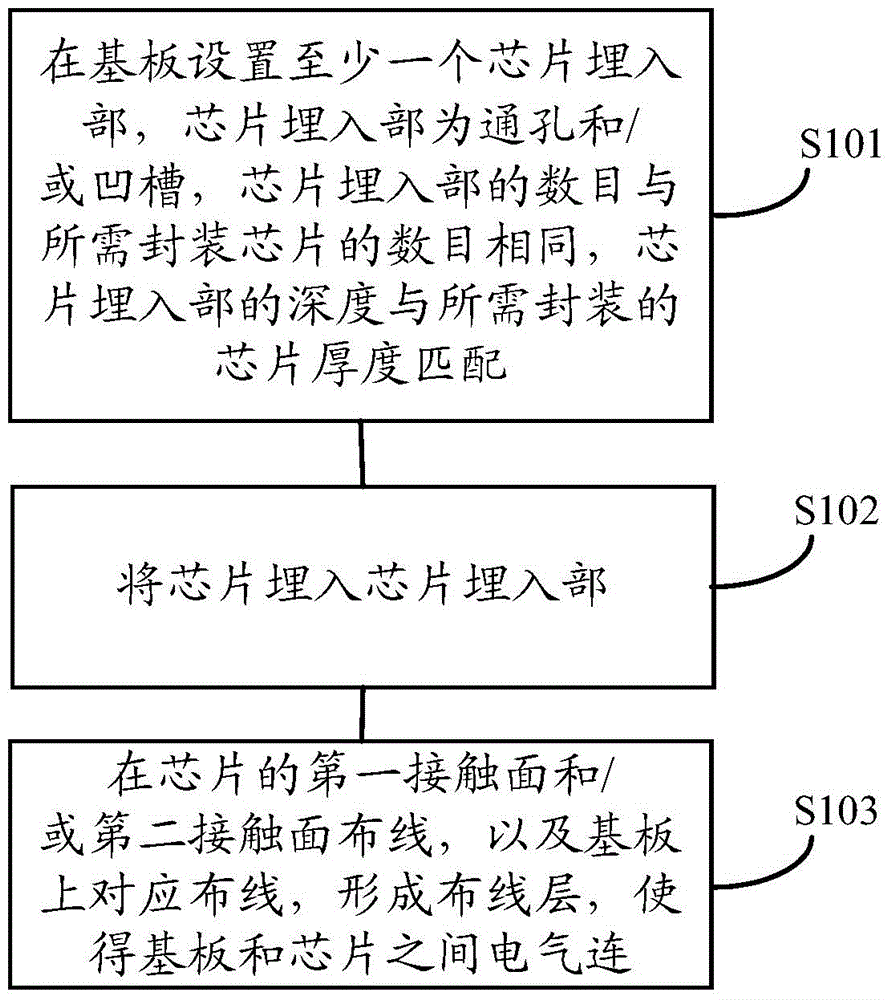

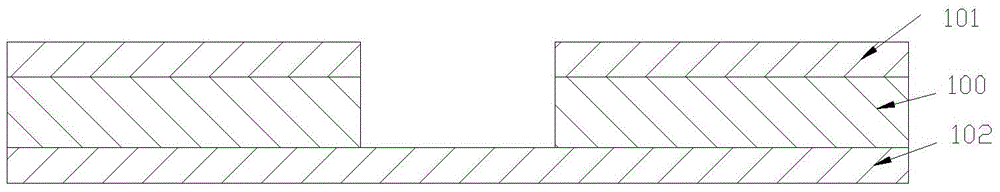

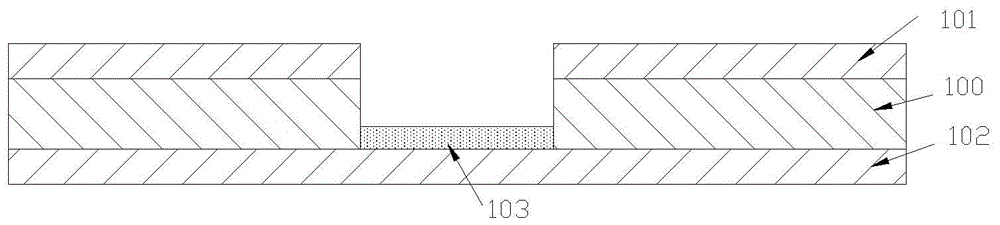

Packaging method and structure of chip embedded in substrate

ActiveCN103477423BStrong scalabilityImprove applicabilitySemiconductor/solid-state device detailsSolid-state devicesElectrical bondingElectrical and Electronics engineering

Provided are an encapsulation method for embedding a chip into a substrate and a structure thereof. The method includes: providing at least one chip embedding part inside a substrate, the chip embedding part being a through-hole and / or a recess, the number of chip embedding parts being equal to that of the chip (107) to be encapsulated, the depth of the chip embedding part matched with the thickness of the chip (107) to be encapsulated; embedding the chip (107) into the chip embedding part; wiring on a first contact face and / or a second contact face of the chip (107), and wiring correspondingly on the substrate to form a wiring layer, so that the substrate and the chip (107) are electrically connected to each other.

Owner:SHENNAN CIRCUITS

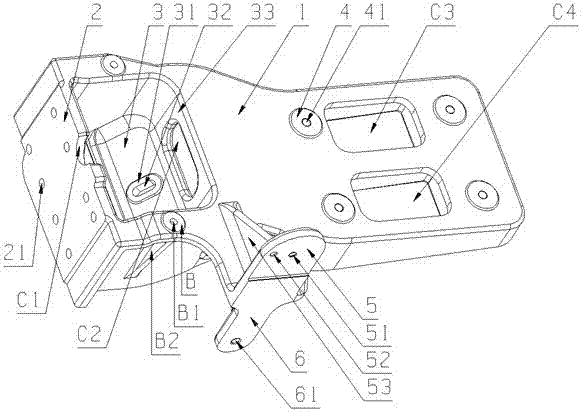

Display connector and fabrication method thereof

InactiveCN106207586AGood for hot melt operationGood hot melt effectContact member assembly/disassemblyCoupling contact membersEngineeringCrosstalk

The invention discloses a display connector and a fabrication method thereof. The display connector comprises an insulation base, a terminal group, an insulation rear plug and a metal shell, wherein the insulation rear plug is used for limiting and hot-melting wrapping the terminal group. In the display connector, the insulation rear plug is additionally arranged at a rear end of the insulation base, a second contact part surface of a lower-layer terminal is in contact with a bottom surface of the insulation rear plug by the insulation rear plug, a first contact part surface of an upper-layer terminal is flush with a boss surface of the insulation rear plug, the insulation rear plug is subjected to hot melting by a jig to form plastic barriers so as to wrap contact parts of the upper-layer terminal and the lower-layer terminals and achieve a fixing effect, the coplanarity and the alignment degree of welding parts of the upper-layer terminal and the lower-layer terminal can be effectively ensured, high stability is achieved, terminal pins are not needed to be adjusted by manual, and the production efficiency is improved; and moreover, after the upper-layer terminal and the lower-layer terminal are assembled, a first pin part and a second pin part are staggered vertically, and crosstalk can be enabled not to be generated in high-frequency signal transmission of the upper-layer terminal and the lower-layer terminal very well.

Owner:东莞市竞跃电子有限公司

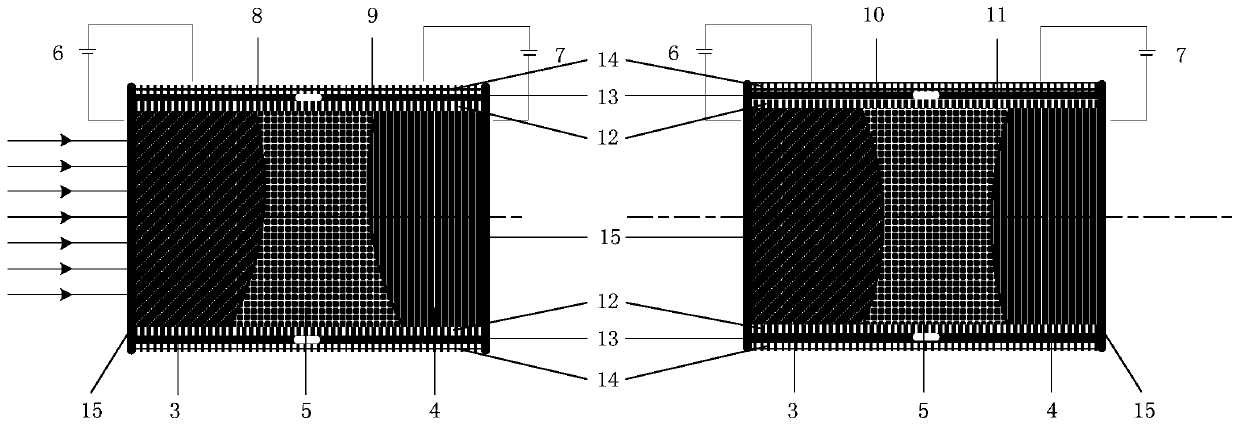

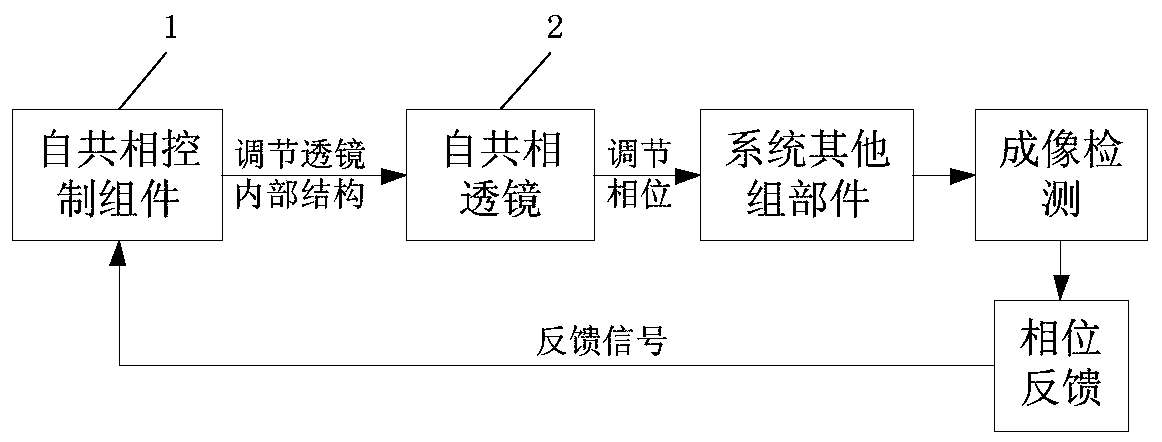

Automatic phase adjustment unit and an adjustment method

InactiveCN109709668AGuaranteed coplanarityImplement phase adjustmentOptical elementsSystems designImaging quality

The invention relates to an automatic phase adjustment unit and an adjustment method. The adjustment unit comprises a self-in-phase control assembly and a self-in-phase lens. The self-in-phase lens isfilled with conductive liquid and non-conductive liquid and is controlled by the self-in-phase control assembly and thus the internal liquid interface of the self-in-phase lens deforms, thereby realizing phase adjustment. According to the invention, the liquid lens based on the dielectric wetting effect is used for realizing effective modulation of the light phase effectively. The adjustment unithas characteristics of mechanical moving part prevention, high self-adaptability, short response time and good integration performance. A novel way of in-phase adjustment of spliced sub mirrors is provided. The automatic phase adjustment unit and an adjustment method are applied to the distributed synthetic aperture optical interference imaging system, thereby reducing the design difficulty of the system and greatly improving the imaging quality.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Advertisement pasting device

ActiveCN107767792AGuaranteed pasteGuarantee that the outer sides are coplanarBoardsAgricultural engineering

Owner:安徽源美广告传媒有限公司

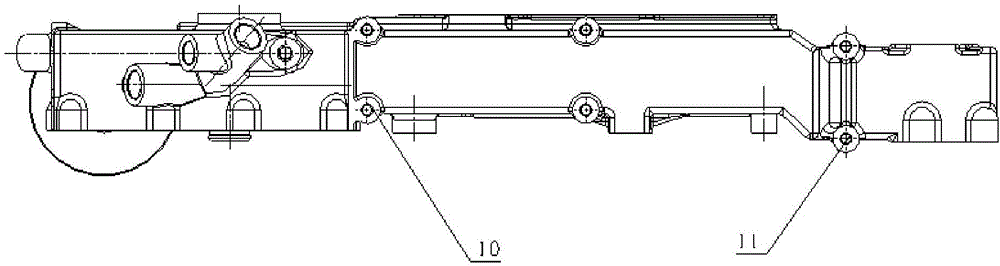

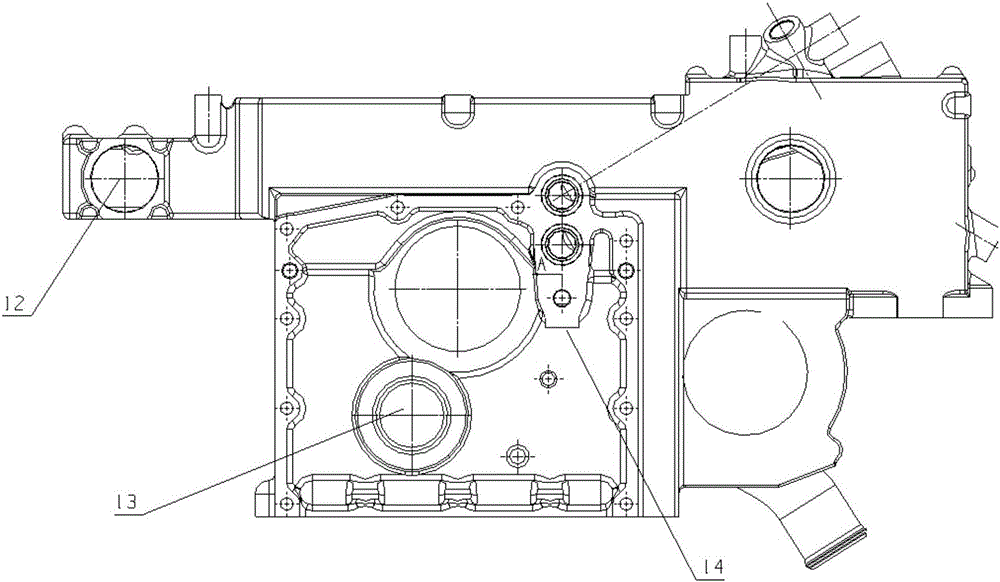

Multifunctional cooler cover

The invention discloses a multifunctional cooler cover. The multifunctional cooler cover comprises an air conditioner compressor installation hole, a generator installation hole, a water pump eddy water cavity, a plurality of engine installation holes and a crankshaft sensor installation hole, wherein the generator installation hole and the air conditioner compressor installation hole are parallel and formed in the upper side of a cooler cover body; the water pump eddy water cavity is formed in the cooler cover body and used for being connected with a water pump; the multiple engine installation holes are perpendicularly formed in the cooler cover body; the crankshaft sensor installation hole is formed in the cooler cover body; and an air conditioner compressor, a generator and the water pump are coplanar through the positions of the air conditioner compressor installation hole, the generator installation hole and the water pump eddy water cavity in the cooler cover body. In this way, according to the multifunctional cooler cover, the functions of multiple parts can be achieved only through one part, the coplanarity of an engine is effectively guaranteed, and the fault rate of a transmission belt is greatly reduced.

Owner:GUANGXI YUCHAI MASCH CO LTD

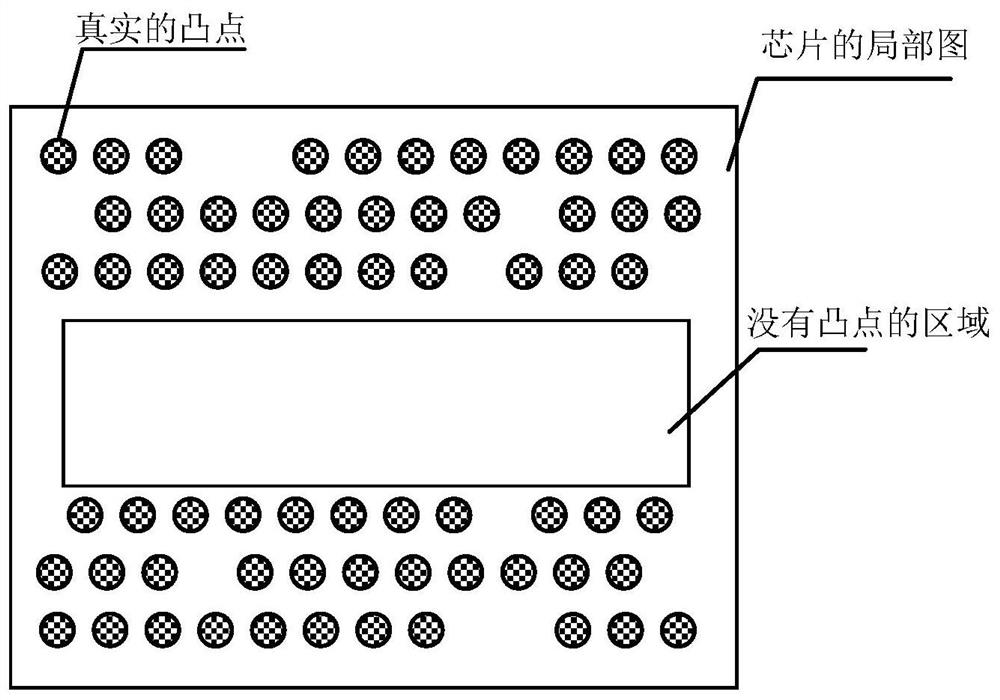

3DIC chip and preparation method of 3DIC chip

PendingCN113628984ASolve concentrated stressSolve for uniformitySemiconductor/solid-state device detailsSolid-state devicesComputer hardwareHeight difference

The invention relates to a 3DIC chip and a preparation method of the 3DIC chip. The 3DIC chip comprises a chip body which is provided with a window in a first surface thereof; a first bump which is arranged in the window; and a second bump which is arranged on the first surface of the chip body and staggered from the window in position. The first bump is used for transmitting signals, the second bump is used for dispersing stress of the first bump, and the height difference between the first bump and the second bump is smaller than or equal to a threshold. According to the invention, the technical problem of stress concentration and non-uniformity caused by bumps in the existing 3DIC chip is solved, the height difference between the first bump and the second bump is ensured to be within a predetermined range, the coplanarity of a virtual bump and a real bump is ensured, and the cold solder joint risk during flip chip mounting is avoided.

Owner:XI AN UNIIC SEMICON CO LTD

Multifunctional cooler cover

The invention discloses a multifunctional cooler cover. The cooler cover comprises an air conditioner compressor mounting hole, an electric generator mounting hole, a water pump eddy water cavity, an idle wheel mounting hole and an automatic tensioning wheel mounting hole. The electric generator mounting hole is parallel to the air conditioner compressor mounting hole, and the air conditioner compressor mounting hole and the electric generator mounting hole are formed in the upper side of a cooler cover body; the water pump eddy water cavity is formed in the cooler cover body and is used for being connected with a water pump; the idle wheel mounting hole is formed in the cooler cover body; the automatic tensioning wheel mounting hole is formed in the cooler cover body; the air conditioner compressor mounting hole, the electric generator mounting hole and the water pump eddy water cavity are formed in the position of the cooler cover body to enable an air conditioner compressor, an electric generator and a water pump to share the same face. Accordingly, by means of the multifunctional cooler cover, one part can achieve the function of multiple parts, coplanarity of an engine is effectively ensured, and the failure rate of a transmission belt is greatly reduced.

Owner:GUANGXI YUCHAI MASCH CO LTD

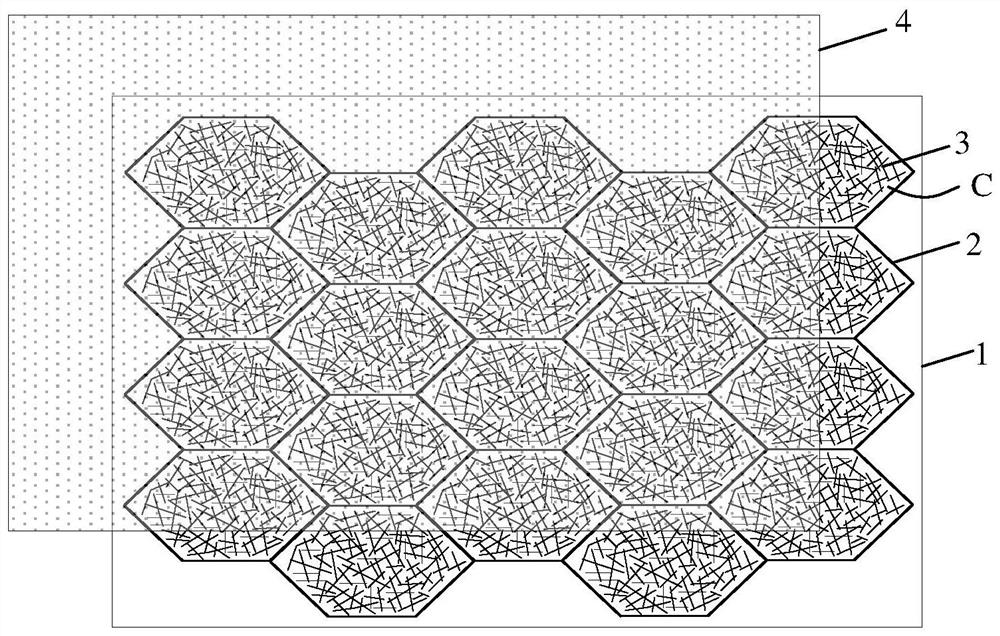

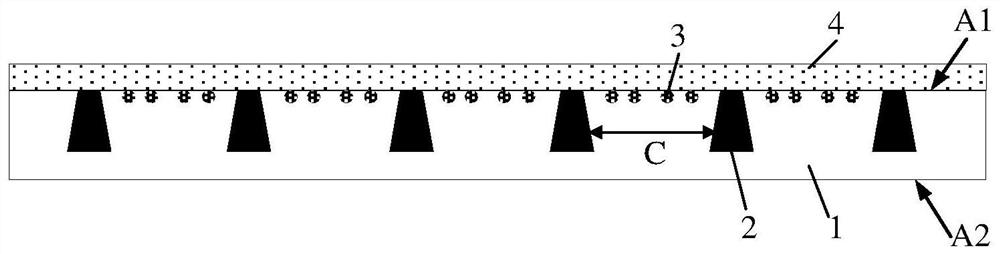

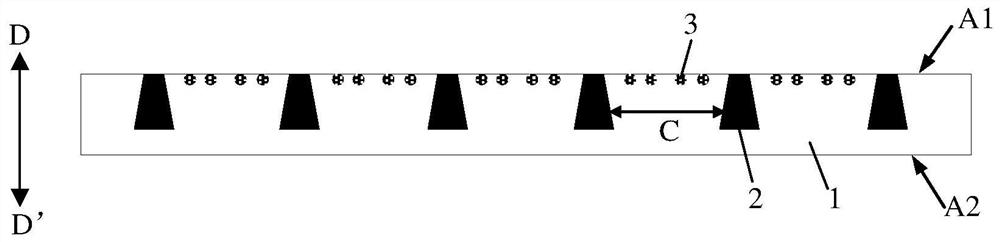

Transparent conductive electrode, preparation method thereof, and electronic device

ActiveCN113936844AReduce square resistanceAvoid failureMaterial nanotechnologyConductive layers on insulating-supportsMetal nanowiresMaterials science

The invention provides a transparent conductive electrode, a preparation method thereof, and an electronic device, and relates to the technical field of transparent conduction. The sheet resistance of the transparent conductive electrode is reduced. The transparent conductive electrode comprises a transparent substrate, a metal grid and a metal nanowire network, wherein the metal grid and the metal nanowire network are embedded in the transparent substrate; the metal nanowire network is located in a mesh area of the metal grid; the transparent substrate comprises a first surface located in the thickness direction; the metal grid and the metal nanowire network are exposed out of the first surface and are flush with the first surface; the transparent conductive electrode further comprises a transparent conductive modification layer; and the transparent conductive modification layer covers the first surface and the metal grid and the metal nanowire network exposed out of the first surface.

Owner:HUAWEI TECH CO LTD

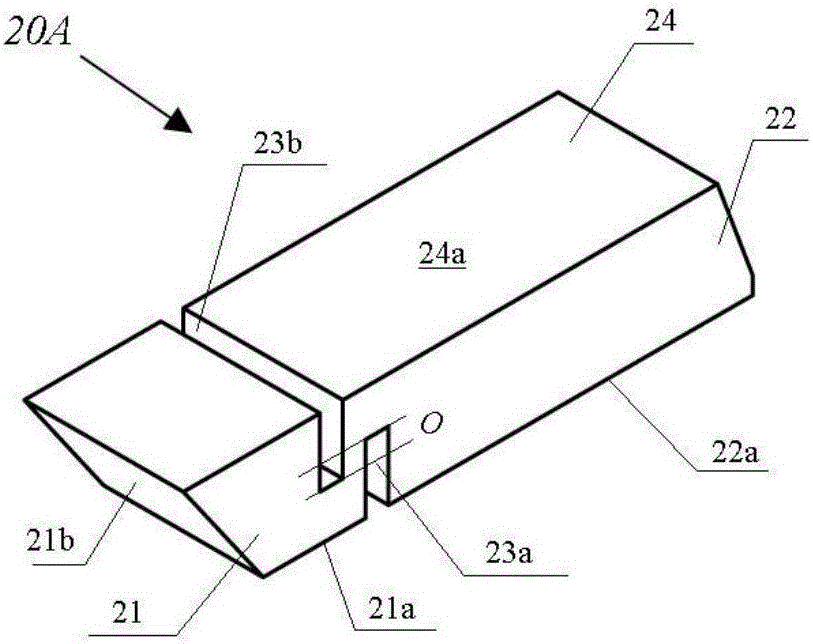

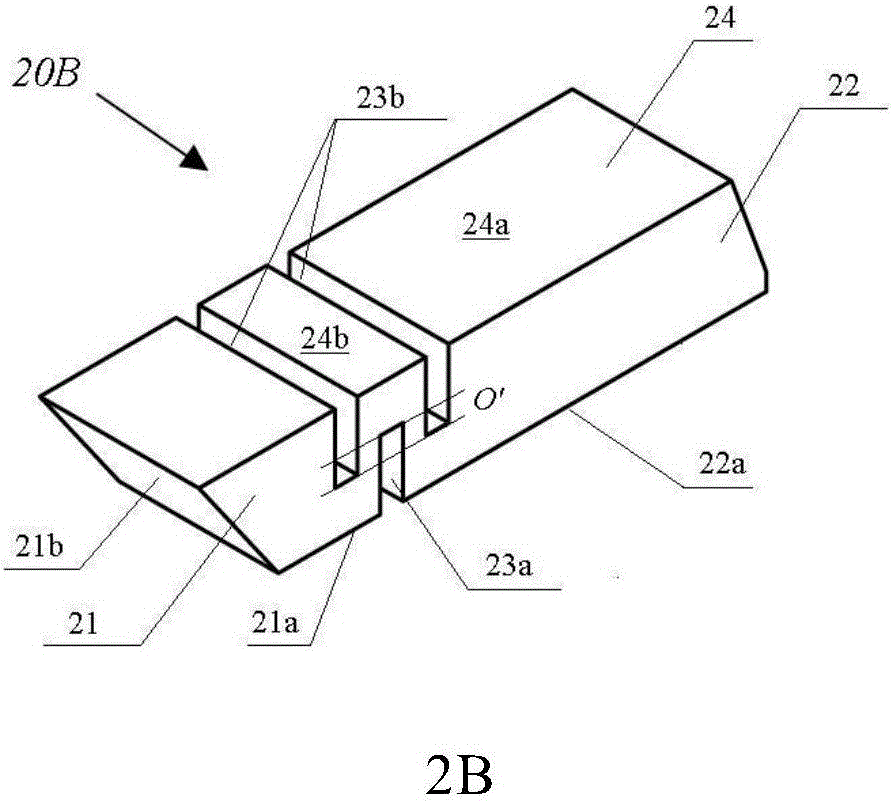

Prism and glass surface stress test device

PendingCN106324730ACompact structureEasy to manufacturePrismsForce measurement by measuring optical property variationSurface stressPrism

The application discloses a prism and a glass surface stress test device using the prism as a test prism. The prism comprises an import prism part and an export prism part, which are formed integrally. The import prism part and the export prism part are respectively provided with a first working surface and a second working surface, which are coplanar. The prism is provided with at least one groove which is between the import prism part and the export prism part and perpendicular to the first working surface and the second working surface, and the at least one groove forms a diaphragm used for stopping light from being propagated from one side of the first working surface to one side of the second working surface. The import prism part and the export prism part are formed integrally, and the diaphragm is formed on the integrated prism by grooving, so that coplanar working surfaces are ensured on one hand, and on the other hand, the prism has a simple and compact structure and is easy to manufacture.

Owner:BEIJING JEFFOPTICS CO LTD +1

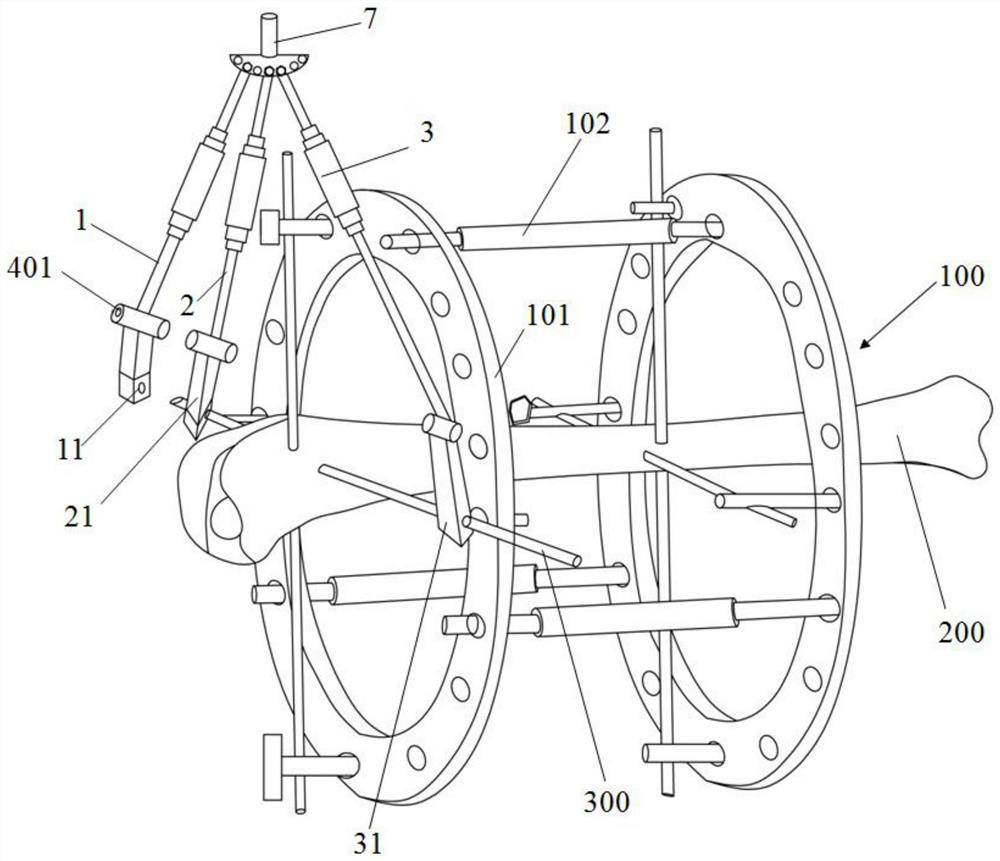

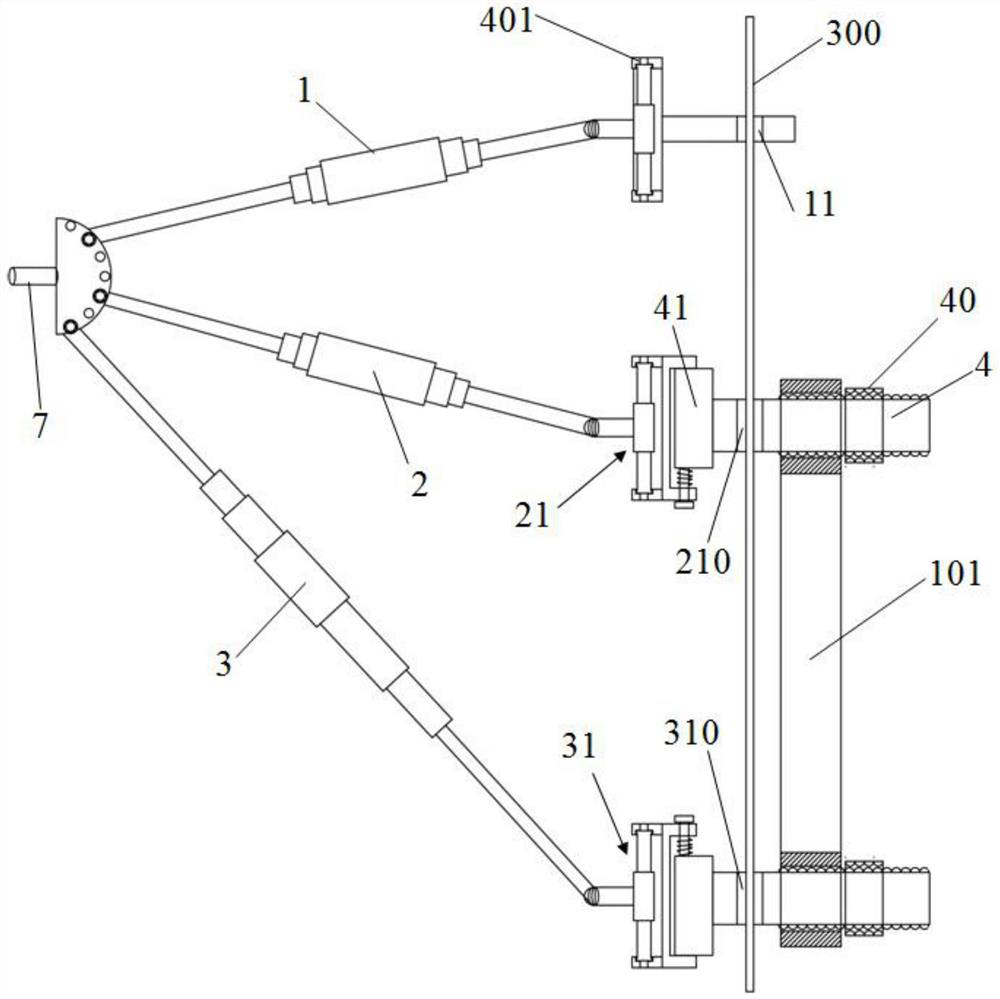

Sighting device of bone penetrating fixing needle

PendingCN114191060AHigh precisionGuaranteed coplanarityExternal osteosynthesisBone qualityEngineering

Owner:BEIJING JISHUITAN HOSPITAL

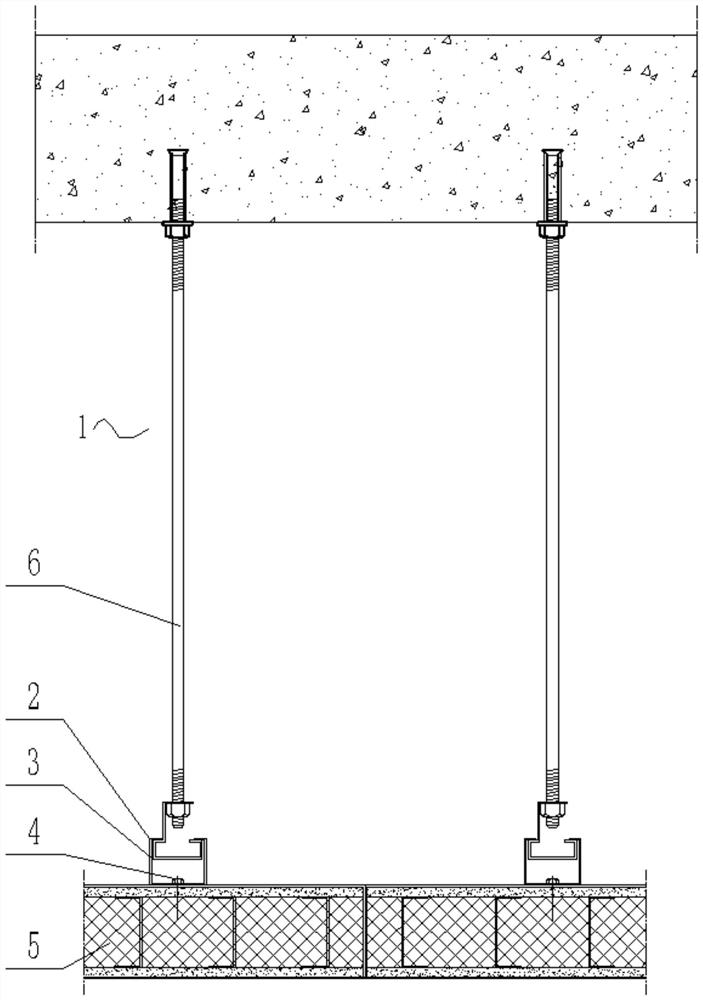

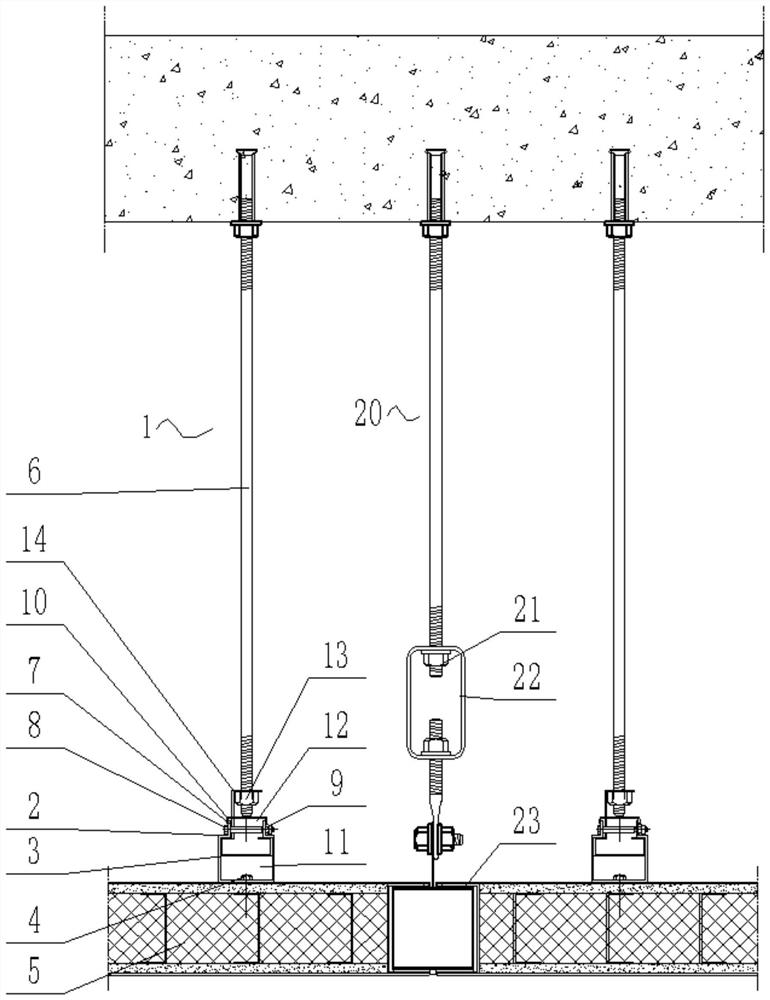

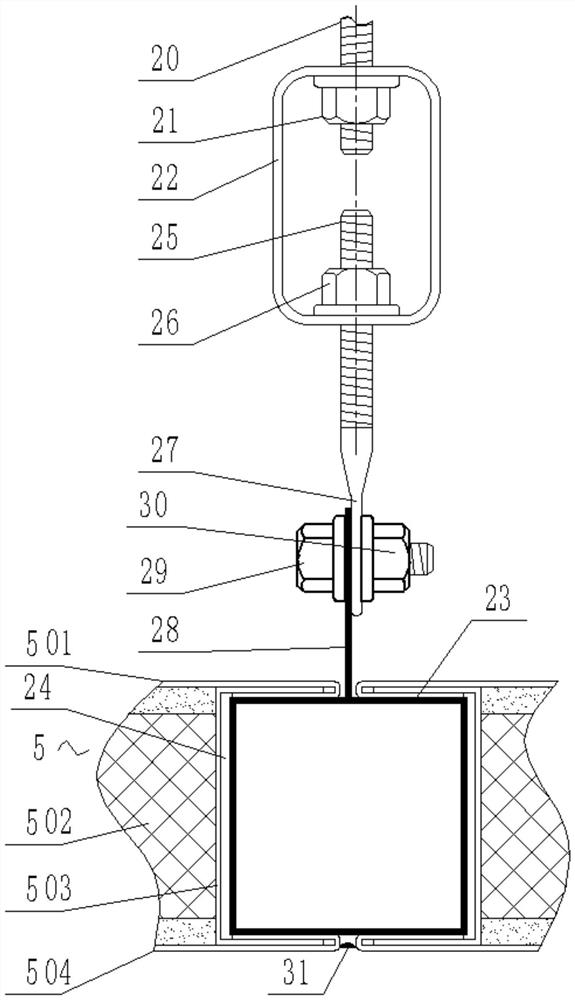

Ceiling splicing method of color steel sandwich plates

ActiveCN112411849AGuaranteed coplanarityPrevent downward tiltCeilingsClimate change adaptationStructural engineeringMechanical engineering

The invention discloses a ceiling splicing method for color steel sandwich plates. The ceiling splicing method comprises the following steps that firstly, the N-1th color steel sandwich plate is hoisted; then the Nth color steel sandwich plate is spliced, firstly, the Nth color steel sandwich plate is placed on one side of the N-1th color steel sandwich plate; then, a positioning strip in a middlepositioning assembly is placed between the Nth color steel sandwich plate and the N-1th color steel sandwich plate, and the two sides of the positioning strip are inserted into the color steel sandwich plates correspondingly; then the head of a middle expansion bolt in the middle positioning assembly is installed in a cross beam, the bottom end of a threaded rod of the middle expansion bolt penetrates through the upper side of a middle connecting part and then is in threaded connection with an upper nut, and the upper end and the lower end of a connecting assembly A are connected with the middle connecting part and the positioning strip; and finally, the Nth color steel sandwich plate is hoisted. According to the ceiling splicing method for the color steel sandwich plates, the ends of thesandwich color steel plates can be effectively prevented from inclining downwards, so that the sandwich color steel plates are horizontal, the coplanarity of every two adjacent sandwich color steel plates is guaranteed, and therefore the flatness of a ceiling laid by the sandwich color steel plates is improved.

Owner:深圳新美装饰建设集团有限公司

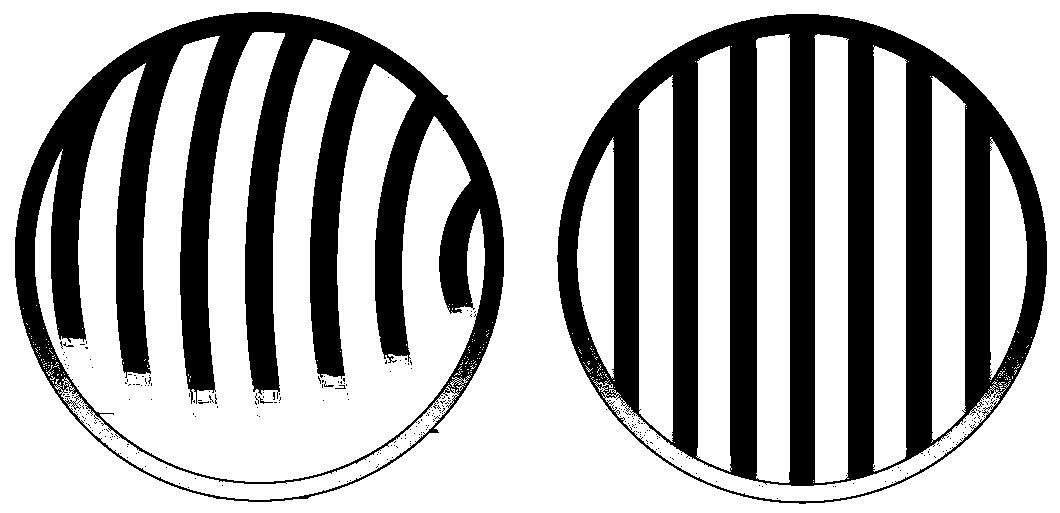

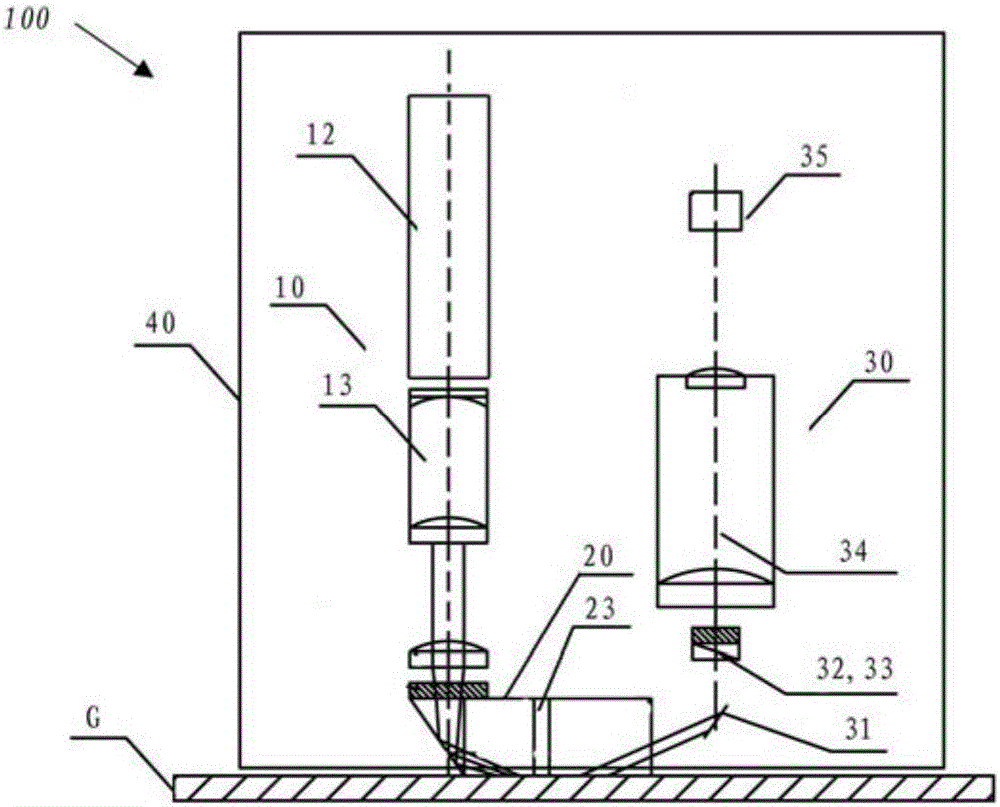

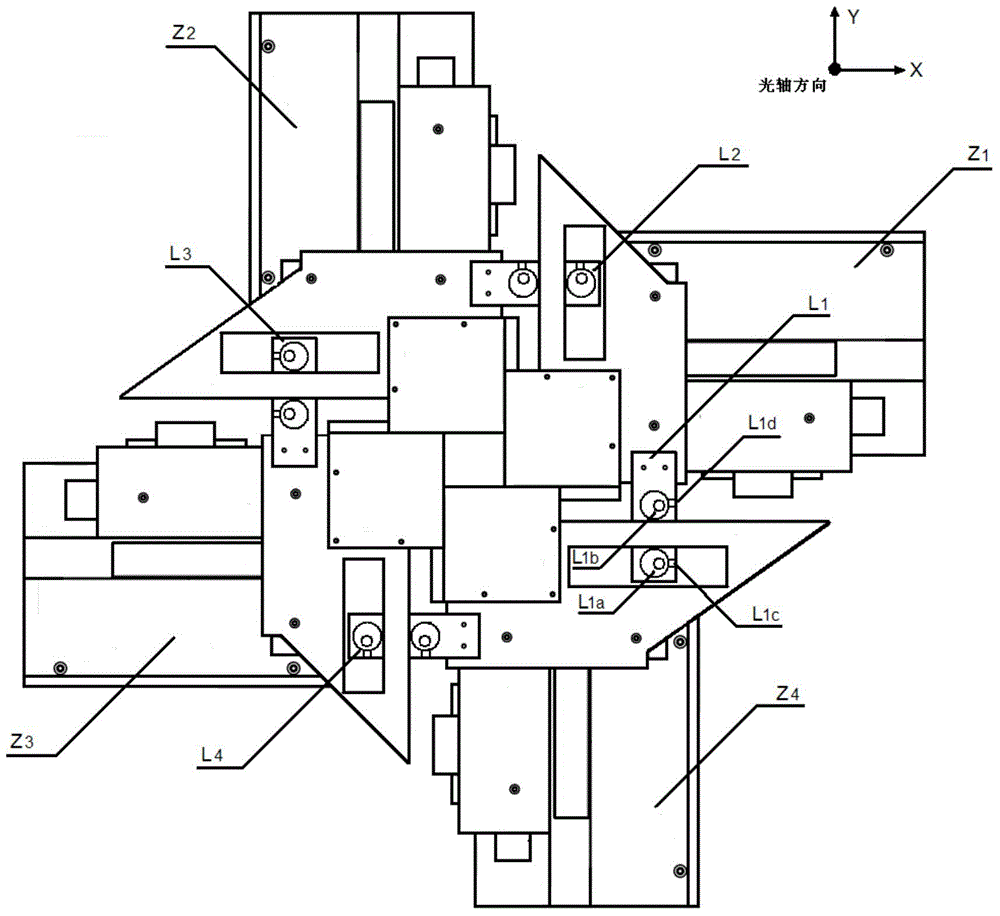

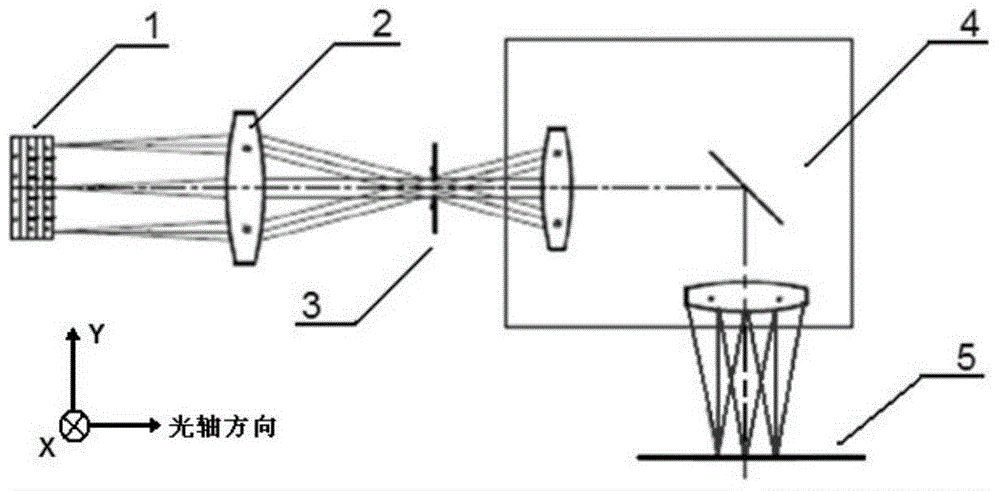

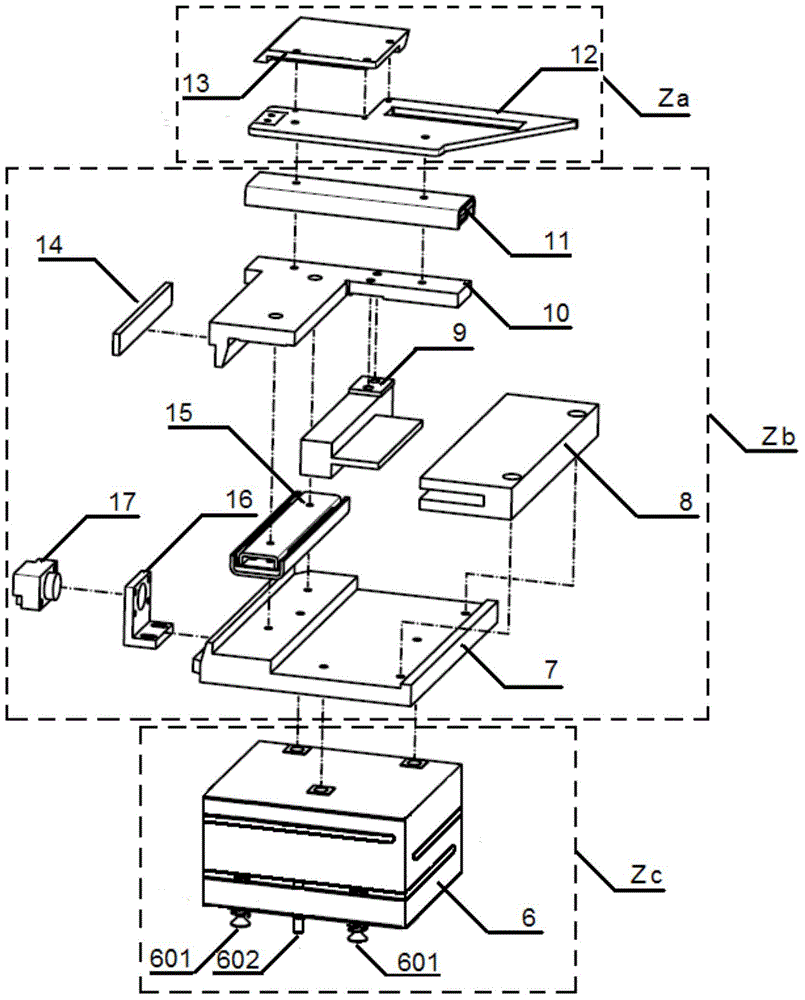

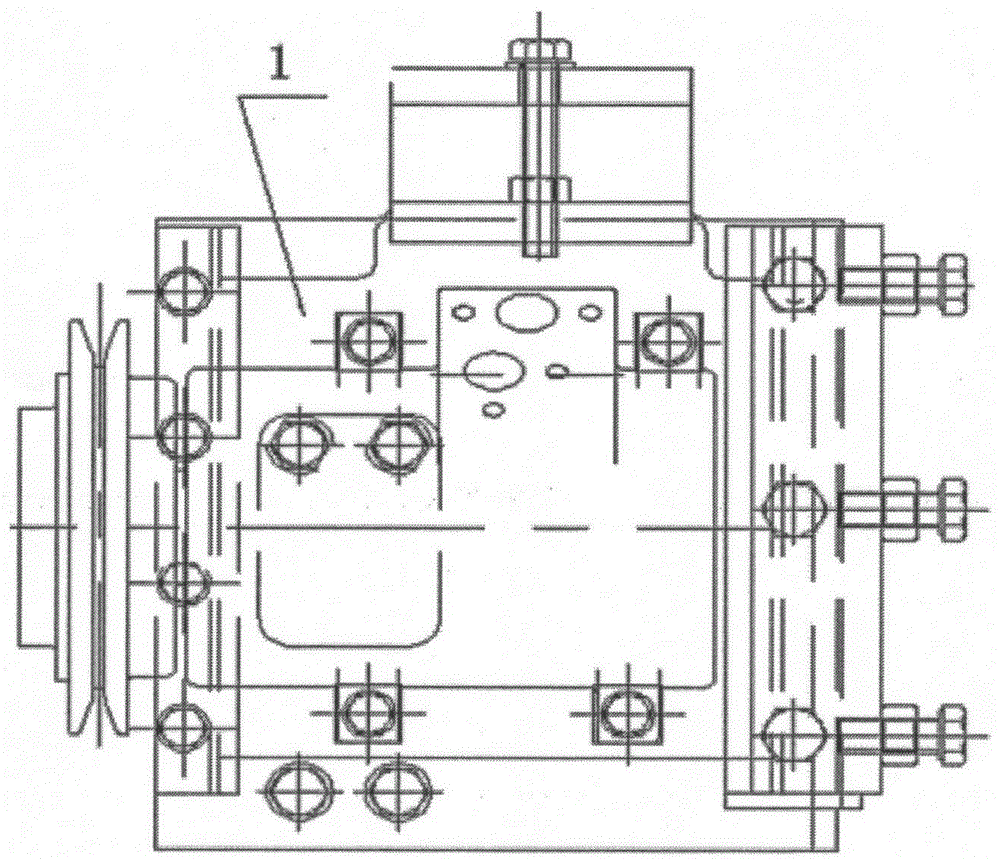

Scanning slit device used in stepping scan lithography machine

ActiveCN103439865BGuaranteed coplanarityRealize high-precision 2D scanningPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistOptical axis

A scanning slit device used in a stepping scan lithography machine is formed by connecting four identical blade components through four limit connecting pieces, the four limit connecting pieces are used for closely connecting every two adjacent blade components, four blade components are integrated in two orthogonal directions according to a rotary and symmetrical manner, knife edges of the adjacent blade components are mutually perpendicular to each other, four knife edges are coplanar and perpendicular to an optical axis of a system, and openings formed between the four knife edges are scanning slits. The invention not only can realize high-precision two-dimensional scanning at an optional plane range in a maximum stroke, but also can ensure coplanarity of the scanning knife edges in the two-dimensional directions.

Owner:BEIJING GUOWANG OPTICAL TECH CO LTD

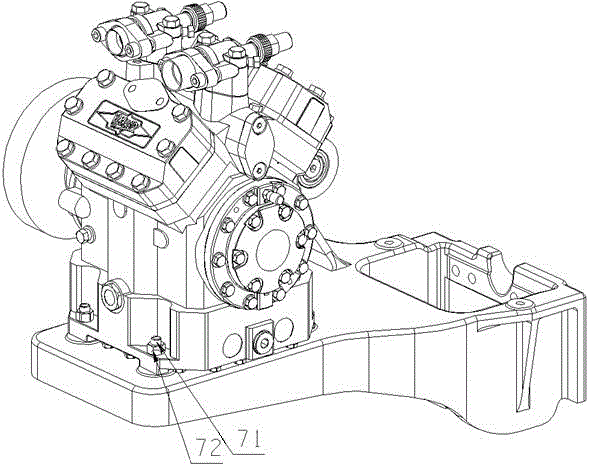

An air-conditioning compressor fixing and driving belt tensioning device for an excavator

ActiveCN104565243BReduce distortionReduce wearCompressorPositive displacement pump componentsDrive wheelEngineering

Owner:龙工(上海)挖掘机制造有限公司

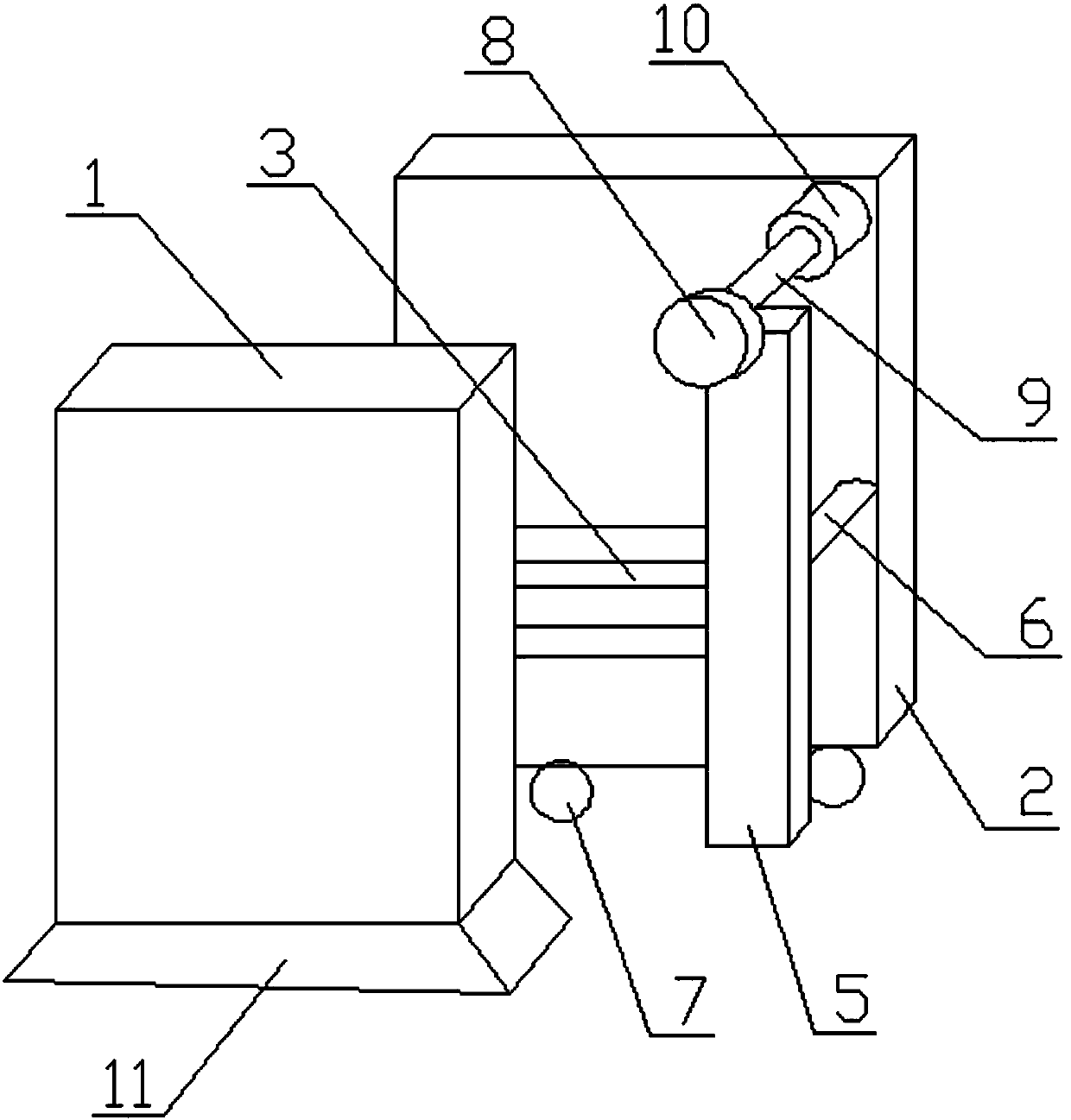

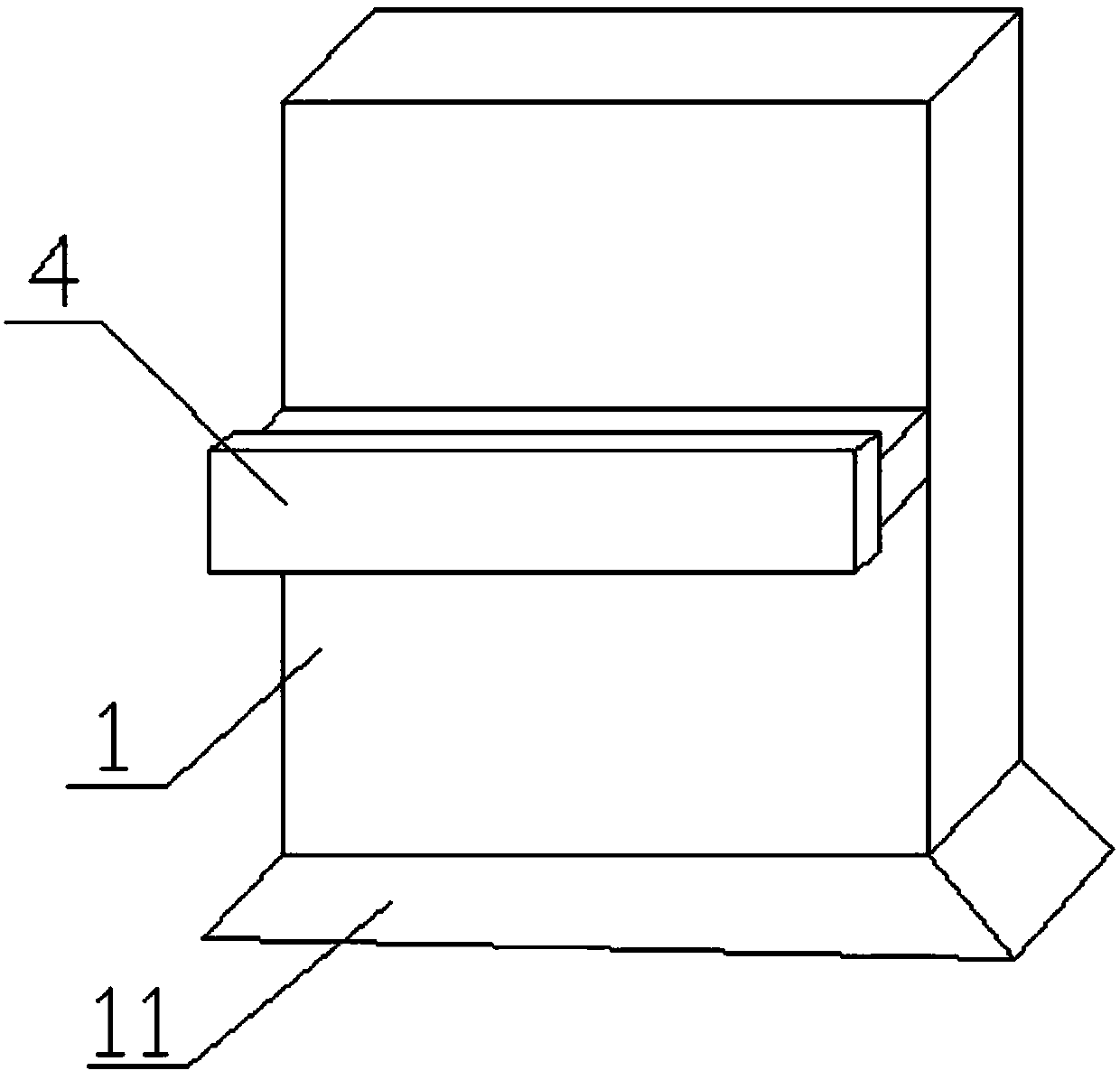

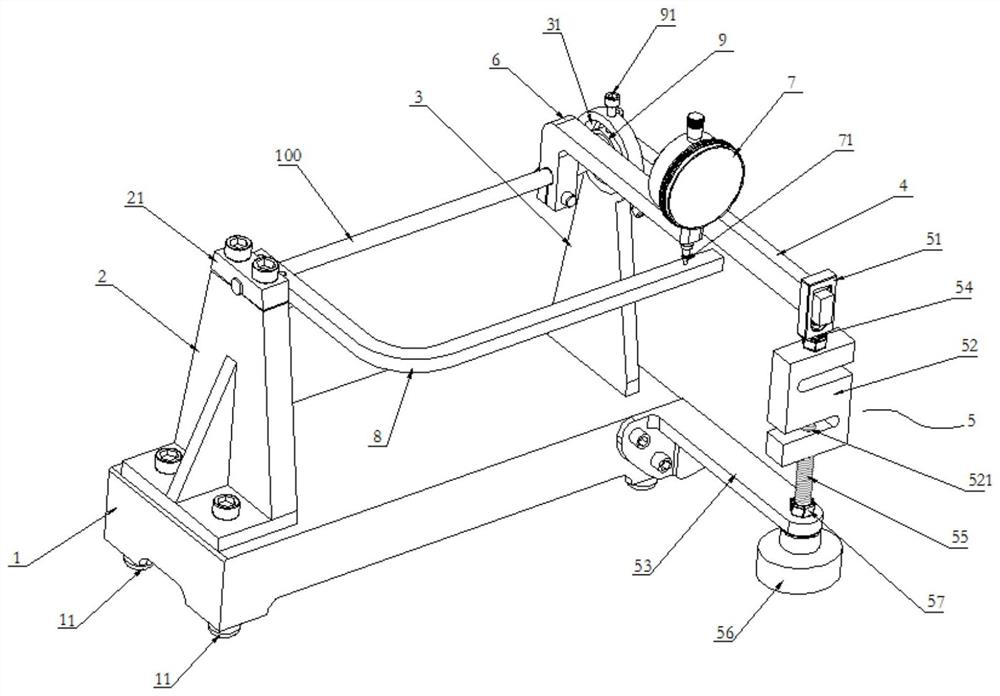

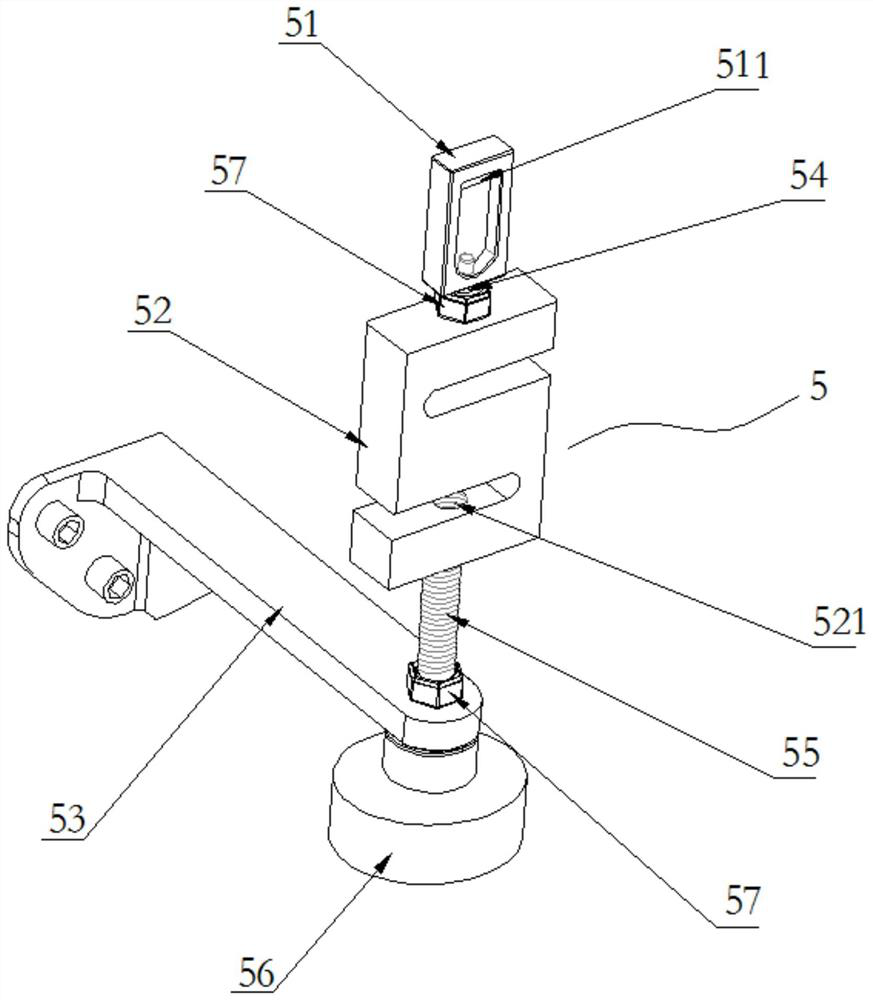

Continuous variable force type torsional angle instrument

InactiveCN112798161AReduce weightReduce mistakesWork measurementTorque measurementTorsional angleGravity center

The invention discloses a continuous variable force type torsional angle instrument. The instrument comprises a machine base, a first supporting arm and a second supporting arm, wherein the first supporting arm and the second supporting arm are arranged on the two sides of the upper end of the machine base, a to-be-tested piece round rod is arranged between the first supporting arm and the second supporting arm, a force arm is arranged at a tail end of the to-be-tested piece round rod, a spiral force increasing mechanism is arranged at a front end of the force arm, and one end of the round rod of the test piece is provided with an L-shaped support rod, the other end of the to-be-tested piece round rod is provided with a second L-shaped supporting rod, a tail end of the second L-shaped supporting rod is provided with a dial indicator, and a lower end of a measuring rod of the dial indicator is in contact with the first L-shaped supporting rod. The continuous variable force type torsion angle instrument is simple, practical and compact in structure, the load borne by the force arm is linearly changed through the use of the spiral reinforcement mechanism, the test error is reduced, and test accuracy is improved; and meanwhile, the device is light in weight, convenient to carry, low in gravity center, good in stability, firm in fixation and convenient to use.

Owner:ANHUI AGRICULTURAL UNIVERSITY

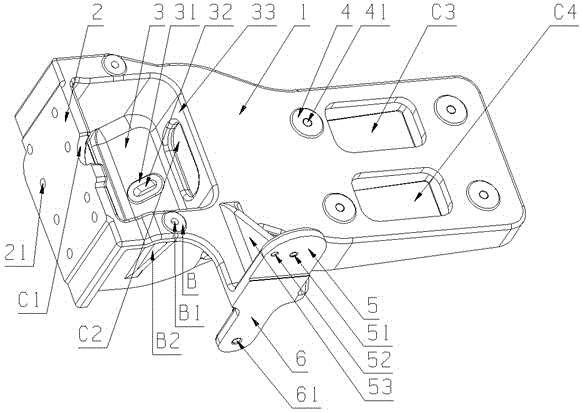

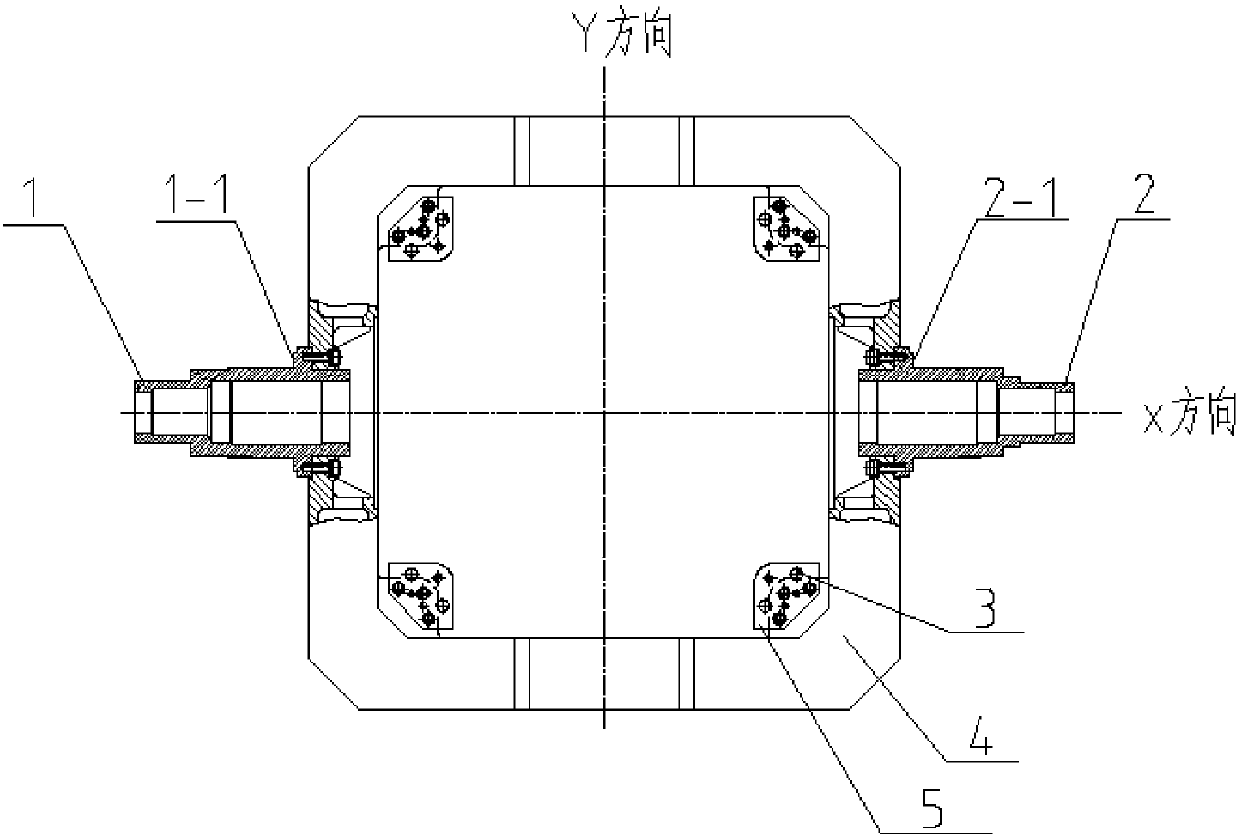

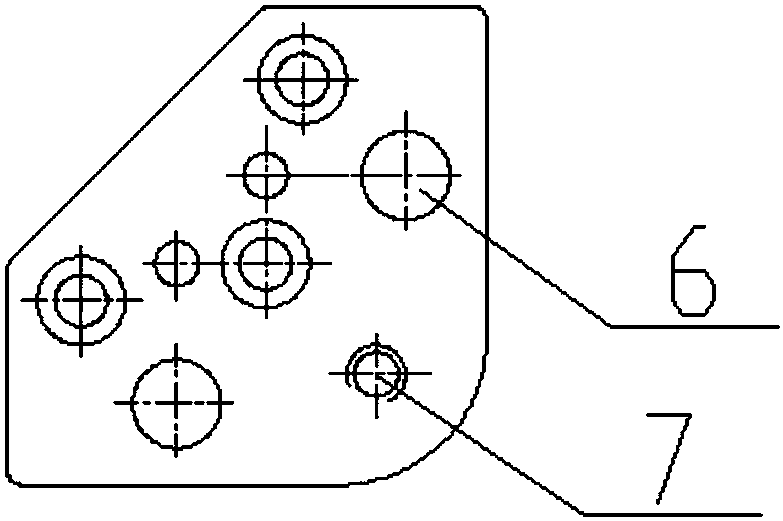

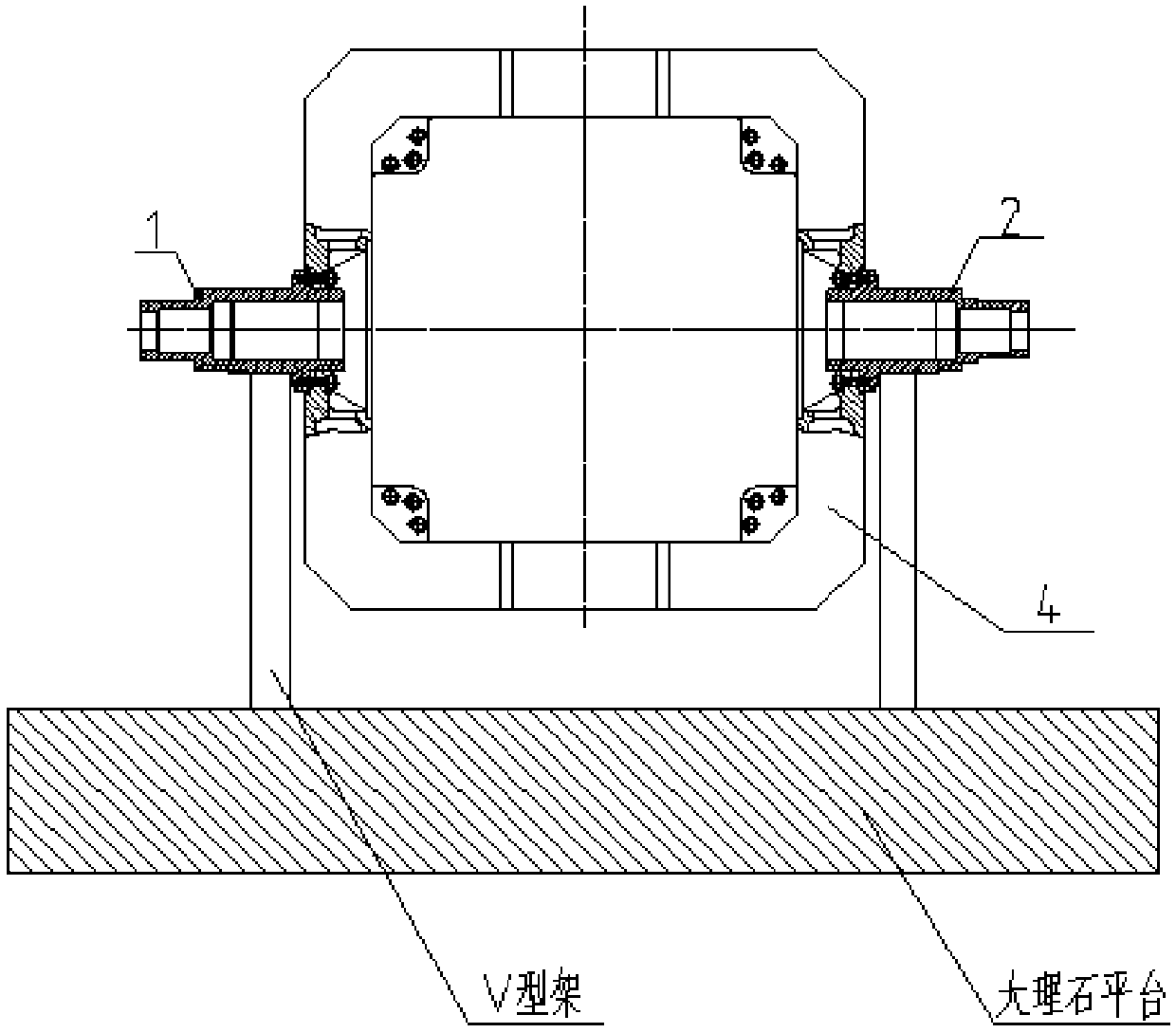

Assembling method for inner frame assembly of three-axis rotary table

ActiveCN107650089AReduce the amount of repeated trainingHigh precisionWork benchesEngineeringScrew thread

The invention discloses an assembling method for an inner frame assembly of a three-axis rotary table. The inner frame assembly of the three-axis rotary table comprises an inner frame, a first inner frame trunnion, a second inner frame trunnion, four product mounting blocks and abutting pins. The method specifically comprises the steps that the first inner frame trunnion and the second inner frametrunnion are symmetrically arranged in mounting holes of the inner frame; the inner frame is placed on a V-shaped frame and is rotated, and the degree of parallelism of the first inner frame trunnionand the second inner frame trunnion is adjusted to meet the requirement; the inner frame is placed on a marble platform, and the first inner frame trunnion and the second inner frame trunnion are scrapped and ground, so that the axes of the first inner frame trunnion and the second inner frame trunnion are at equal height; four bosses on the inner frame are scrapped and ground so as to meet the coplanarity requirement; the four product mounting blocks are arranged; the inner frame assembly is placed on a workbench of a machining machine tool, abutting pin holes are machined, and threaded holes are machined; and the abutting pins are pressed into the abutting pin holes. The method has the advantages that the precision in the assembling process of the product mounting blocks of the inner frame has the examinability, the operation is convenient and visual, the positioning precision is high, the stability of the inner frame assembly can be improved, and the assembling efficiency can be improved.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

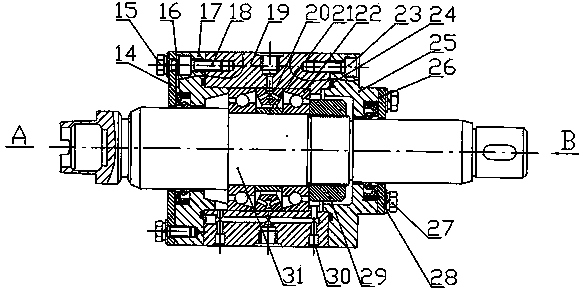

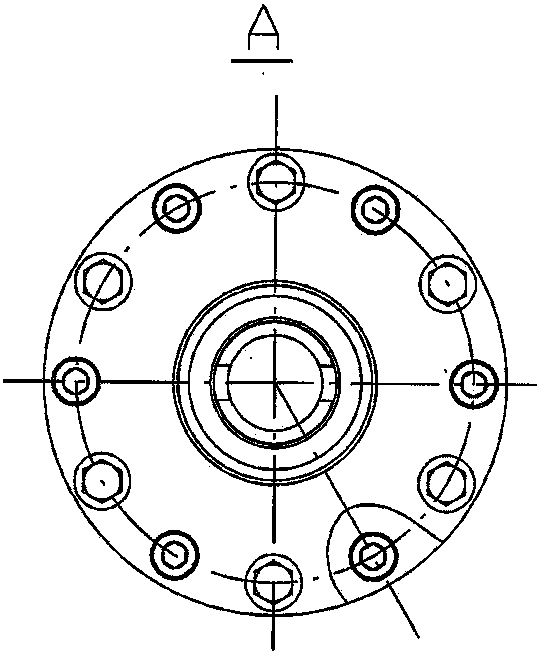

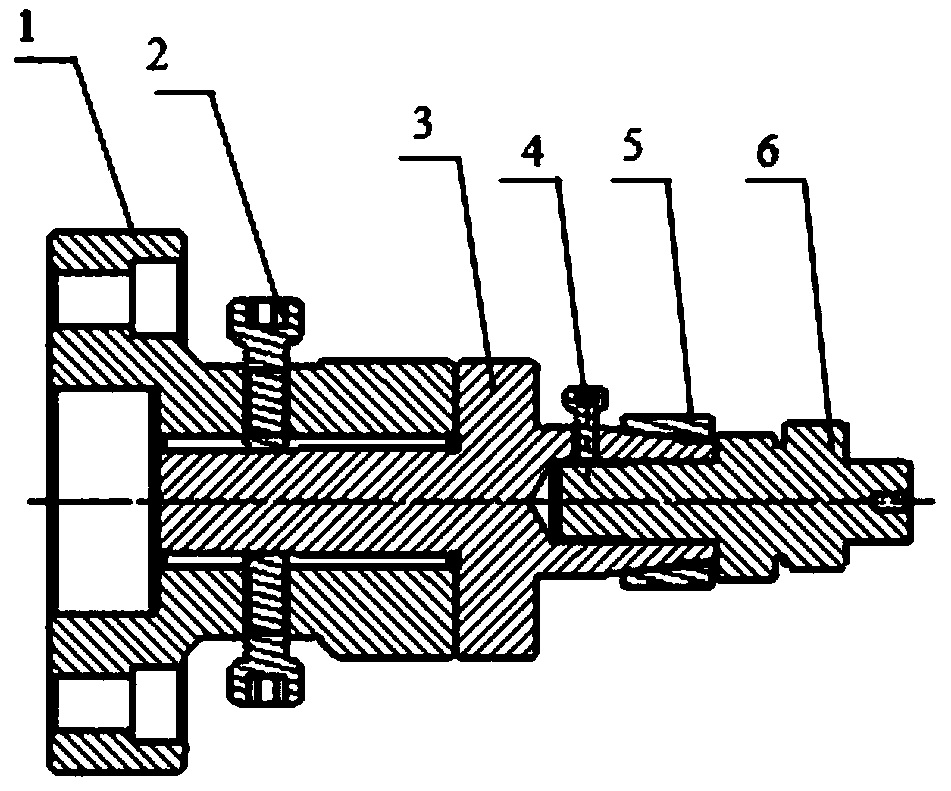

A precision grinding method for eccentric circle of crankshaft and special eccentric fixture

ActiveCN108907901BRealize flexible processingGuaranteed coplanarityGrinding work supportsJackshaftCrank

The invention relates to a precision grinding method for the eccentric circle of a crankshaft and a special eccentric tool fixture. The method mainly comprises the following steps that 1, a base of the eccentric tool is connected with a machine tool spindle; 2, an eccentric adjustment sleeve is installed, and an eccentric reference zero position is determined; 3, the crankshaft is installed; 4, the eccentric adjustment sleeve is moved up and down through eccentric adjustment nuts to achieve accurate control over the eccentricity, and eccentric external grinding on one side of the part is performed; 5, the eccentric adjustment nuts are reversely adjusted to move the eccentric adjustment sleeve reversely, it is ensured that the eccentricity is equal to that in step 4, eccentric external grinding on the other side of the part is performed, and finally part machining is completed. Based on a conventional external grinding machine, the eccentricity-adjustable dual-eccentric grinding tool and a part machining process scheme thereof are developed, which are a completely independent design proposed for the first time in China.

Owner:天津旗领机电科技有限公司

Preparation method of optical imaging device with array reflective unit

An embodiment of the present application provides a method for preparing an optical imaging device with an arrayed reflective unit, including: setting one of the surfaces of the transparent sheet as a reflective surface, and connecting the transparent surface of one transparent sheet with the other transparent sheet The reflective surface of the reflective surface is bonded by glue; repeat the above process until multiple light-transmitting sheets are stacked into a laminate with a preset height; the laminate is cut into multiple laminates with the same thickness along the direction perpendicular to the reflective surface; The laminations are laid flat on a plane, and the laminations laid on the plane are spliced in a way of "spiral splicing" with glue to form the first lens in the same way as the reflective surface faces; the second lens is formed in the same way ; Superimpose the first lens and the second lens in a way that the reflective surfaces are orthogonal, and bond them with glue to obtain a composite lens. The reflective surfaces of each layer of the first lens and the second lens obtained by the method are coplanar, which can achieve the imaging effect of the optical imaging device.

Owner:中显全息(北京)科技有限公司

Sample treatment device

InactiveCN105445069AGuaranteed coplanarityNot easy to losePreparing sample for investigationSiliconSemiconductor

The invention relates to the field of semiconductor manufacturing, and in particular relates to a sample treatment device. The sample treatment device fixes a sample to be treated in three directions; the part, which is in contact with the sample to be treated, of each fixing device is made from a silicon material, thus fulfilling an aim of fixing the sample to be treated; furthermore, the sample to be treated cannot be damaged by a metal material; meanwhile, one of the three-dimensional fixing devices is a mechanical structure with an adjustable depth, to control the height of the sample, and two fixing devices are used for fixing the position of the sample; a glass plane is used for guaranteeing the coplanar degree of the sample; on such basis, the sample can be fixed, and the coplanar degree of the sample can be guaranteed; therefore, the aim of easiness in grinding is fulfilled, and the sample is difficult to lose.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

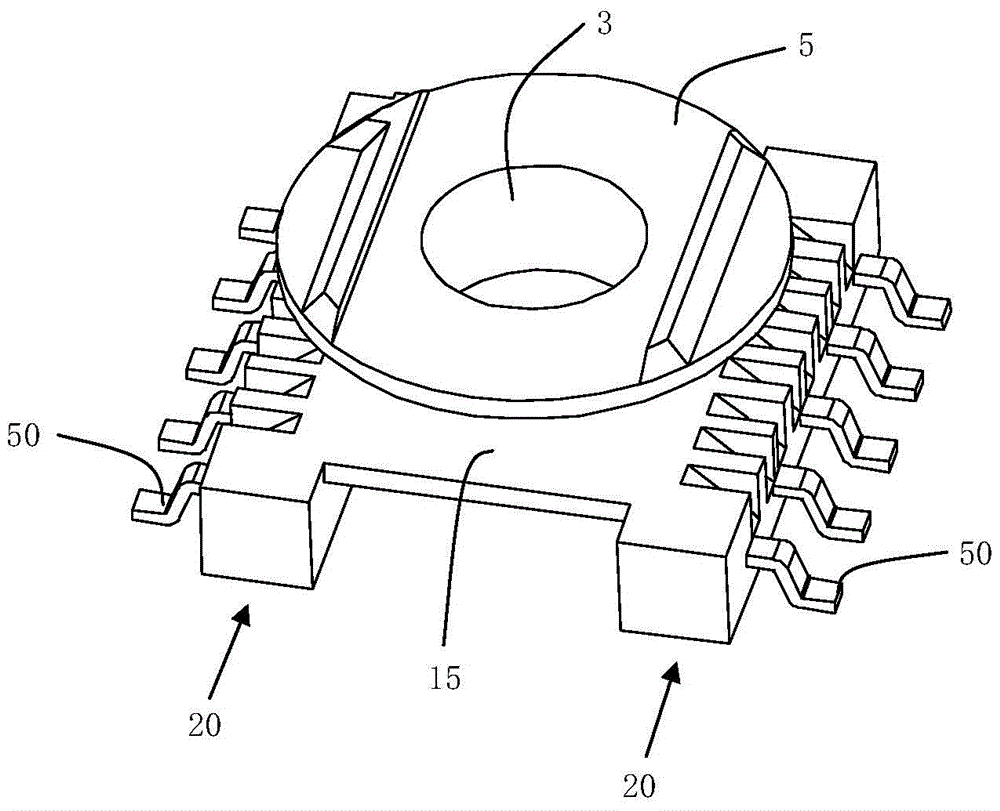

Manufacturing method of transformer bobbin based on lead frame

ActiveCN104505229BFew sharesIncrease productivityTransformers/inductances coils/windings/connectionsCoils manufactureBobbinEngineering

Owner:MORNSUN GUANGZHOU SCI & TECH

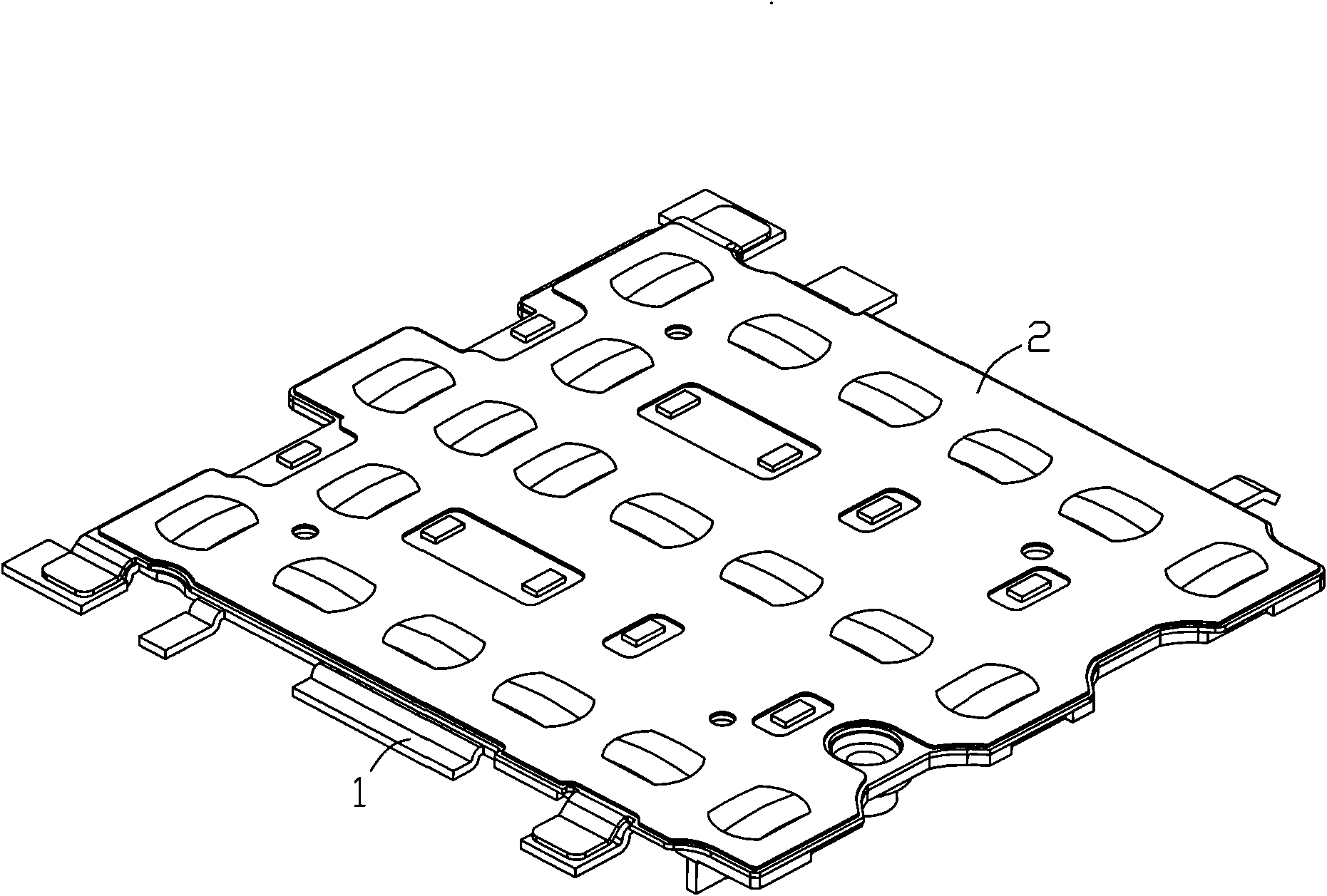

Battery cell module assembling and forming machine, assembling method thereof and battery cell module assembling and forming system

PendingCN111540943AAvoid hard contactAvoid damageAssembling battery machinesFinal product manufactureMechanical engineeringBattery cell

The invention discloses a battery cell module assembling and forming machine, an assembling method thereof and a battery cell module assembling and forming system. The assembly forming machine comprises: a placement base, wherein a limiting face and a fixing clamping jaw which are located at the first end of a platen of the placement base are arranged on the platen, the limiting face is parallel to the end face of the platen, and the fixing device is provided with a structure for fixing an object abutting against the limiting face to the platen; and a pasting device, wherein the pasting devicecomprises a grabbing clamping jaw, and the grabbing clamping jaw can linearly move from one end of the containing base to the other end of the containing base and can reciprocate in the direction perpendicular to the containing base. According to the scheme, the limiting surface is arranged on the placement seat, so that the battery cells can be effectively positioned and supported, and the firstbattery cell can be effectively positioned in combination with the fixing device, so that errors caused by movement of the first battery cell are avoided; and by adopting the clamping jaw type attaching device, each battery cell can be positioned and unified in position, so that each surface of each battery cell can be kept in a coplanar state, the assembling process is automatically carried out,the efficiency is high, the assembling quality is good, and the assembling consistency is good.

Owner:SUZHOU JEE INTELLIGENT EQUIP CO LTD

Precision grinding method for eccentric circle of crankshaft and special eccentric tool fixture

ActiveCN108907901ARealize flexible processingGuaranteed coplanarityGrinding work supportsMachining processEngineering

The invention relates to a precision grinding method for the eccentric circle of a crankshaft and a special eccentric tool fixture. The method mainly comprises the following steps that 1, a base of the eccentric tool is connected with a machine tool spindle; 2, an eccentric adjustment sleeve is installed, and an eccentric reference zero position is determined; 3, the crankshaft is installed; 4, the eccentric adjustment sleeve is moved up and down through eccentric adjustment nuts to achieve accurate control over the eccentricity, and eccentric external grinding on one side of the part is performed; 5, the eccentric adjustment nuts are reversely adjusted to move the eccentric adjustment sleeve reversely, it is ensured that the eccentricity is equal to that in step 4, eccentric external grinding on the other side of the part is performed, and finally part machining is completed. Based on a conventional external grinding machine, the eccentricity-adjustable dual-eccentric grinding tool and a part machining process scheme thereof are developed, which are a completely independent design proposed for the first time in China.

Owner:天津旗领机电科技有限公司

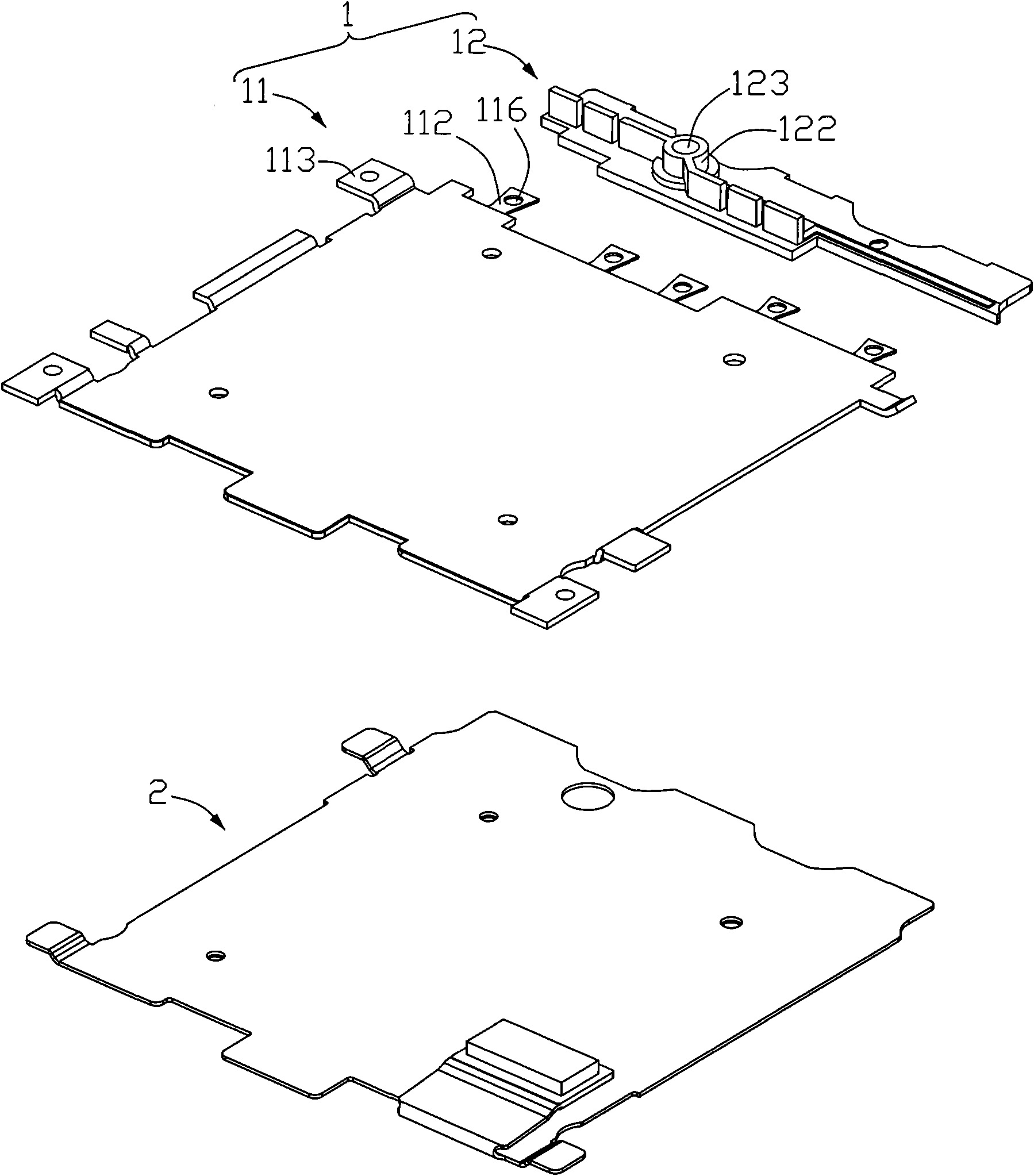

Support frame

InactiveCN101635748AStable structureGuaranteed coplanarityTransmissionTelephone set constructionsEngineeringBearing surface

The invention discloses a support frame supporting a mobile phone keyboard. The support frame comprises a metal frame and a plastic body combined with the metal frame. The metal frame is platy and has a first bearing surface; and the plastic body has a second bearing surface. The metal frame has a plate body part and at least one protruding part extended from one end of the plate body part, wherein the thickness of the protruding part is smaller than that of the plate body part and the protruding part is combined with the plastic body in an embedment forming mode, so the structure of the support frame is stable and the coplanarity of the first and second bearing surface is ensured to bear the keyboard stably.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

An integrated multifunctional air conditioner compressor bracket

ActiveCN105332896BVibration syncReduce vibrationPositive displacement pump componentsPiston pumpsEngineeringAir conditioning

The invention discloses an integrated multifunctional air conditioner compressor holder. The integrated multifunctional air conditioner compressor holder is characterized in that an engine front suspension holder body and an air conditioner compressor holder body are integrated; an engine mounting board is provided with eight engine mounting holes and connected with an engine; the holder is provided with a front suspension cushion mounting hole connected with a whole vehicle connecting suspension cushion; the air conditioner compressor supporting face of the holder is used for supporting an air conditioner compressor, and a tensioning wheel for tensioning an air conditioner compressor belt and an idle wheel are mounted on the other mounting face perpendicular to the air conditioner compressor supporting face. According to the integrated multifunctional air conditioner compressor holder, the air conditioner compressor holder body and the engine front suspension holder body are integrated, and therefore the air conditioner compressor and the engine can vibrate synchronously, vibration of a whole vehicle is reduced, and the comfort level of the whole vehicle is improved; meanwhile, the coplanarity of the air conditioner compressor belt is easily ensured, and the transmission reliability is high.

Owner:GUANGXI YUCHAI MASCH CO LTD

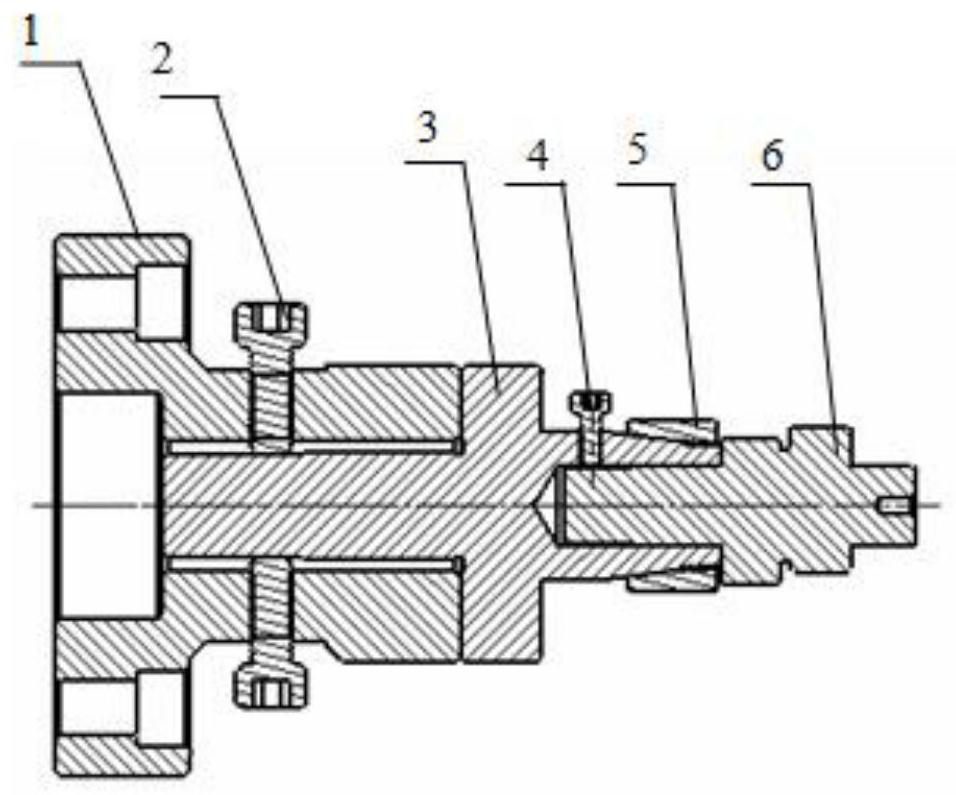

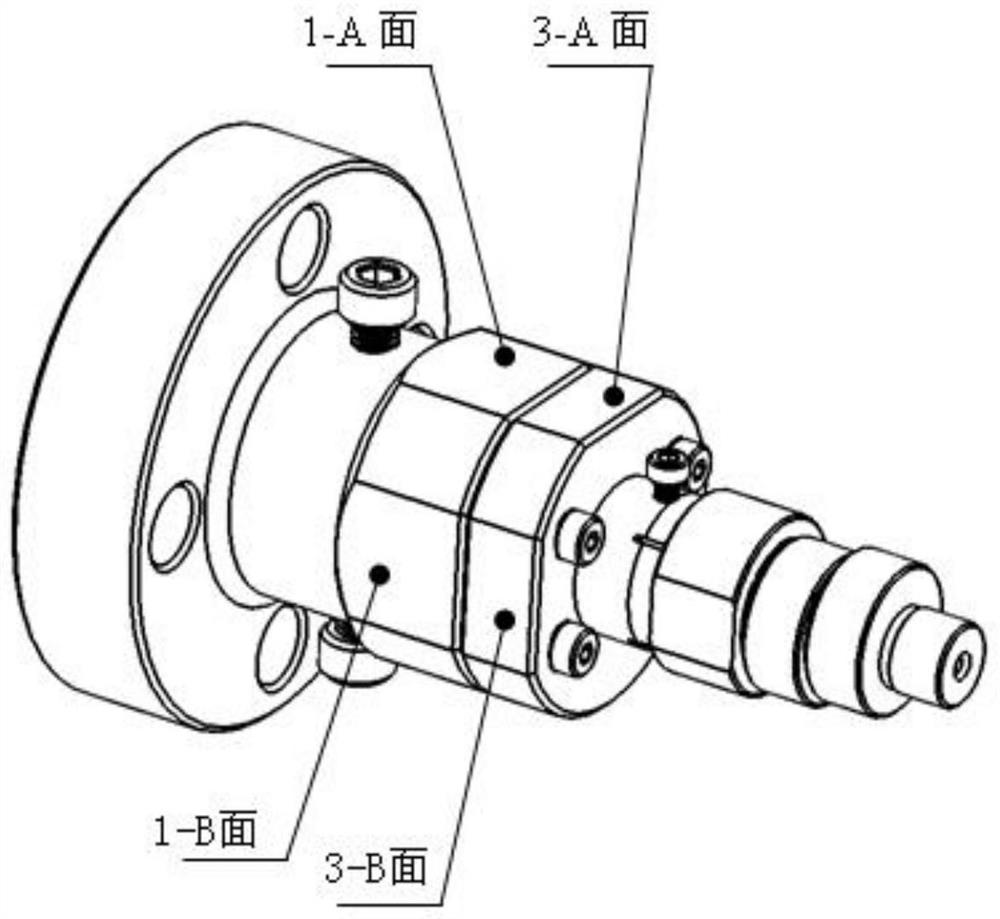

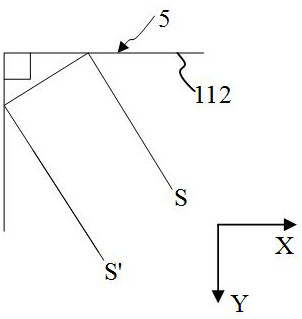

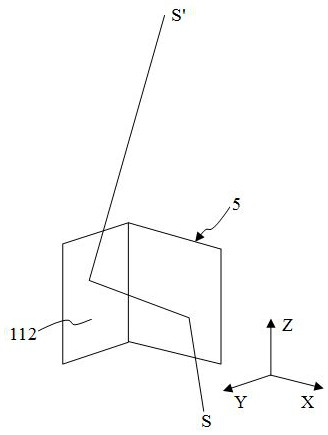

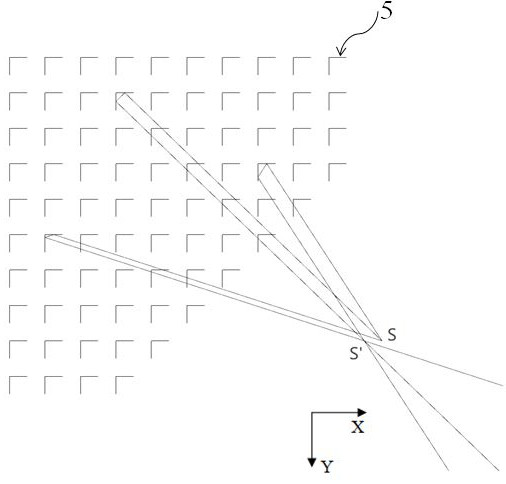

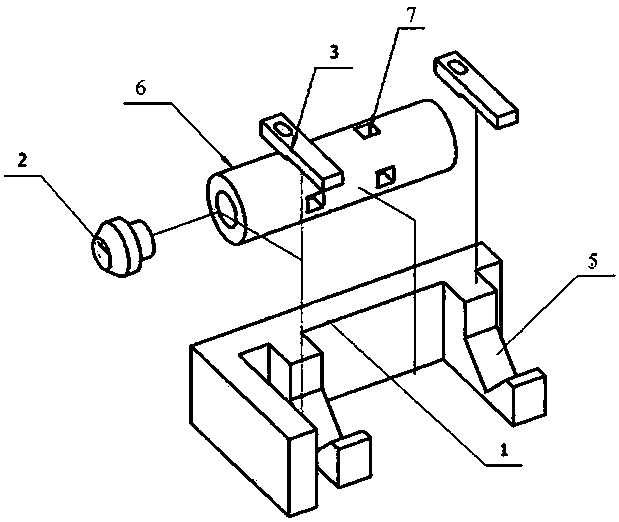

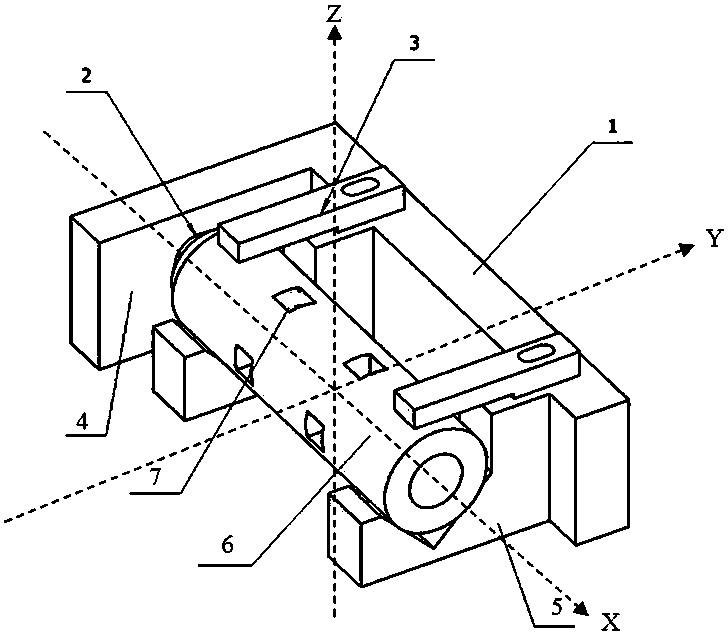

Ultra-high precision servo valve sleeve square orifice wire cutting positioning tool and method thereof

ActiveCN106041233BPrecise clampingReduce or even eliminate the impact of manufacturing errorsElectrical-based auxillary apparatusEngineeringMechanical engineering

The invention discloses a square throttling hole linear cutting positioning tool of a ultrahigh-precision servo valve sleeve. The valve sleeve has a shaft hole; a space coordinate system is built with the center axis of the shaft hole as an X axle; a Y axle is perpendicular to the X axle in the horizontal direction; and a Z axle is perpendicular to the X axle in the vertical direction. The positioning tool is characterized by comprising a stopper, a pair of V-shaped grooves and an axial positioning nail; one end surface of the stopper is parallel to a Y-Z axle plane; the pair of V-shaped grooves are positioned on one side of one end surface of the stopper; the center axis of the pair of V-shaped grooves is relatively perpendicular to one end surface of the stopper; the valve sleeve is positioned in the pair of V-shaped grooves; and one end of the axial positioning nail is connected with the shaft hole of the valve sleeve, and the other end is contacted with one end surface of the stopper. The positioning tool has the following advantages: the valve sleeve can be quickly and accurately clamped and positioned; the influence caused by manufacturing errors of procedures before cutting a square hole of the valve sleeve is reduced or even eliminated; and the coplanarity of a square hole throttling working edge machined by linear cutting is guaranteed to achieve high precision.

Owner:上海脉迪机电技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com