Ultra-high precision servo valve sleeve square orifice wire cutting positioning tool and method thereof

A technology for positioning tooling and servo valves. It is used in manufacturing tools, accessories, metal processing equipment, etc. It can solve the problems of poor quality consistency, unstable processing accuracy, and low production efficiency, and achieve elimination of manufacturing errors, accurate clamping, High-precision coplanarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

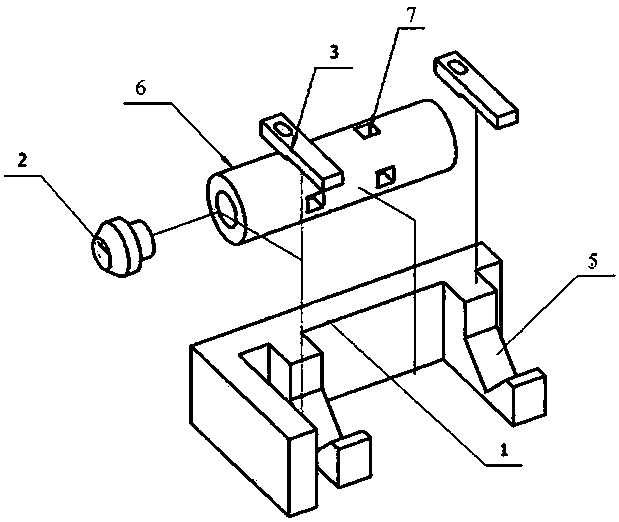

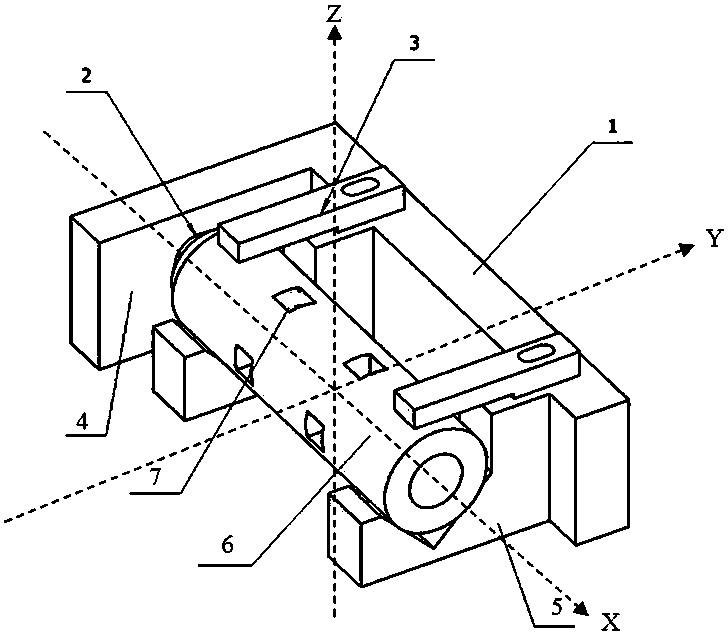

[0033] like figure 1 , 2 As shown, an ultra-high-precision servo valve sleeve square orifice line cutting positioning tool, the valve sleeve 6 has a shaft hole, the center of the shaft hole is taken as the origin, and the axis of the shaft hole is the X-axis to establish a space coordinate system, The horizontal direction perpendicular to the X axis is the Y axis, and the vertical direction perpendicular to the X axis is the Z axis. The positioning tool includes: a stopper 4, one end surface of which is parallel to the Y-Z axis plane; a pair of V-shaped grooves 5, located at the stopper On the side where one end face of the block 4 is located, the central axis of the pair of V-shaped grooves 5 is relatively perpendicular to one end face of the block 4, and the valve sleeve 6 is placed in the pair of V-shaped gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com