Centering and clamping assembling machine for H-shaped steel of corrugated web plates

A corrugated web, H-beam technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complex equipment structure, unstable alignment, high energy consumption, and improve assembly quality. And the effect of production efficiency, simple and innovative design, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] How the present invention is further implemented now in conjunction with accompanying drawing:

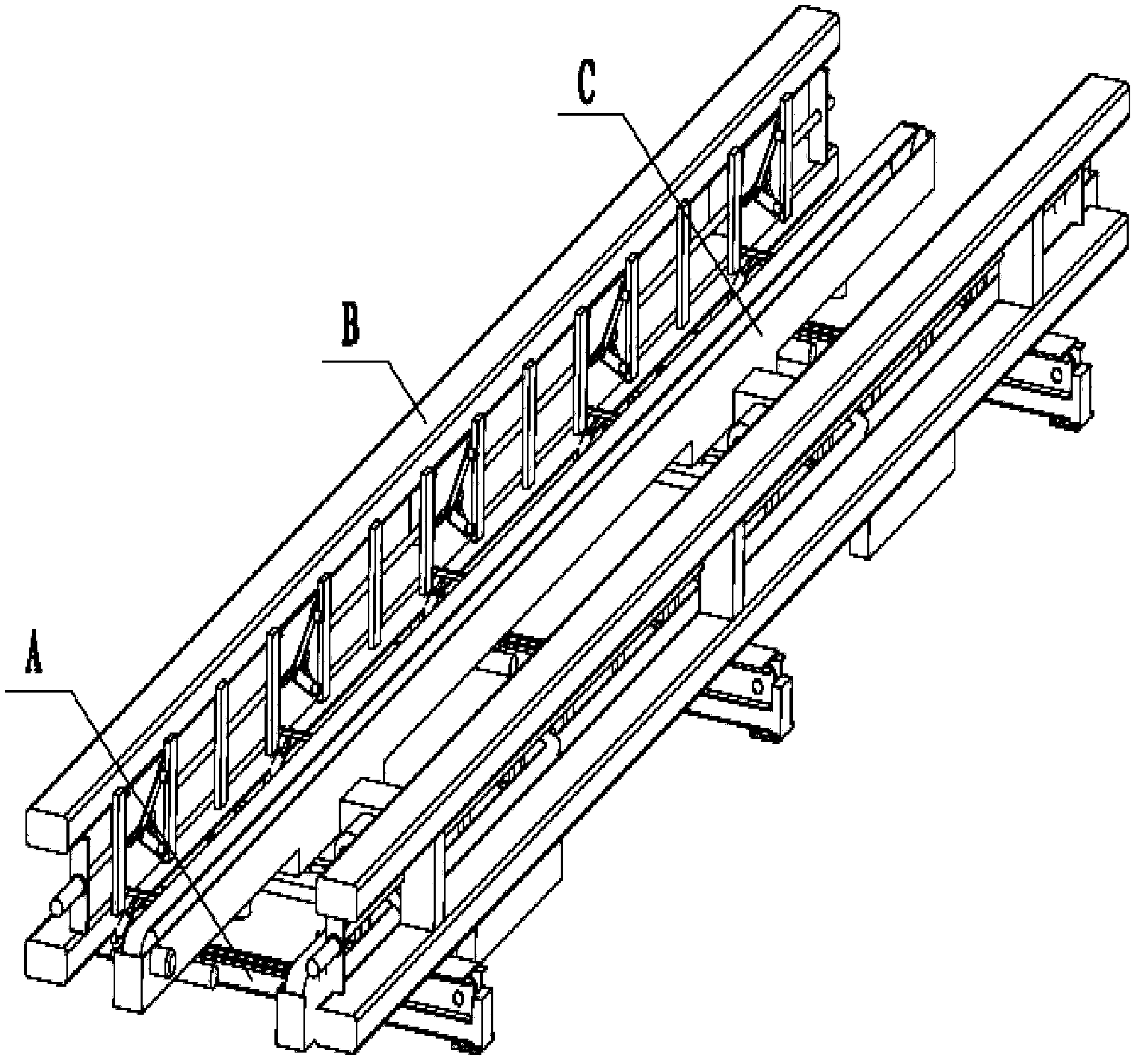

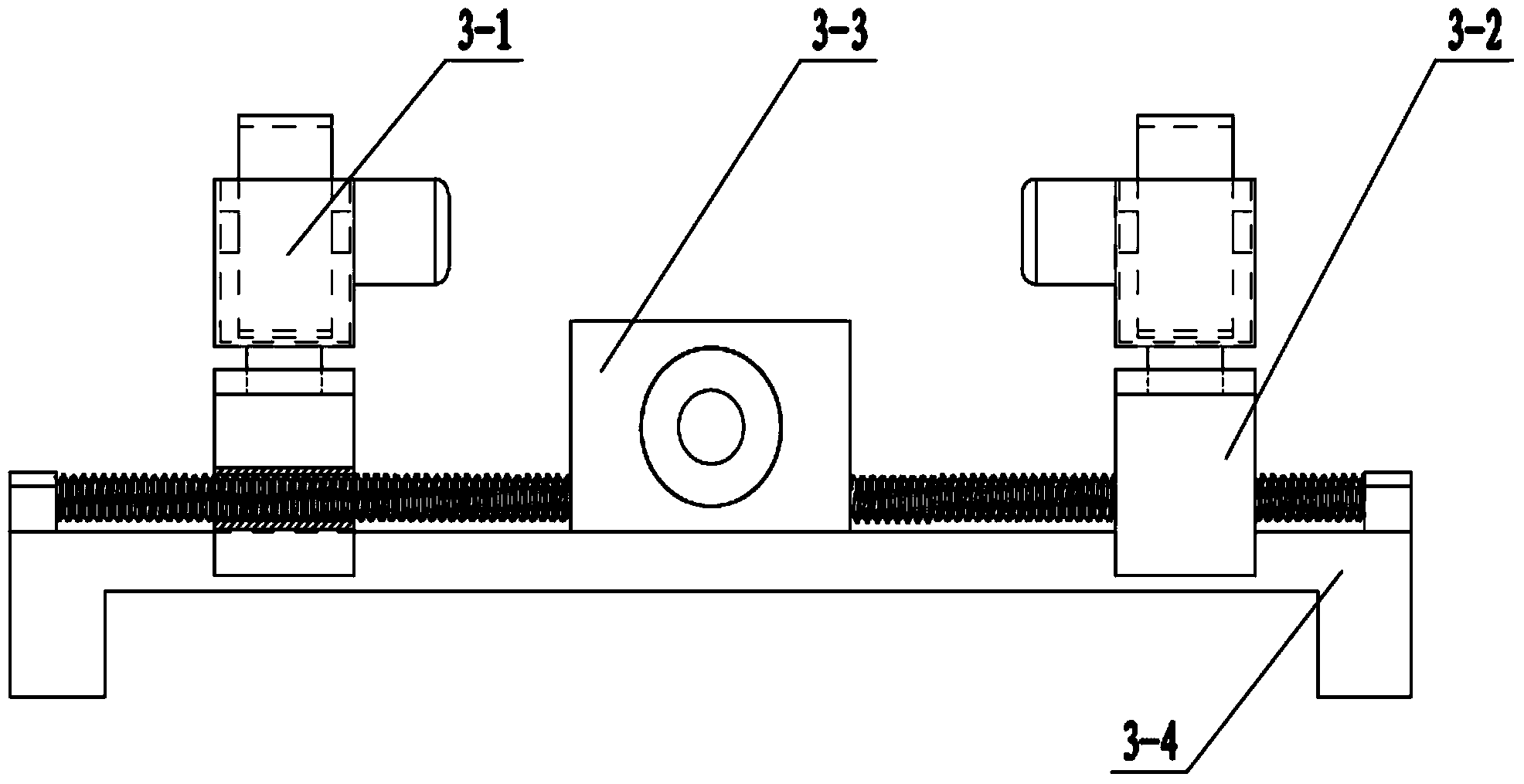

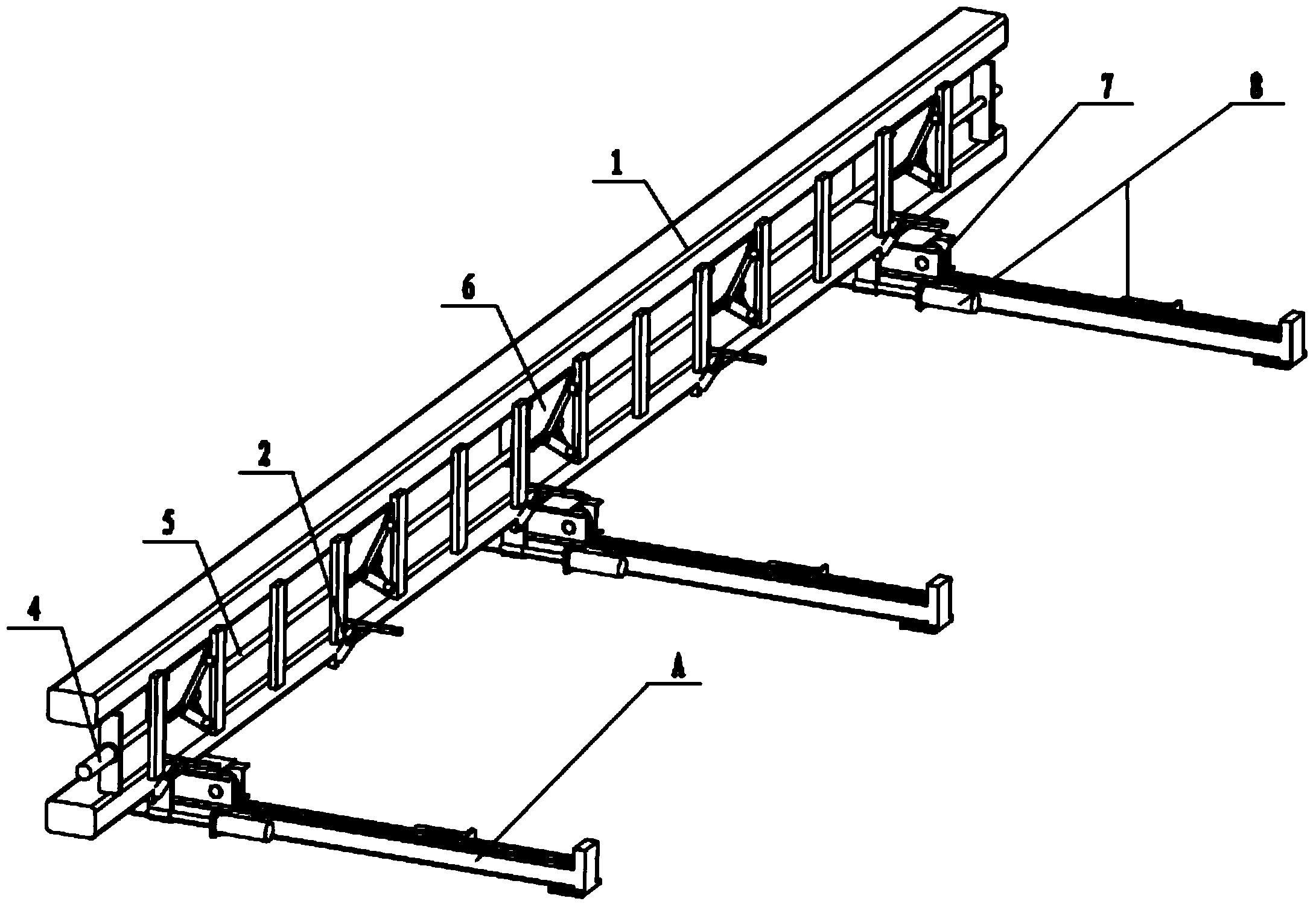

[0018] A centering and clamping corrugated web H-shaped steel assembly machine of the present invention comprises a base A, a centering clamping device B, a web conveying device C, a hydraulic drive device and a manual spot welding machine; the web conveying device is provided with C In the longitudinal center of the base A, two sets of centering clamping devices B are longitudinally and symmetrically arranged on both sides of the web conveying device C to connect with the base A, and the horizontal hydraulic drive device 8 is arranged at both ends of the base A, and the telescopic ends of the oil cylinders are connected with the base A respectively. Two sets of centering clamping device B are connected; each set of centering clamping device B is composed of clamping frame, turning device, flange plate centering clamping mechanism and running mechanism, and running mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com