Experimental device for detecting aeroengine guider

An aero-engine and experimental device technology, applied in the direction of engine testing, measuring devices, jet engine testing, etc., can solve the problems affecting the authenticity and accuracy of test data, cumbersome operation, time-consuming and labor-intensive, etc., and achieve high test efficiency and easy operation Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

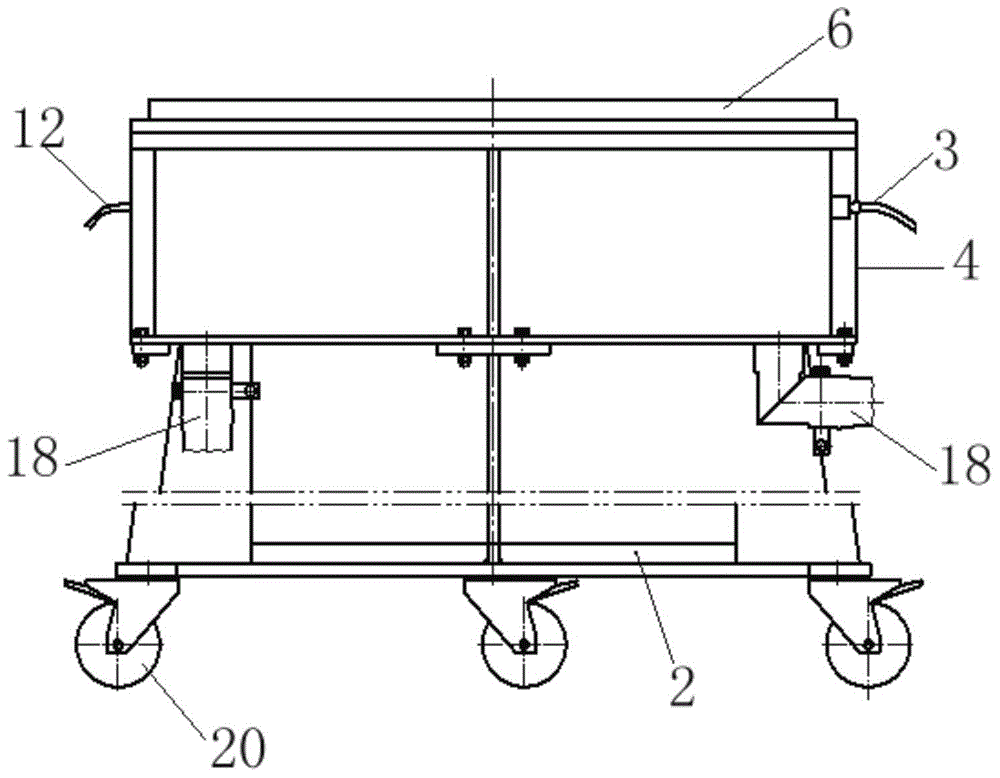

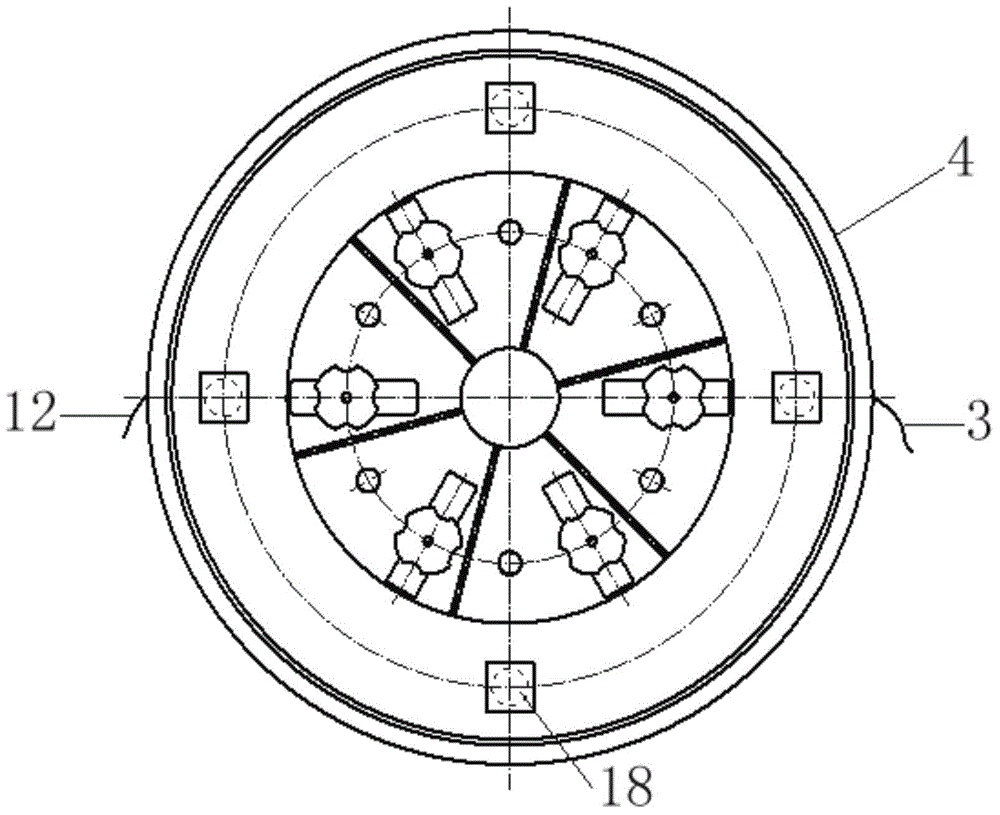

[0027] In this embodiment, the outline structure of the experimental device used to detect the aeroengine guide is as follows: Picture 1-1 and Figure 1-2 As shown, the local structure of the tested aero-engine guide is as follows diagram 2-1 and Figure 2-2 shown. The experimental device includes a device bracket 2, a cylinder chamber installed on the bracket for installing the guide 11 to be tested, a first annular chamber A located in the cylinder chamber, a second annular chamber B above the first annular chamber A, The sealing assembly used to measure the airtightness of the guider flow channel to be detected, the sealing assembly of the outlet of the sealing guider flow channel, the measuring airflow distribution device 1, the pressure sensor 3 and the temperature sensor 12 arranged on the second annular cavity B, and the pressure sensor 3 and the temperature sensor 12 arranged on the measuring airflow Flow sensor on the inlet duct of the dispensing unit.

[0028]Th...

Embodiment 2

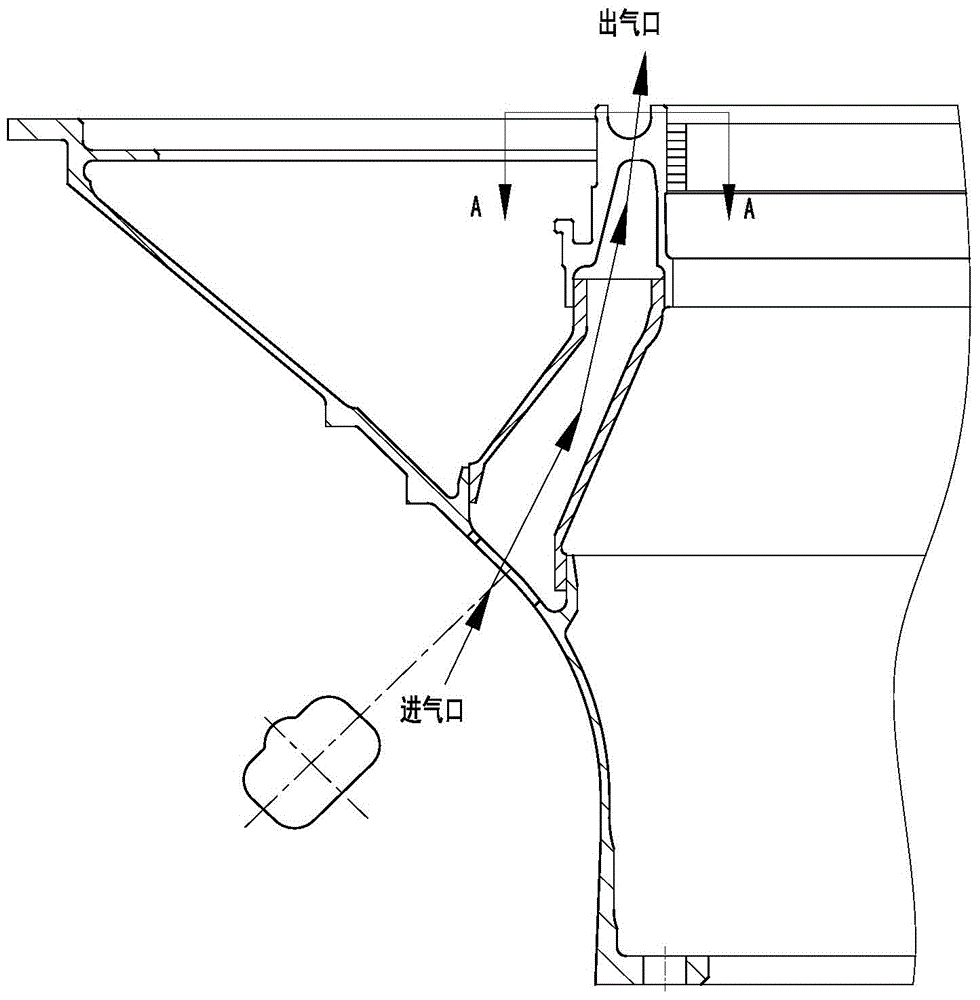

[0030] In the present embodiment, adopt the experimental device of the present invention to carry out the air flow experiment on the guider of the aeroengine, put the guider 11 to be tested into the experimental device described in embodiment 1, and place the guider 11 small end flange to be tested 6 sets of pressing components 7 are airtightly compressed on the annular plate of the first annular chamber A, and the large end flange of the guide to be tested 11 is airtightly connected with the upper end of the outer cylinder through the coupling member 10, and the guide to be tested is guided by the sealing component. The outlet of the flow channel of the device 11 is sealed, and the sealing member 9 and the sealing member 13 are respectively arranged at the contact position between the guider 11 to be tested and the outer cylinder body 4 and the annular plate 15 (see Figure 3-1 ). Use a hose to connect the inlet pipe port and the air outlet pipe port, specifically, the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com