Scanning slit device used in stepping scan lithography machine

A step scanning and lithography technology, applied in the field of lithography, can solve the problems of different diffraction effects, inability to realize plane scanning motion, and no scanning function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

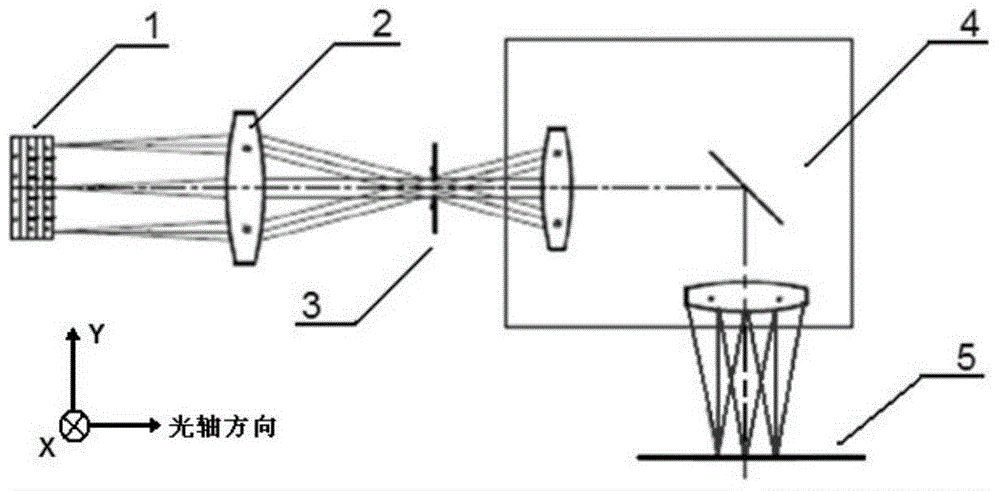

[0022] Below in conjunction with accompanying drawing and specific implementation example, the present invention is described in detail:

[0023] see figure 2 , figure 2 It is a schematic diagram of a part of the optical path of an exposure system including a scanning slit device for a step-and-scan lithography machine according to the present invention. The illuminating light beam from the front end passes through the homogenizing element 1 and converges on the knife-edge surface of the scanning slit 3 through the condenser lens group 2 . The knife-edge surface of the scanning slit 3 is perpendicular to the optical axis, and the outline of the field of view formed by the knife-edge surface is projected onto the mask surface 5 through the illumination mirror group 4 .

[0024] In this implementation example, if figure 2 As shown, two directions perpendicular to each other are set on the knife-edge surface of the scanning slit 3, wherein the direction perpendicular to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com