Manufacturing method of transformer bobbin based on lead frame

A technology of a transformer skeleton and a manufacturing method, which is applied in the field of transformers, can solve the problems of reducing production efficiency, increasing labor cost, and small winding space for a wire binding portion, and achieves the effects of improving production efficiency and ensuring coplanarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

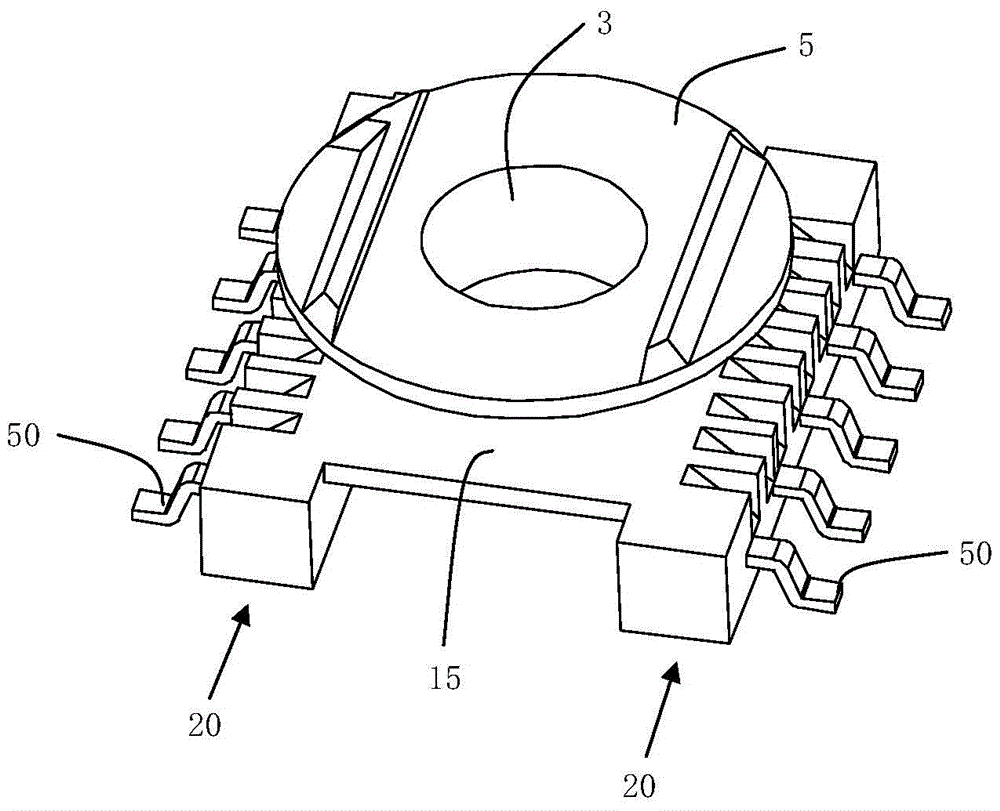

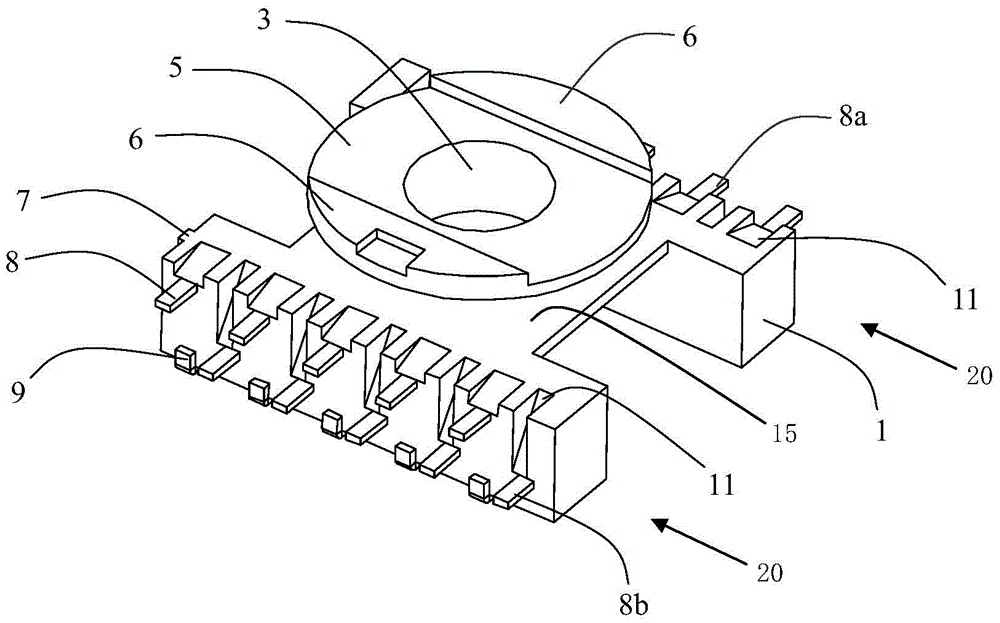

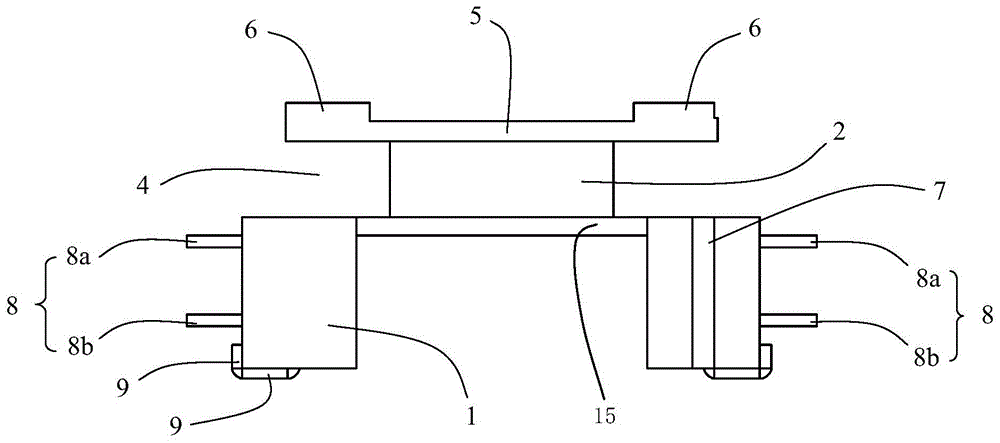

[0055] Figure 2-1 to Figure 2-4 It is a structural diagram of the transformer skeleton of the first embodiment of the present invention, diagram 2-1 is a perspective view of the transformer skeleton of the first embodiment of the present invention, Figure 2-2 It is the front view of the transformer skeleton of the first embodiment of the present invention, Figure 2-3 It is a top view of the transformer skeleton in the first embodiment of the present invention, Figure 2-4 It is a side view of the transformer skeleton in the first embodiment of the present invention. It includes coil bobbin 1, winding post 2, magnetic core assembly hole 3, winding package limit slot 4, transformer winding package block 5, magnetic core assembly limit strip 6, pin position identification point 7, wire binding guide Pin 8, patch pin 9, connecting arm 10, lead groove 11.

[0056] The winding post 2 is located on the coil bobbin 1, and a magnetic core assembly hole 3 is provided inside the ...

no. 2 example

[0061] Figure 5-1 to Figure 5-4 It is a structural diagram of the transformer skeleton of the second embodiment of the present invention, Figure 5-1 is a perspective view of the transformer skeleton of the second embodiment of the present invention, Figure 5-2 It is the front view of the transformer skeleton of the second embodiment of the present invention, Figure 5-3 It is a top view of the transformer skeleton of the second embodiment of the present invention, Figure 5-4 It is a side view of the transformer skeleton of the second embodiment of the present invention. The difference from the first embodiment of the present invention lies in the structure and quantity of the binding pins 8 and patch pins 9 , as well as the number of lead slots 11 , and other structures are the same as the first embodiment.

[0062] There are two straight wire-binding pins in each group of wire-binding pins 8 in the first embodiment, and here there is only one straight wire-binding pin....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com