Display connector and fabrication method thereof

A connector and integrated technology, which is applied in the directions of computer peripheral equipment connectors, connections, and parts of connecting devices, etc., can solve the problems of poor thermal fusion effect, skewed terminal pins, and easy deviation of the pin parts of the terminals. Improve production efficiency, ensure coplanarity, and ensure the effect of alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

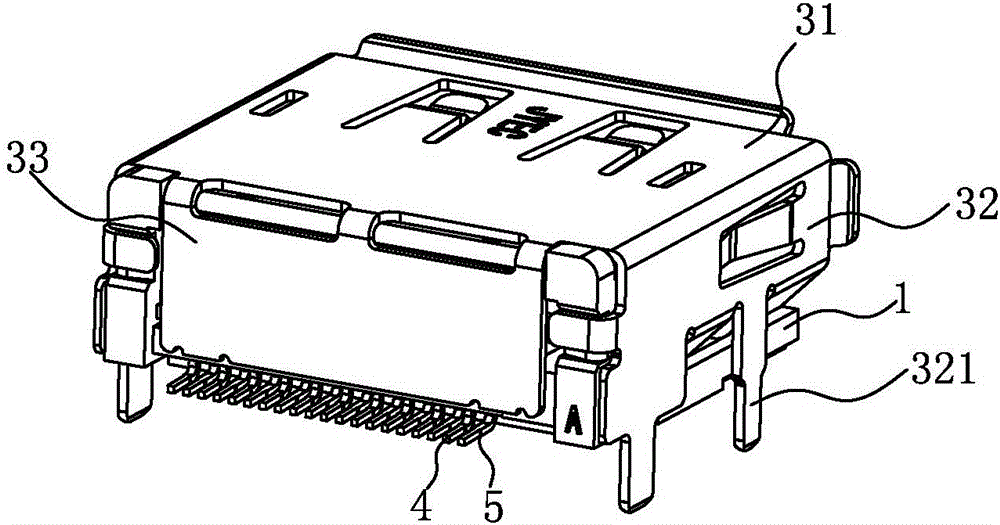

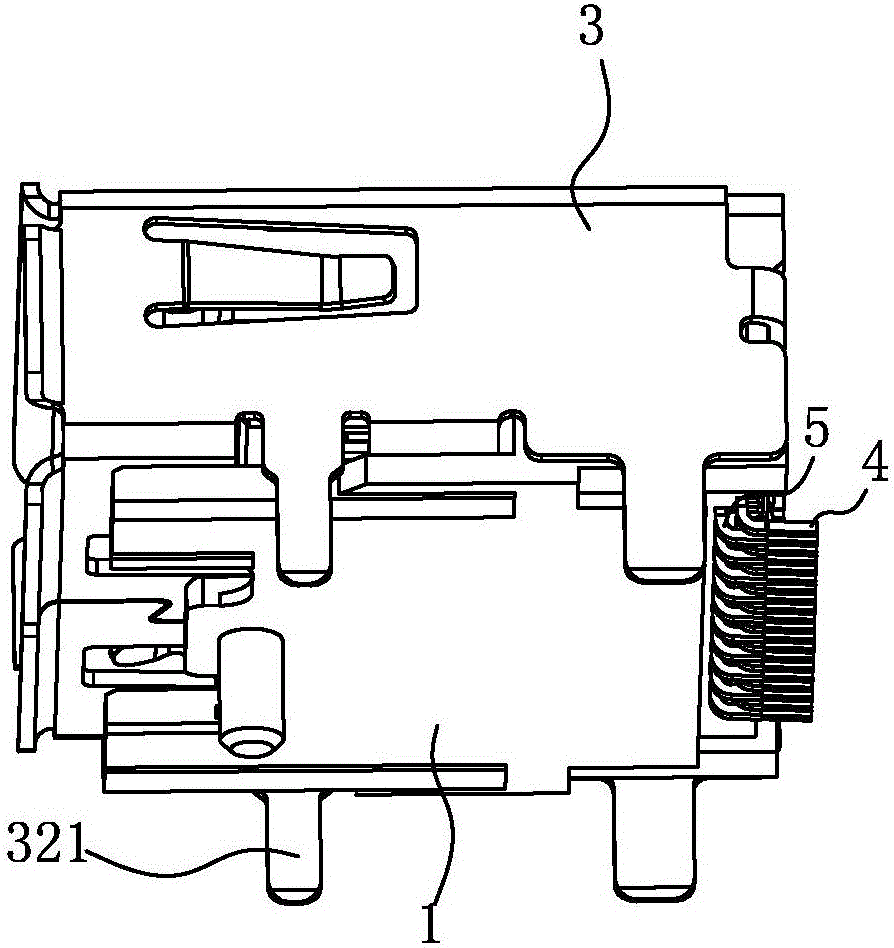

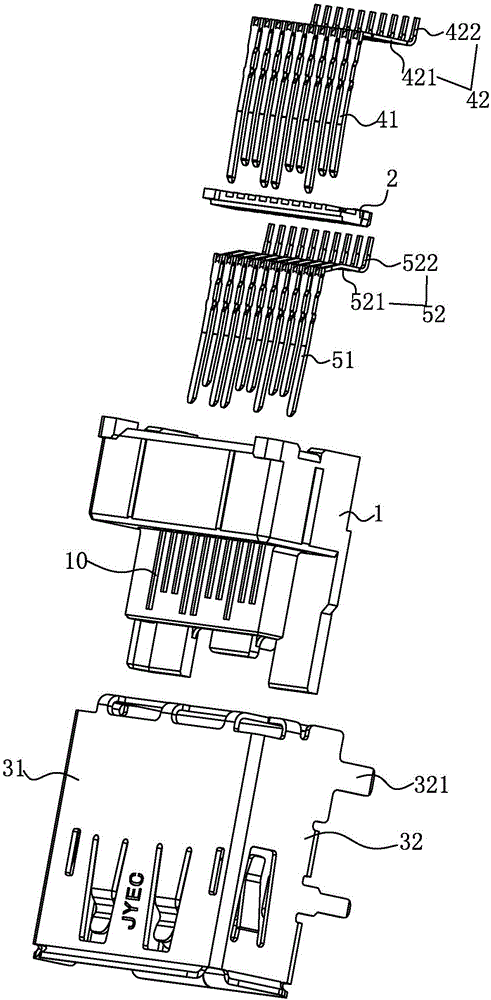

[0038] See Figure 1-3 As shown, a display connector includes: an insulating base 1, a terminal group installed on the insulating base 1, an insulating rear plug 2 installed on the rear end of the insulating base 1 to limit the terminal group and thermally coated , Metal shell 3.

[0039] See Figures 4A-4B As shown, the insulating base 1 is provided with a socket cavity 10 for terminal group installation. The socket cavity 10 is opened horizontally from the rear end to the front end of the insulating base 1. The socket cavity 10 includes the first socket cavity distributed up and down. 101 and the second socket cavity 102, the terminal group is inserted and installed in the socket cavity 10 from the rear end of the insulating base 1, a socket is formed on the front of the insulating base 1, and the external connecting plug is inserted into the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com