Sample treatment device

A sample processing and sample technology, applied in the field of sample processing devices, can solve the problems of excessive grinding, scrapped samples, difficult grinding, etc., and achieve the effect of easy grinding and not easy to lose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

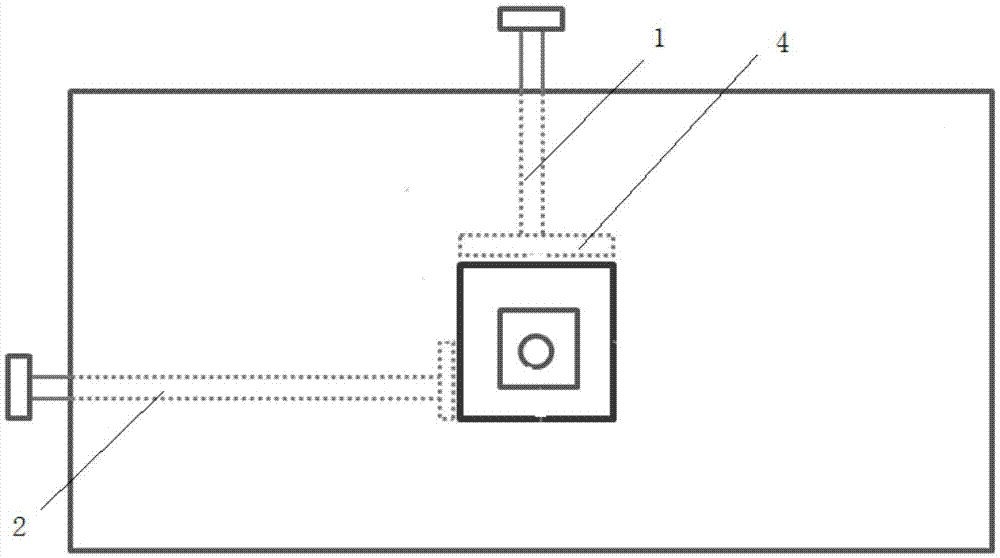

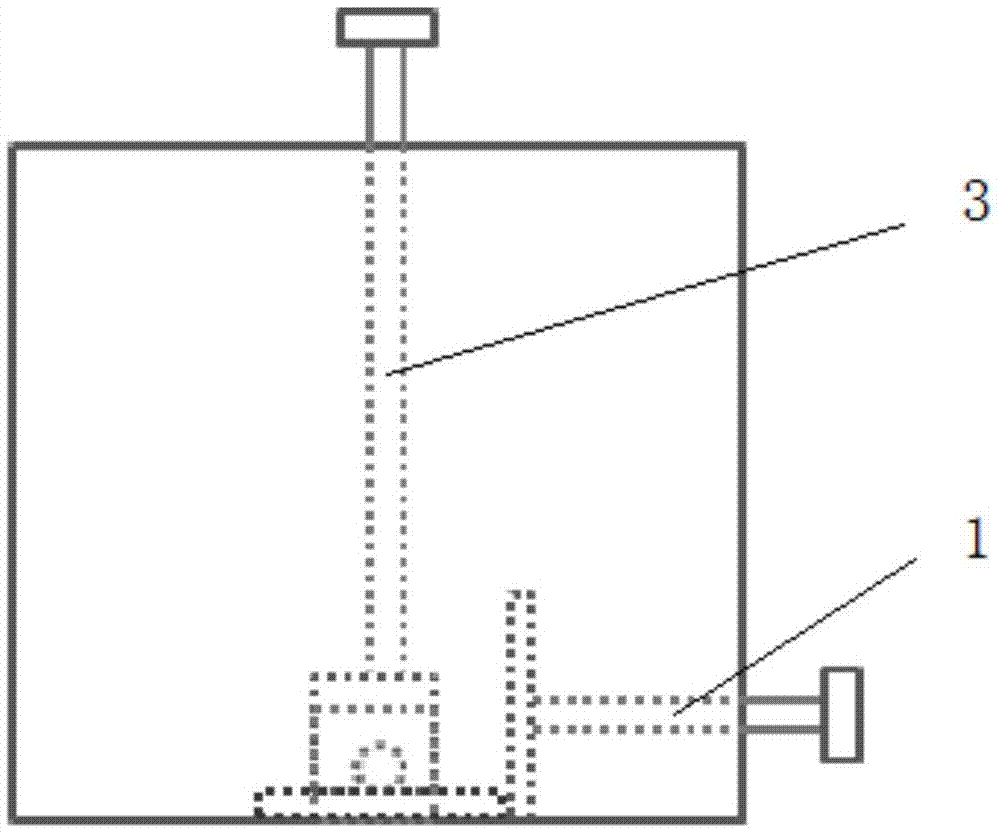

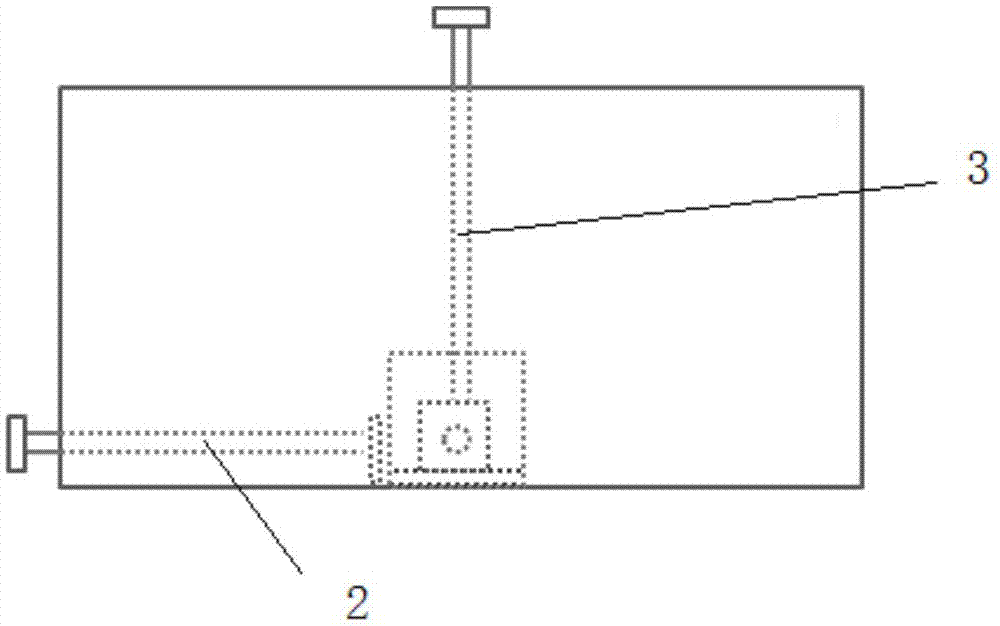

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0030] At present, semiconductor samples need to be processed when doing failure analysis of semiconductor samples, but some semiconductor samples are small in size, or very small, and it is very difficult to grind these small-sized samples, so according to the current operation, rely on Personal experience to control the grinding can easily lead to problems with the uniformity of the grinding cloth. Moreover, if the edge of the sample is ground, it will be more difficult to control, which will easily lead to the scrapping of the sample, making the failure analysis unable to continue.

[0031] After the failure analysis of the sample, it will be dried with a nitrogen gun. The sample size is small, and it is easy to be blown away by the nitrogen gun, and the problem of loss occurs, which eventual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com