Patents

Literature

173 results about "Torsional angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Torsion angle. the angle between the axes of any two different portions of long bones, such as between the head and neck of the femur and its long axis.

Calibration method of fish-eye lens imaging system applied to target detection

InactiveCN101577002ASimplify Mathematical ModelingCalibration results are reliableImage analysisCamera lensPhysical model

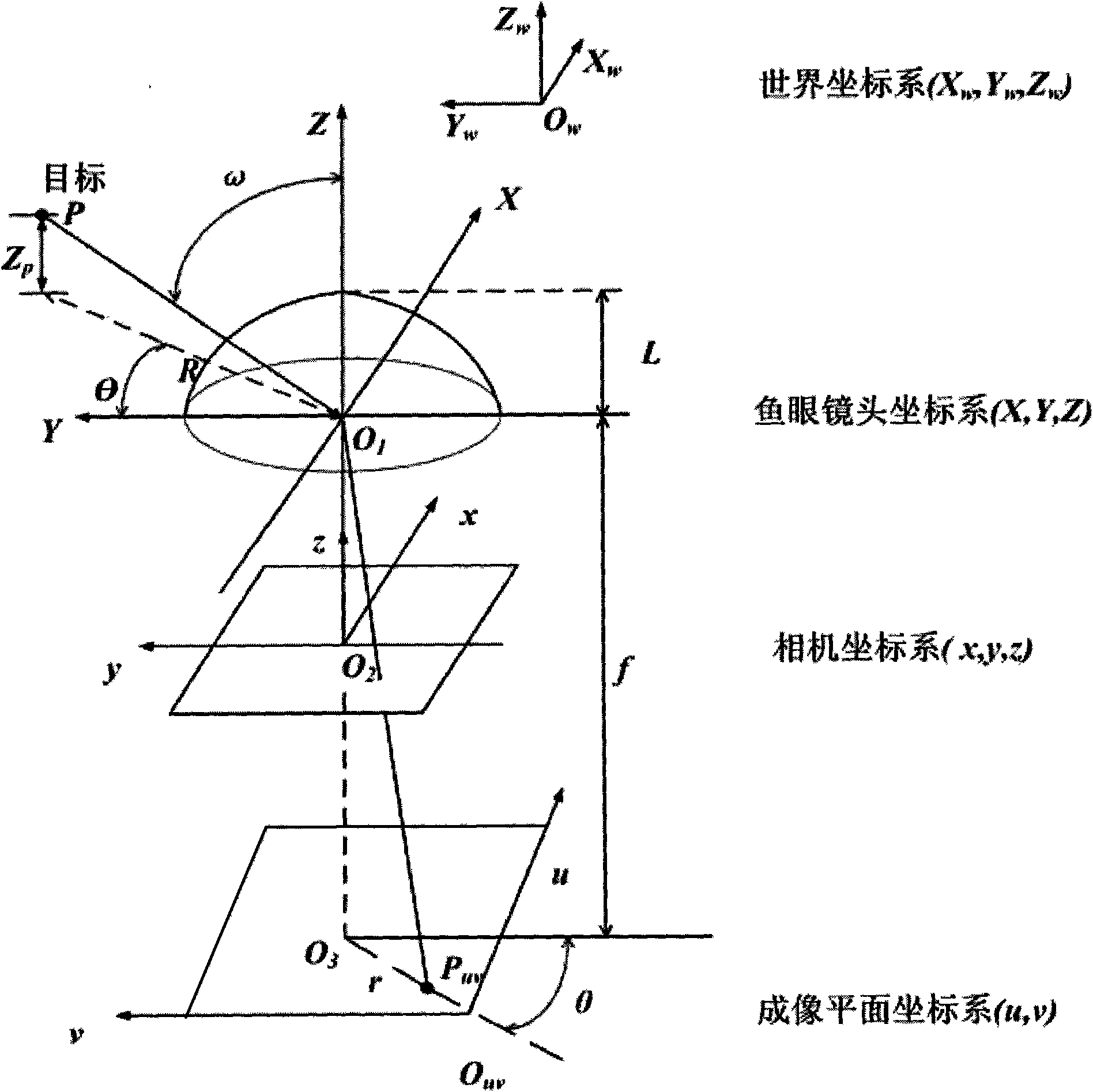

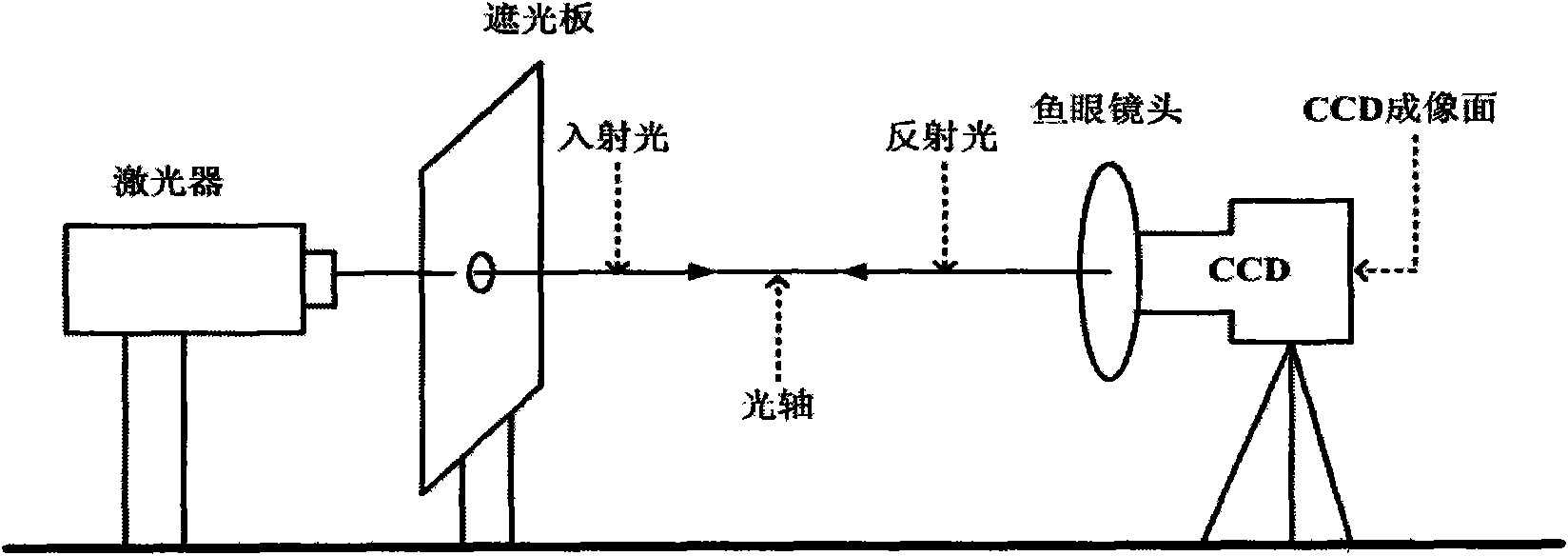

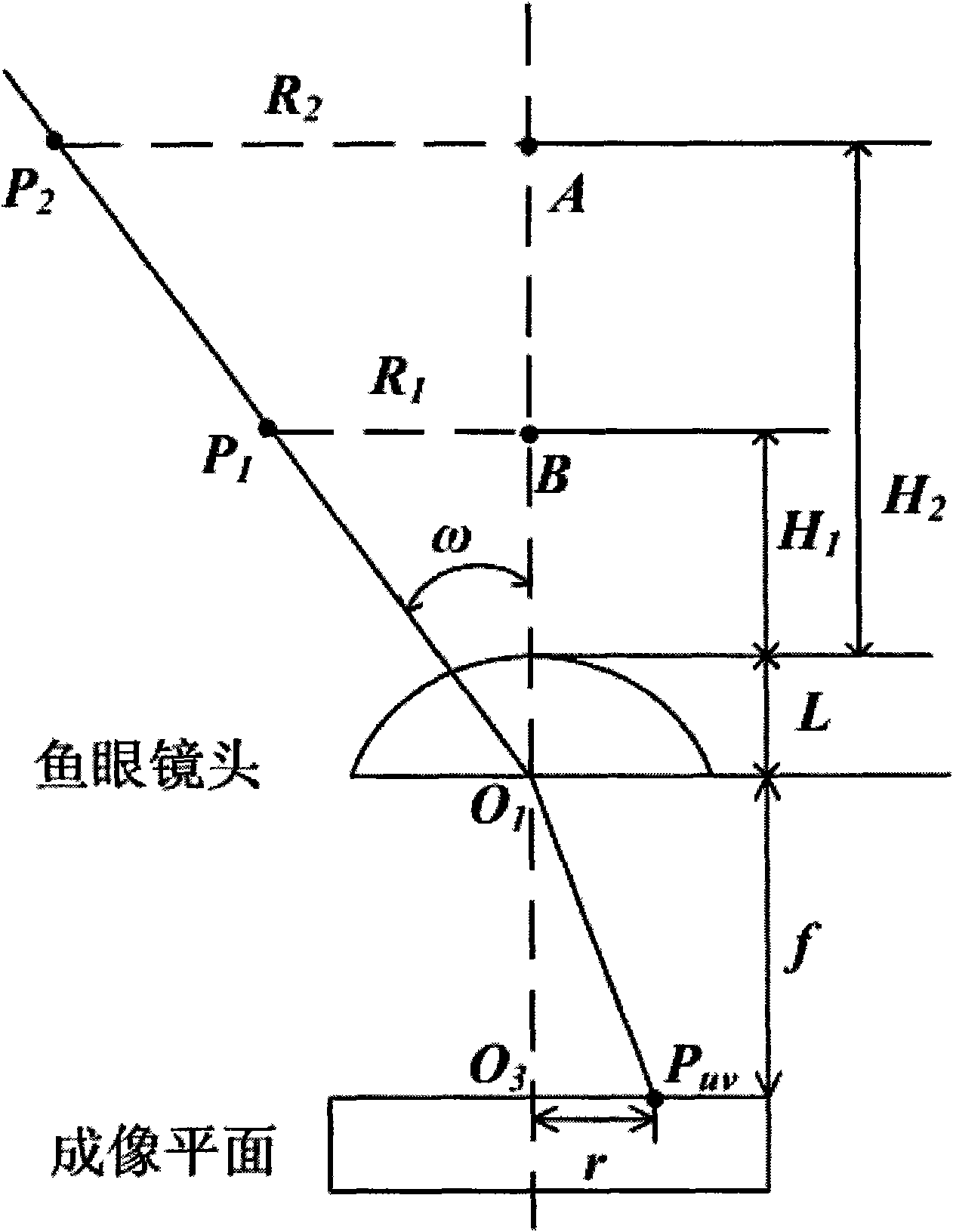

The invention discloses a calibration method of a fish-eye lens imaging system applied to target detection, which comprises the step of mathematical modeling of the fish-eye lens imaging system based on an equidistant projection and the precise calibrations of the intrinsic parameters of the imaging system (including the central point O3(u,v) of an imaging surface), the distance L between the top section of the fish-eye lens and a theoretic refractive optical center plane, the radial distortion coefficient K of the fish-eye lens, an image element aspect scale factor i, the plane torsional angle gamma between a camera coordinate system and an imaging surface coordinate system, various parameter calibration methods and matched software. The method aims at the omnidirectional vision system based on the fish-eye lens, analyzes the optical structure and the imaging principle of the fish-eye lens and introduces deformation parameters so as to establish the physical model of the fish-eye lens imaging system and then deduce the mathematical model of the system. With an independently-developed calibration procedure, three-dimensional space information is obtained from a two-dimensional image and applied to the calibration of imaging system parameters. The method is applicable to the calibration of various fish-eye type panoramic lenses, is convenient and accurate and has strong practicability.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

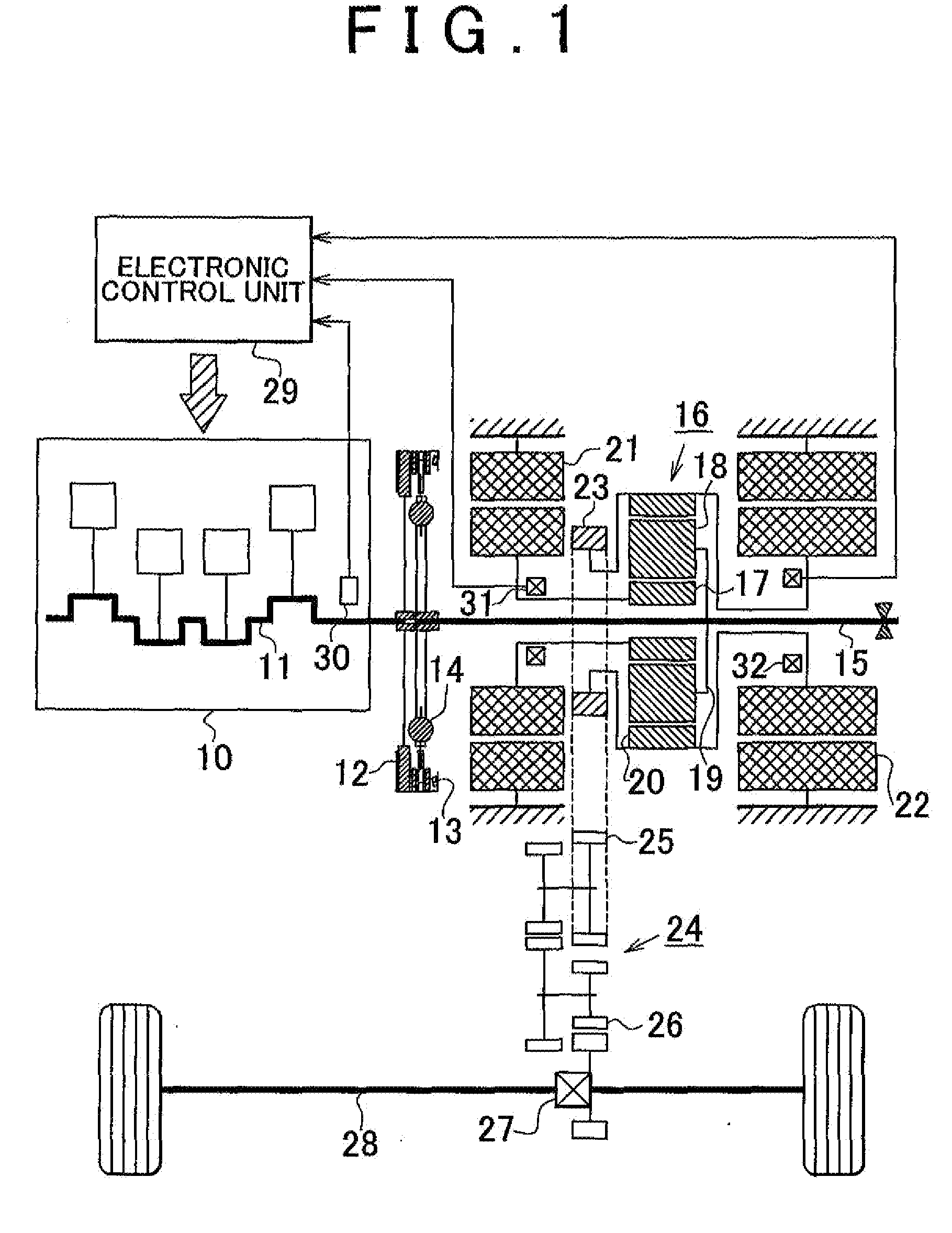

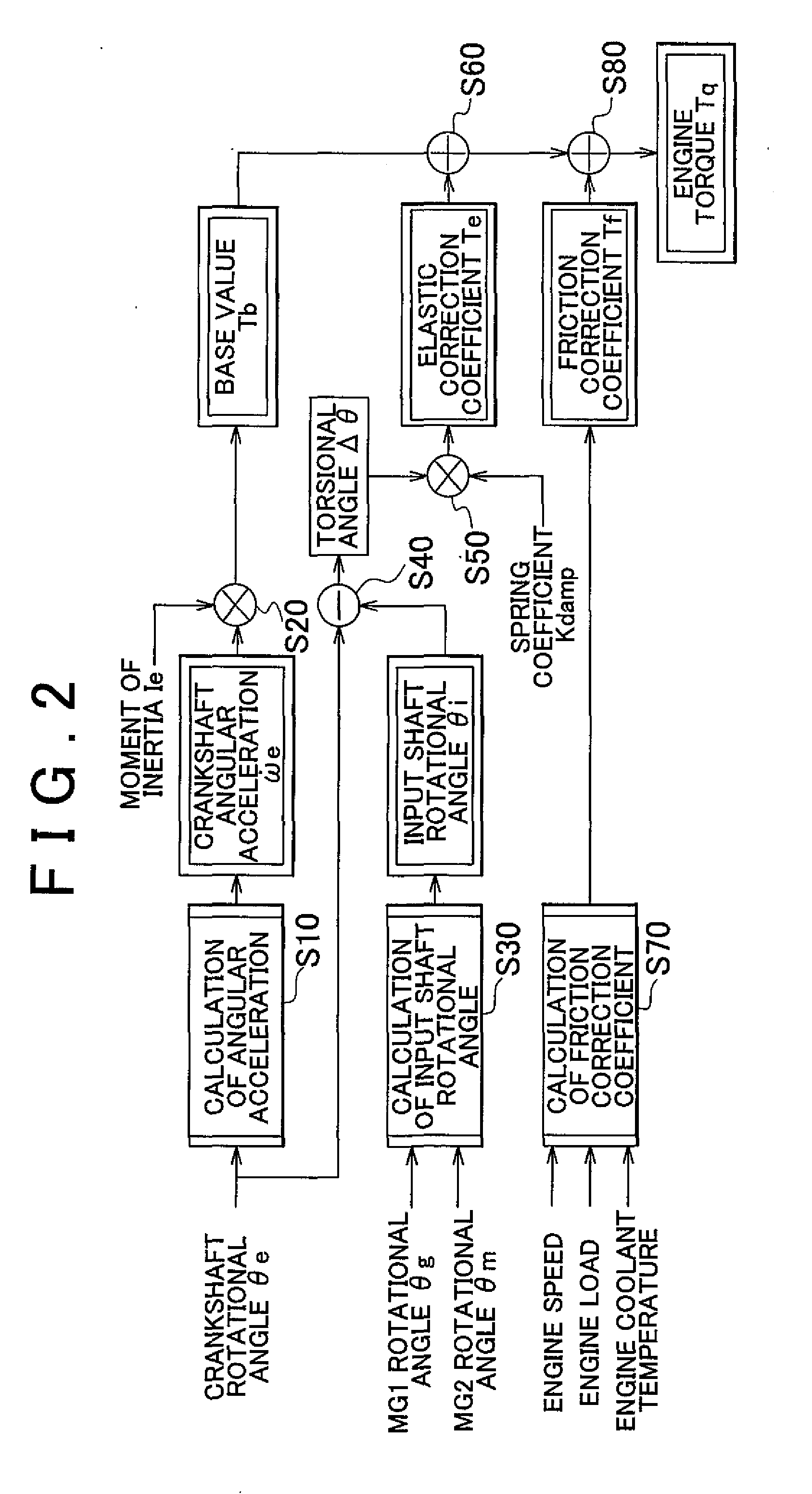

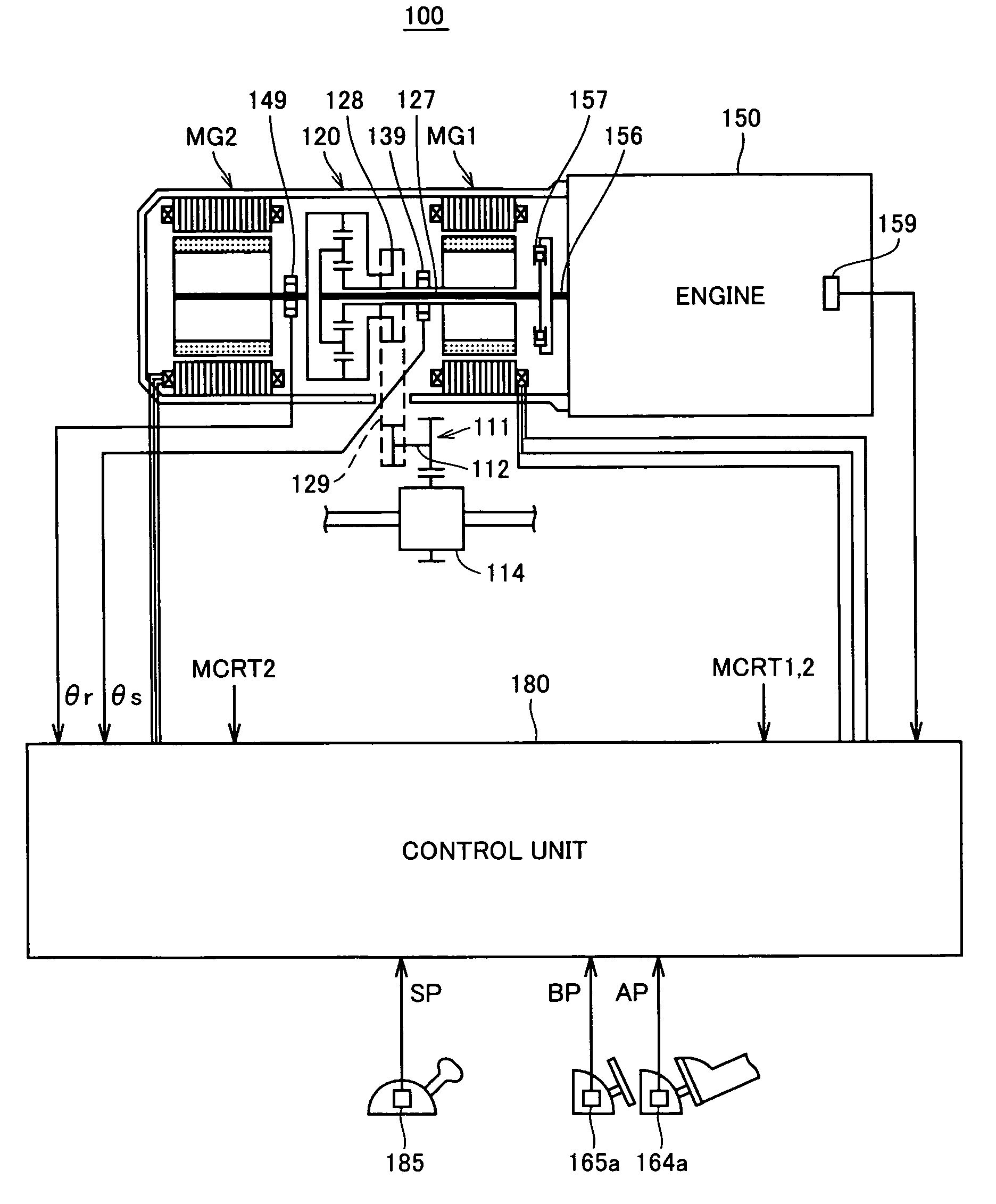

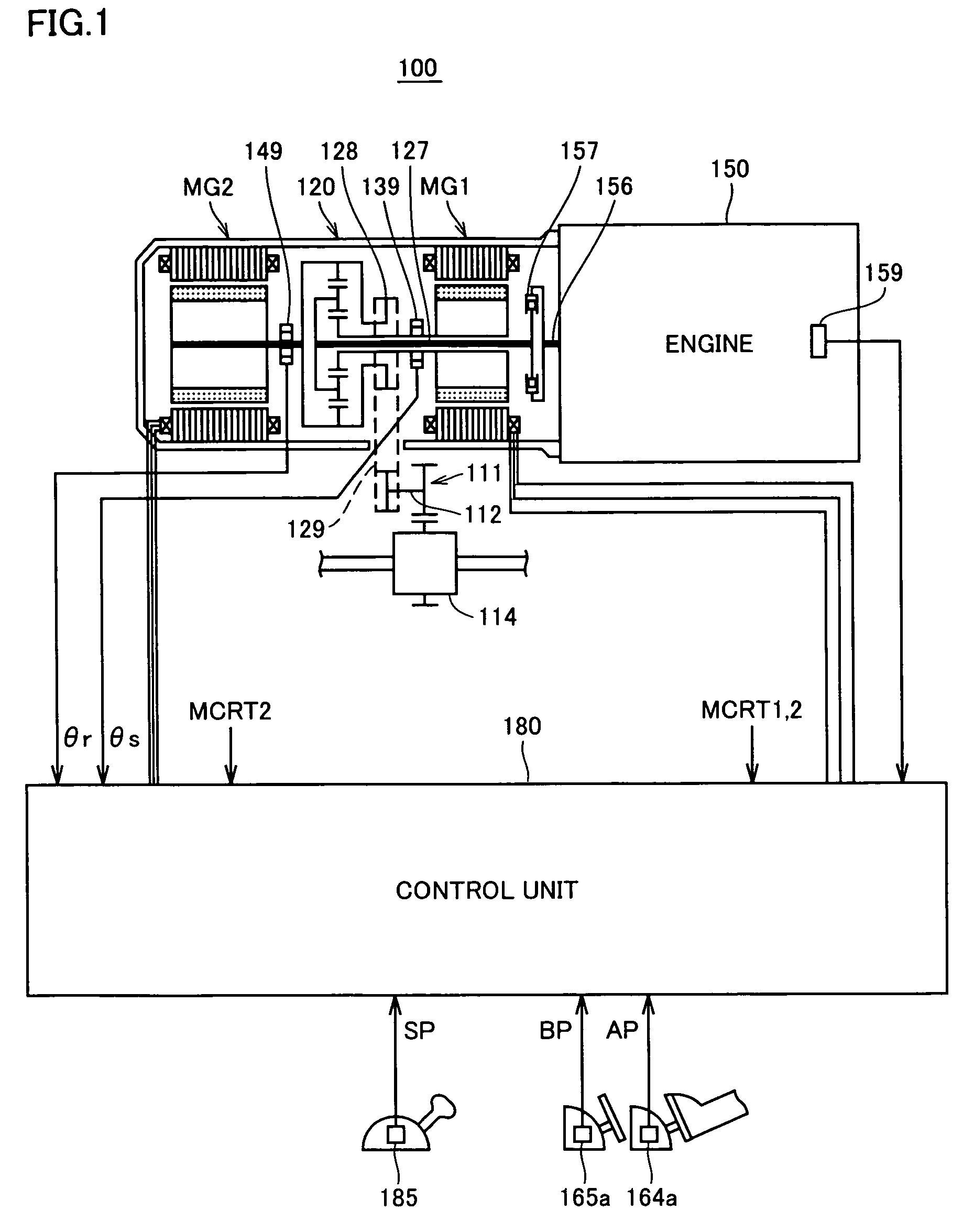

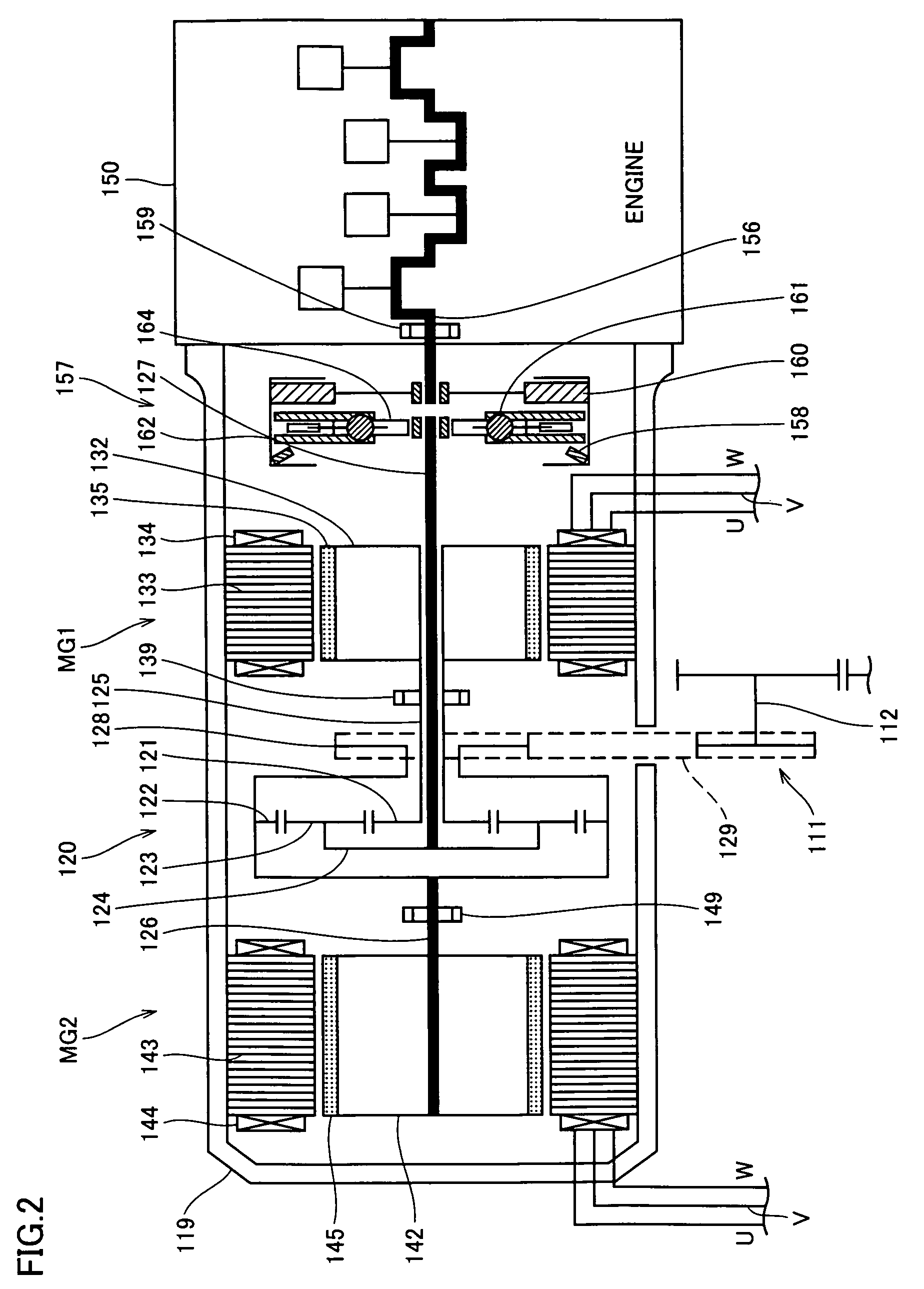

Engine control system

InactiveUS20090229897A1Accurate calculationEasy to controlHybrid vehiclesElectrical controlControl systemTorsional angle

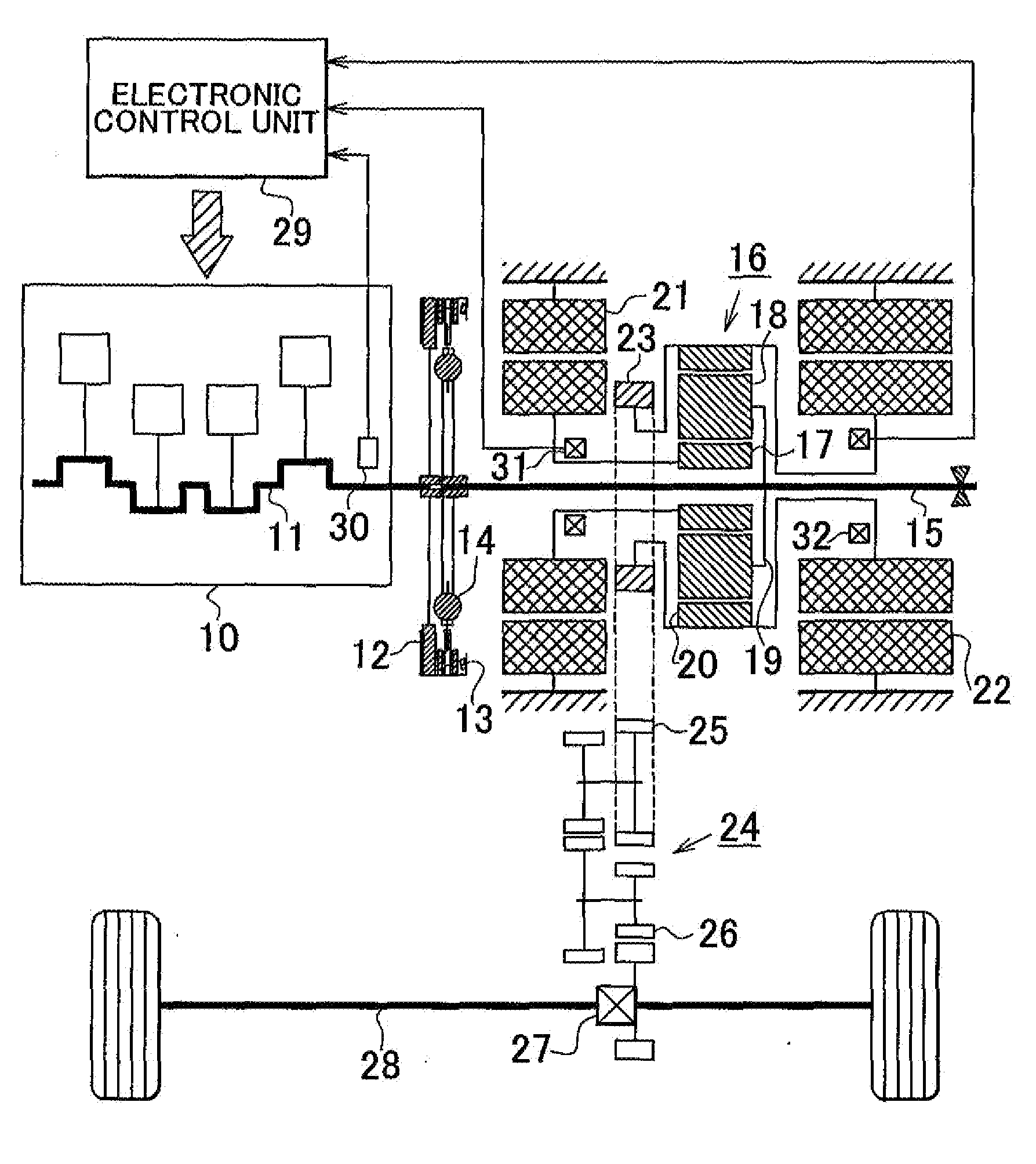

An engine control system includes an engine that outputs a rotation of a crankshaft through a torsional damper; a calculation portion that calculates a value of engine torque based on an angular acceleration of the crankshaft and a moment of inertia of the crankshaft; and a correction portion that calculates a correction value based on a torsional angle of the torsional damper, and corrects the calculated value of the engine torque using the correction value.

Owner:TOYOTA JIDOSHA KK +1

Method for processing TC11 material blade

ActiveCN101363327ASave materialUniform back arc allowanceBlade accessoriesMachines/enginesAviationTorsional angle

The present invention relates to a method for processing a TC11 material vane. The method can conveniently machine out a TC11 material aviation vane which has large torsional angle, large string width, large rough blank profile margin and uneven margins at all positions and is easy to machine. The method comprises the steps as follows: retesting a central forging hole, processing the back of a middle body, a technical reference of the air outlet side and a vane top axial reference face, rough machining a vane root and a vane root bottom surface technical button, processing for reverse adjustment, finish milling the profile, polishing the profile, processing the total length, removing a vane top central hole and removing the vane root bottom surface button. The present invention is characterized in that the vane top central hole during swaging processing is always kept until the total length is cut; a forging vane top central hole is considered as the reference; after the distressing treatment, the reverse adjustment is conducted, and the vane root and the surface of the vane root bottom surface technical button is fine finished; a vane root positioning area is increased, so the technical button is reserved at the vane root bottom surface, a vane root molding knife is used for processing the vane root and the surface of the vane root bottom surface technical button to ensure that the surface of the vane root bottom surface technical button is consistent with the vane root; and when milling comprehensively, the vane root and the surface of the vane root bottom surface technical button are used for positioning, and the vane profile is rough milled and fine milled.

Owner:WUXI TURBINE BLADE

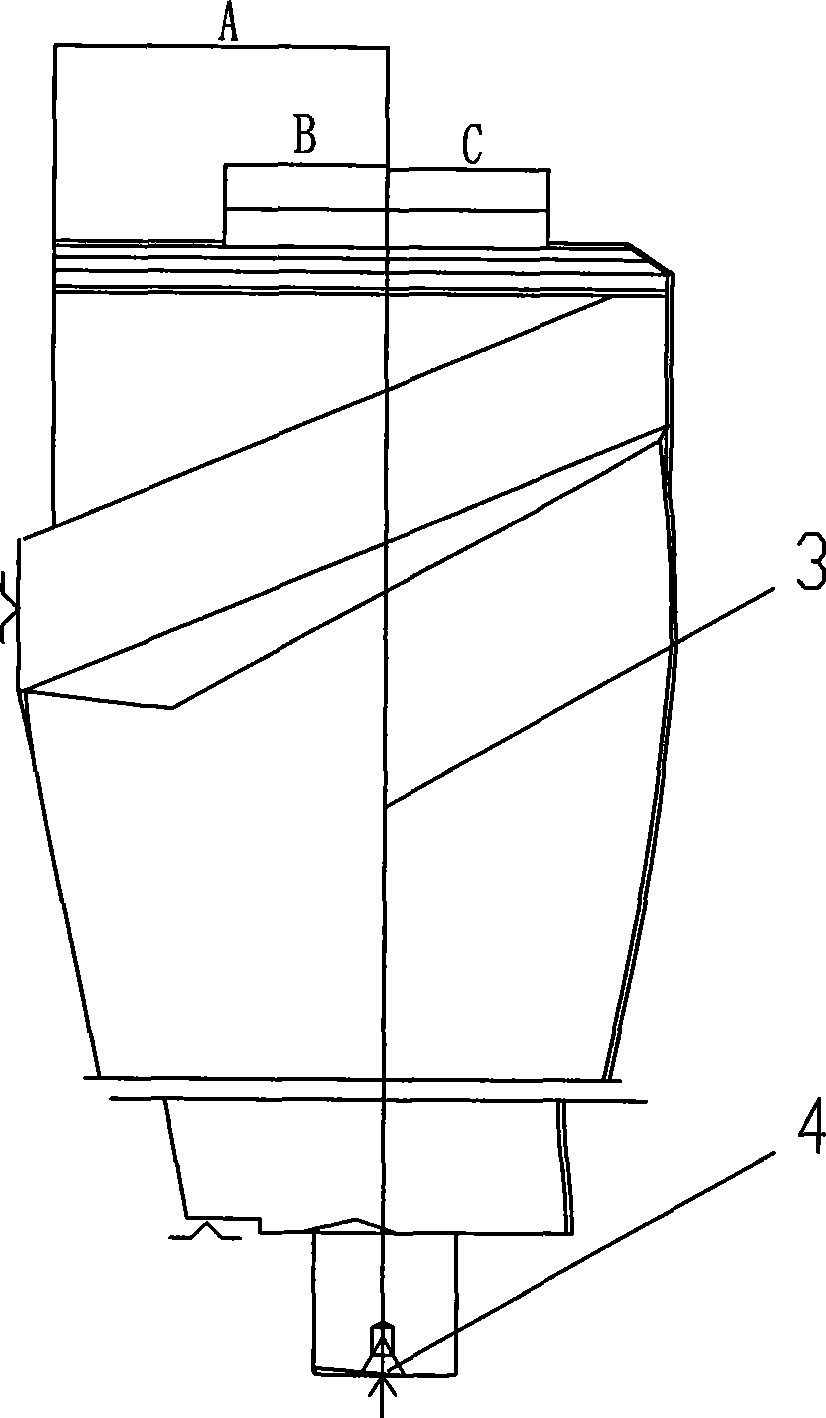

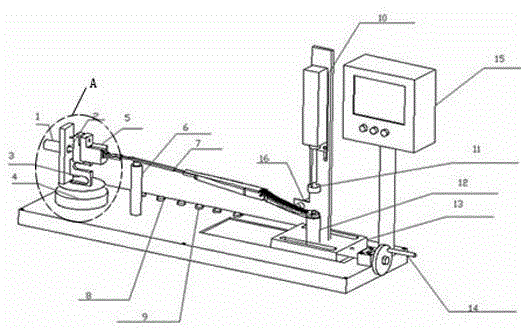

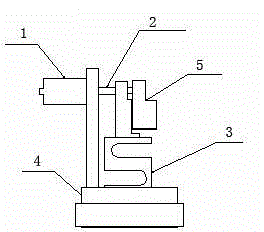

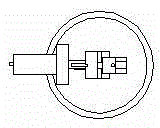

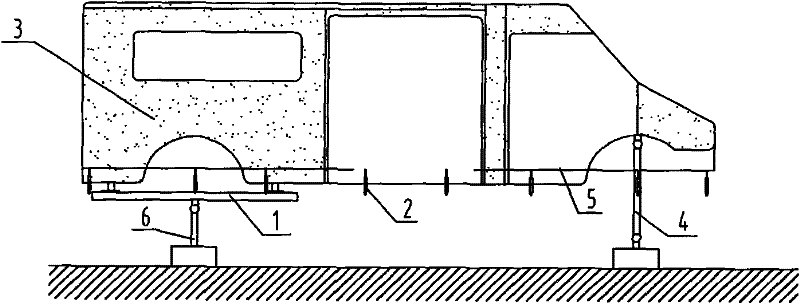

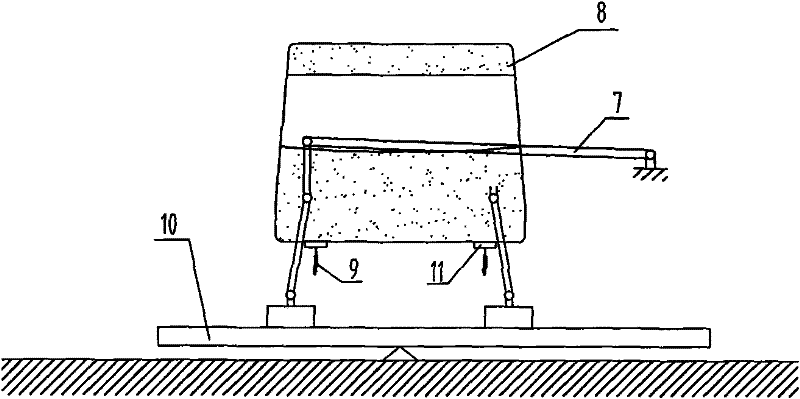

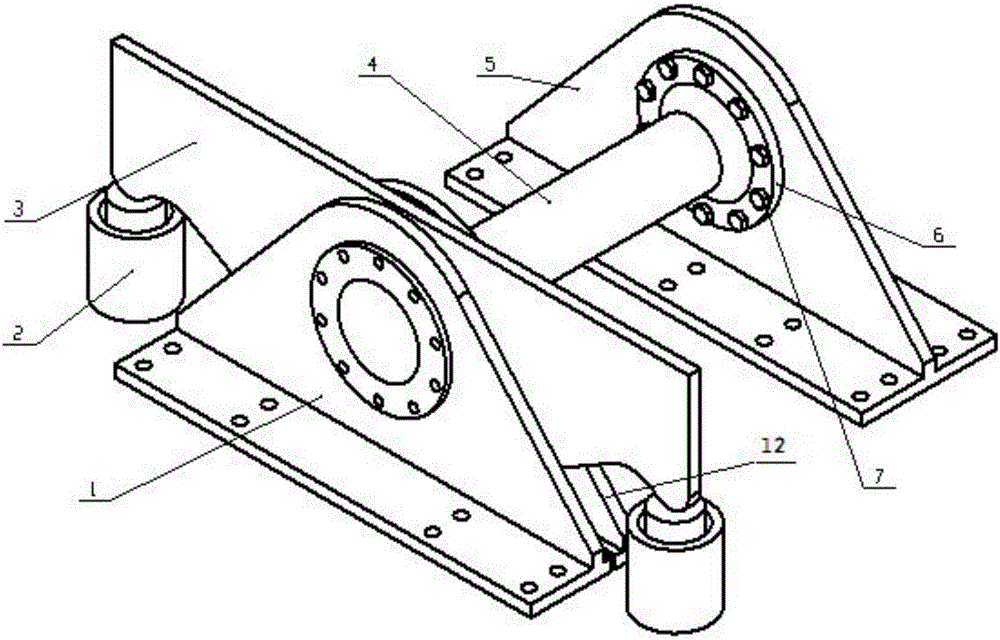

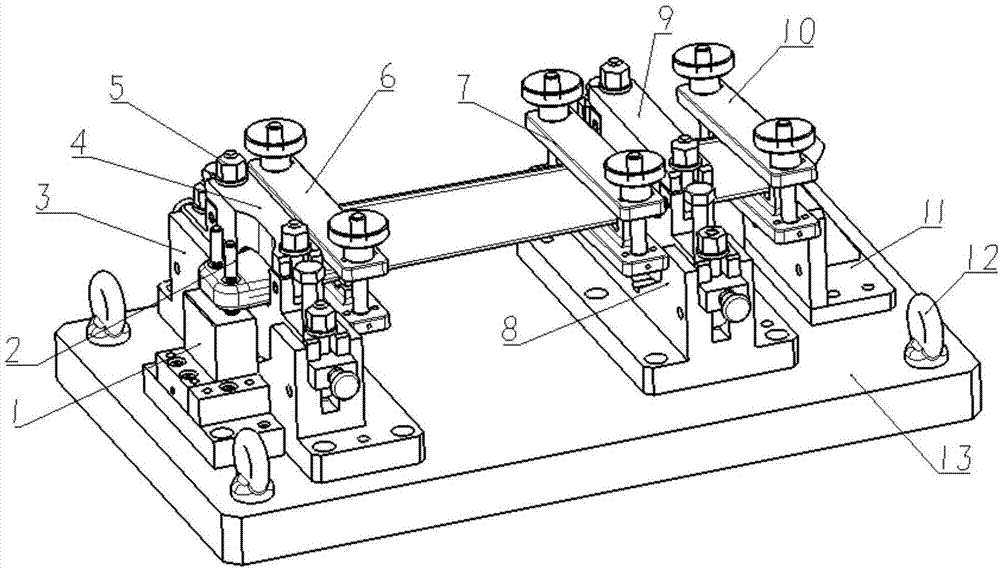

Method and device for detecting torsional angle, arch rise and pressure of wiper arm

ActiveCN104019787AImprove detection efficiencyImprove detection reliabilityForce measurementTorsional angleEngineering

The invention discloses a method and a device for detecting a torsional angle, arch rise and a pressure of a wiper arm. A wiper arm (7) placement detection piece, a display screen (15), a torsional angle alarm lamp (8), and a pressure alarm lamp (9) are arranged on a working platform; the placement detection piece comprises a rotary installation disc (4), a pressure sensor (3), a coder (1), a connecting shaft (2), a detection block (5), an arch rise detection sensor (6), an air cylinder (10) and a wiper arm rotary positioning base (12); an air cylinder rotary pressure head (11) is arranged under the air cylinder (10), an air cylinder pushing detection photoelectric sensor (16) is arranged near the air cylinder rotary pressure head (11), the wiper arm rotary positioning base (12) is arranged on a horizontal sliding block (13), and the horizontal sliding block (13) is provided with a horizontal movement screw rod (14). The device is capable of simultaneously measuring the torsional angle, the pressure and the arch rise of the wiper arm, capable of displaying specific values of the torsional angle and the pressure, and capable of performing alarming through an indication lamp for unqualified torsional angle, pressure and arch rise.

Owner:GUIYANG WANJIANG AVIATION ELECTROMECHANICAL

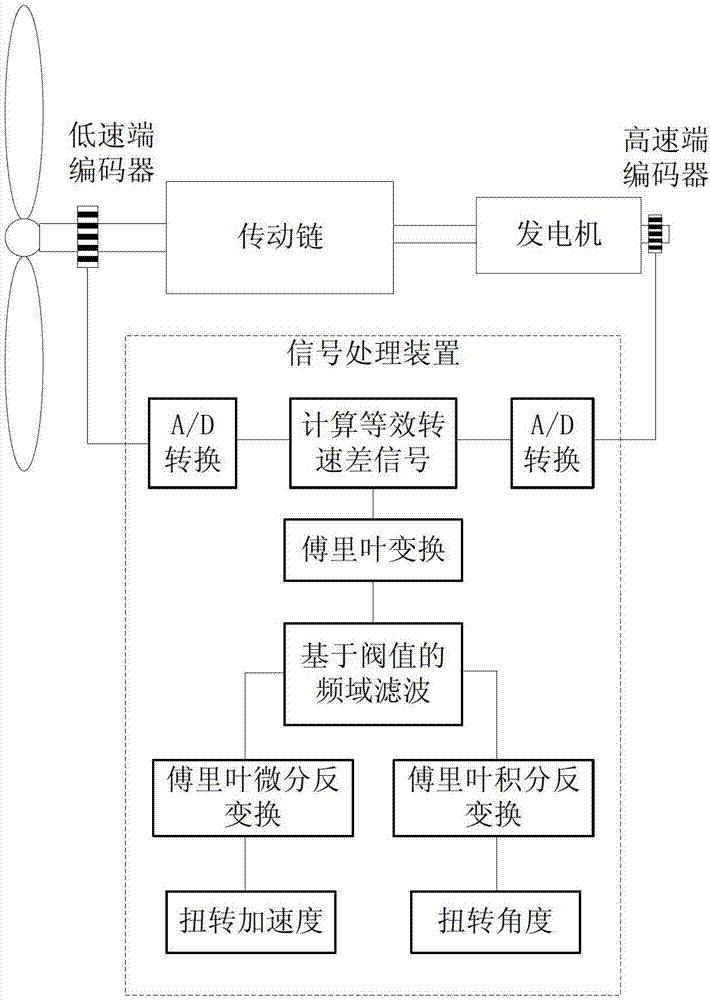

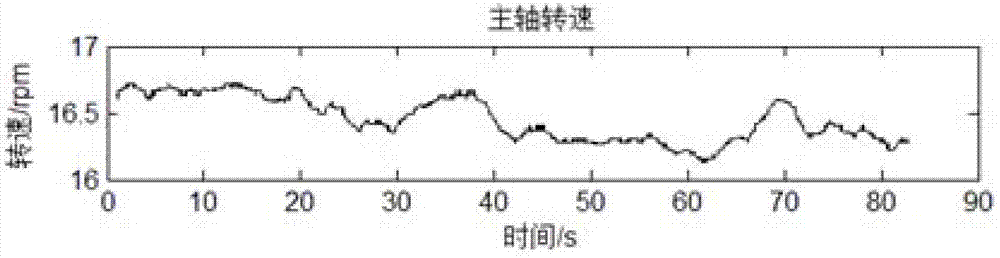

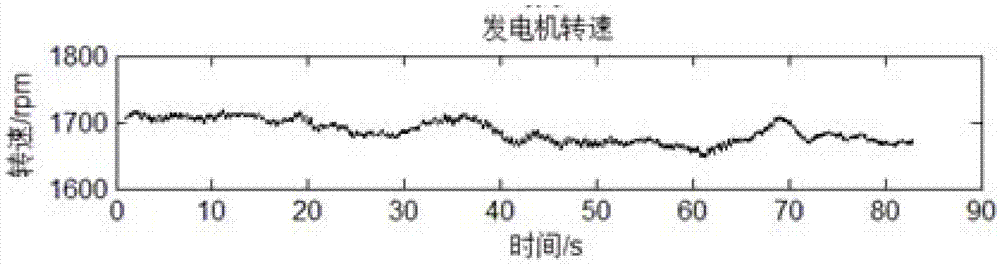

Wind turbine driving system torsional vibration measurement method and device

ActiveCN102809422ASimple structureReduce volumeSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansSequence signalMeasurement device

The invention relates to a wind turbine driving system torsional vibration measurement method and a wind turbine driving system torsional vibration measurement device. The method includes the steps of: synchronously collecting pulse signals of the rotating speed of the front end of a principal shaft of a driving chain and the rotating speed of the tail end of a power generator, and conducting A / D (Analog to Digital) conversion on the signals; calculating the shafting equivalent speed difference of the driving chain; conducting fast Fourier transformation on an equivalent speed difference sequence signal to obtain a frequency domain signal of the equivalent speed difference sequence signal; filtering the frequency domain signal; and working out the torsional angle acceleration and the torsional angle through Fourier differential and integral inverse transformation. The device comprises two rotary encoders which are respectively installed at the front end of the principal shaft and the tail end of the power generator, and a signal processing unit connected with the two rotary encoders. The device disclosed by the invention requires no independent signal acquisition unit and is simple in structure, small in size, stable and reliable in performance, long in service life, and can effectively get rid of noises and interfering signals to obtain accurate shafting torsional angle.

Owner:GUODIAN UNITED POWER TECH

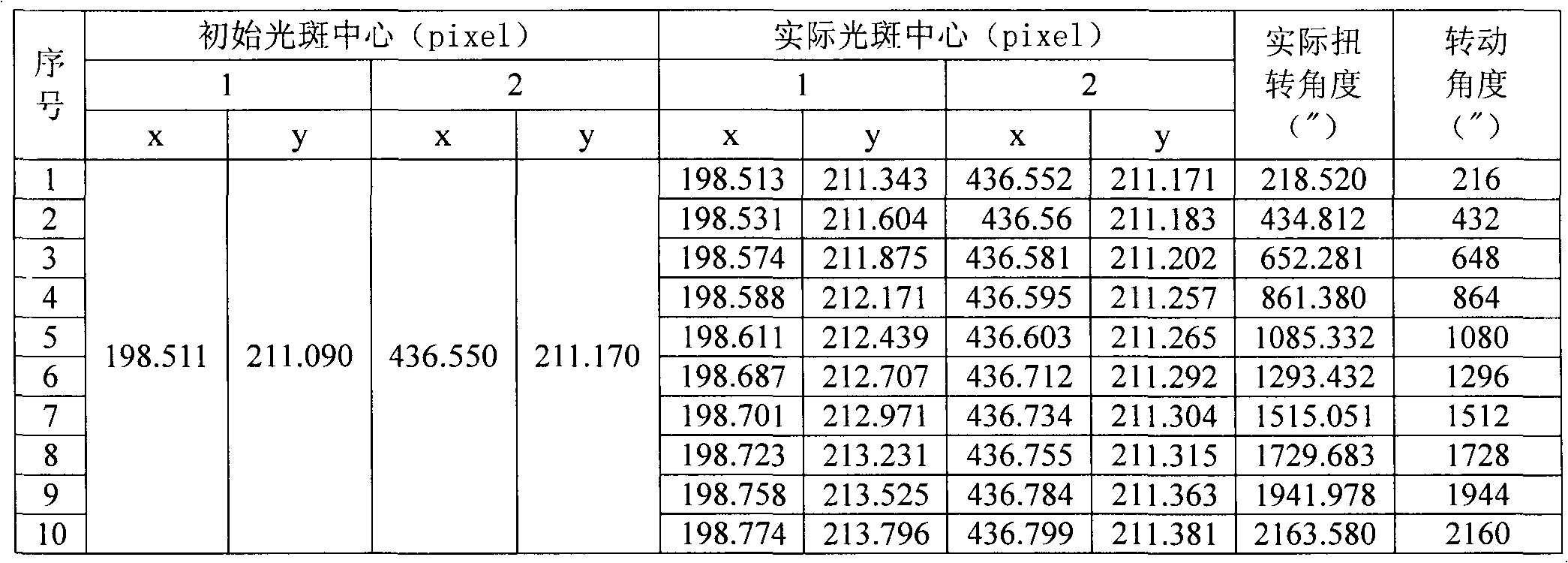

Device for testing torsional angle of mast system based on high speed camera and design method thereof

InactiveCN102032879ATroubleshooting Torsion Angle TestsHigh precisionTransmission systemsUsing optical meansElectricityLight spot

The invention relates to a device for testing the torsional angle of a mast system based on a high speed camera and a design method thereof, belonging to the field of image testing. The method comprises the following steps: fixing two high-energy lasers at the top of a tested mast system at a certain interval, so that the laser beams emitted from the high-energy lasers are respectively irradiated on an imaging plate arranged on a base so as to form two circular light spots; simultaneously, acquiring an image on the imaging plate in real time by the high speed camera, and extracting the central positions of the two light spots in the image; and in the process of lifting the tested mast system, twisting the two high-energy lasers with the tested mast system, recording the positions of determined initial lines of the light spots and the positions of real-time lines of the light spots in the process of twisting by the high speed camera, and calculating the torsional angle of the tested mast system. The device can test the torsional angle of a mast lifting system in a scout car, and has the advantages of high precision, good real-time property, and electricity saving and reduction of cable connections.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

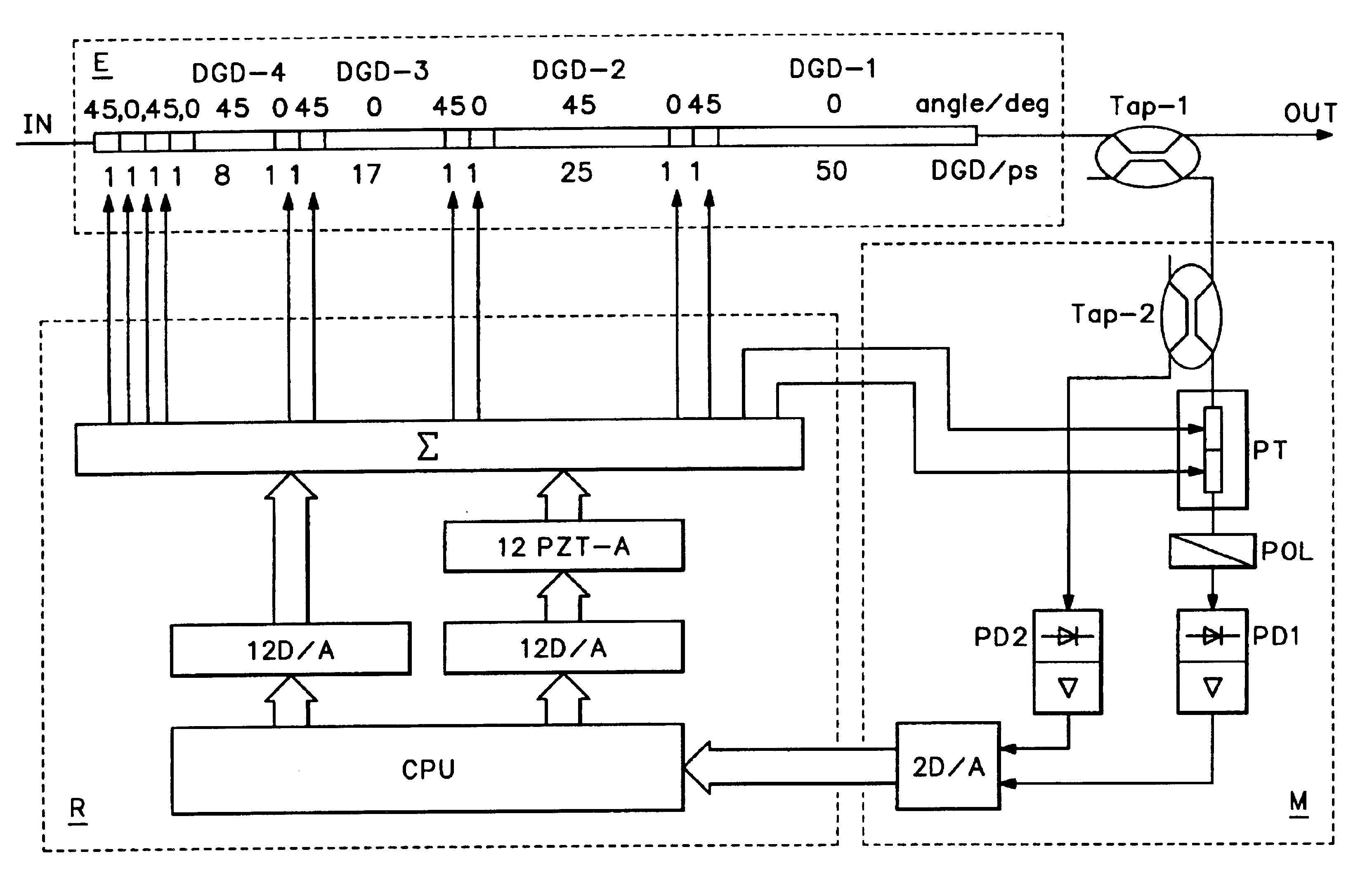

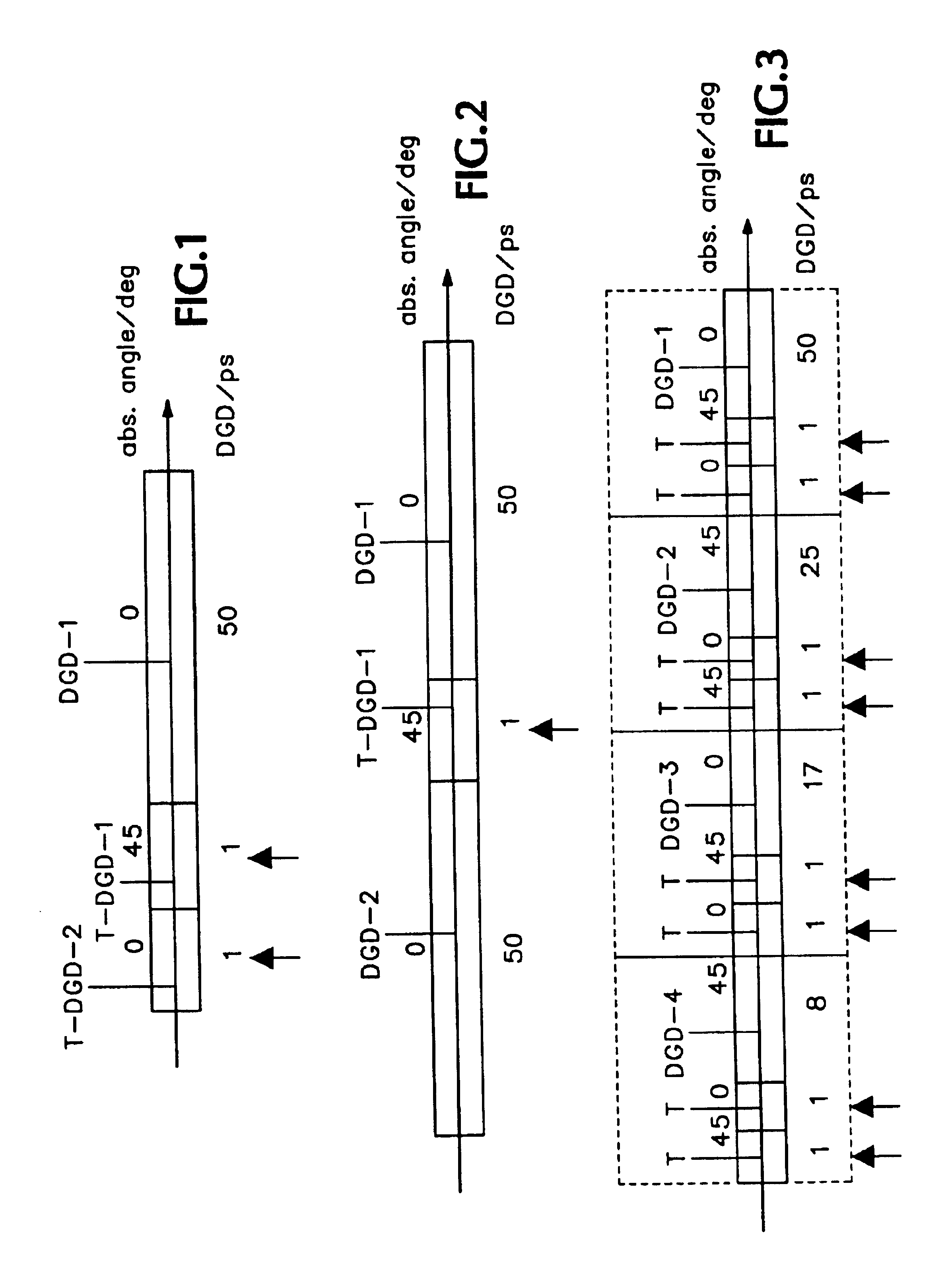

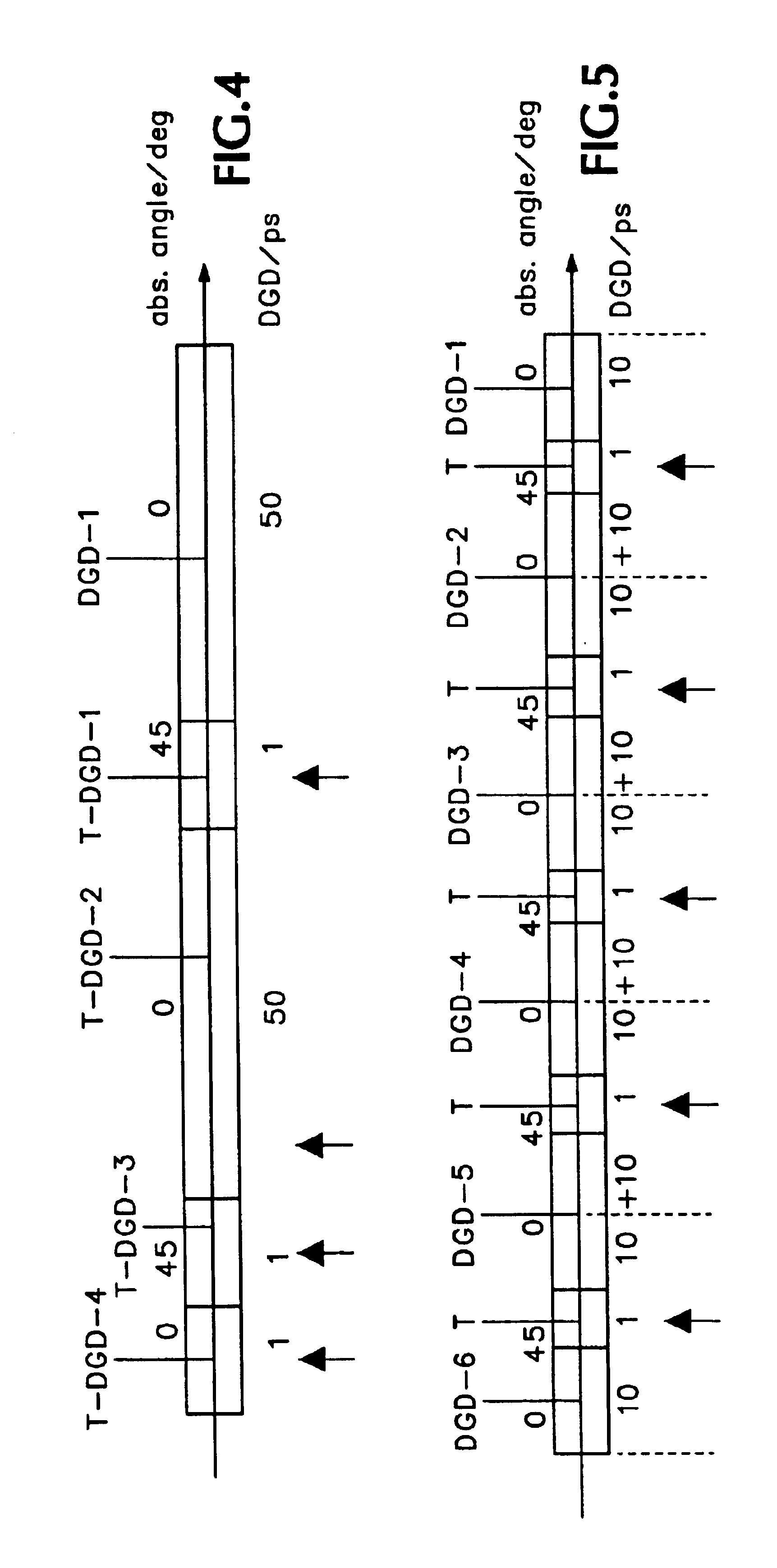

PMD emulation, measurement and compensation device

InactiveUS6996297B2Simple adjustabilityExact reproductionPolarising elementsElectromagnetic transmissionFiberMeasurement device

A PMD emulation, measurement and compensation device is based upon an emulation device having a piece of fiber having a fixed differential group delay (DGD) and another short piece of fiber (or double refracting crystal) having a variable differential group delay (T-DGD). The two pieces of fiber are coupled with a non-zero torsional angle between their respective double refractive axes, preferably 45°. A fiber squeezer / stretcher is used to provide the variable DGD for the short piece of fiber. Various serial couplings of DGD and T-DGD fiber may be added to provide greater control and accuracy, with the torsional angles preferably alternating. Such an emulation device may be incorporated into a measurement device to measure the PMD-related distortion of an optical signal. Further the measurement device may be used in a PMD compensator where an emulation device in series with the optical signal path is controlled until the measured PMD in the PMD-related distorted optical signal is minimized.

Owner:THORLABS INC

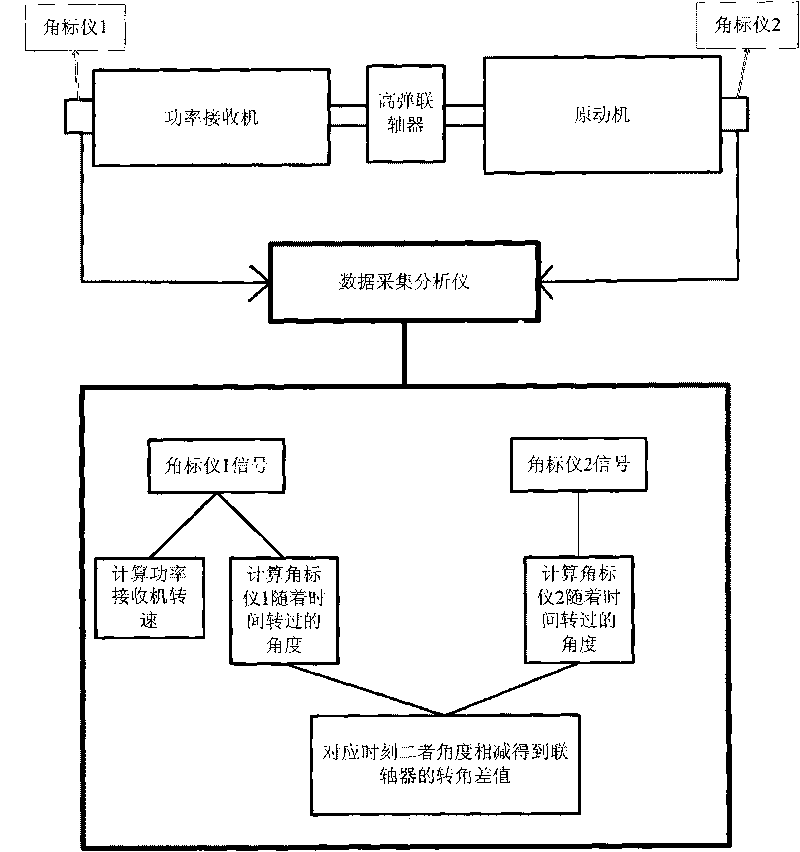

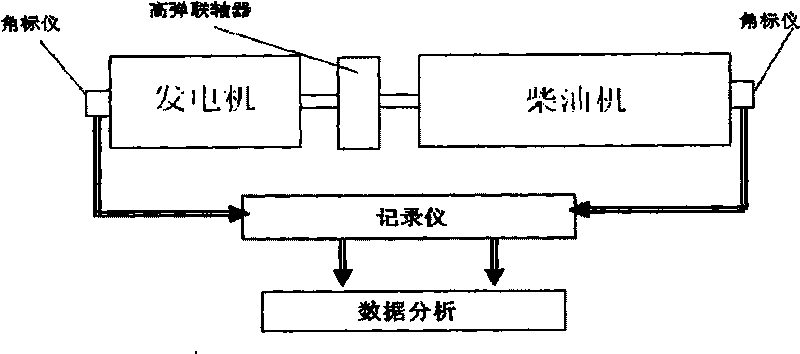

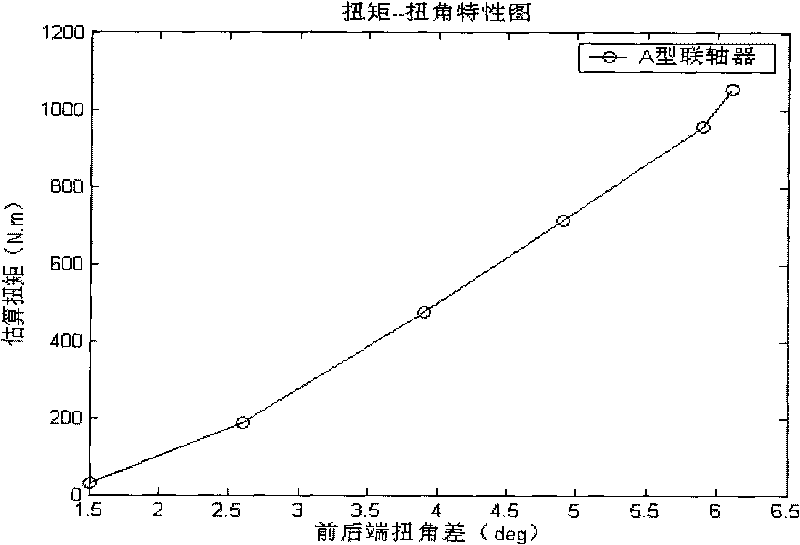

Dynamic and static torsional stiffness simultaneous measurement method of elastic coupling in working state

InactiveCN101718612AMachine part testingMaterial strength using steady torsional forcesTurn angleCoupling

The invention provides a dynamic and static torsional stiffness simultaneous measurement method of a resilient coupling in working state. A corner mark instrument is respectively arranged at both ends of a dynamic device comprising a power receiver, a prime motor and the elastic coupling connected between the power receiver and the prime motor, a data acquisition instrument acquires pulse signals sent by the two corner mark instruments when the dynamic device starts, the pulse signals of the two angle standard instruments are converted to torsional angles, then the angles of the corresponding time of the two corner mark instruments subtract each other to obtain turn angle difference responding to the torque born by the resilient coupling, and the torsional rigidity of the resilient coupling is further obtained. The measurement method of the invention can be carried out on an actual device, and a special experimental bench is not needed to be designed. By the measurement method of the invention, the torsional rigidity of the resilient coupling in actual working condition is obtained, and on-line measurement can be carried out when the dynamic device runs.

Owner:HARBIN ENG UNIV

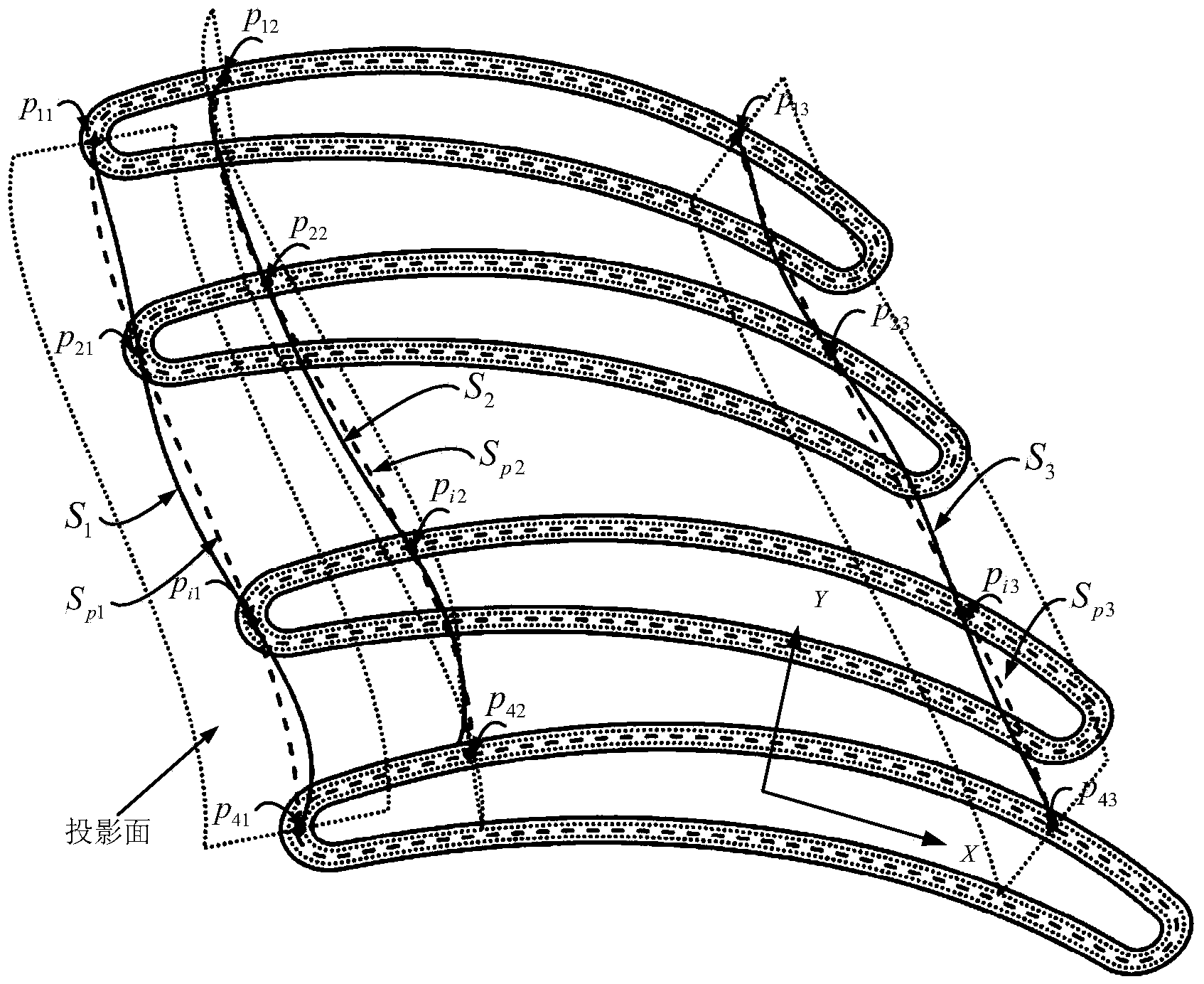

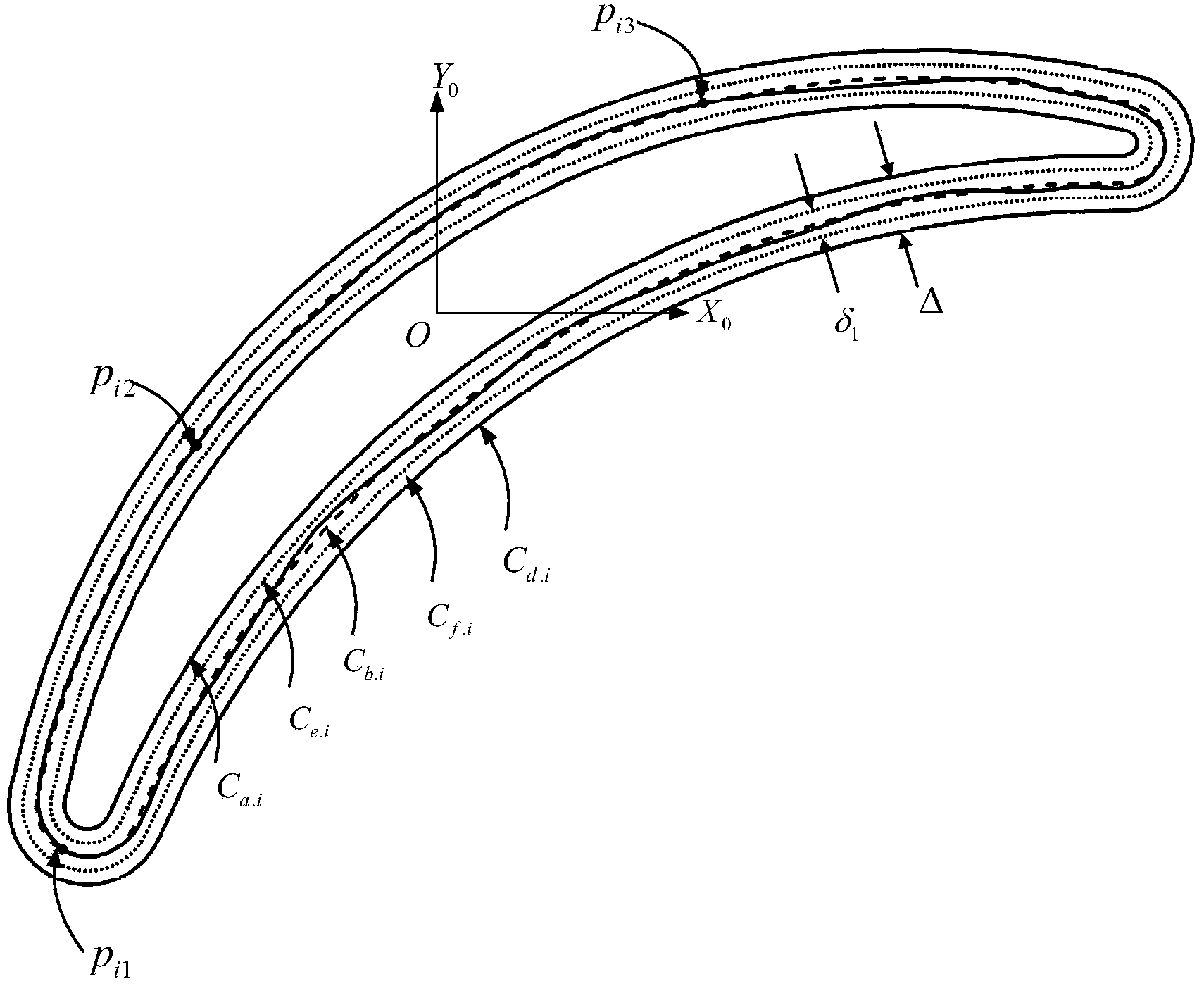

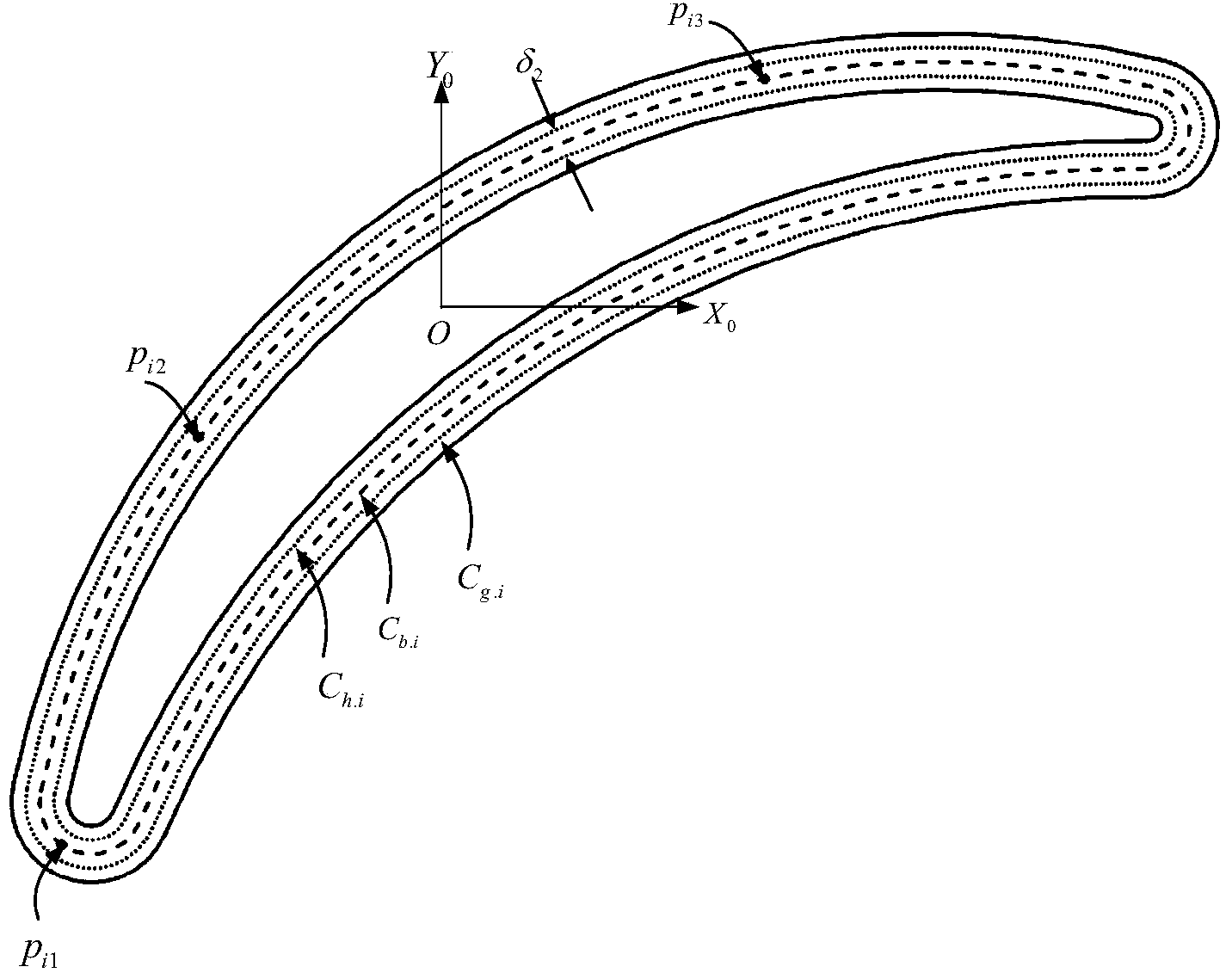

Layered fairing method for complex curved surface

ActiveCN103761389AMeet the design requirementsMeet processing requirementsSpecial data processing applicationsKeelTorsional angle

Disclosed is a layered fairing method for a complex curved surface. The method particularly includes the following steps: step 1, adopting a cubic B-spline curve to respectively interpolate given design data points to acquire all section shape lines namely tolerance baselines; step 2, fairing each section shape line, and lofting to acquire a reference curved surface; step 3, extracting three iso-curvature lines on the curved surface according to a preset method to serve as keel lines, respectively projecting the keel lines on a ruled surface of average normal vector span of curved surface points where the keel lines are positioned, and acquiring three projection keel lines; step 4, integrally fairing the projection keel lines in a projection plane according to a constraint condition that scaling, rotating and translation transformation of the section shape lines in a projection plane meets profile degree, position degree and torsional angle tolerance of the section shape lines to acquire transformation amount of the section shape lines, and re-lofting to acquire a faired curved surface. By the layered fairing method, the problem of fairing of the curved surface is converted into the problem of fairing of the section shape lines and the keel lines of the curved surface, so that the problem is greatly simplified, and the curved surface after being faired is ensured to be capable of meeting requirements on designing and processing.

Owner:BEIHANG UNIV +1

Method for detecting static rigidity of light passenger car body

InactiveCN101750196AImprove accuracyIncrease credibilityMaterial strength using steady bending forcesMaterial strength using steady torsional forcesTorsional angleBody flex

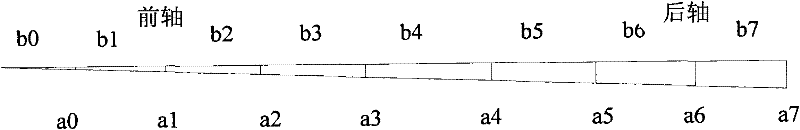

The invention relates to a static rigidity detection method, in particular to a method for detecting static rigidity of a light passenger car body, which comprises the following steps: applying a certain torque to the front part of the passenger car body by utilizing a lever, acquiring displacement deformations at two longitudinal beams of the passenger car body, calculating a torsional angle of the passenger body and calculating the slope f a fitting straight line according to the results of opposite torsional angles between a front axle and a rear axle of the passenger car body to obtain the torsional rigidity of the passenger car body; then, applying a certain bending moment to the middle part of the passenger car body by utilizing the lever or a weight, acquiring displacement deformations at the two longitudinal beams of the passenger car body, calculating the bending rigidity of the passenger car body according to maximal applying force and maximal deformation; finally, describing a torsional and bending curve by utilizing the data of the torsional and bending displacement deformations of the passenger car body and judging whether the partial performance of the passenger car body is proper according to the curve. The invention not only can obtain the static rigidity value of the passenger car body, but also can validate the accuracy of CAE analysis results and detect the result accuracy, thereby having higher reliability.

Owner:NANJING AUTOMOBILE GROUP CORP

Low-wind-speed variable-speed variable-pitch wind turbine blade optimum design method

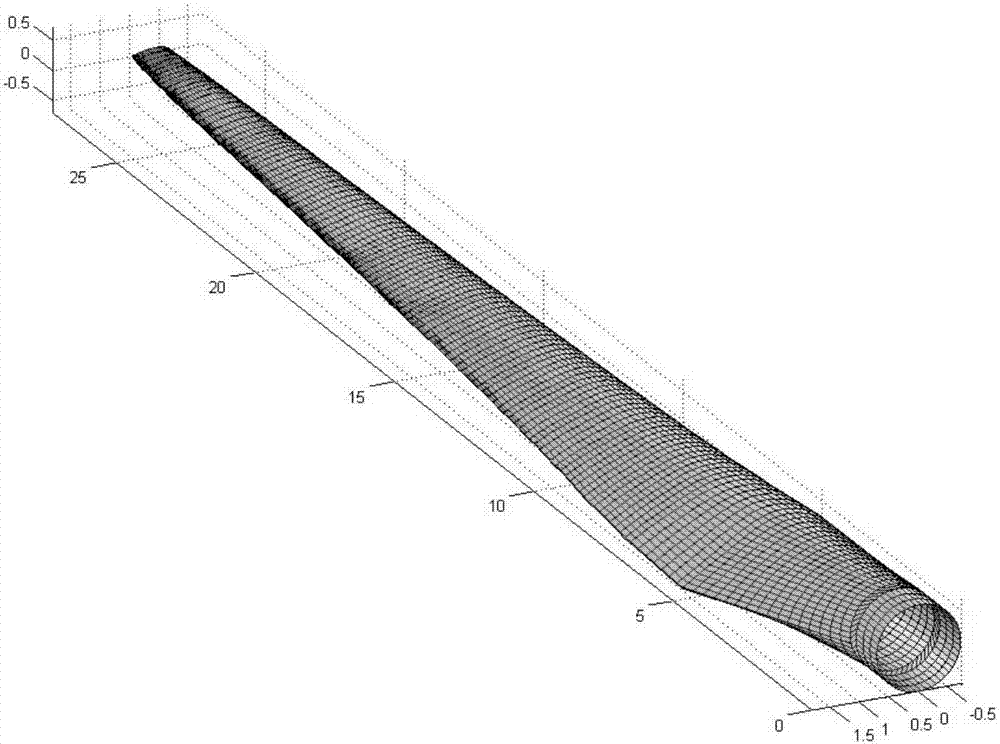

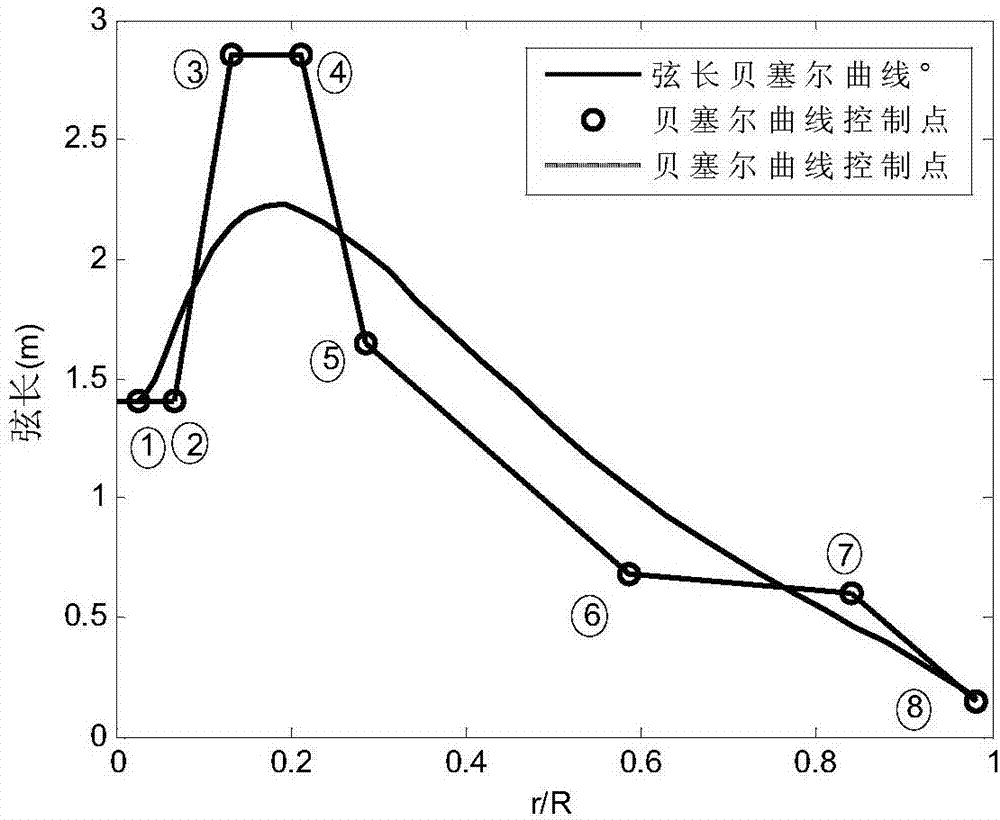

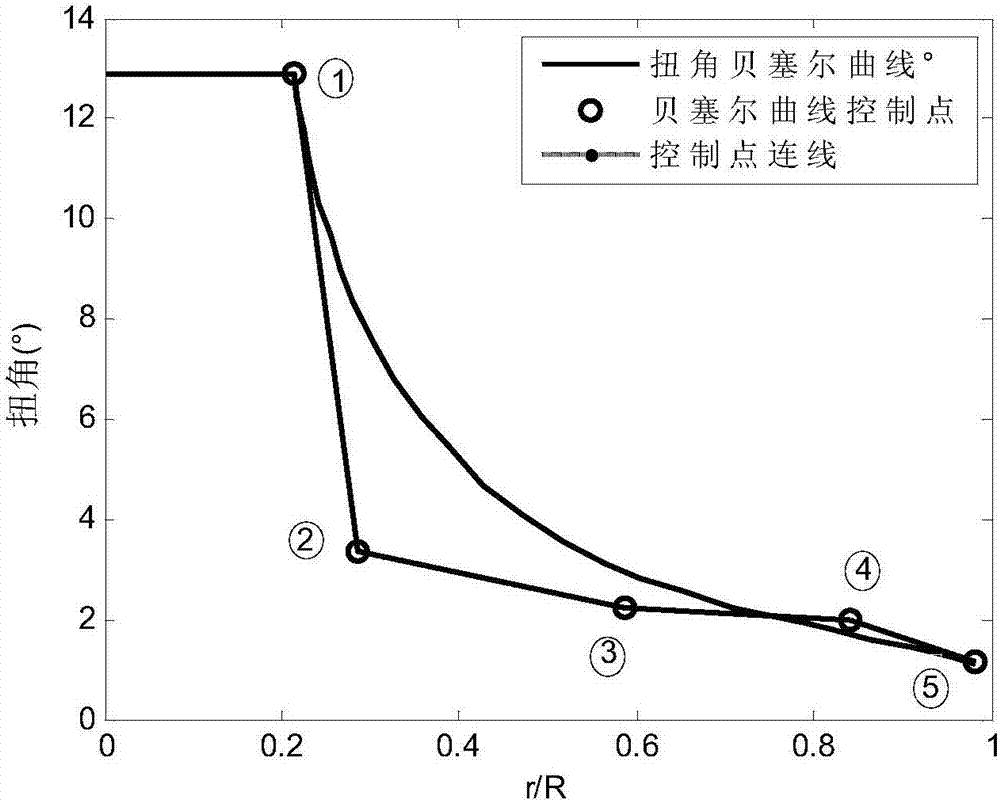

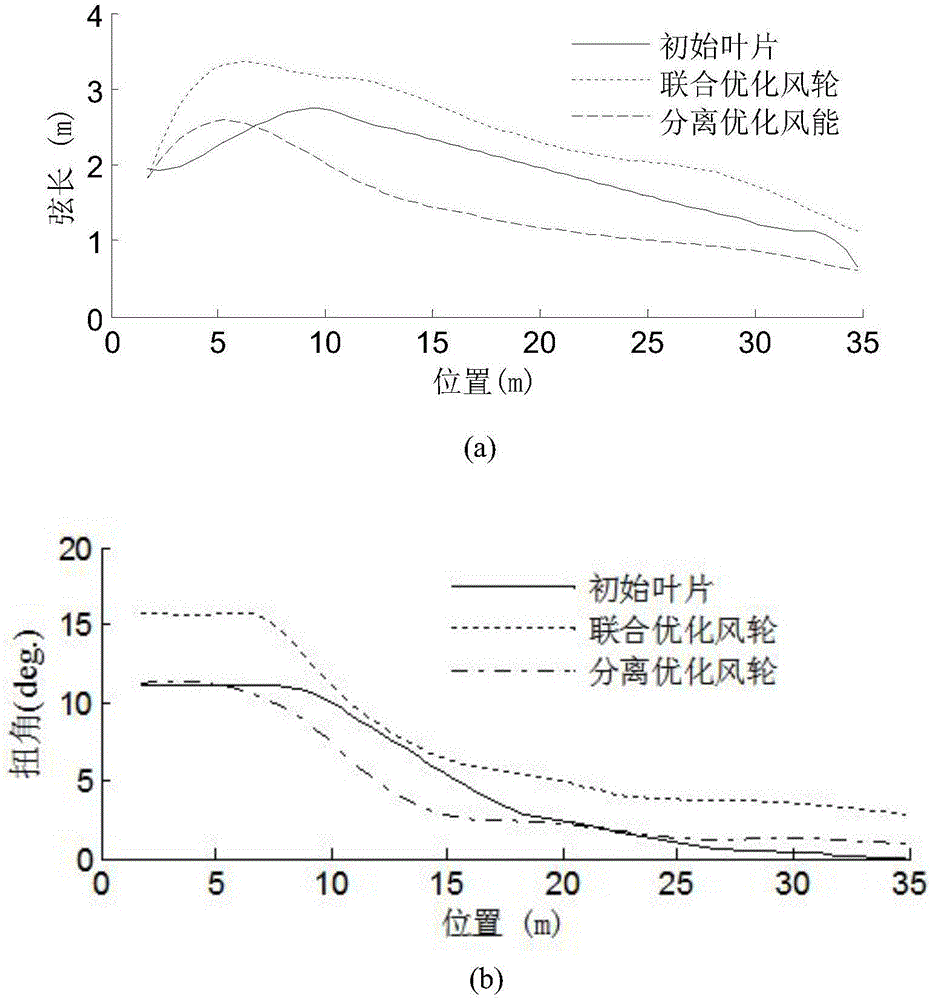

InactiveCN106894947ALower chord lengthLow costGeometric CADFinal product manufactureTurbine bladeTorsional angle

The invention relates to a low-wind-speed variable-speed variable-pitch wind turbine blade optimum design method, and belongs to the technical field of wind power generation. According to the low-wind-speed variable-speed variable-pitch wind turbine blade optimum design method, the largest annual energy output and the lowest material cost under the low-wind-speed condition serve as targets, a high order bezier curve is used for defining the chord length and the torsional angle of a blade on the overall length, and optimum control over the best pitch angle and torque-rotating speed is carried out while blade pneumatic shape optimization is carried out. Meanwhile, on the premise that the power generation amount and the lowest material cost are guaranteed, optimal solutions of the chord length and the torsional angle of each cross section of a blade are calculated through an optimization algorithm. The chord length of the wind turbine blade optimized through the method is greatly reduced, the blade area is reduced, the manufacturing material is effectively saved, reduction of the manufacturing cost is facilitates, and meanwhile, the annual energy output is effectively increased.

Owner:CHONGQING UNIV

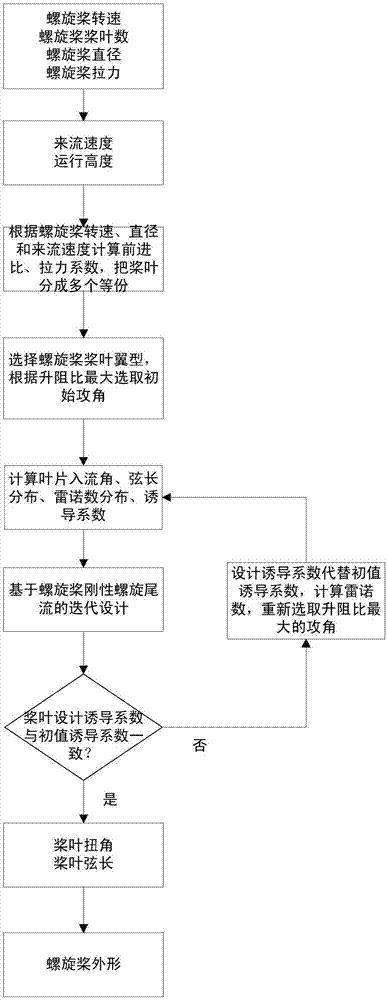

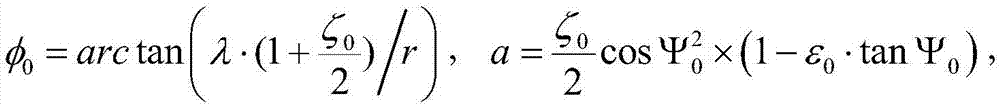

Low Reynolds number air propeller profile determining method

ActiveCN106945846AImprove design reliabilityImprove design efficiencyPropellersGround installationsHypothesisTorsional angle

A low Reynolds number air propeller profile determining method comprises the technological approach of determining blade chord length distribution and corresponding torsional angle distribution. The influence of the Reynolds number on blade aerofoil aerodynamic performance is introduced in the low Reynolds number air propeller profile determining method. Based on a hypothesis of a propeller rigidity helical trailing vortex, the blade chord length and the torsional angle distribution of a propeller are solved through an analysis and iteration method, the optimal chord length and the optimal torsional angle distribution of blades under the low Reynolds number are obtained, and accordingly aerodynamic profile determining of the low Reynolds number air propeller is completed. Rapid and efficient determining of the low Reynolds number air propeller profile is achieved, the tension requirement is automatically met, and aerodynamic profile shaping of the low Reynolds number air propeller is completed with maximum efficiency.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

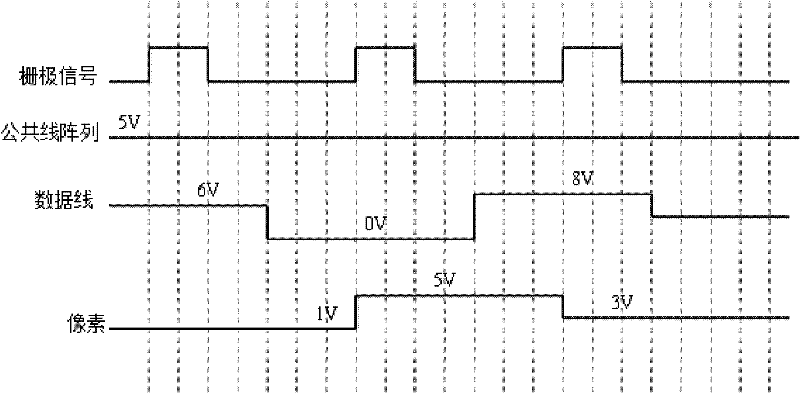

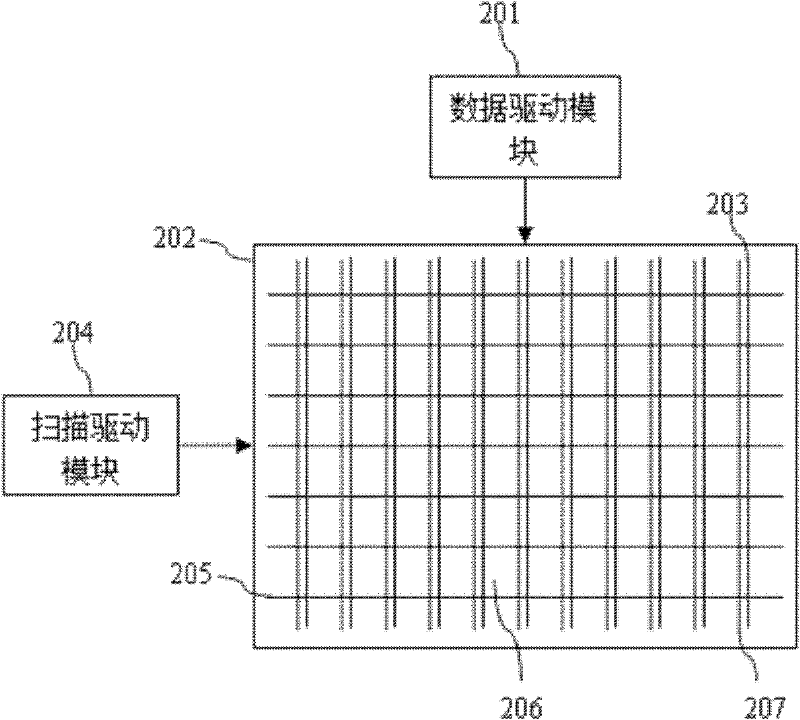

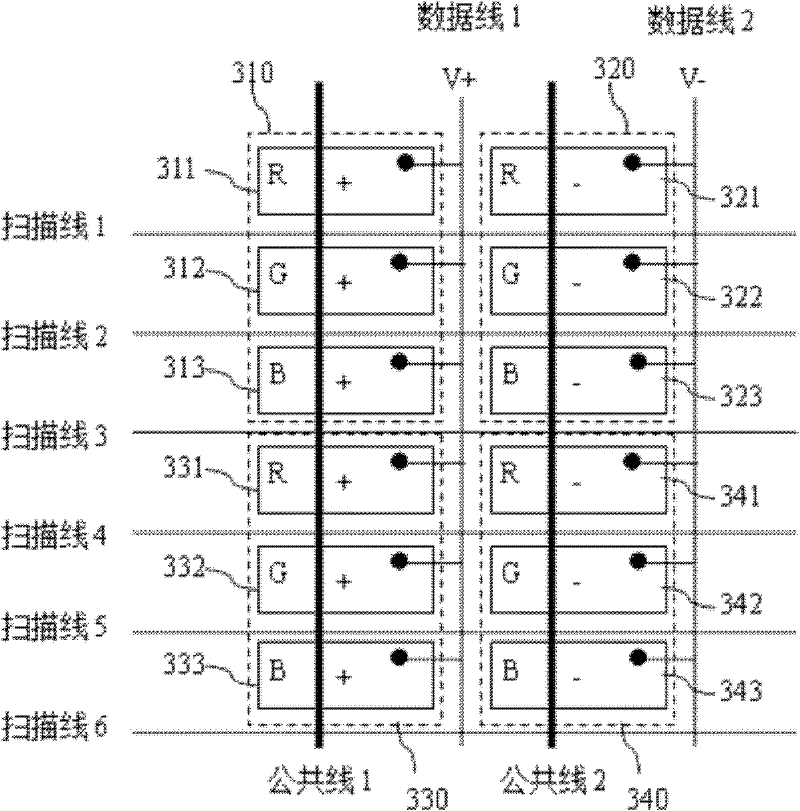

Liquid crystal display device and signal driving method thereof

ActiveCN102243853AAvoid incorrect twist anglesLow costStatic indicating devicesLiquid-crystal displayTorsional angle

The invention discloses a liquid crystal display device. The liquid crystal display device is characterized in that, based on the matching of intraframe precharging and high-low level signals of array common lines, high-voltage charging is carried out on pixels before each correct data signal is written to the pixels, i.e., the overdrive is carried out before the correct data signals are written to the pixels. The invention also discloses a signal driving method of the liquid crystal display device. Compared with the prior art, the liquid crystal display device has the following advantages: firstly, a frame buffer is not used, so that the cost is saved; secondly, a complex timing function is not needed for overdrive; and thirdly, if the traditional mode that signals are compared accordingto a table for carrying out overdrive, the phenomenon that the liquid crystal is driven instantaneously to cause incorrect torsional angles can be greatly avoided.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

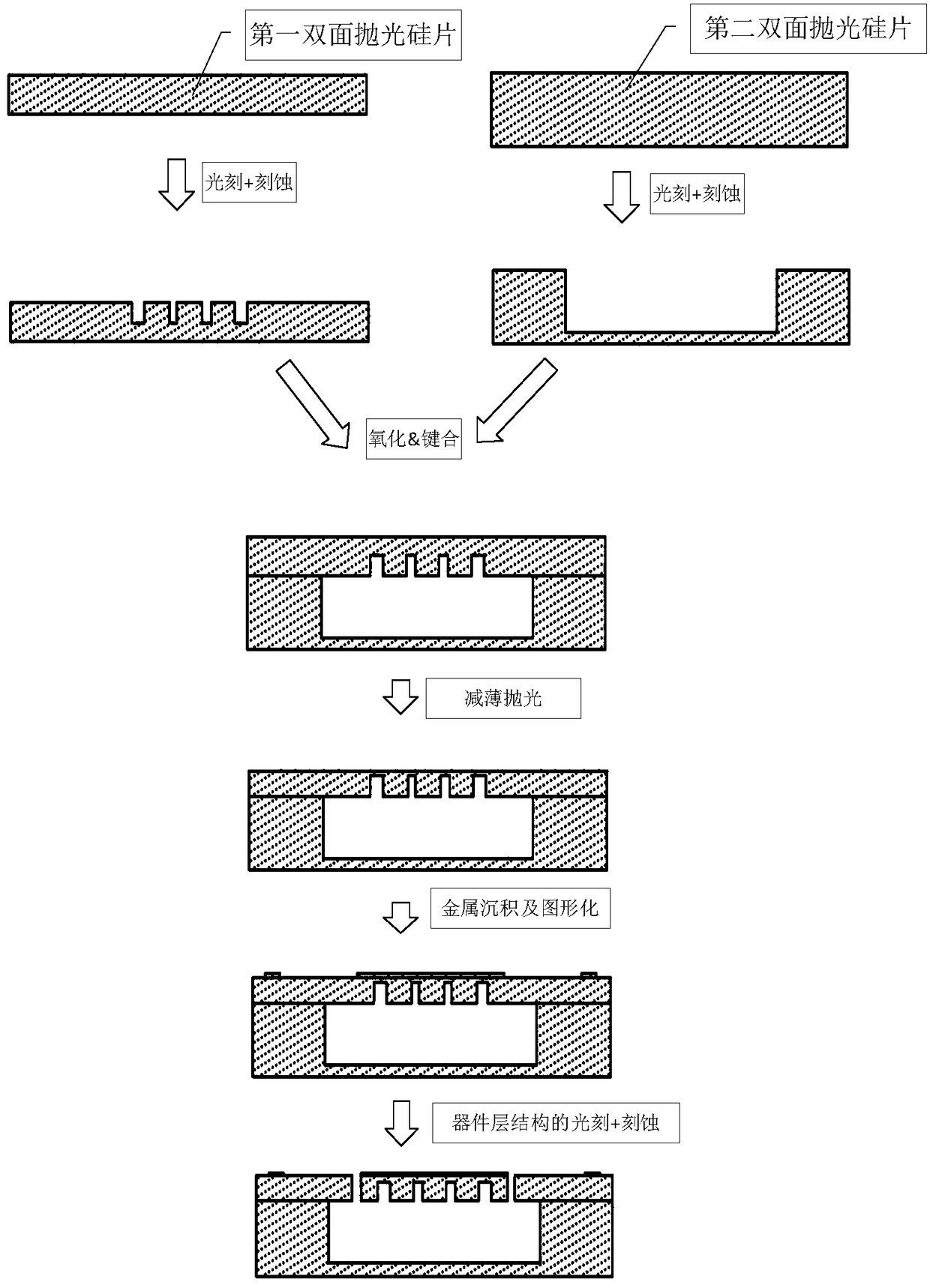

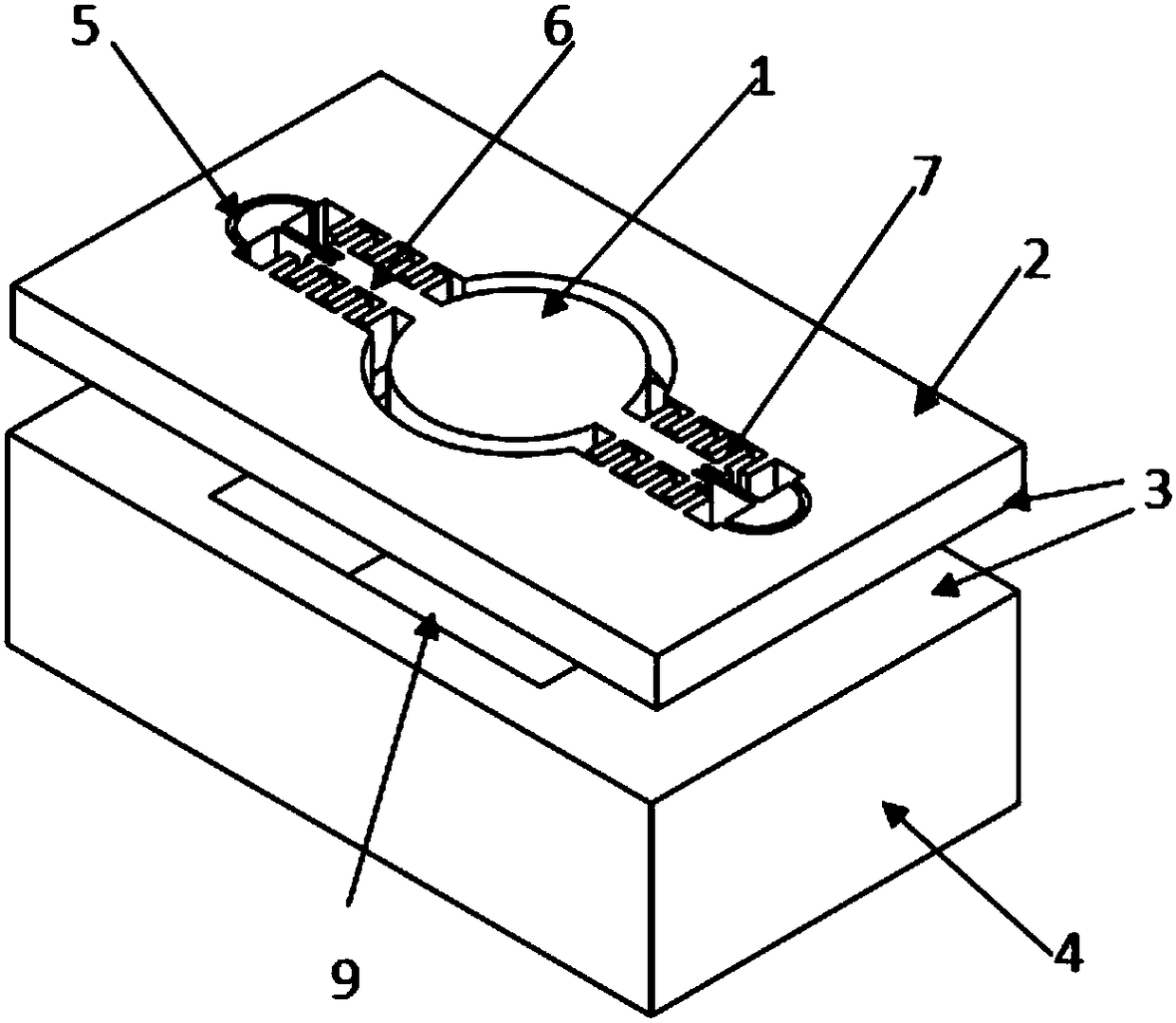

MEMS micro vibrating mirror and manufacturing method for prefabricating MEMS micro vibrating mirror based on SOI top silicon

ActiveCN108594428AImprove performanceImprove electrical isolationOptical elementsTorsional angleDegrees of freedom

The invention provides a MEMS micro vibrating mirror and a manufacturing method for prefabricating an MEMS micro vibrating mirror based on SOI top silicon. Before bonding to form an SOI wafer, a specific microstructure is prepared by micromachining on the back side of the top silicon to remove the partial mass of the mirror surface and maintain the structural strength and size of the mirror, meanwhile, a chamber is prepared in advance on the front side of the bottom silicon according to the size of the space required for the torsional motion of the mirror, then the micro-structured sides of the top silicon and the bottom silicon are aligned and bonded to form the SOI wafer and then thin the SOI wafer to the target thickness by the grinding and polishing process, and finally, a metal reflective layer and a mirror movable structure required are processed and manufactured on the front surface of the top silicon, so that the problem of torsional angle and performance of the vibrating mirror due to overlarge mass of the large-sized mirror surface structure of the MEMS micro vibrating mirror processed by the conventional SOI wafer is solved, thereby expanding the degree of freedom of MEMS micro vibrating mirror design and processing, and improving the performance of the MEMS micro vibrating mirror, and being of great significance especially for the fabrication of the MEMS micro vibrating mirror with high reliability and large mirror size.

Owner:XI AN ZHISENSOR TECH CO LTD

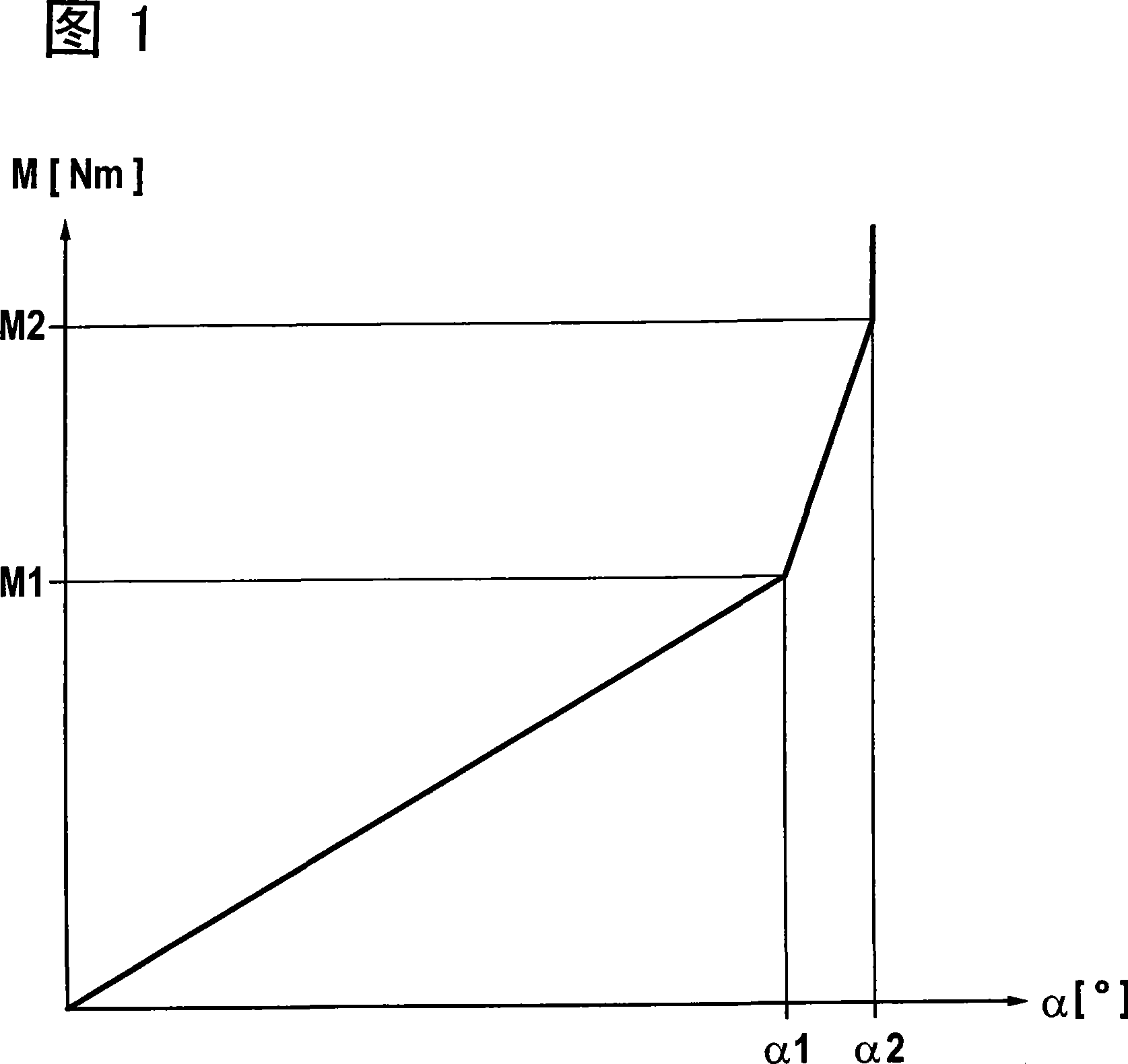

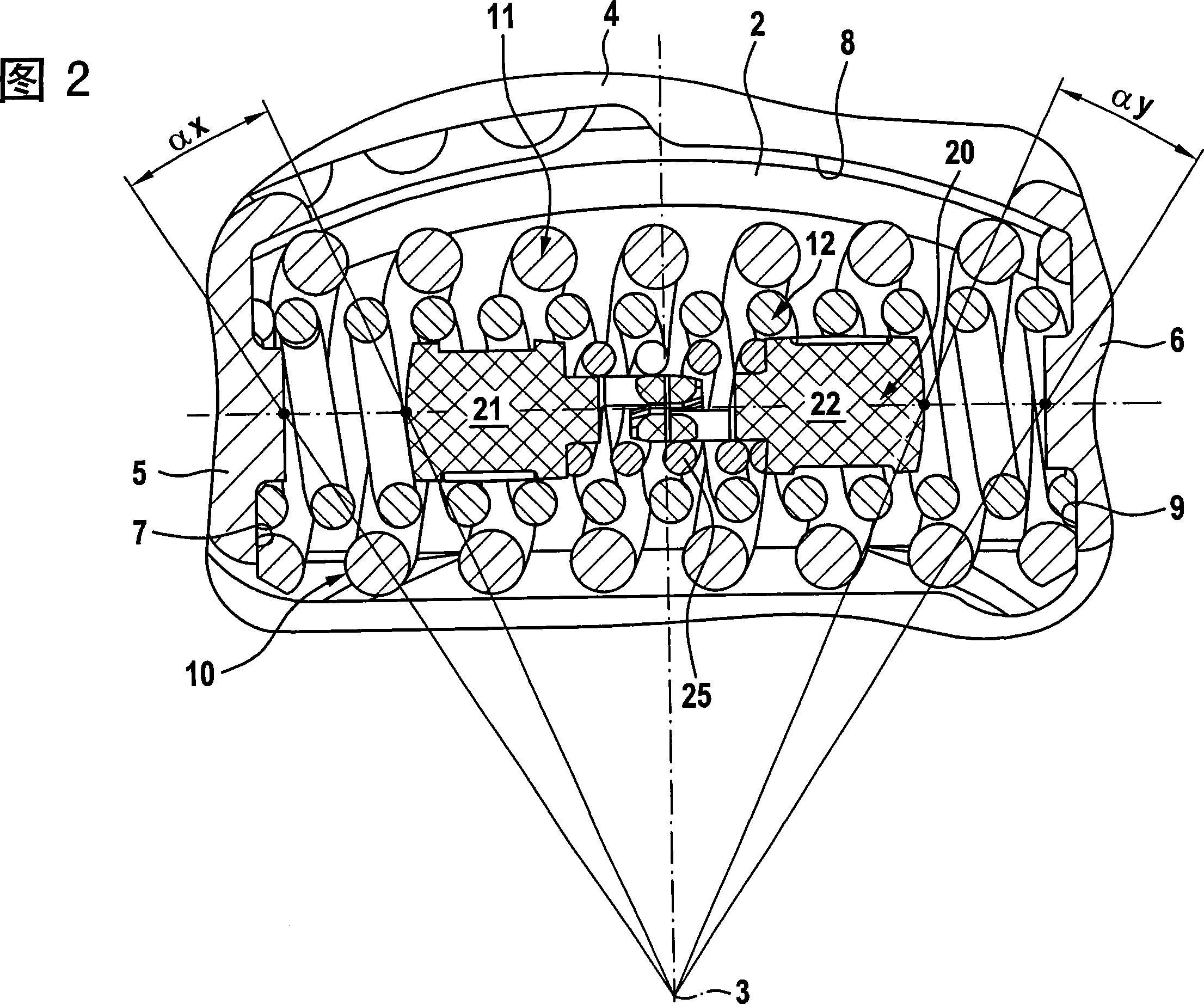

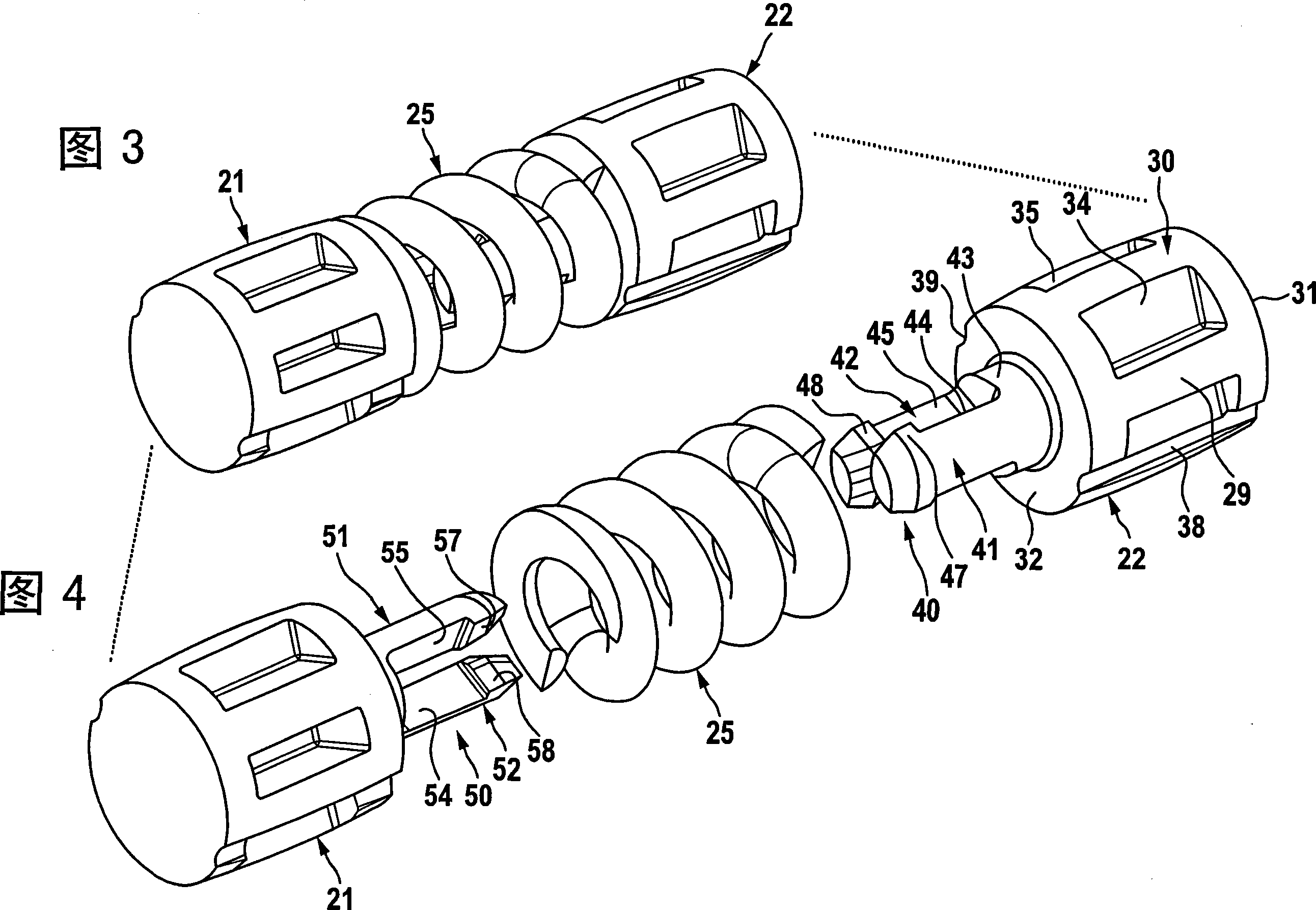

Torsional vibration damper

InactiveCN101205959AEnough capacityEasy to assembleSpringsVibration suppression adjustmentsTorsional angleTorsional vibration

The invention relates to a torsional vibration damper, in particular to a separated flywheel. The invention is provided with an enter piece and an output piece. The output piece stands against the resistance of at least one energy storage device. Besides, the output piece can turn relative to the enter piece from a certain torsional angle, resisting the resistance of a floating stop spring device relative to the energy storage device additively. The invention is characterized in that the stop spring device comprises two end parts coupled with each other, and these end parts can restrictedly move towards the same direction or opposite directions.

Owner:SCHAEFFLER TECH AG & CO KG

Online diagnosis method for reciprocating mechanical failure

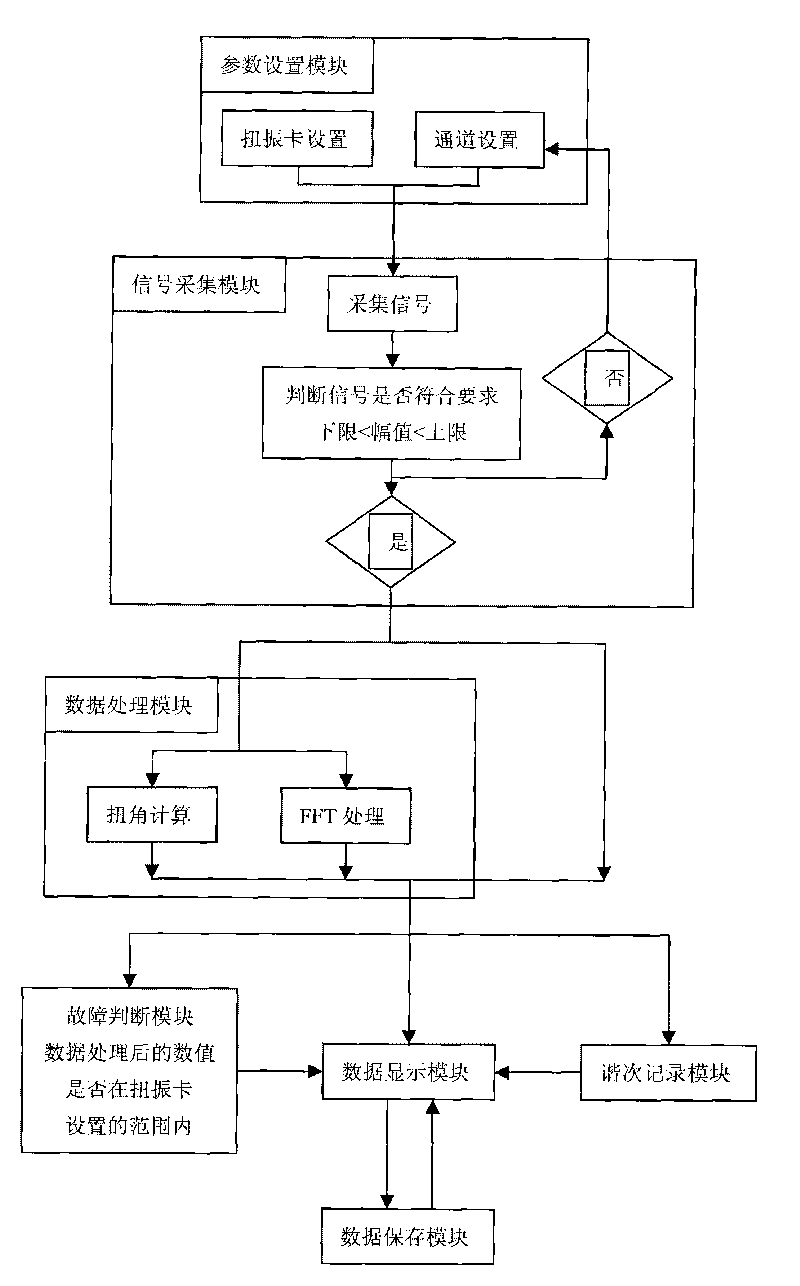

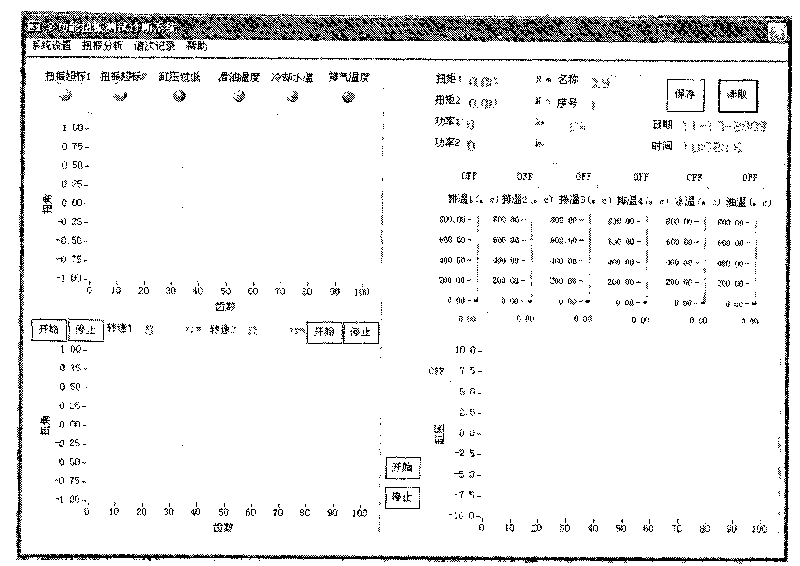

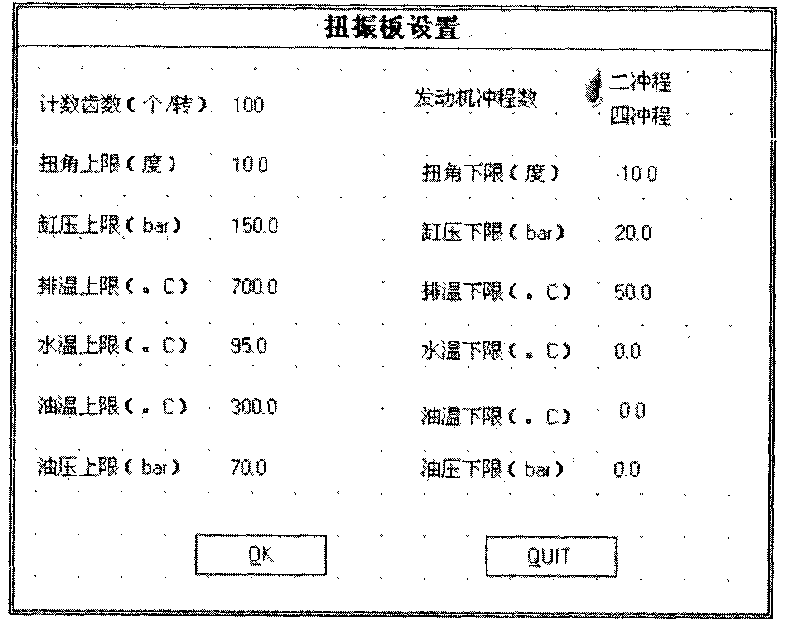

InactiveCN101762381AEasy to drawWith save functionVibration measurement in solidsMachine part testingData displayTorsional vibration

The invention provides an online diagnosis method for reciprocating mechanical failure, which includes a parameter setting module, a signal collecting module, a data processing module, a failure judging module, a humorous frequency recording module, a data displaying module and a data keeping module. The parameters set by the parameter setting module are connected into the signal collecting module to measure the signals like torsional vibration, pressure and temperature, etc, of a target to be measured, and judge whether a voltage signal is within the parameter scope in channel setting or not, partially access the torsional vibration signal in the collected signals into the data processing module, implement FFT treatment on data and implement calculation treatment on torsional angles; the signals except the torsional vibration signal directly enter the next flow and the data respectively enters the humorous frequency recording module, the failure judging module and the data displaying module. The online diagnosis method for reciprocating mechanical failure can judge the types of the generated failures according to the torsional vibration signal and the spectrum analysis result thereof as well as the parameters like cylinder pressure, oil temperature, water temperature and temperature discharge.

Owner:HARBIN ENG UNIV

Wind turbine aerodynamic-designing method considering static and dynamic influence of designed tip speed ratio on wind wheel

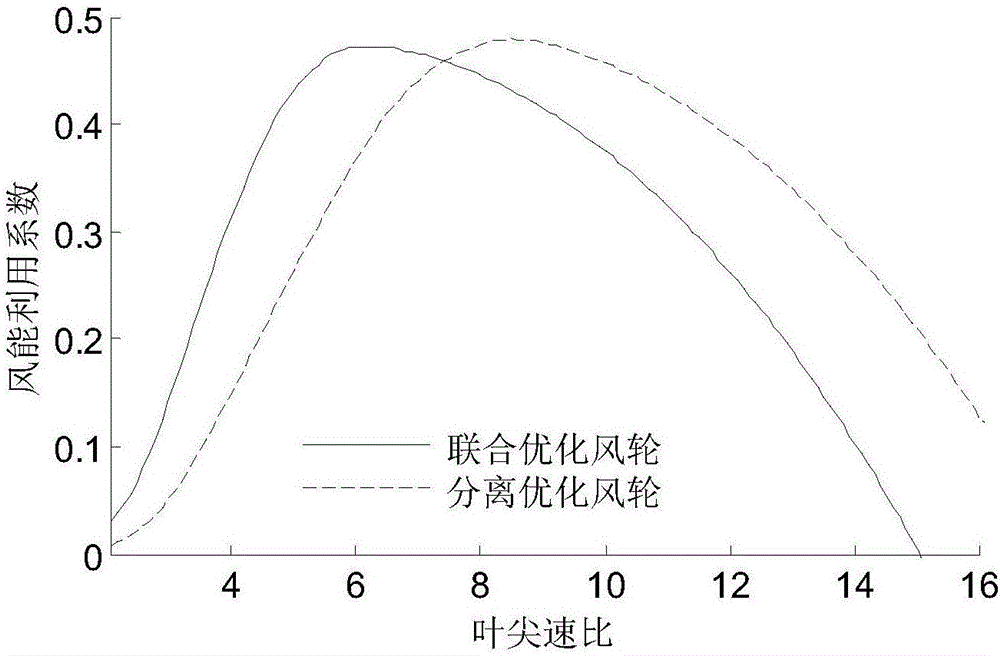

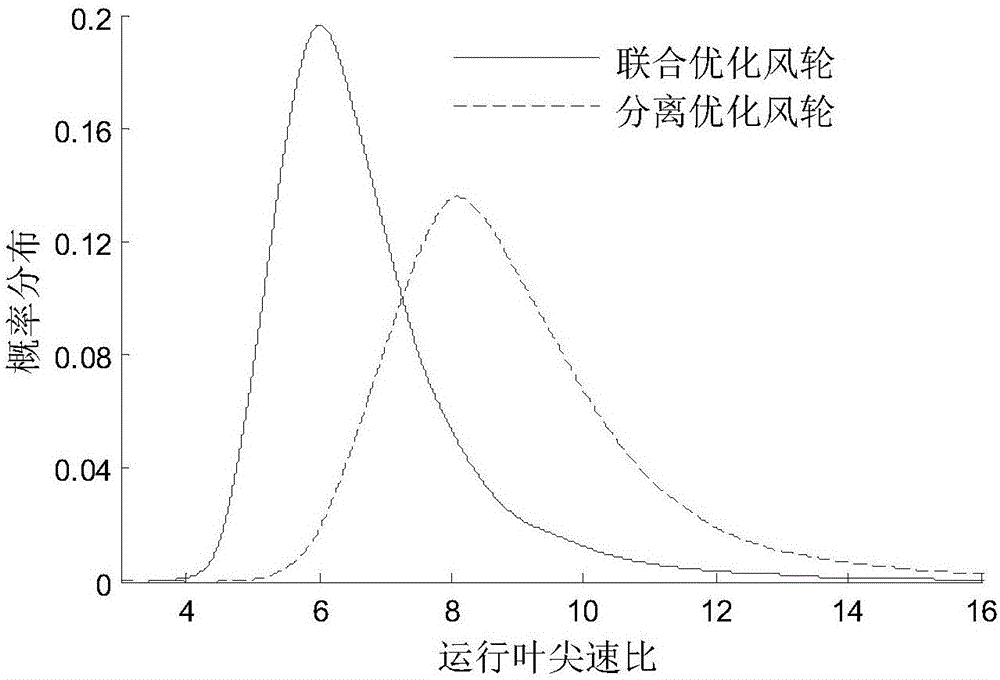

ActiveCN106777525AImproving Wind Energy Capture EfficiencyVerify validityDesign optimisation/simulationSystems intergating technologiesTorsional angleClosed loop

Owner:NANJING UNIV OF SCI & TECH

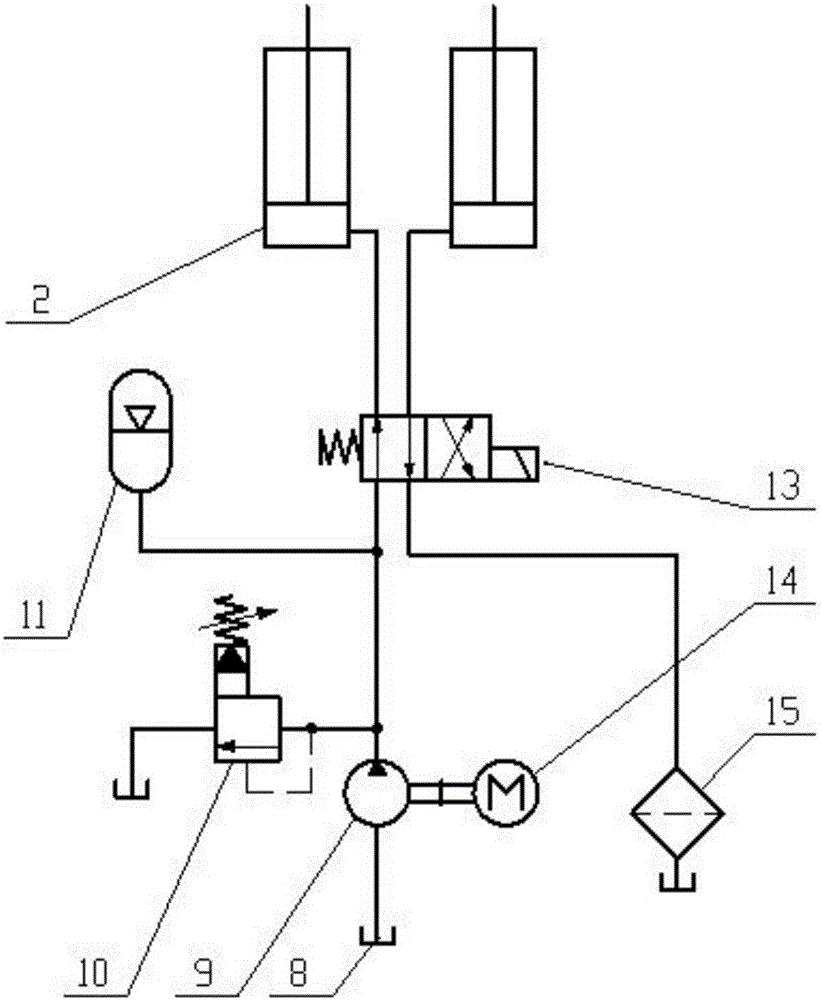

Apparatus for large-torque torsional fatigue tests of shaft parts

ActiveCN106525616ASimple structureLow costMaterial strength using repeated/pulsating forcesFatigue loadingControl system

The invention provides an apparatus for large-torque torsional fatigue tests of shaft parts, belonging to the technical field of material testing. The apparatus comprises two hydraulic oil cylinders, two crossbeam pedestals, a crossbeam, a testing shaft, a connecting flange, a fixed pedestal, a torsional angle displacement sensor, an oil pressure sensor and a hydraulic pressure control system. The two crossbeam pedestals and the fixed pedestal are fixed via foundation bolts, and then pressure oil is controlled to separately and alternately enter the two hydraulic oil cylinders, so alternate fatigue load can be applied to a to-be-tested shaft; and pressure oil is controlled to enter one of the two hydraulic oil cylinders while the other hydraulic oil cylinder is unloaded, and oil supply pressure is continuously increased, so the limit torsional load of the to-be-tested shaft can be tested. The apparatus provided by the invention can realize testing of the alternate fatigue load and limit torsional load of shaft parts, and is simple in structure, great in loading capability, high in work efficiency and easy to operate.

Owner:UNIV OF SCI & TECH BEIJING

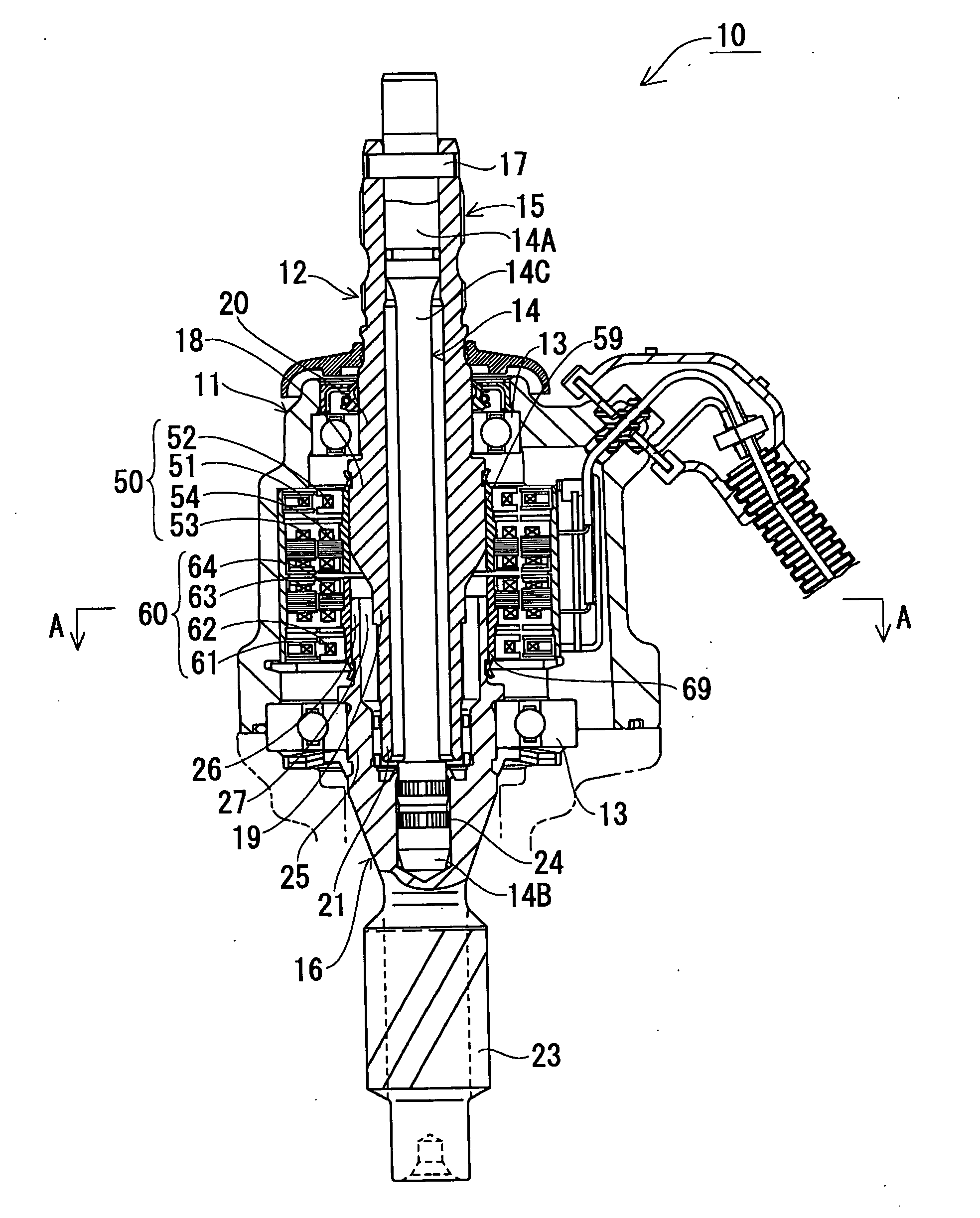

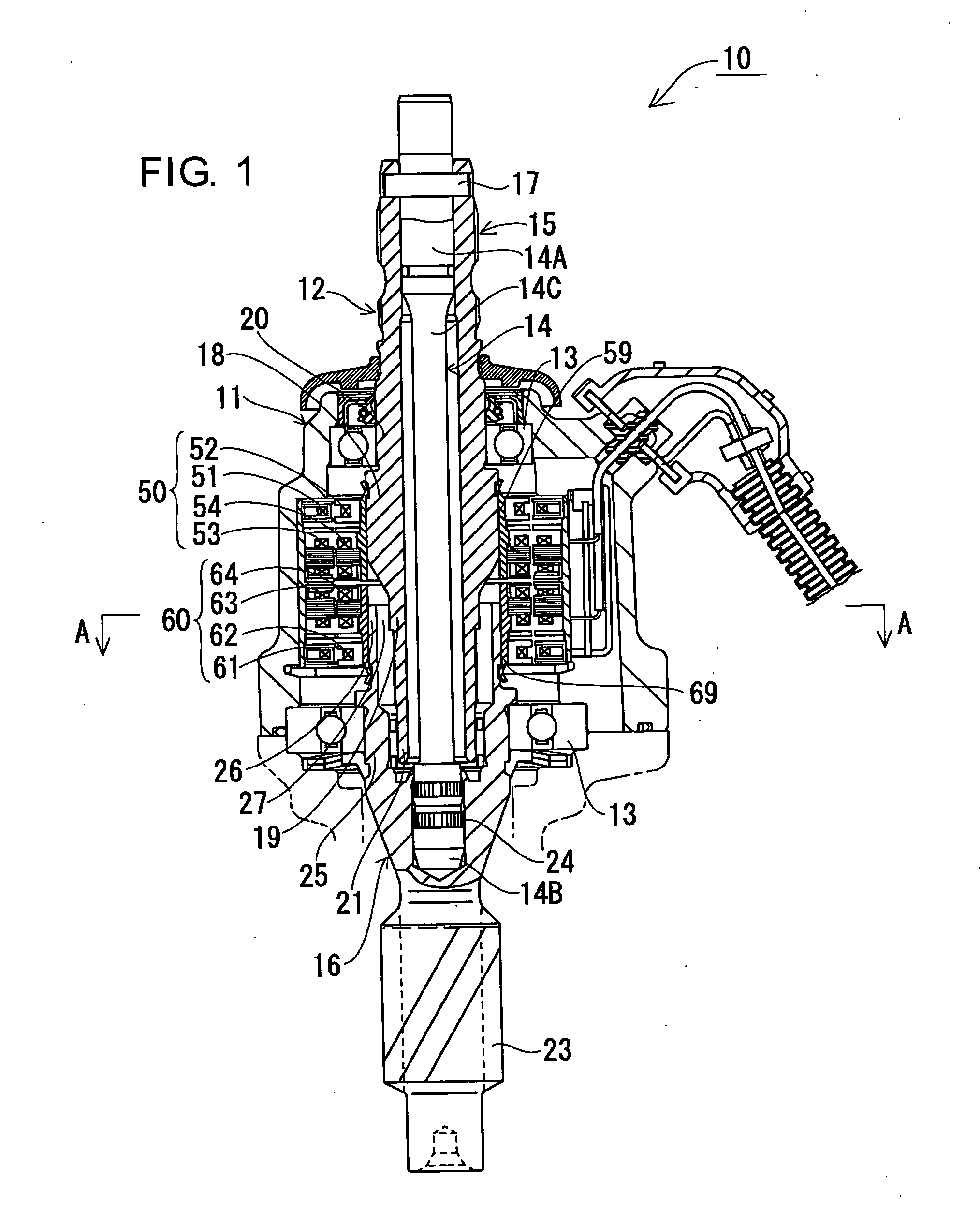

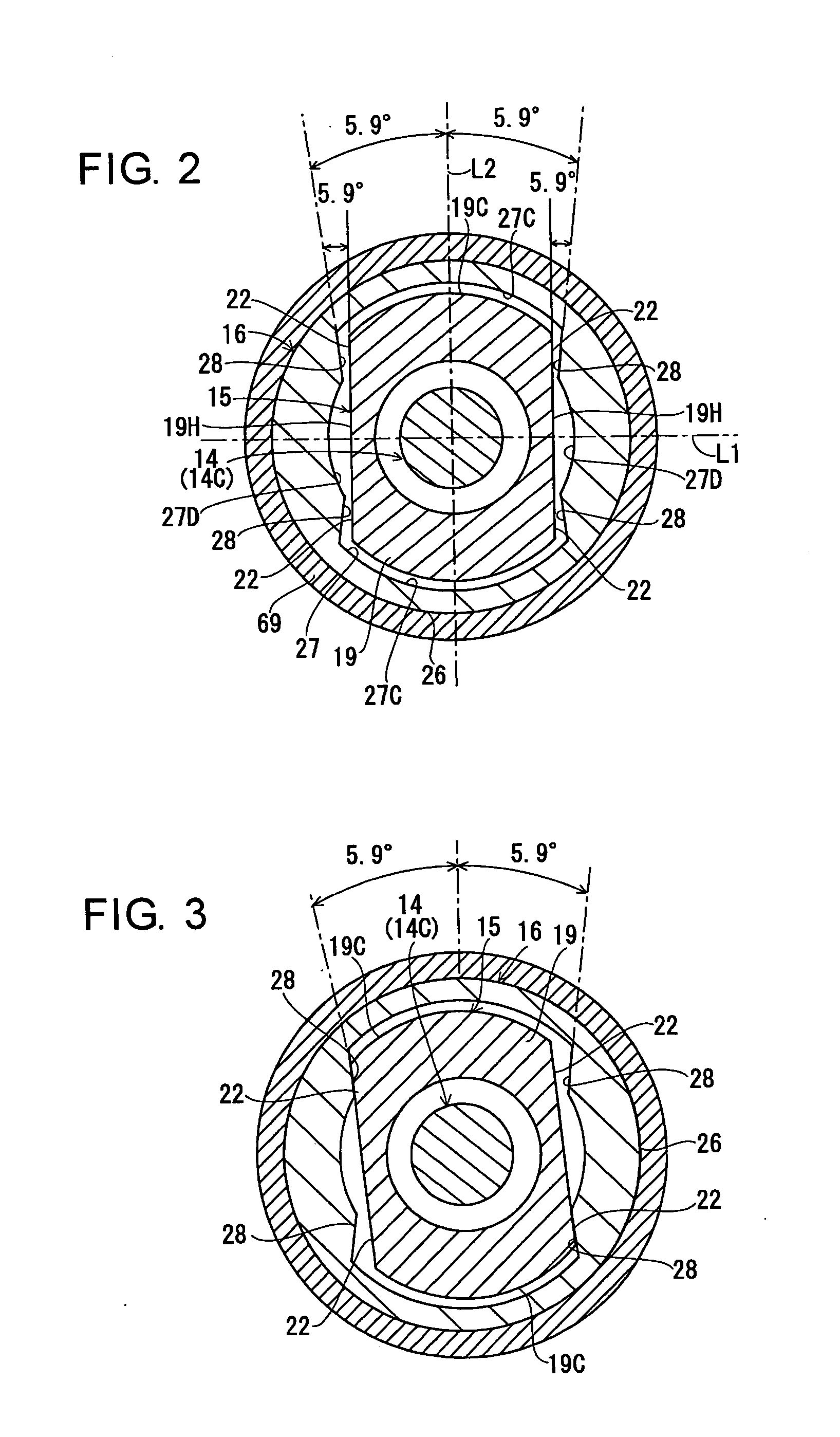

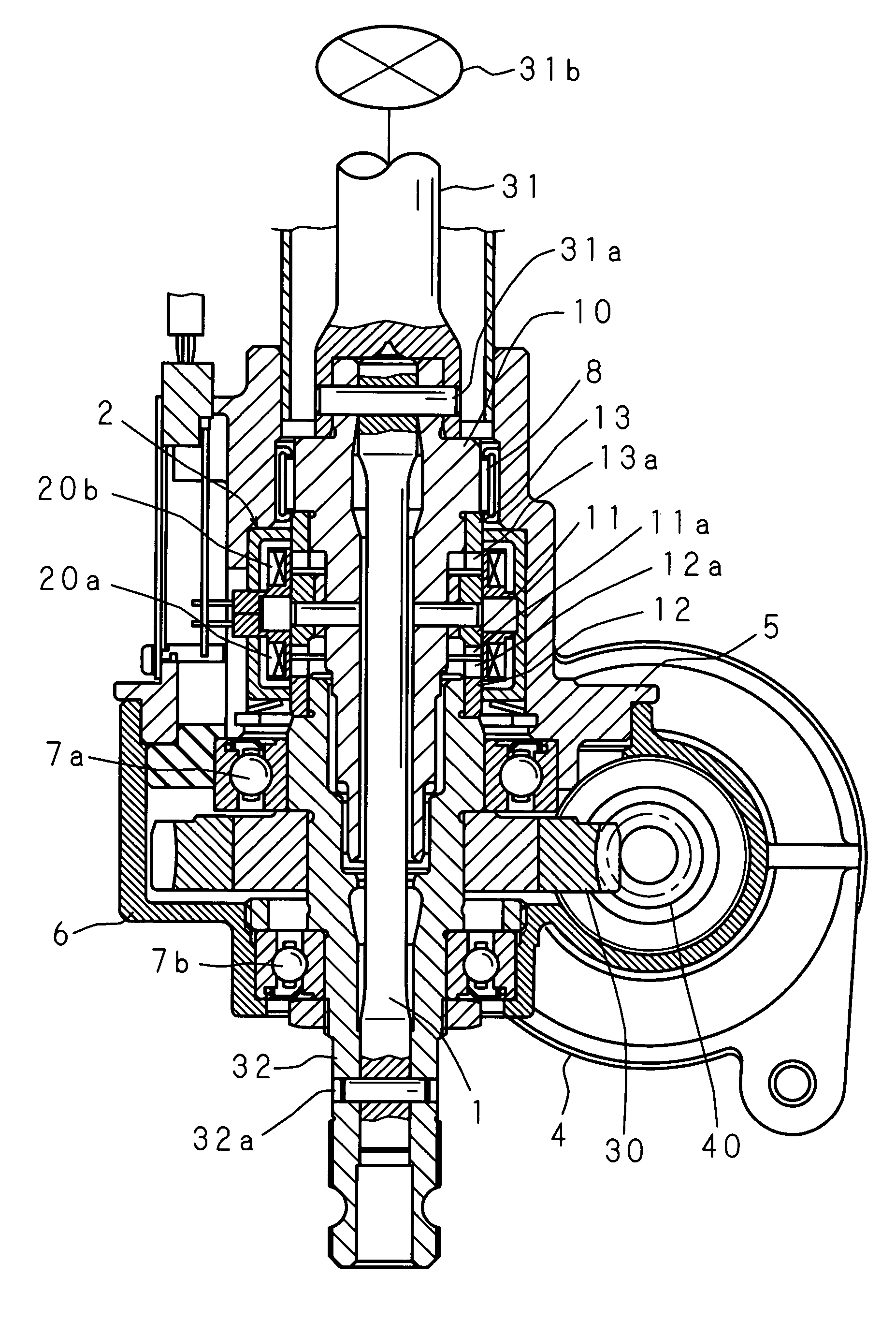

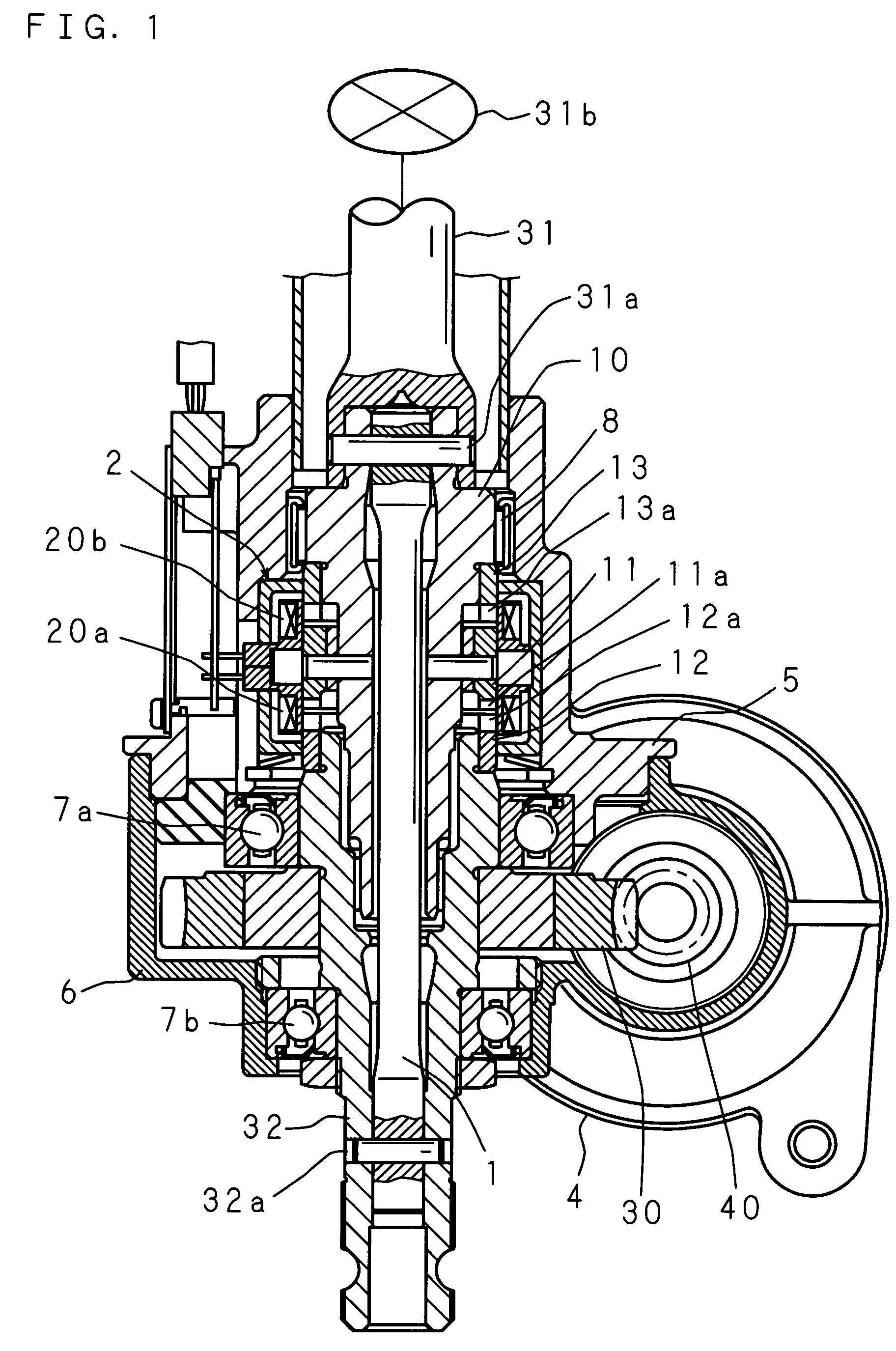

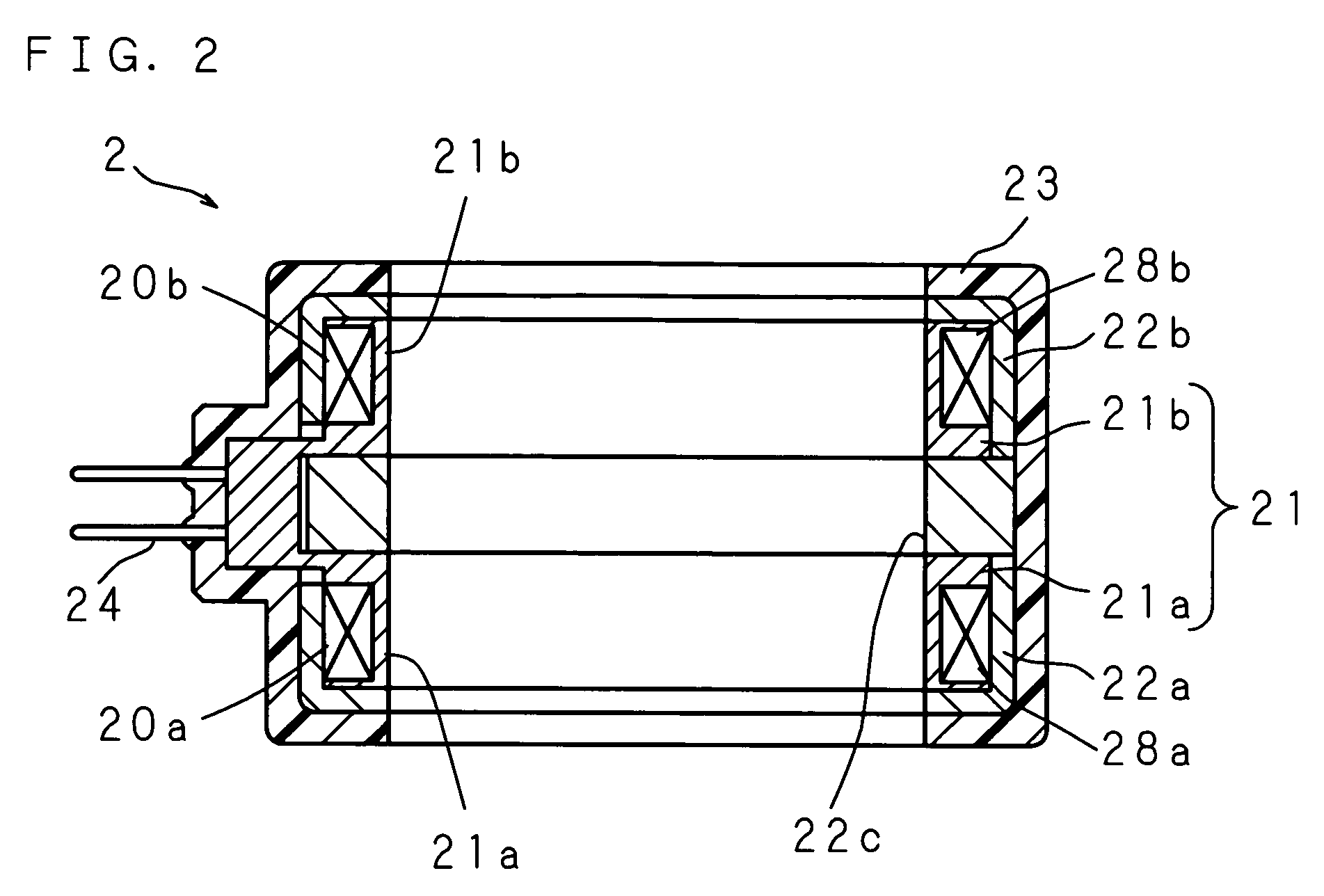

Torque sensor and electric streering device using the same

InactiveUS20050022614A1Downsizing and miniaturizing constructionPreventing a torsion bar from being twisted excessivelySteering linkagesWork measurementTorsional angleControl theory

A torque sensor is provided with a torsion bar, first and second elongate sleeves respectively secured to one and the other ends of the torsion bar, and a pair of resolvers respectively mounted on the first and second elongate sleeves. First and second stop portions are provided respectively at overlapping portions of the first and second elongate sleeves where the second elongate sleeve is fit partly on the external surface of the first elongate sleeve with a play. A rotary sleeve given to one of the resolvers is press-fit on the external surface of the stop portion provided on the second elongate sleeve for mounting one of the resolvers thereon as well as for reinforcing the mechanical strength of the stop portion provided on the second elongate sleeve. Further, the resolvers used therein are chosen as those respectively having n-poles and m-poles. Where the torsional angle of the torsion bar is represented by symbol “θ”, the first and second stop portions are constructed to satisfy an expression (θ<180·|1 / n−1 / m|). The torsional angle of the torsion bar is limited to being smaller than the angle determined by the expression, and hence, the resolvers are prevented from having the same values in their electrical angles, so that incorrect detection in torque can be obviated.

Owner:TOYODA MASCH WORKS LTD

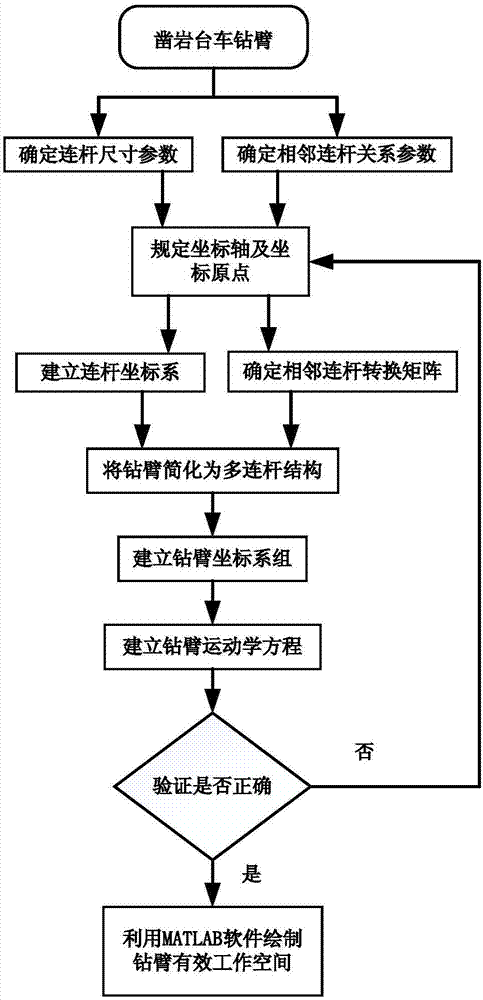

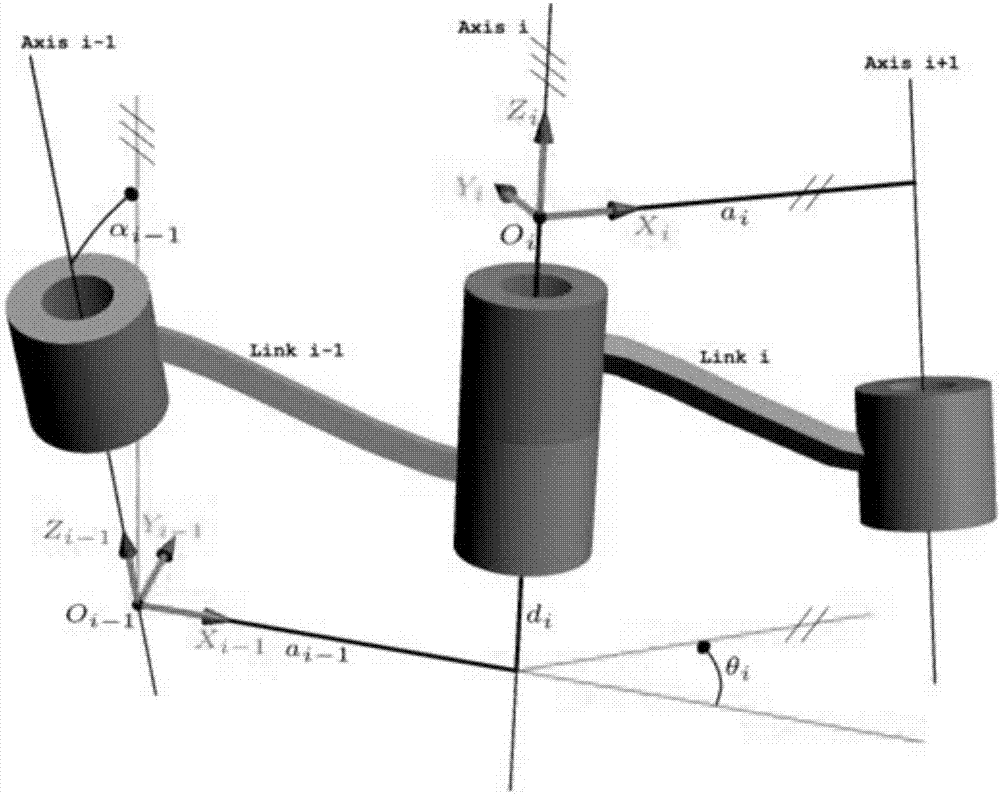

Kinematics analysis method for drilling arm of drill jumbo based on coordinate fixed denavit- hartenberg (CFDH) method

InactiveCN107885916ASolving identified difficult problemsCreate intuitive and accurateGeometric CADDesign optimisation/simulationKinematics equationsMATLAB

The invention relates to a kinematics analysis method for a drilling arm of a drill jumbo based on a coordinate fixed denavit- hartenberg (CFDH) method. The method includes the steps of firstly determining link parameters including dimension parameters of linkages and relation parameters of adjacent linkages, wherein the dimension parameters include link length and link torsional angle, and the relation parameters include link distance and joint rotation angle; simplifying the drilling arm into a structure of a multi-joint robot; by setting each rod piece coordinate system of the drilling arm,determining a coordinate conversion matrix of adjacent rod pieces, and applying the CFDH method to establish a kinematics equation of the drilling arm of the drill jumbo; and finally drawing an effective working space of the drilling arm of the drill jumbo in a MATLAB according to the established kinematics equation. According to the method, the problem that it is difficult to determine a coordinate system in drilling arm research is solved, and the establishment of a coordinate system group is intuitive and accurate, which provides an effective means for the kinematics analysis of the drilling arm of the drill jumbo.

Owner:XIAN TECHNOLOGICAL UNIV

Abnormality detection apparatus and abnormality detection method for internal combustion engine

A crankshaft of an engine is connected to a carrier shaft of a planetary gear via a damper. The damper includes a torsion member generating elastic force for suppressing relative rotation, when the crankshaft and the carrier shaft are relatively rotated. A control unit estimates engine torque with using rotation angular acceleration of the crankshaft calculated from a detected value of an engine speed sensor, and corrects the estimated engine torque with a correction term of the elastic force of the damper calculated based on a damper torsional angle. Then, the control unit diagnoses an abnormality of the engine based on the estimated engine torque after correction.

Owner:TOYOTA JIDOSHA KK +1

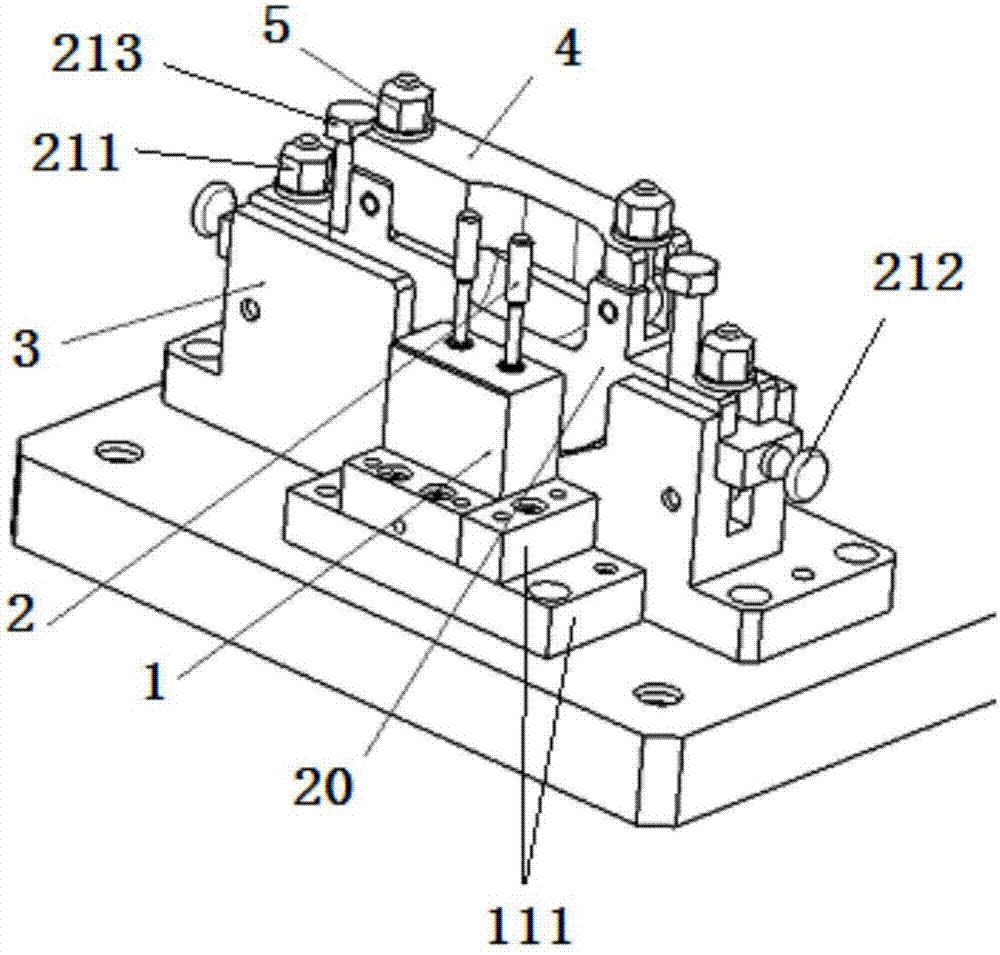

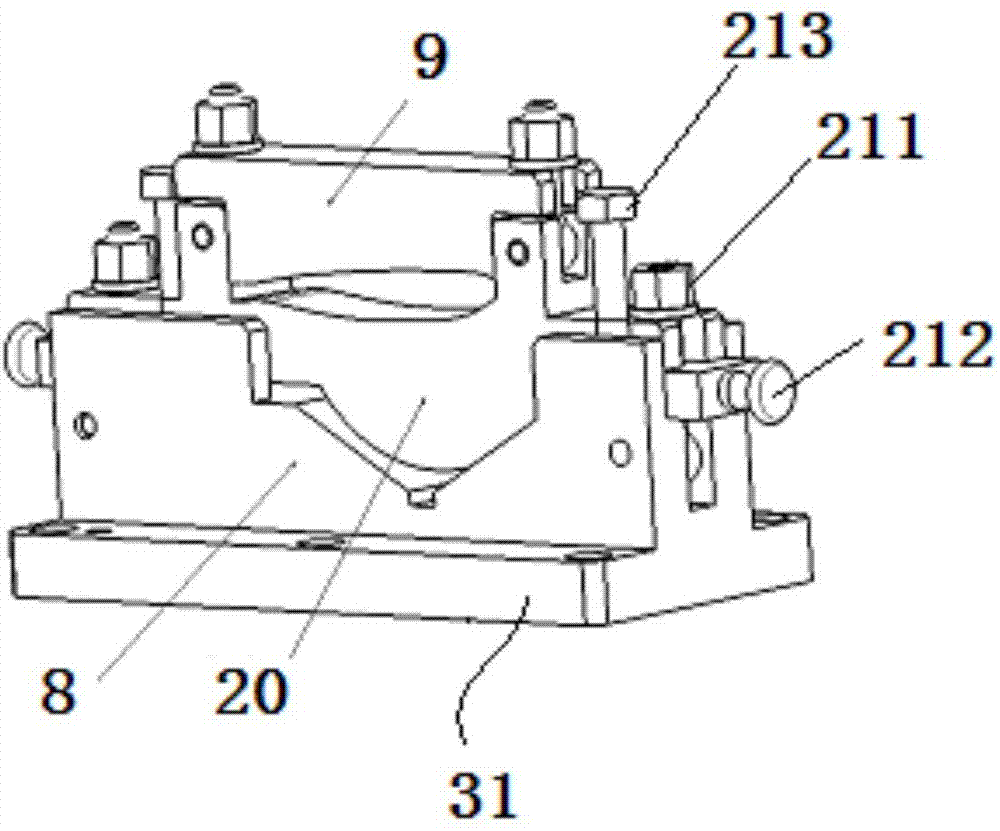

Composite-material-based paddle torsional angle detection device of unmanned aerial vehicle

ActiveCN107966128AQuality assuranceStable structureMeasurement devicesMeasuring instrumentUncrewed vehicle

The invention relates to the field of aircraft paddle torsional angle detection, in particular to a composite-material-based paddle torsional angle detection device of an unmanned aerial vehicle. Thedetection device is composed of a pedestal, a lower paddle root fixation block, an upper paddle root fixation block, a lower profile fixation block, an upper profile fixation block, a tip support block fixed on the pedestal, a paddle root profile measuring clamp clamped at a paddle root of a to-be-detected paddle, a first profile measuring clamp clamped at a body of the to-be-detected paddle, a second profile measuring clamp clamped at the body of the to-be-detected paddle. The lower paddle root fixation block and the upper paddle root fixation block form a first clamping part jointly and thelower profile fixation block and the upper profile fixation block form a second clamping part jointly. According to the composite-material-based paddle torsional angle detection device, the profile measuring clamps are installed at a to-be-detected profile of a paddle naturally and then an angle measuring instrument is installed at a measuring clamp platform, so that a torsional angle is measureddirectly. The detection device has a reliable and stable structure; the measured data are accurate; the paddle quality is ensured greatly; the working efficiency is improved, and the production cost is reduced.

Owner:CHINA HELICOPTER RES & DEV INST

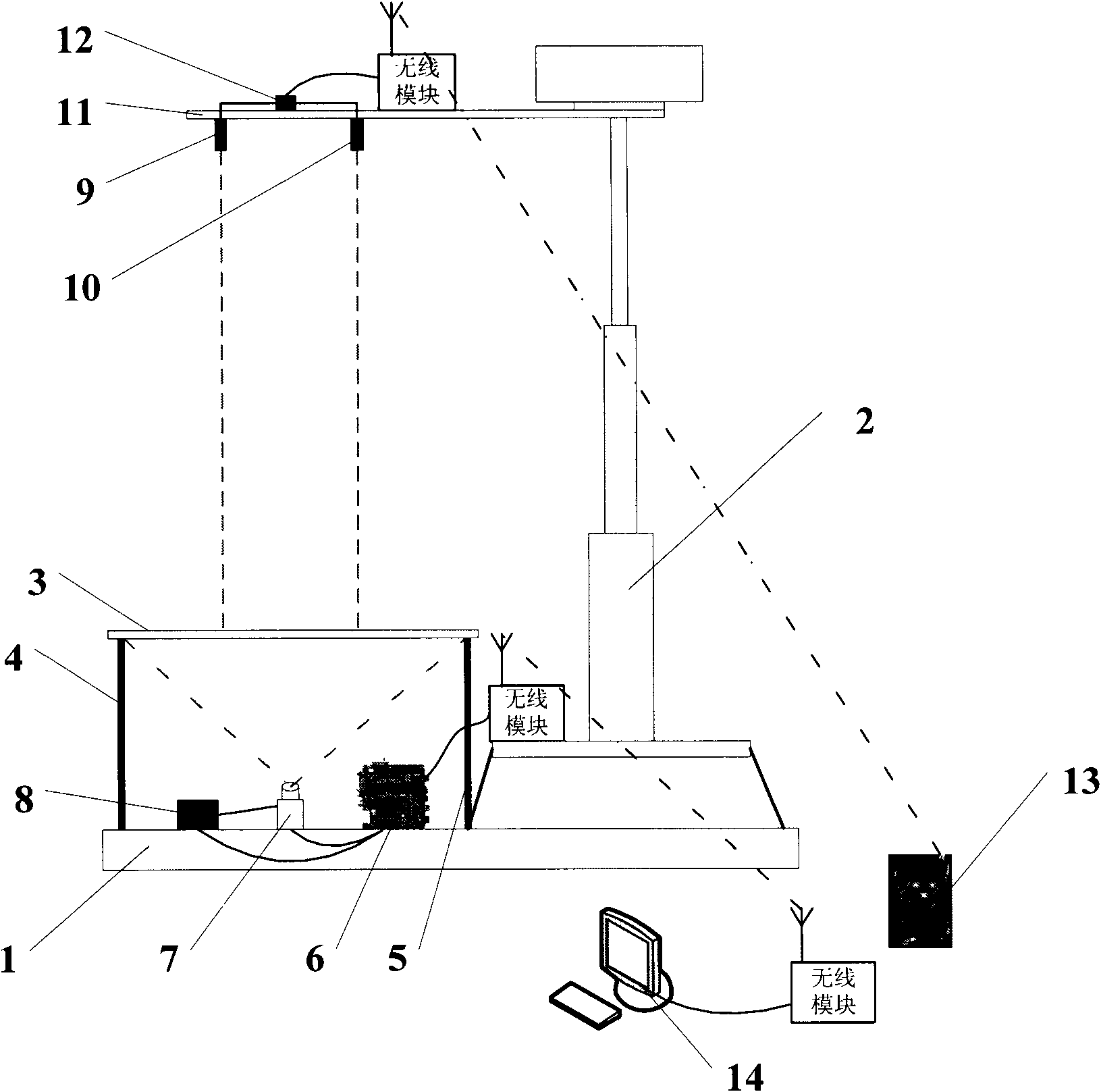

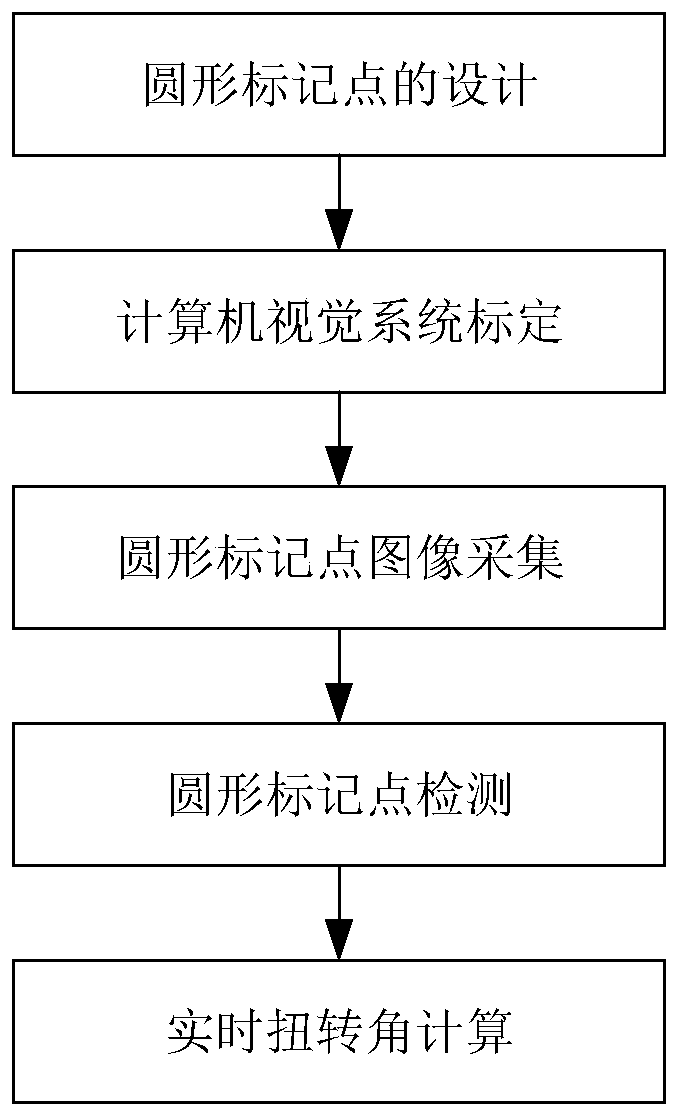

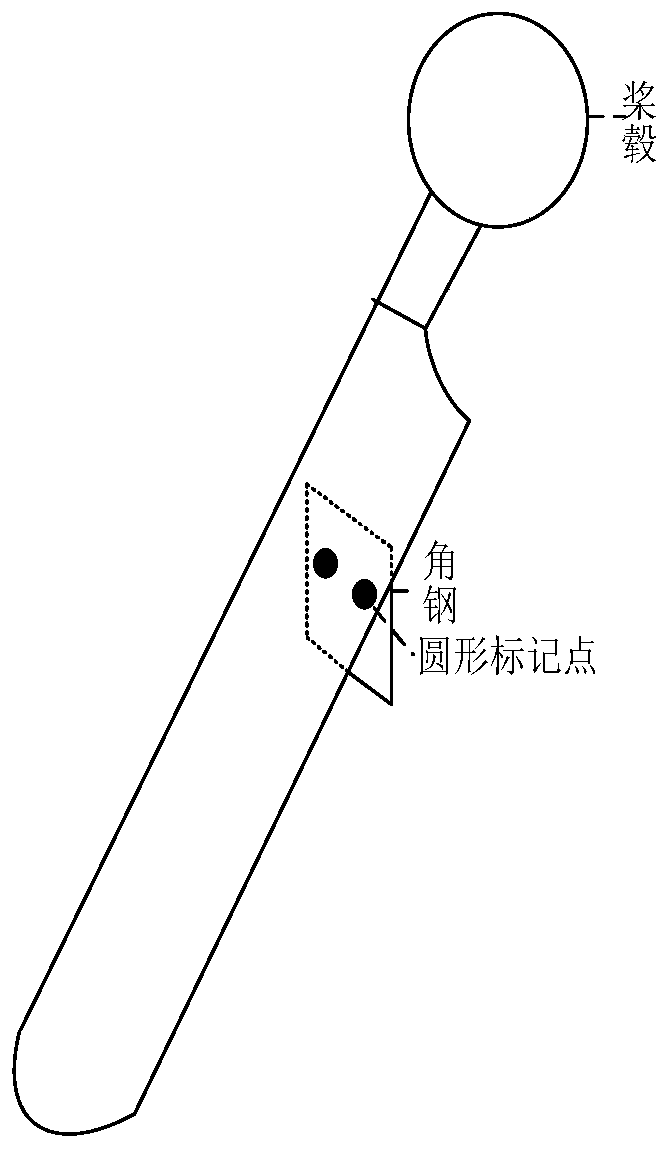

Paddle torsion angle real-time monitoring method based on mark point detection

InactiveCN110879048ARealize real-time monitoringHigh precisionUsing optical meansAlgorithmTorsional angle

The invention discloses a paddle torsion angle real-time monitoring method based on mark point detection. The method comprises the following steps: firstly, separating a foreground from a background by utilizing an Otsu threshold algorithm to obtain a binary image with a connected domain; secondly, matching out circular mark points by adopting a minimum circumcircle method to realize coarse positioning of the circular mark points; thirdly, removing singular points through a circle fitting method to improve the circle center positioning precision of the mark points and achieve fine positioningof the circular mark points; and finally, calculating an included angle between straight lines formed by the circle centers of the mark points obtained twice to obtain a torsion angle. The method hasthe advantages of simplicity in operation, high precision, high speed and no contact, and is particularly suitable for real-time monitoring of the torsion angle of a paddle in a high-speed motion state.

Owner:NANCHANG HANGKONG UNIVERSITY

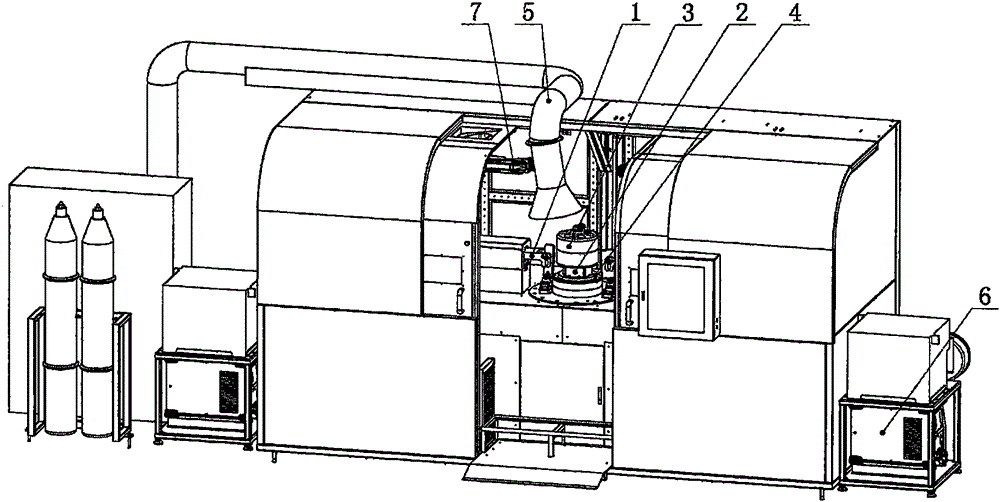

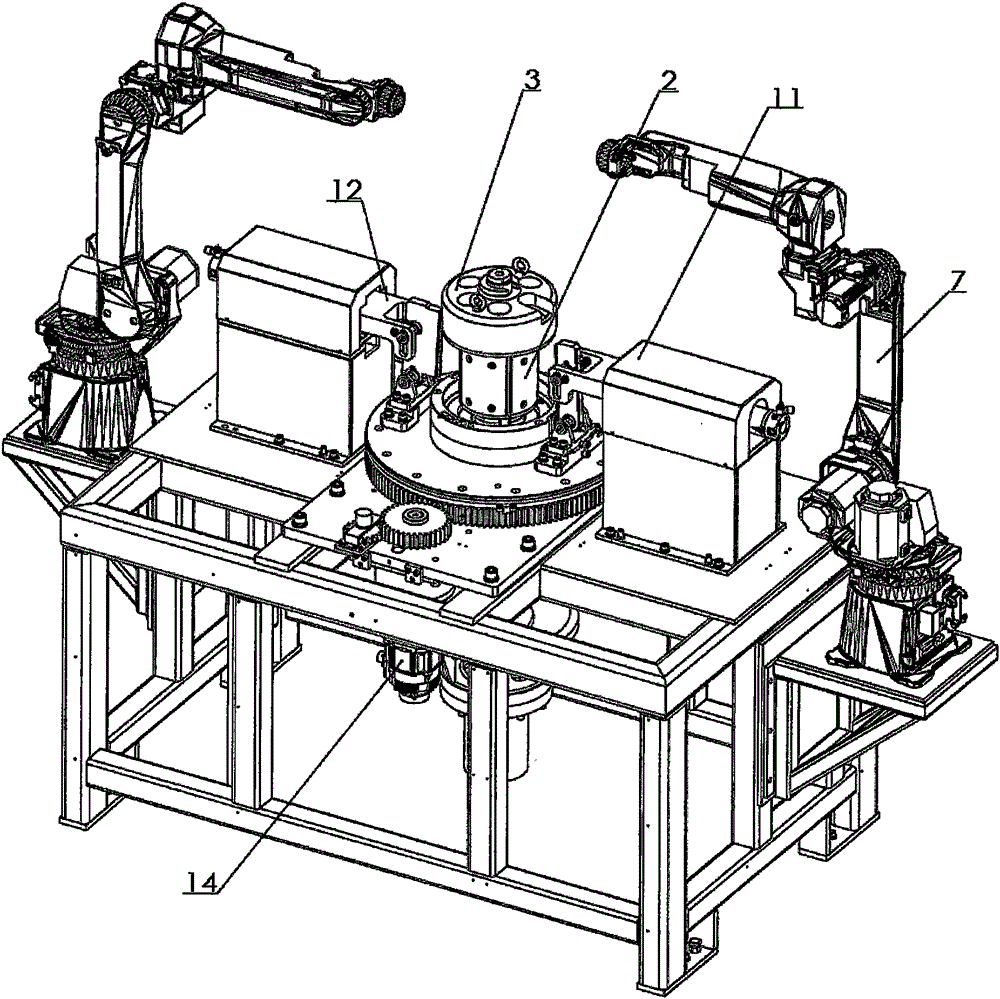

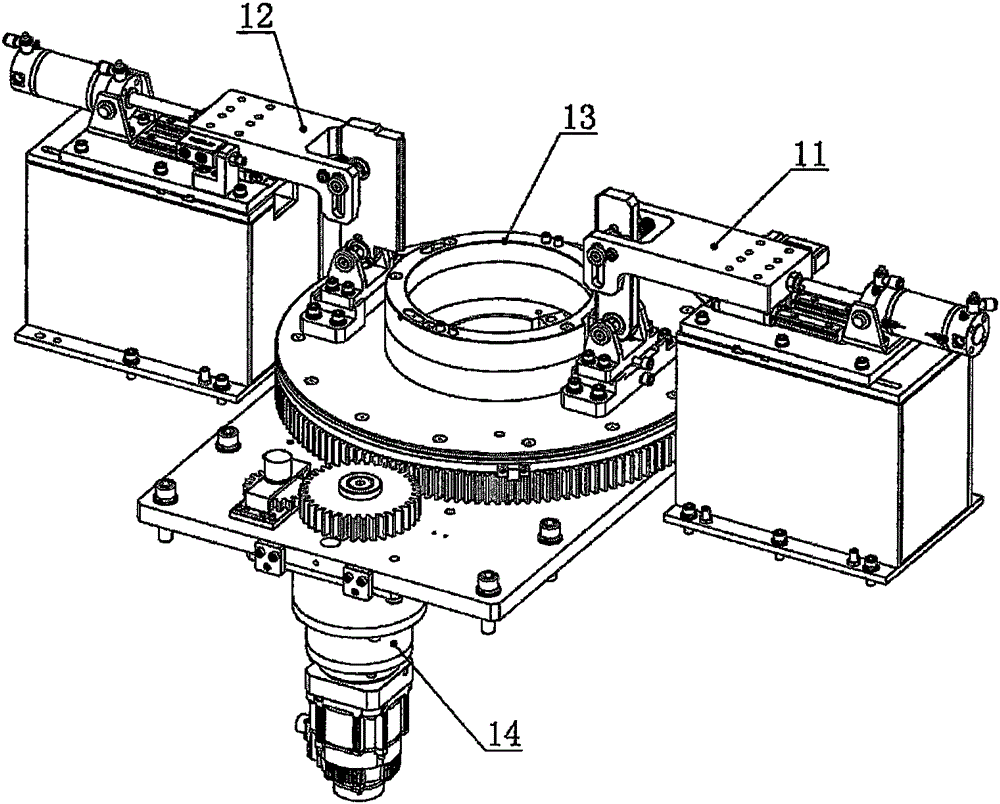

Automatic motor stator welding system

ActiveCN105290561AEnsure consistencyPrecise structureWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderRobotic systems

Owner:AMET WELDING AUTOMATION TECH BEIJING

Self-lubricating rubber bushing and preparation method thereof

InactiveCN104448422AImprove low temperature performanceIncrease elasticityHollow articlesPolymer scienceStearic acid

The invention relates to a self-lubricating rubber bushing and a preparation method thereof and particularly relates to a self-lubricating rubber bushing for an automobile and a preparation method of the self-lubricating rubber bushing. The self-lubricating rubber bushing comprises natural rubber SIR20, butadiene rubber BUNACB22, zinc oxide, stearic acid SA, an anti-aging agent RD, carbon black N550, naphthenic oil Nytex820, oleamide KEMAMIDEU, ultra-high molecular weight polyethylene XM220, paraffin Antilux654, an accelerant CBS and sulphur S200-1. The rubber bushing disclosed by the invention has high radial rigidity and approximately-zero torsional rigidity so as to be suitable for a special service condition with large torsional angle for a long term; and if being used for a long term, the bushing is low in abrasion and long in service life and can still be favorably used under a low-temperature condition.

Owner:TENNECO SUZHOU CO LTD

Method for locating girder of megawatt-grade wind wheel blade

The invention discloses a method for locating a girder of a megawatt-grade wind wheel blade, comprising the following steps of: a. prefabricating a girder; b. prearranging a shell glass steel shell plate at the position 2-4m away from the tip part in a blade shell mold; c. completing rest layering structure; d. hoisting the girder, using a locating bracket and the shell glass steel shell plate tolocate the girder, and removing the locating bracket after installation is finished; and e. laying rest inner skin, wherein the rest inner skin is laid in the way of being jointed with the inner skinof the shell glass steel shell plate layer by layer, installing a vacuum system, vacuumizing, filling the blade and finally curing. The method is applicable to a blade with large torsional angle and formed by vacuum filling process. After the girder is located and installed, the locating bracket is removed, and the girder does not slide downwards when core material and the inner skin are laid, sothat the locating accuracy of the girder, as well as the strength of the blade and the product quality can be ensured.

Owner:LIANYUNGANG ZHONGFU LIANZHONG COMPOSITES GRP

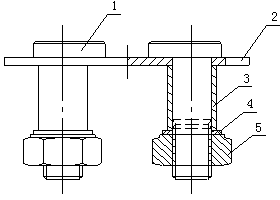

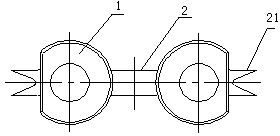

Mutual locking type positioning bolt component

InactiveCN104454907AAvoid direct interferenceAvoid Diffusion BondingWashersNutsTorsional angleEngineering

A mutual locking type positioning bolt component comprises two or more D-head bolts and a locking and positioning pad, wherein each D-head bolt is provided with a bolt head notch, bolt holes are formed in the locking and positioning pad, the number of the bolt holes is the same as that of the D-head bolts, a locking and positioning reed is arranged beside each bolt hole of the locking and positioning pad, the D-head bolts are installed after penetrating through the locking and positioning pad, and the locking and positioning reeds interfere with the bolt head notches after being folded to prevent the D-head bolts from rotating. According to the mutual locking type positioning bolt component, the locking and positioning reeds can transmit torque and prevent bolt heads from rotating accordingly after being folded, other assembly interference is avoided, wrenching space is not needed, the relative torsional angle positional relations between connecting parts are restrained, and locking effect is good; a lining enables the positions of a base body and a part to be fastened to be adjustable during installation, so that an ideal installing and fastening effect is realized; installation requirements are met, performance is reliable, structure is simple, cost is low, and usage and maintenance are convenient.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

Torque detecting apparatus

InactiveUS7117753B2Effect torque detection accuratelyReduce the possibilitySteering linkagesWork measurementTorsional angleControl theory

The torque detecting apparatus comprises an input shaft to which a torque is inputted, an output shaft for outputting the inputted torque, a connecting shaft for connecting the input shaft and the output shaft to transmit the torque, a coil for detecting a torque applied from the input shaft to the connecting shaft based on a torsional angle which arises at the connecting shaft, and a holding cylinder for holding the coil coaxially, wherein the holding cylinder has inside thereof a recess extending in the circumferential direction, and the coil is fitted in the recess. Projections for supporting the holding cylinder at a predetermined position are provided on the outer surface of an axial portion which does not have the recess. Accurate torque detection can be effected even when pressure applied to the projections provided at the holding cylinder constituting the torque detecting apparatus is changed.

Owner:KOYO SEIKO CO LTD +1

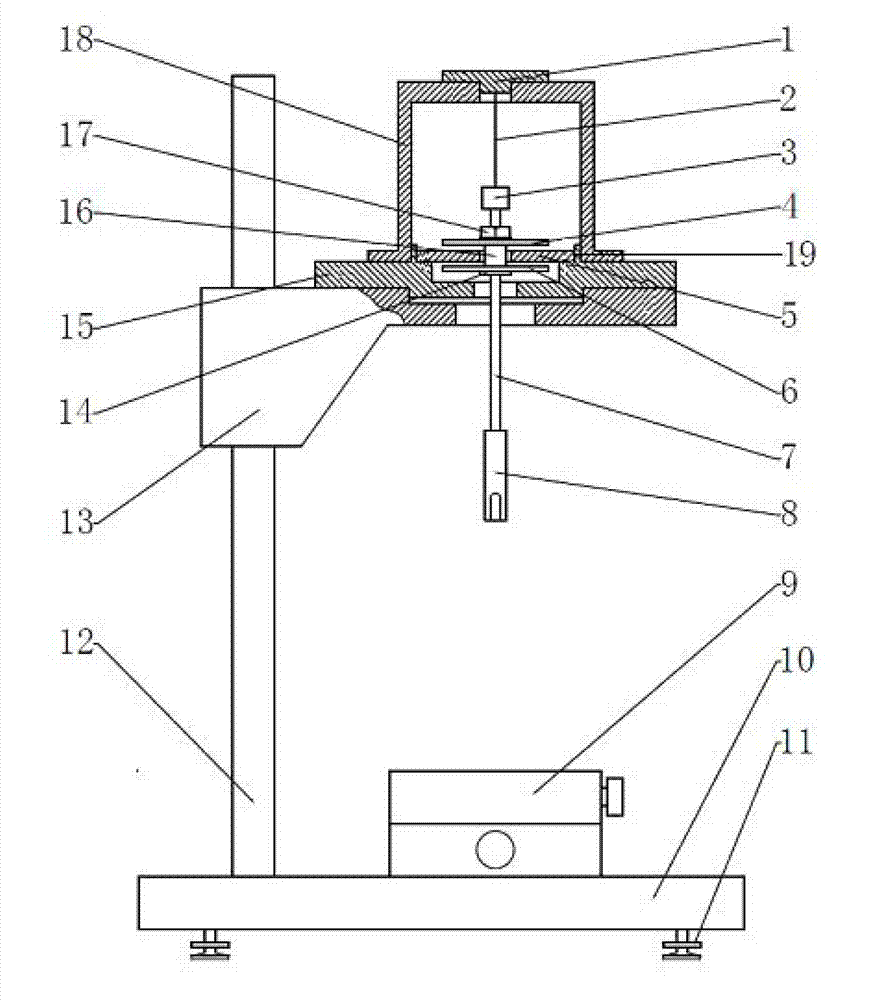

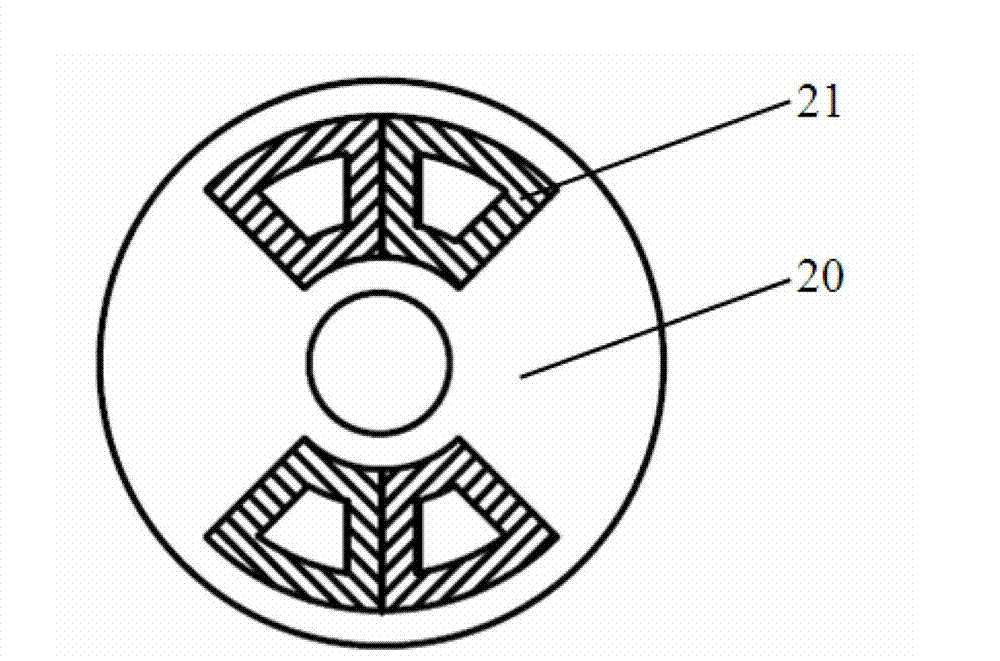

Measuring device and measuring method of microscale torsional angle and torque

ActiveCN103196493ASimple structureEasy to installWork measurementUsing electrical meansTorsional angleEngineering

The invention relates to a measuring device and a measuring method of a microscale tirosional angle and torque. The measuring device comprises a detection mechanism, a controller and an upper computer, wherein the controller is respectively connected with the detection mechanism and the upper computer, the detection mechanism comprises a base, a stand column and a single-freedom-degree support frame, the stand column is arranged on the upper surface of the base, the upper portion of the stand column is provided with the single-freedom-degree support frame capable of moving up and down in the vertical direction in a penetrated mode, a sensor lower shell body is connected with the upper portion of the single-freedom-degree support frame in a clamped mode, a sensor upper shell body and a sensor are respectively connected with the upper portion of the sensor lower shell body, an upper chuck is arranged at the top end of the upper shell body, a torsion wire is connected with the lower end of the upper chuck, the lower end of the torsion wire is fixedly connected with a mandrel through a lower chuck, the sensor is installed on the outer portion of the mandrel in a sleeved mode, and a measuring head is connected with the lower end of the mandrel. The measuring device and the measuring method have the advantages that the structure is simple, design is reasonable, the resolution ratio is high, a harsh industrial application environment is met, repeatability is good, shock-resistant performance is good, installation and maintenance are convenient, and a detection method is reliable and simple in operation.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

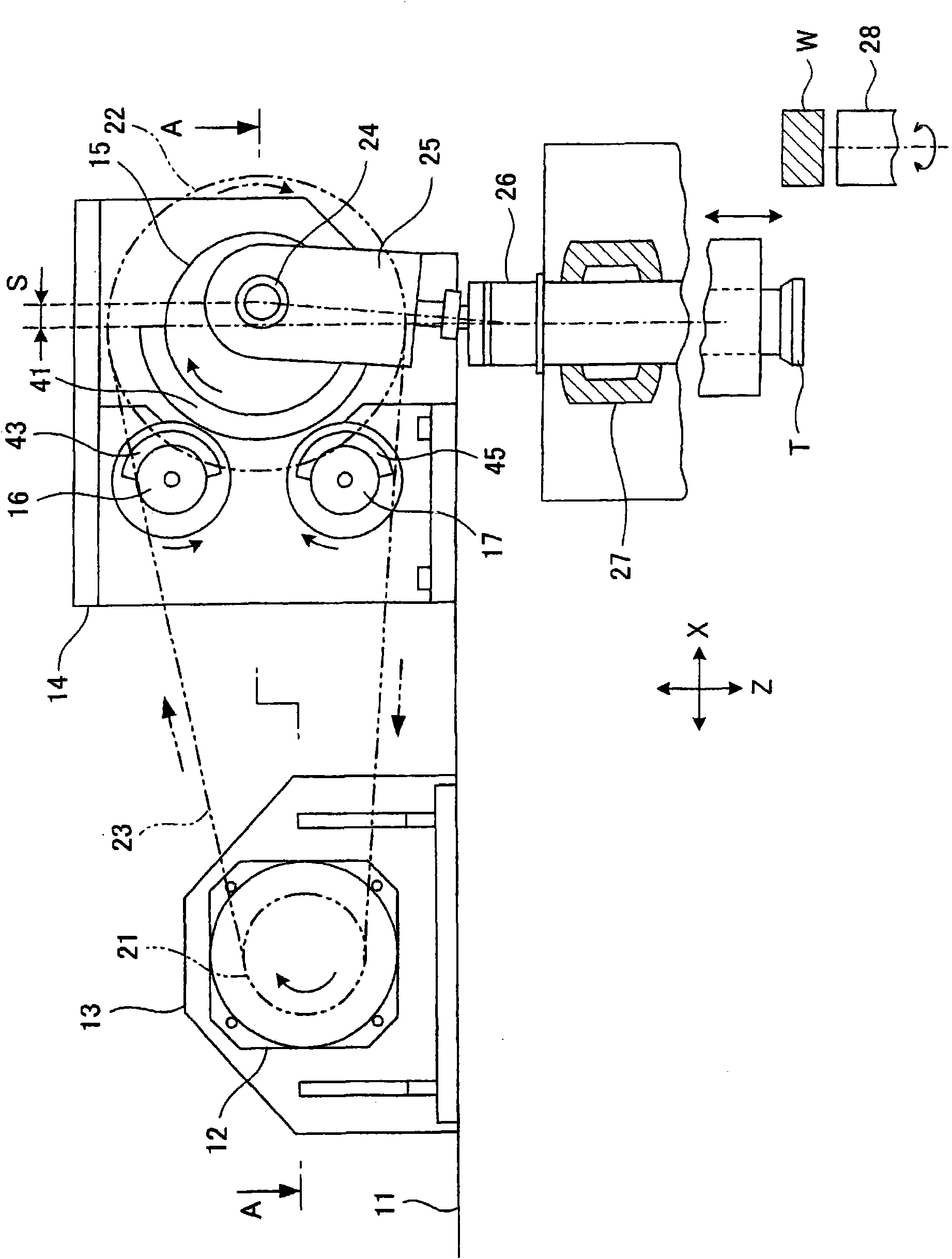

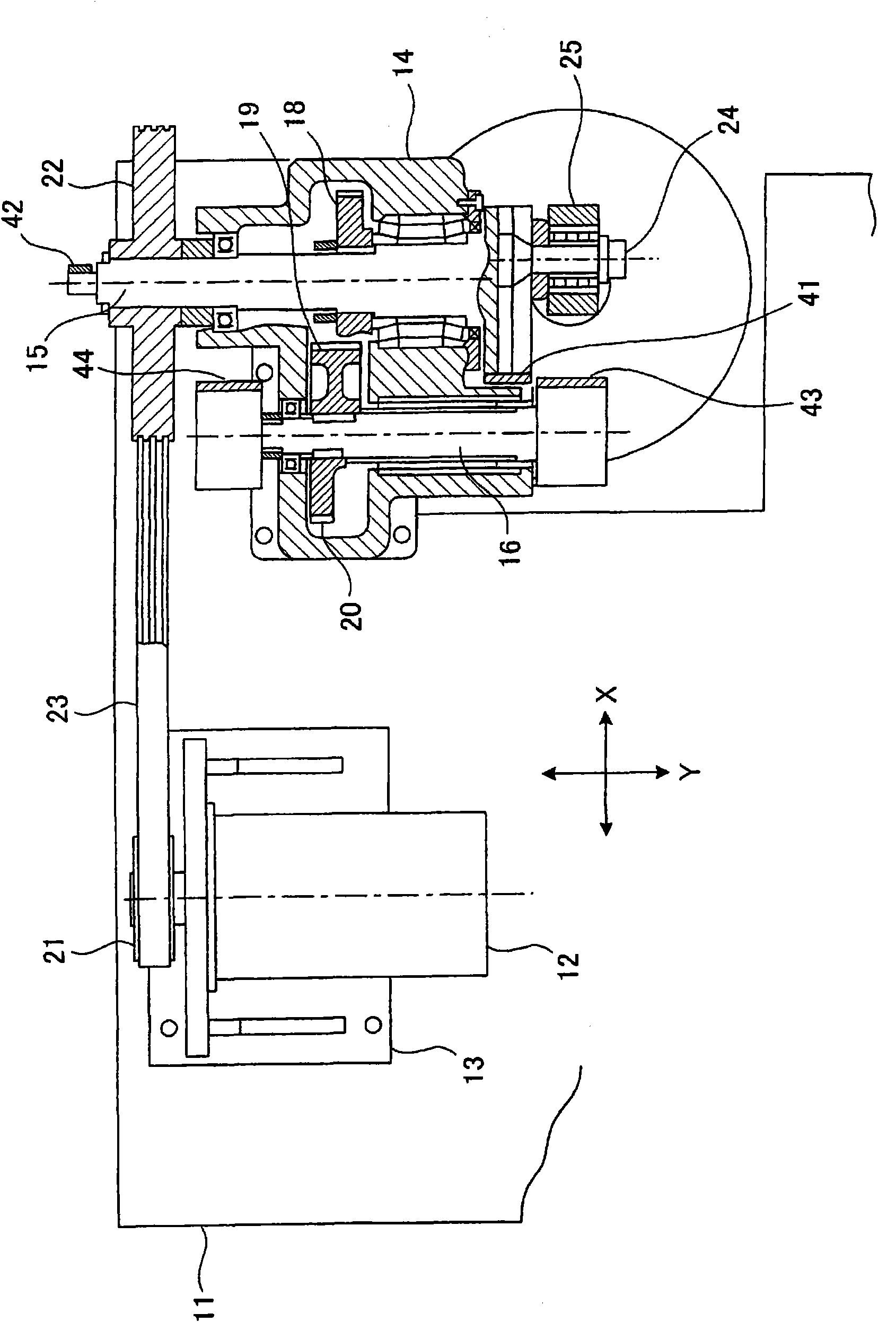

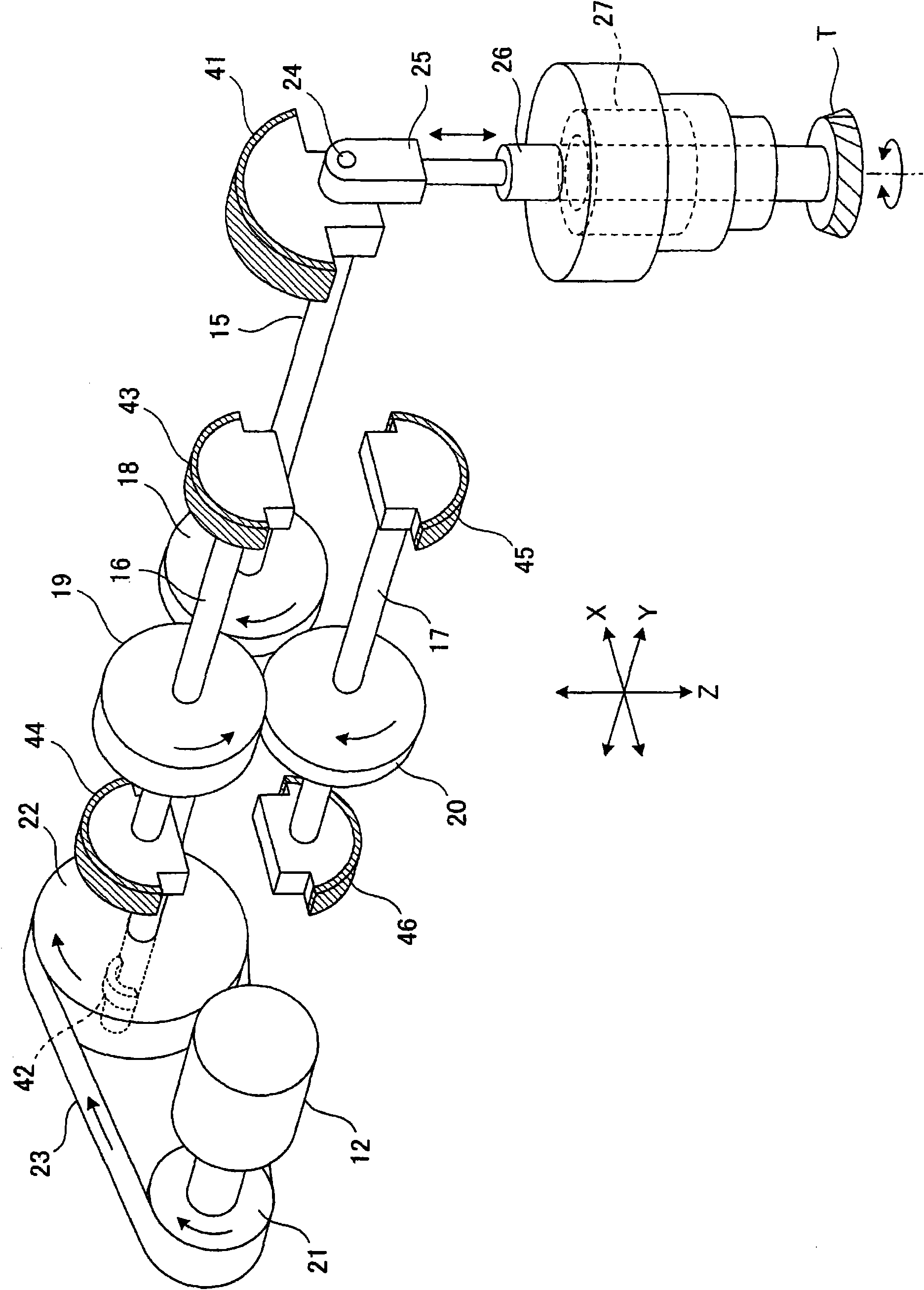

Vibration-suppressing mechanism for gear-shaping machine

ActiveCN101678487AReduce mechanical vibrationGear-cutting machinesMaintainance and safety accessoriesReciprocating motionTorsional angle

This aims to provide a vibration-suppressing mechanism for a gear-shaping machine, which is enabled to suppress mechanical vibrations at the time of shaping a helical gear by selecting an optimum balance weight. The vibration-suppressing machine is provided for the gear-shaping machine which performs the gear shaping on a work (W) with a cutter (T) mounted on a main spindle (26) of crank reciprocations. The vibration-suppressing machine comprises balance shafts (16 and 17) juxtaposed with respect to a crankshaft (15), for rotating at an identical rotation speed in synchronism with the crankshaft (15) and in the same and opposite directions as and to that of the crankshaft (15), main balance weights (41 and 42) removably mounted on the crankshaft (15), for suppressing the axial vibrations of the main spindle (26), and auxiliary balance weights (43 to 46) removably mounted on the balance shafts (16 and 17), for suppressing the vibrations of in directions perpendicular to the axial direction of the main spindle (26). Those individual balance weights (41 to 46) are selected on the basis of leads meeting the stroke width of the main spindle (26) and the torsional angle of the work (W).

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com