Wind turbine driving system torsional vibration measurement method and device

A transmission system and measuring device technology, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of inaccurate measurement of dynamic torsional vibration, reduce costs, etc., and achieve light weight, variety, and high frequency response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

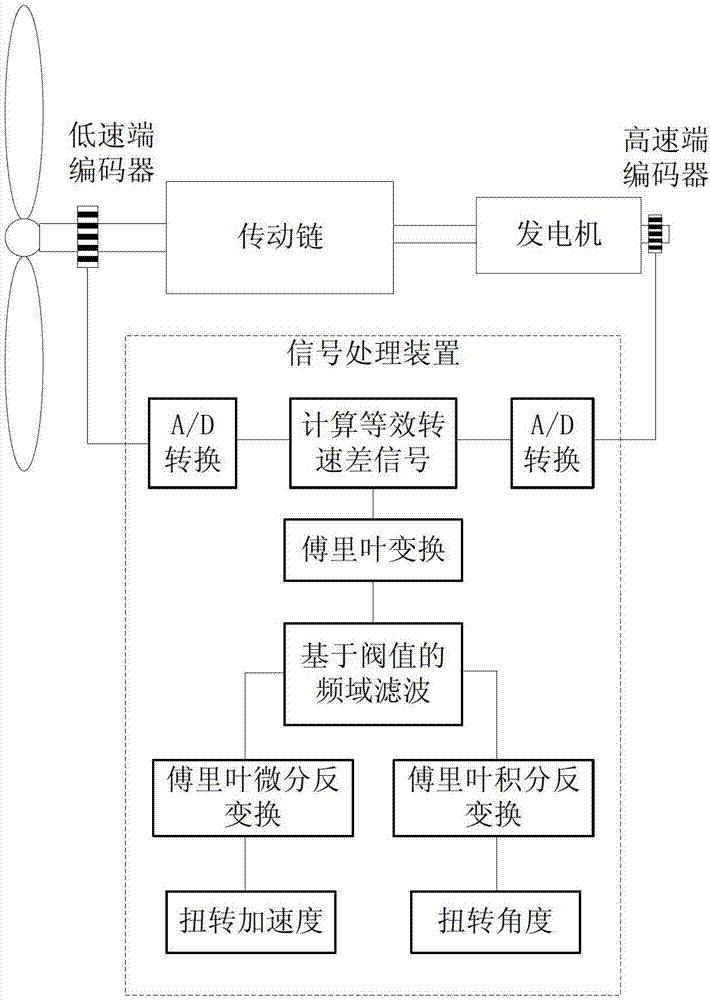

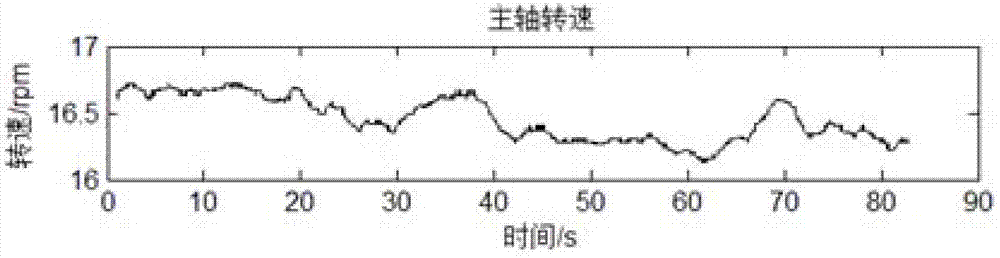

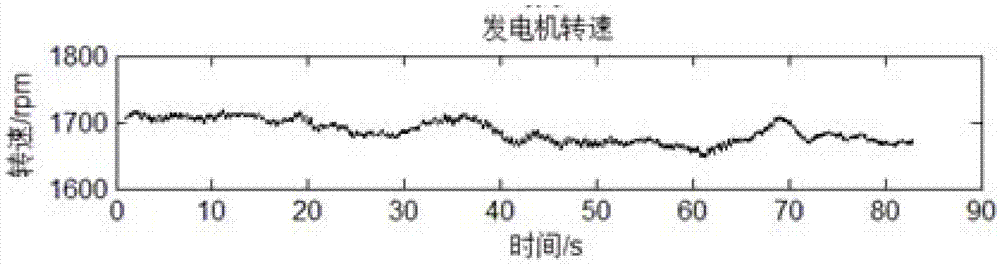

[0035] see figure 1 As shown, the transmission chain of the wind turbine is composed of the hub of the wind turbine, the main shaft, the gearbox, the high-speed shaft, and the generator. The rigidity of the hub is very strong, and its torsional vibration can be ignored. Therefore, the torsional vibration measurement of the transmission chain of the wind turbine is mainly For the part between the main shaft and the end of the generator.

[0036] The torsional vibration measurement device of the wind turbine transmission system of the present invention includes two rotary encoders installed on the front end of the main shaft and the end of the generator respectively (the inherent speed sensor of the wind turbine can also be used), and the signal connected to the two rotary encoders Processing device.

[0037] Preferably, the rotary encoder installed at the front end of the main shaft is an absolute rotary encoder, and the rotary encoder installed at the end of the generator is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com