Apparatus for large-torque torsional fatigue tests of shaft parts

A torsional fatigue and test device technology, applied in measuring devices, using repetitive force/pulse force to test material strength, instruments, etc., can solve the problems of high cost, high power consumption, no energy saving, etc., and achieve high work efficiency and drive The effect of low power and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0017] The invention provides a high-torque torsional fatigue test device for shaft parts.

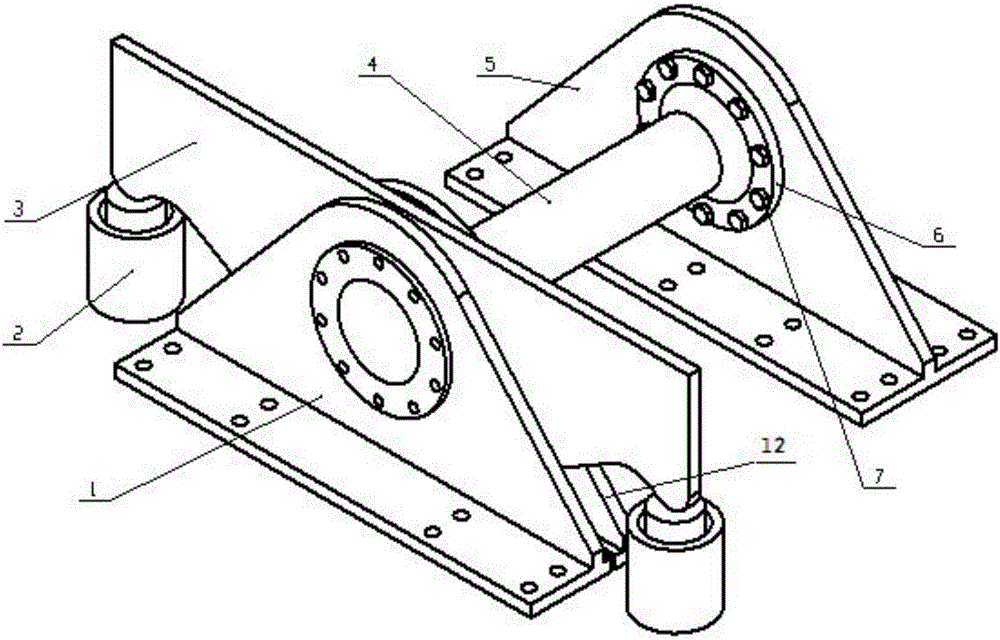

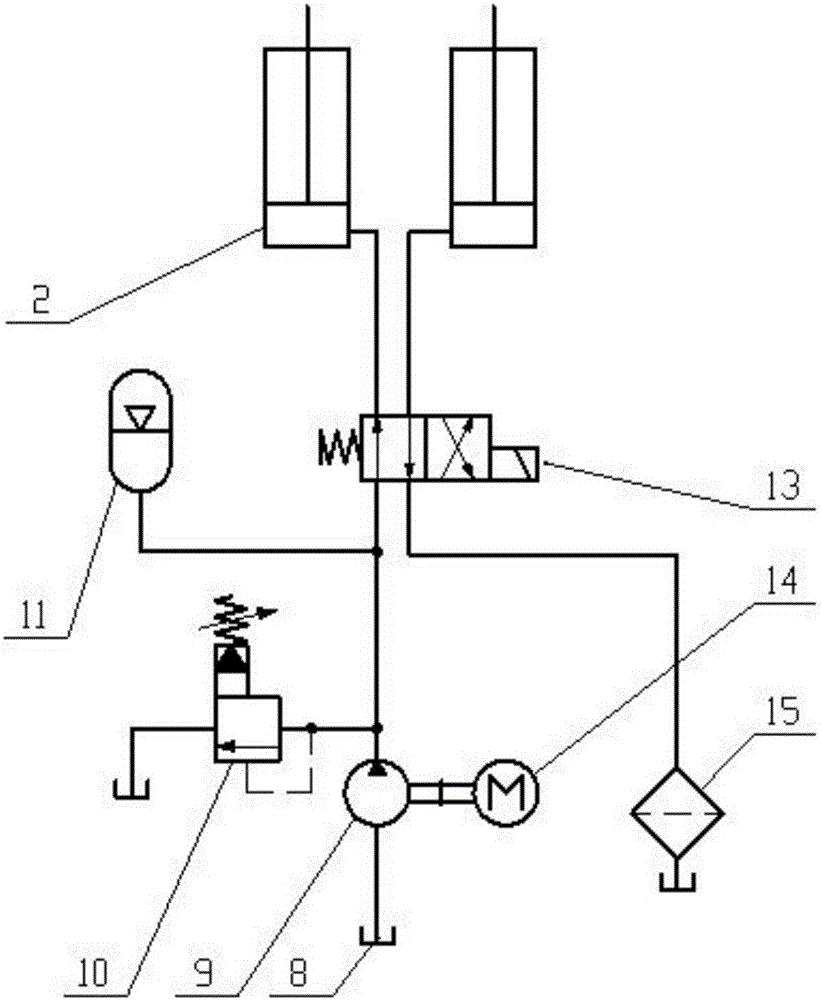

[0018] Such as figure 1 As shown, the crossbeam 3 in the device is erected and connected at the gap between the crossbeam base 1 and the crossbeam base 2 12, and the crossbeam base 1, the crossbeam base 2 12 and the fixed base 5 are fixed on the working surface by anchor bolts; the crossbeam 3 A hydraulic cylinder 2 is installed at the lower part of both ends, and the tested shaft 4 is erected on the beam 3 and the fixed base 5. The torsion angle displacement sensor is used to test the torque of the tested shaft 4, and the oil pressure sensor is arranged at the hydraulic cylinder 2 to test the oil pressure; the hydraulic control system is connected to the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com