MEMS micro vibrating mirror and manufacturing method for prefabricating MEMS micro vibrating mirror based on SOI top silicon

A manufacturing method and technology of micro-galvanometers, which are applied in optical components, optics, instruments, etc., can solve the problems of affecting the torsion angle and performance of the galvanometer, and the large quality of the large-scale mirror structure, so as to shorten the processing time and enhance the electrical power. Isolation effect, the effect of large corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

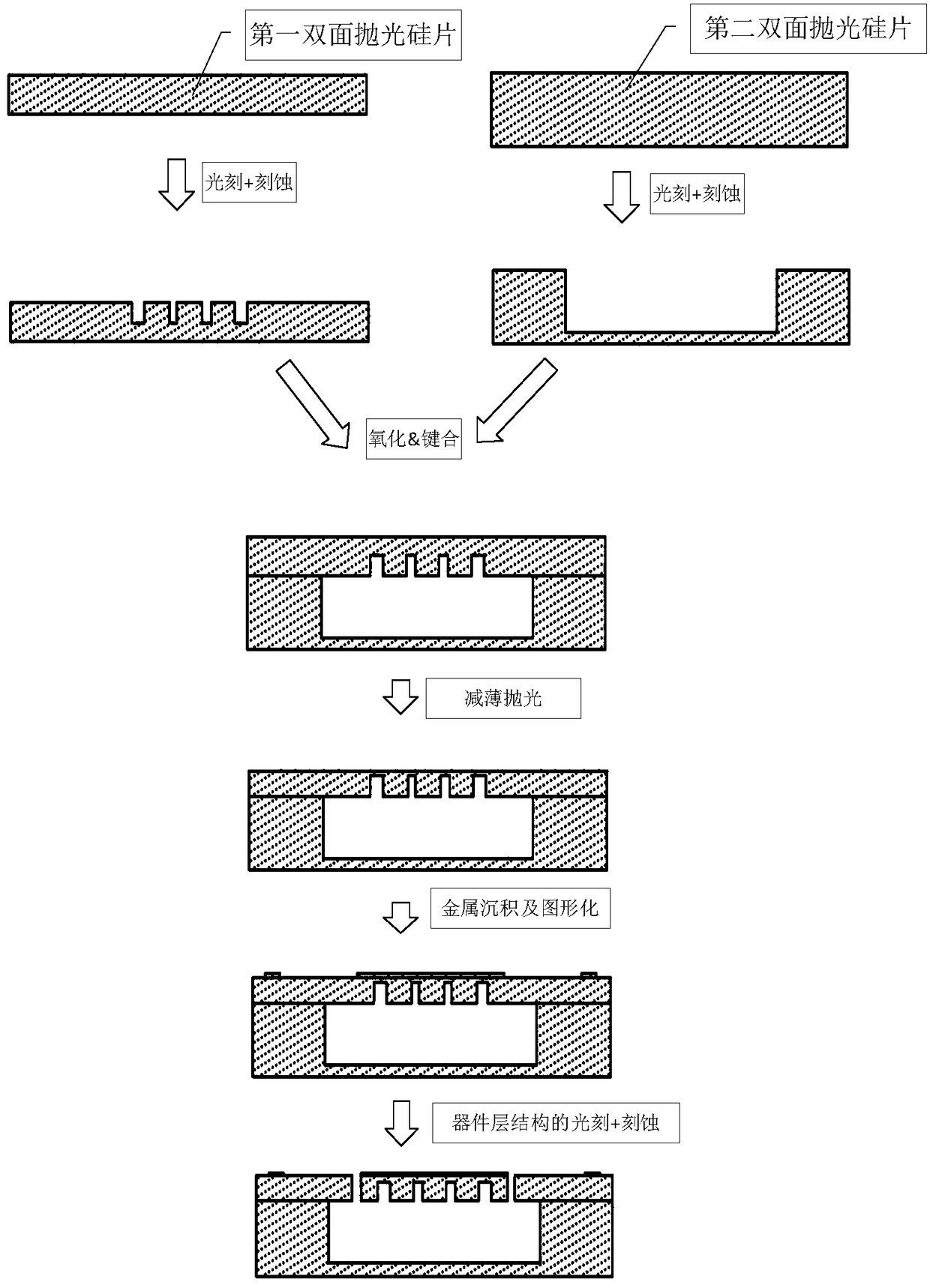

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

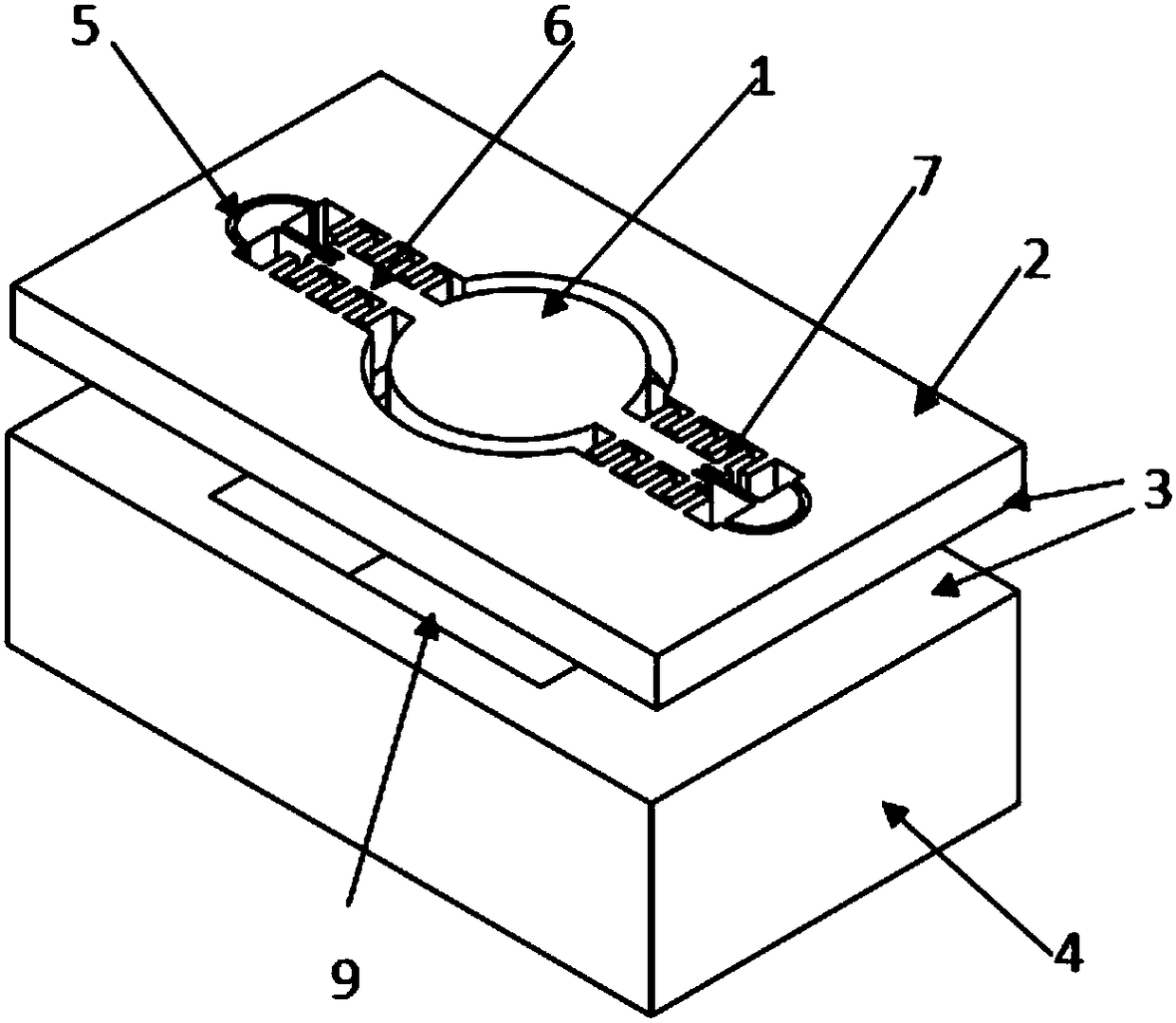

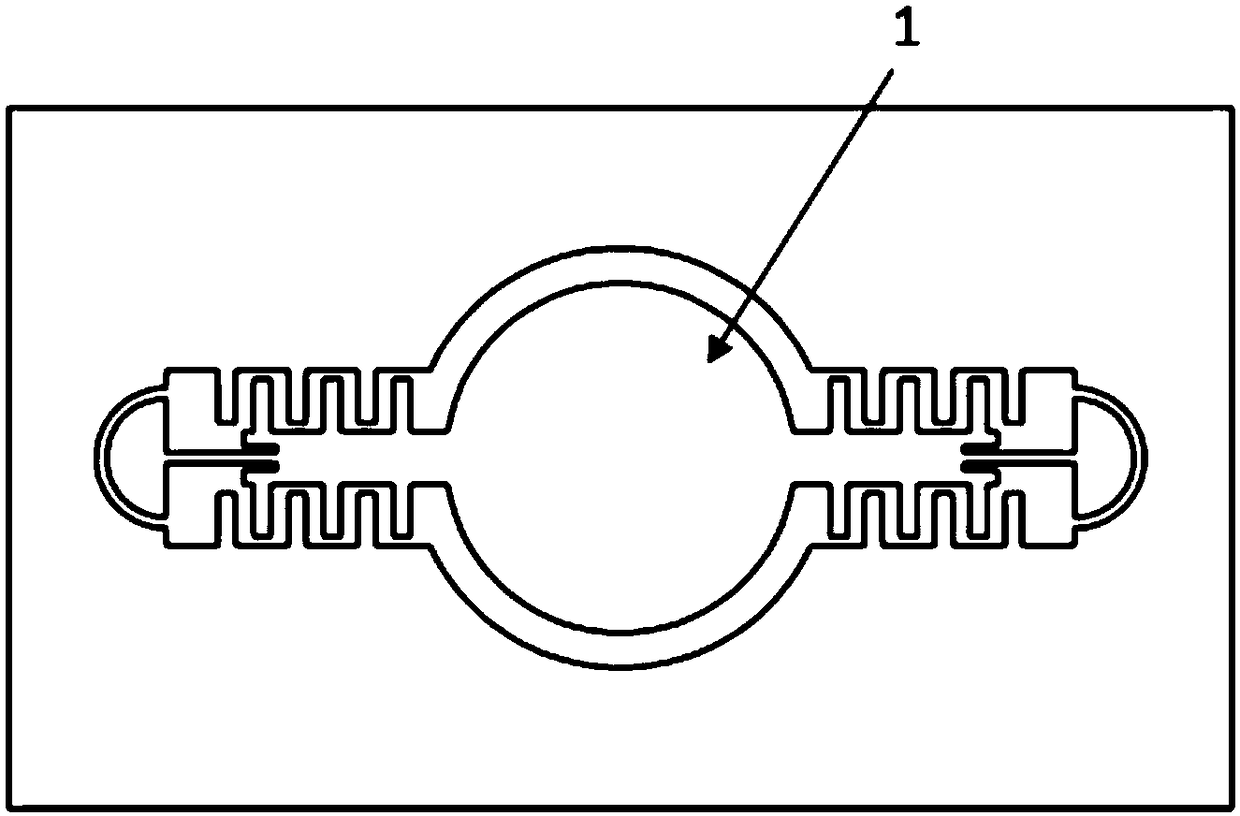

[0033] from figure 2 It can be seen that the MEMS micro-galvo mirror of the present invention includes the bottom layer silicon 4 and the top layer silicon 2 bonded to each other, the movable mirror surface 1, the beam 6, the comb teeth 7, the isolation trench 5 and other structures are located on the top layer silicon, and the movable mirror surface 1 It is connected and fixed by the beam 6, and is isolated by the isolation trench 5, and is independently suspended in the top layer silicon 2. A plurality of first chambers 8 are opened on the back of the movable mirror 1 to reduce the quality of the mirror structure. A second chamber 9 is opened to provide the space required for the movable mirror to twist. The plurality of first chambers 8 are distributed axially symmetrically with respect to the torsion axis of the movable mirror surface, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com