Method and device for detecting torsional angle, arch rise and pressure of wiper arm

A wiper arm and torsion angle technology, applied in the field of wiper arm performance testing, can solve the problems of unintuitive judgment of unqualified products, inconvenient removal, and high labor intensity, so as to improve detection efficiency and detection reliability, placement With easy removal, reduced intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

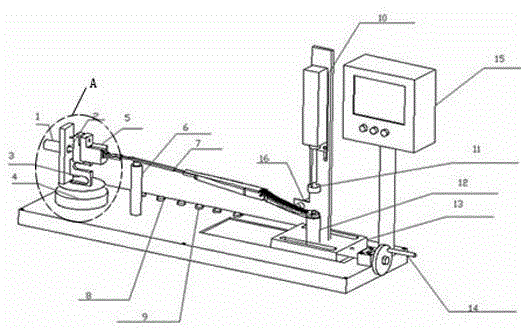

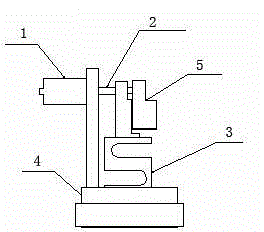

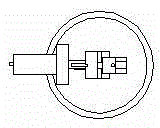

[0043] The method and device for simultaneously detecting the torsion angle, crown height, and pressure of the wiper arm according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0044] see Figure 1-16 , a method for detecting the torsion angle, arch height and pressure of the wiper arm at the same time, comprising the following steps: the first step: in the calibration stage, take the qualified sealed sample of the product to be tested, and adjust the lifting of the cylinder 10 of the special device according to the product parameters Height, meet the detection pressure height difference, and then move the lead screw 14 horizontally to meet the products of different lengths, and then put the scraper arm 7 into the positioning seat 12, at this time, the cylinder presses down to detect the photoelectric sensor 16 to sense that the scraper arm is put in, The cylinder is automatically press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com