Layered fairing method for complex curved surface

A complex surface, smoothing technology, applied in special data processing applications, instruments, electrical digital data processing and other directions, can solve problems such as difficult convergence, and achieve the effect of simplifying the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

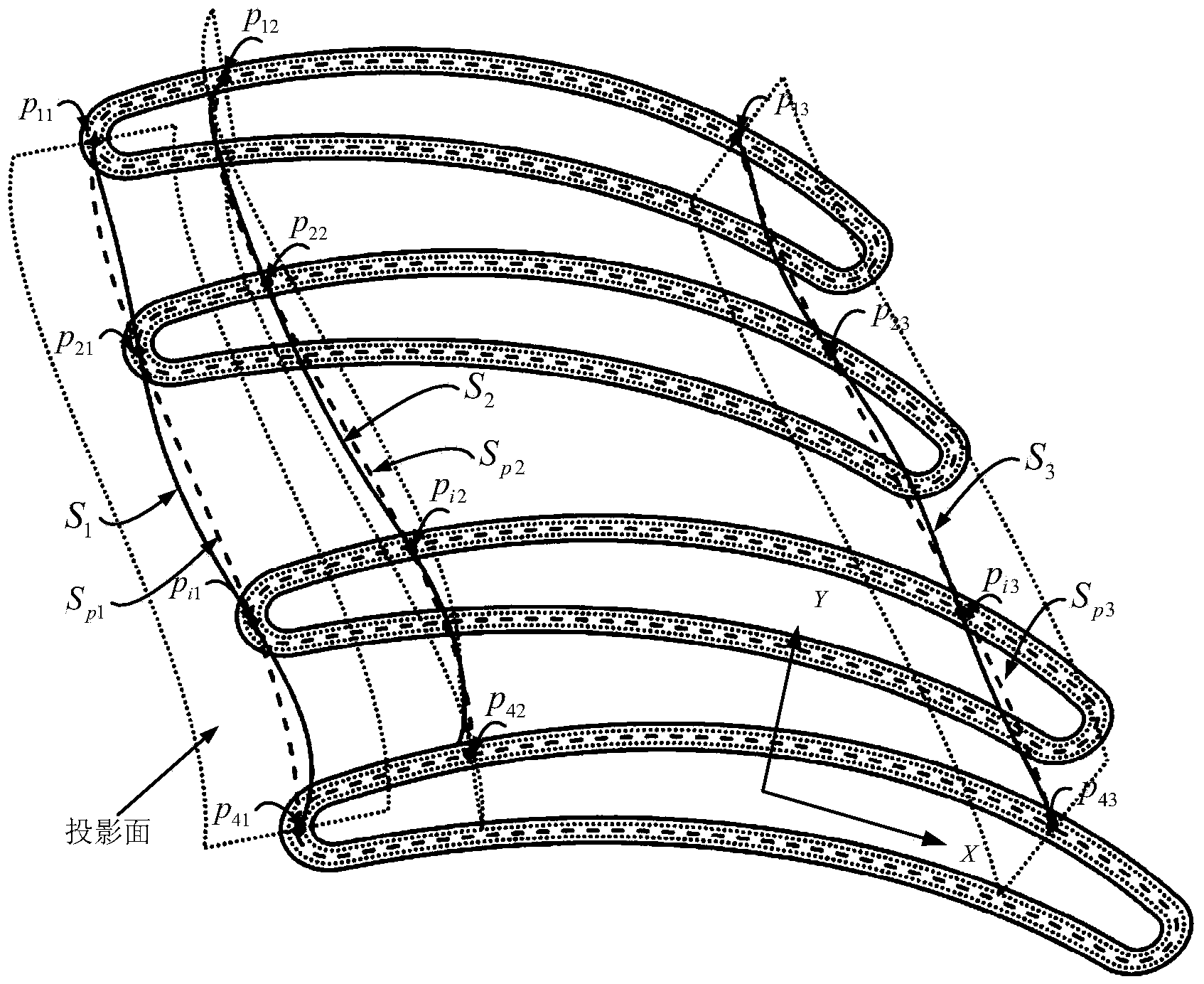

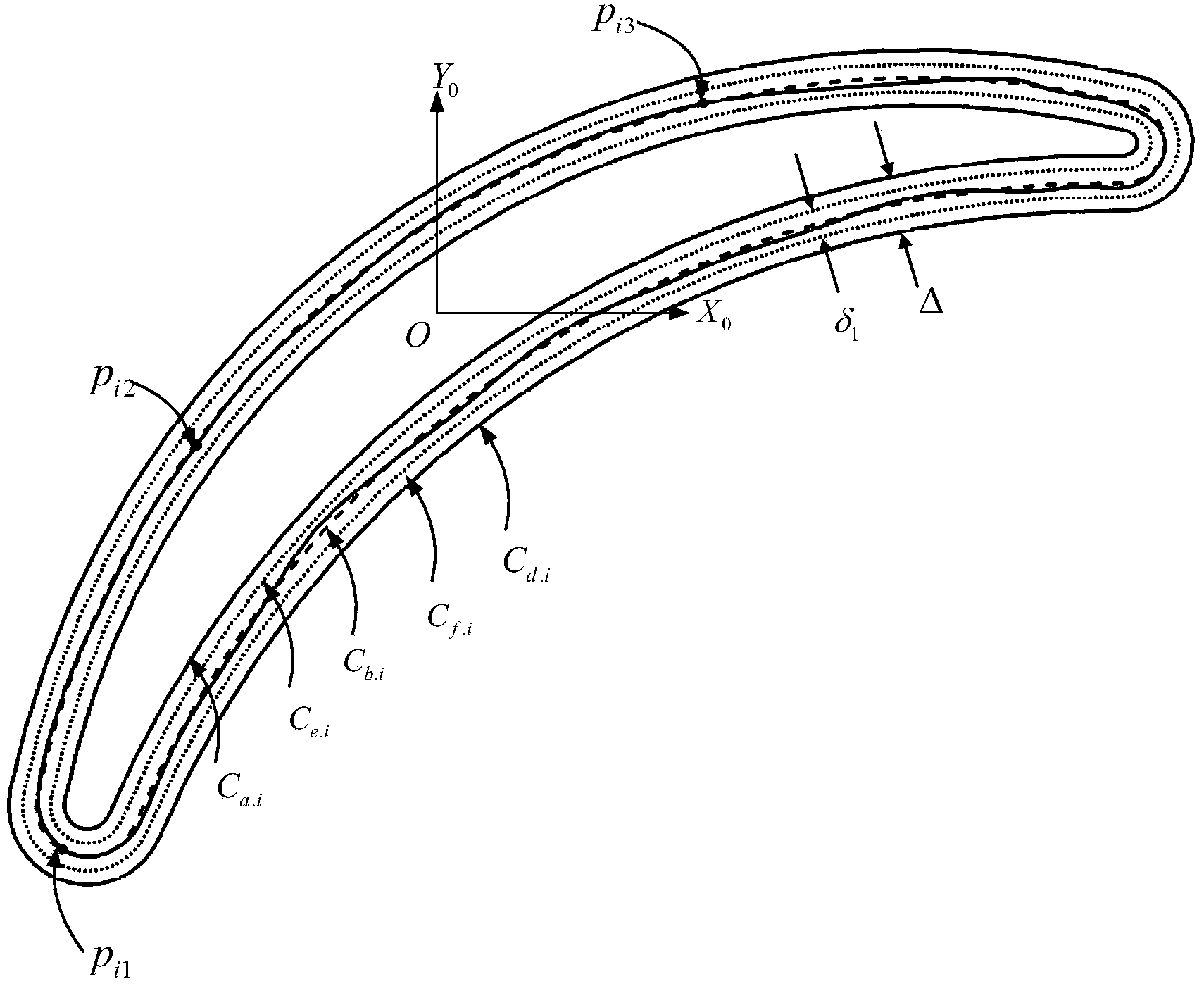

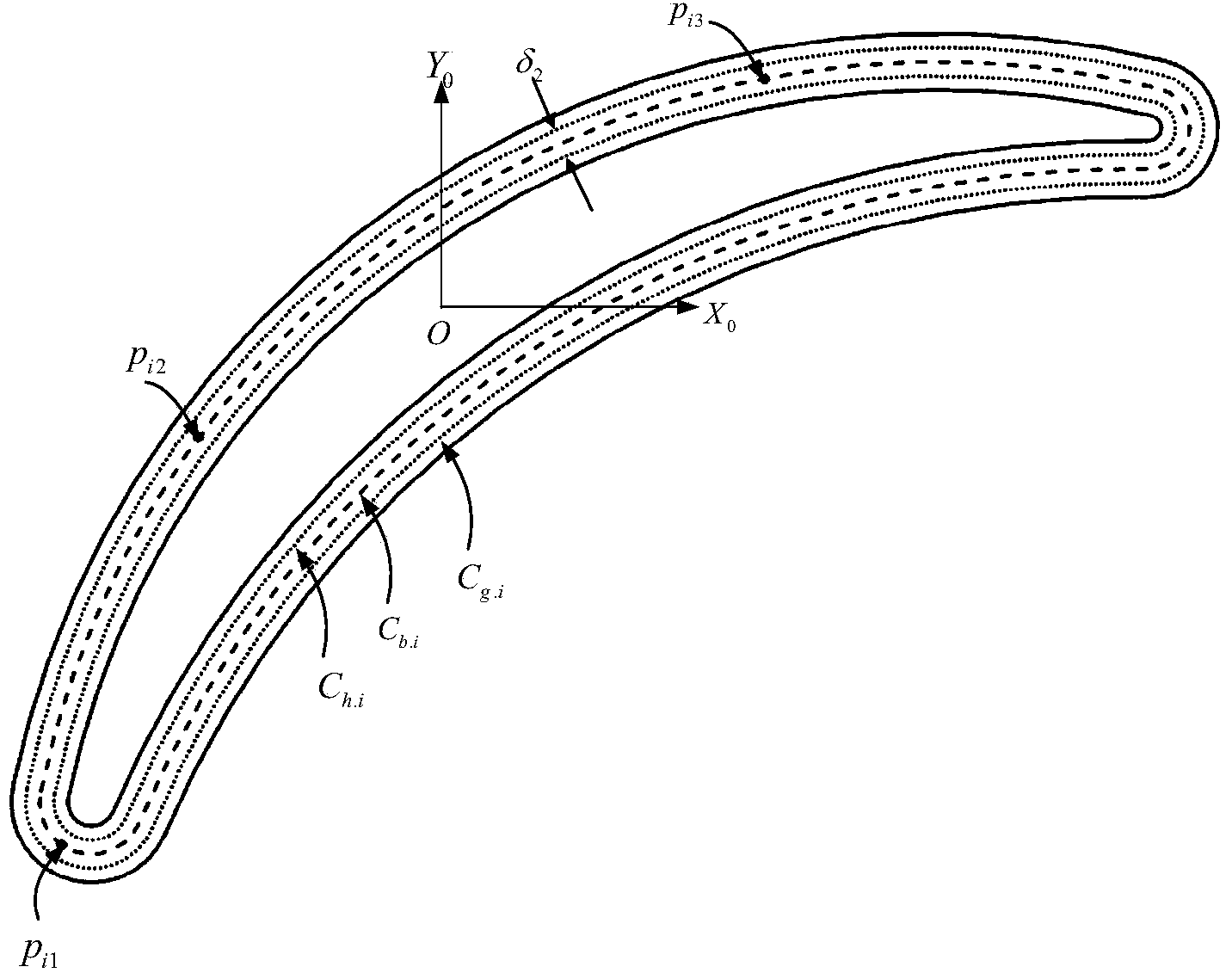

[0037] See figure 1 -6, the specific implementation steps of the present invention are as follows:

[0038] Step 1. Know a given set of data points (that is, type value points) p i (i=0,1,...m), m+1 is the number of type value points. Using parameter cubic non-uniform B-spline curve to interpolate this set of data points to obtain spline curve, the equation is:

[0039] p ( u ) = Σ j = 0 m d j N j , k ( u )

[0040] Among them, d j (j=0,1,...,m) is the control vertex of the interpolation curve, u is the node value, N j,u is the base function. Node vectors are determined according to the Hartley-Judd method, namely:

[0041] u ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com