Torsional vibration damper

A technology of torsional vibration and shock absorber, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, spring, etc. It can solve the problems of small spring capacity and achieve the effect of simplified assembly and simple spring capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

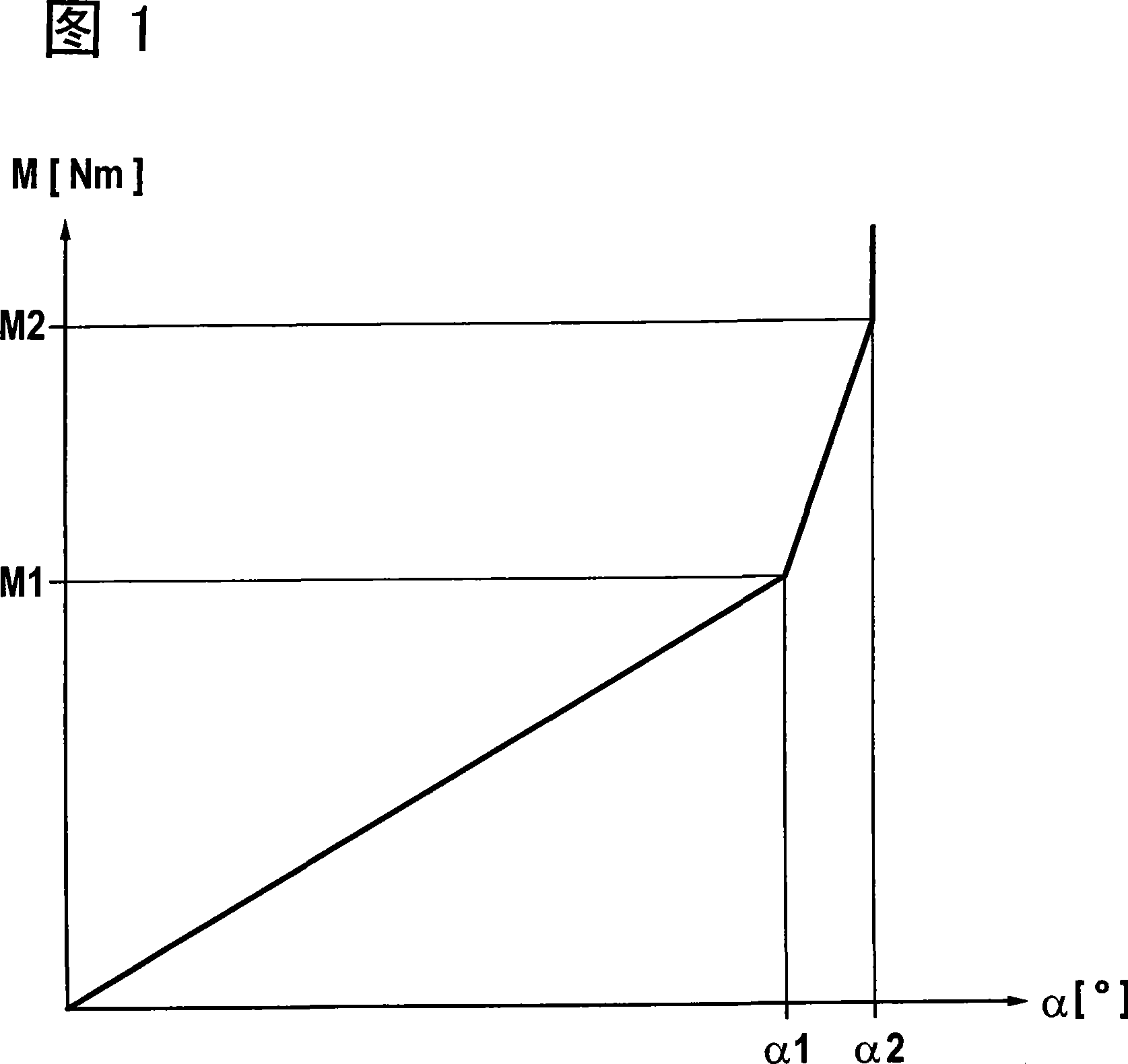

[0029] FIG. 1 shows a Cartesian coordinate diagram in which the torque M in Nm of the torsional vibration damper according to the invention is expressed in degrees in the form of a characteristic curve in the Cartesian coordinate diagram. The relationship between the torsion angle α, this characteristic curve is also called the main shock absorber characteristic curve. The characteristic curve rises linearly from the coordinate origin until a torque M1 corresponding to the maximum engine torque is reached. The dependent torsion angle is α1. In the angular range between α1 and α2 the characteristic curve rises steeply in order to cover the overload moment designated by M2. According to an important aspect of the present invention, a torsional vibration damper is provided, with which the characteristic curve shown in FIG. 1 can be realized in a simple manner. In this case, the known disadvantages of rubber / elastomer springs and of previous steel spring solutions are compensate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com