A clean egr loop system

A loop system and EGR valve technology, which is applied in the field of clean EGR loop system, can solve problems affecting EGR response speed and flow efficiency, power and economic loss, and high control strategy requirements, so as to improve response speed and flow efficiency, Extended service life and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

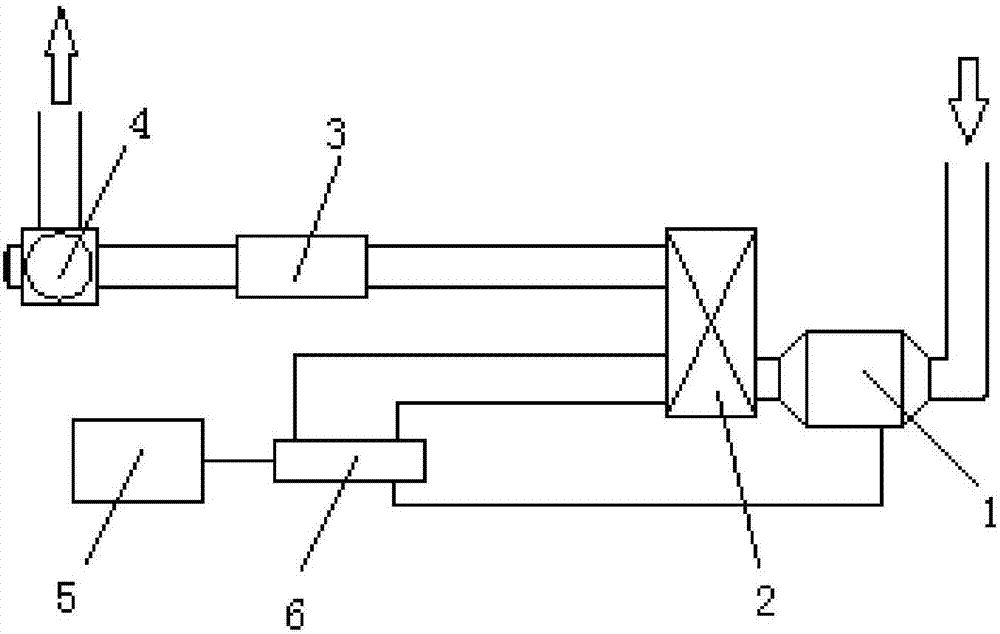

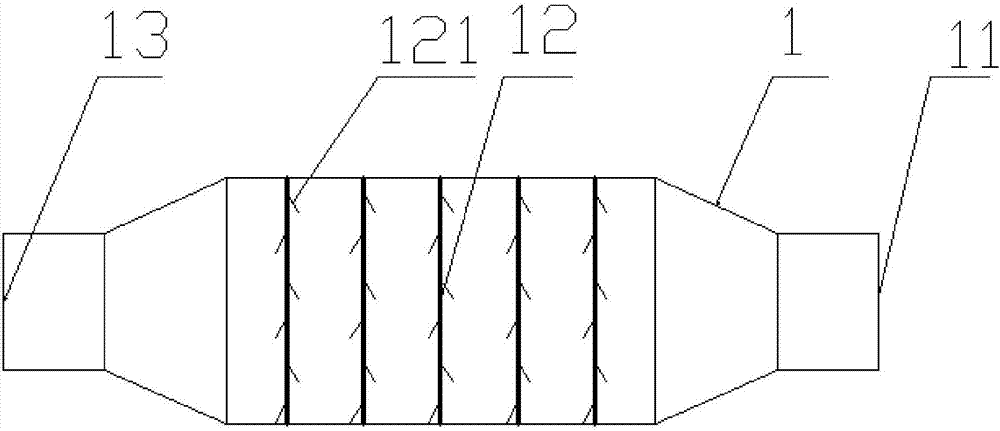

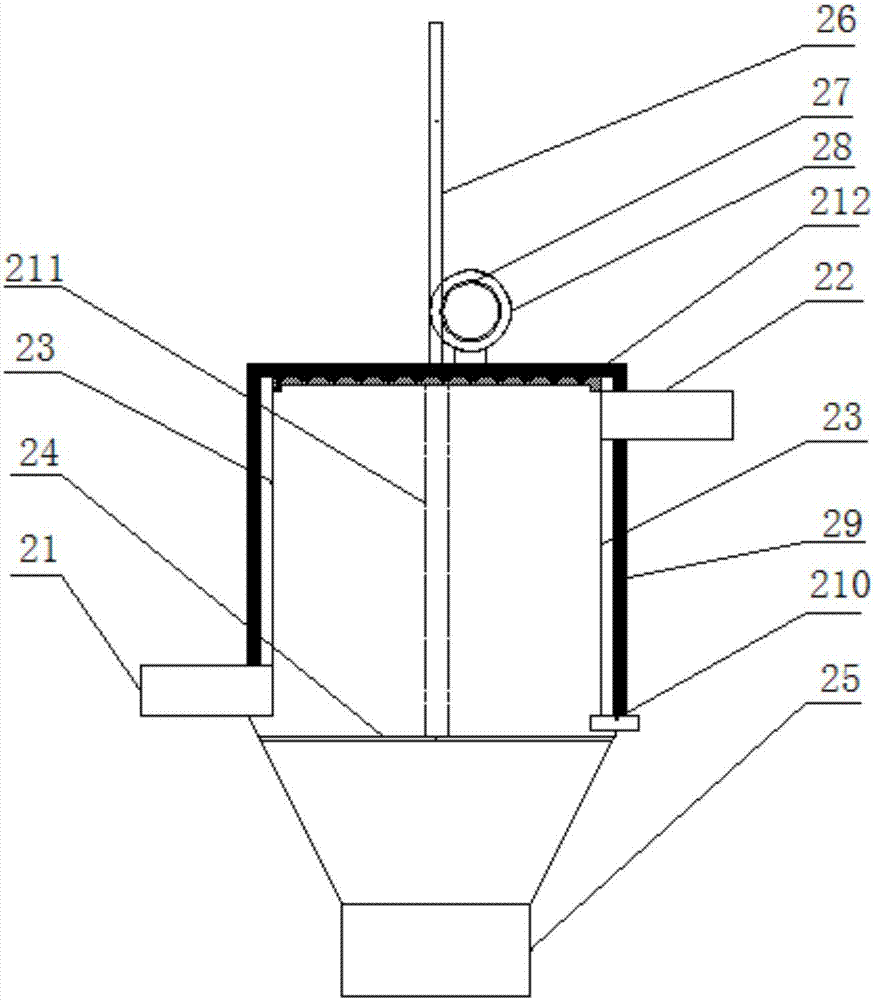

[0030] A clean EGR loop system such as Figure 1-4 As shown, it includes an EGR cooler 3 and an EGR valve 4, and also includes a charge condensation chamber 1 and a trap 2. The charge condensation chamber 1 is a cavity structure provided with an inlet 11 and an outlet 13. The charge condensation chamber 1 The cavity structure is provided with metal strips 12, and the metal strips 12 are arranged side by side at an interval of 20-30 mm inside the charged coagulation chamber 1. In this embodiment, the interval is 20 mm, and the metal strips 12 can be loaded with a pulsed DC voltage of 30-40 kv. For example, 35kv is used, the outlet of the charged coagulation chamber 1 is connected to the inlet of the trap 2, the outlet of the trap 2 is connected to the inlet of the EGR cooler 3, and the outlet of the EGR cooler 3 is provided with an EGR valve 4. The collector 2 is provided with an electrode plate 23, and there are two electrode plates of the collector 2, which are respectively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com