Method for detecting static rigidity of light passenger car body

A detection method and static stiffness technology, which are applied in the field of static stiffness detection of light passenger car bodies, can solve problems such as reliability doubts, adverse vehicle performance problems, and reduced availability of results, and achieve verification accuracy, and the detection method is simple and reliable. , the effect of the detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Torsional stiffness:

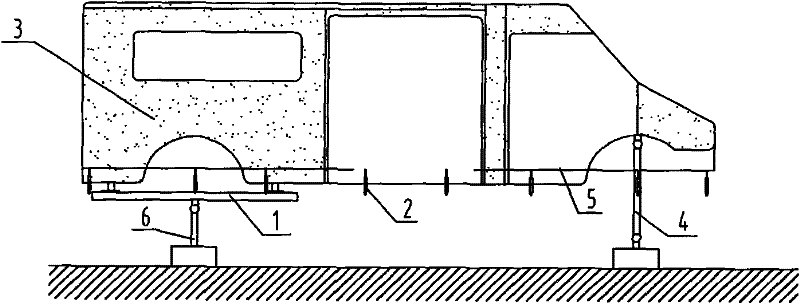

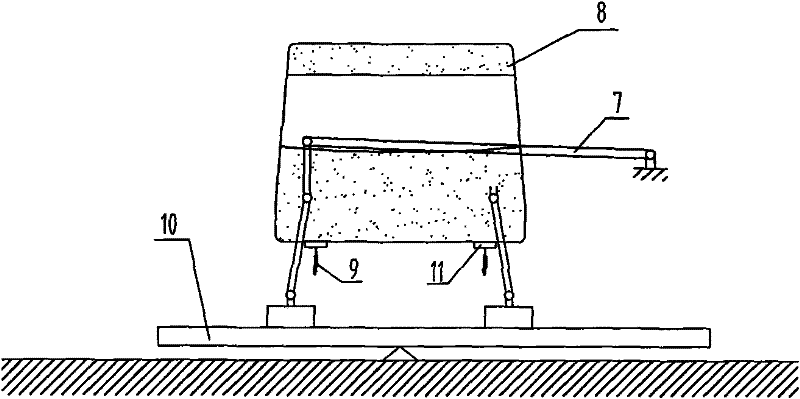

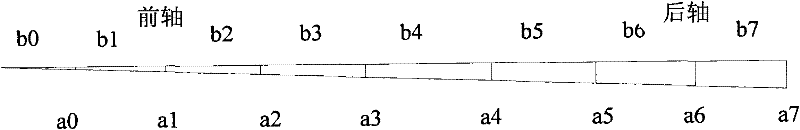

[0017] The diagram of torsional stiffness is shown in figure 1 , the test bench is composed of a body, a bending stiffness table, a body support, a transverse fixed rod, a displacement sensor, and a force sensor. Constraint method of the front axle of the body: constrain the displacement of the front axle in the z direction, release the rotation in the directions of x, y, and z. The constraint method of the rear axle of the body: constrain the displacement of the rear axle in the directions of x, y, and z, and release the rotation in the directions of x, y, and z; Realized by spherical hinge. During the test, ensure that the front, rear, left and right sides of the vehicle body longitudinal beams are horizontal. The principle of arrangement of the displacement sensor and force sensor is that the front and rear axles must be arranged at the corresponding longitudinal beams (left and right longitudinal beams). Other measuring points are arranged ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com