Vibration-suppressing mechanism for gear-shaping machine

一种减振机构、加工机床的技术,应用在金属加工机械零件、切齿机、带有齿的元件等方向,能够解决加工精度影响等问题,达到减小机械振动的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

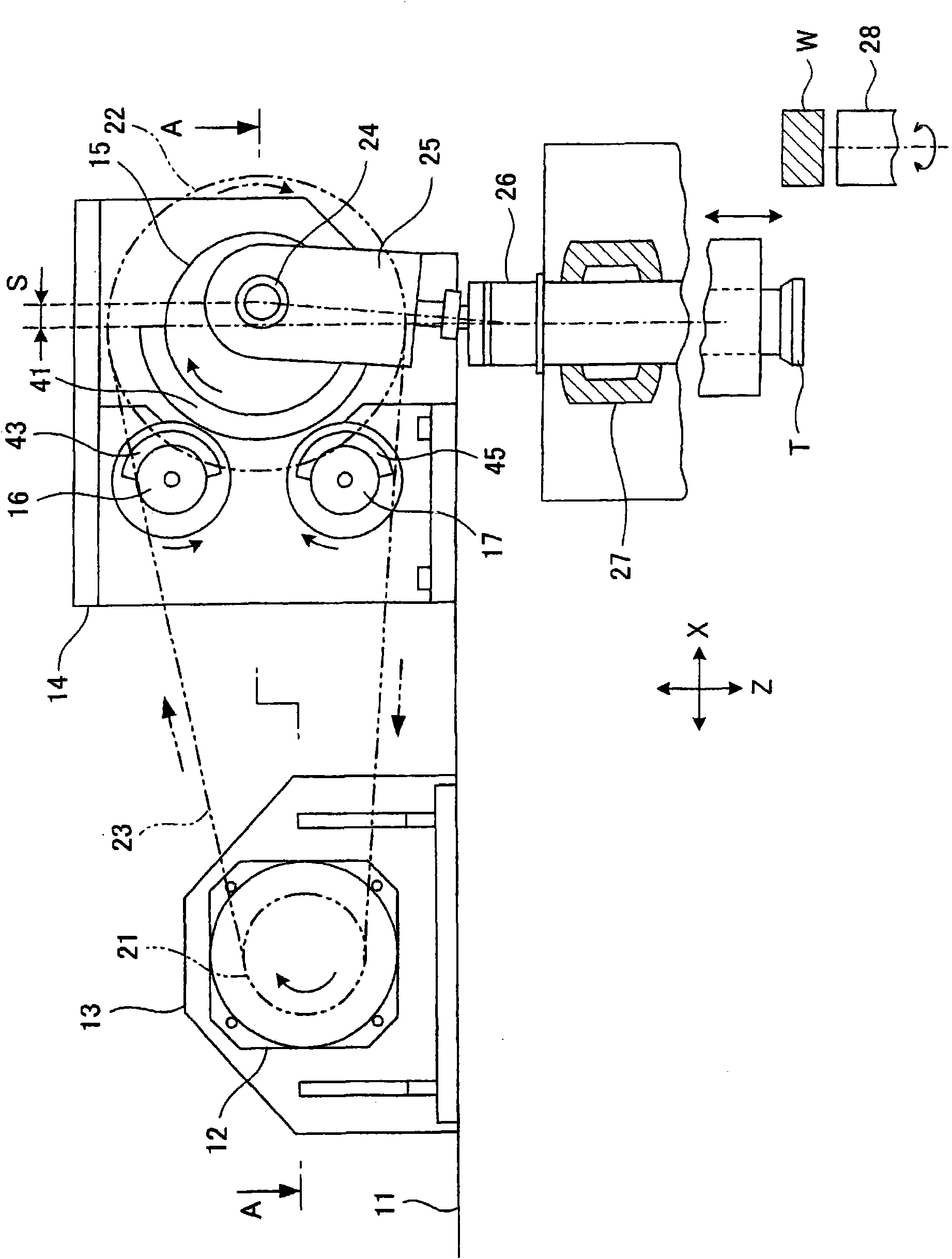

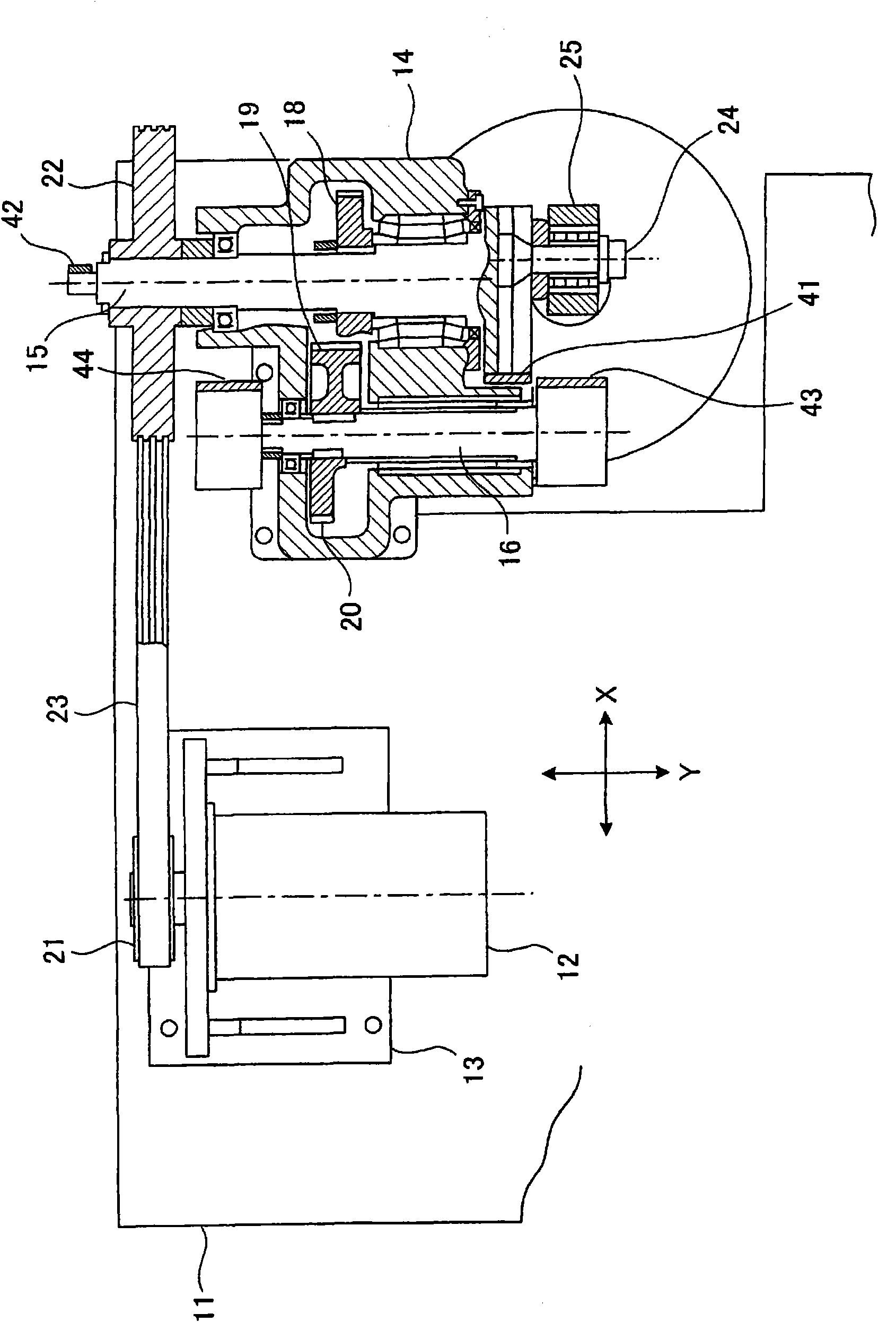

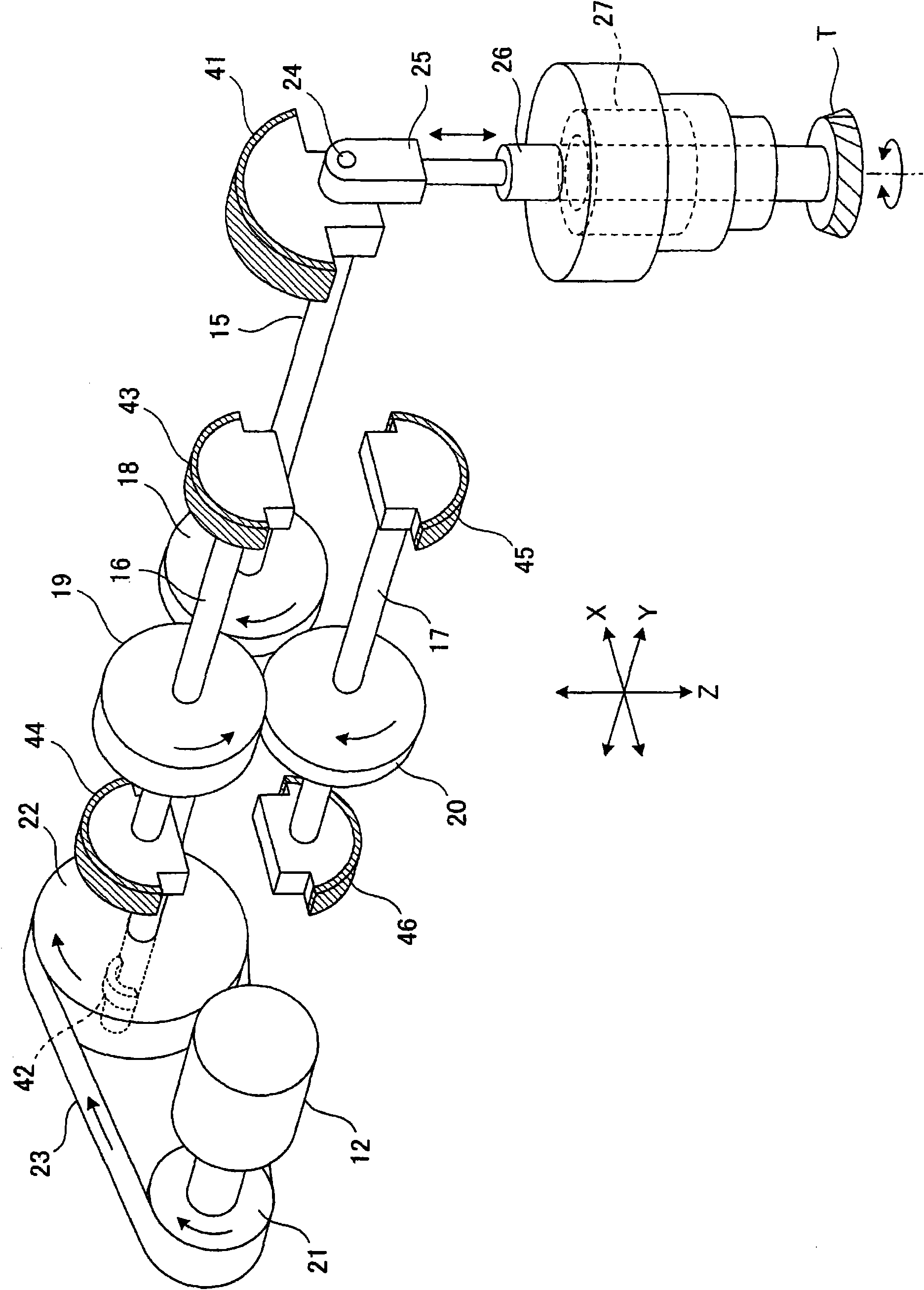

[0032] A vibration damping mechanism for a gear processing machine tool according to the present invention will be described in detail below with reference to the accompanying drawings. figure 1 is a front view illustrating a vibration damping mechanism for a gear processing machine tool according to an embodiment of the present invention. figure 2 is along figure 1 Cross-sectional view of arrow line A-A. image 3 It is the basic structural diagram of the damping mechanism. Figure 4 It is a front view illustrating the basic principle of the damping mechanism. Figure 5 is a top view illustrating the basic principle of the vibration damping mechanism.

[0033] equipped with Figure 1-3 The gear processing machine tool of the vibration damping mechanism shown is a gear shaping machine that shapes a workpiece W into, for example, a helical gear. Note that the X-axis, Y-axis, and Z-axis in the figure are three axes that cross each other perpendicularly. The X-axis directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com