New Spherical Surface Grinding Machine Tool and Its Grinding Method

A spherical grinding and machine tool technology, applied in the field of spherical grinding machine tools and spherical grinding, can solve the problems of not suitable for large-scale production, only suitable, low grinding efficiency, etc., to achieve high productivity, good versatility, sand multiple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

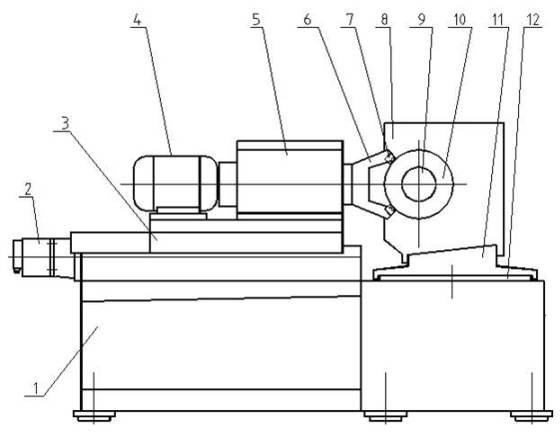

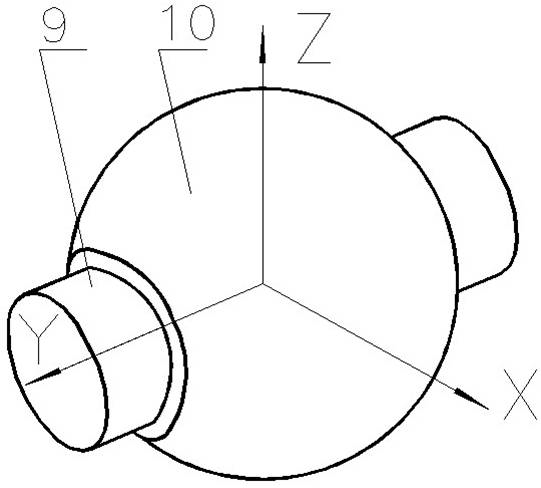

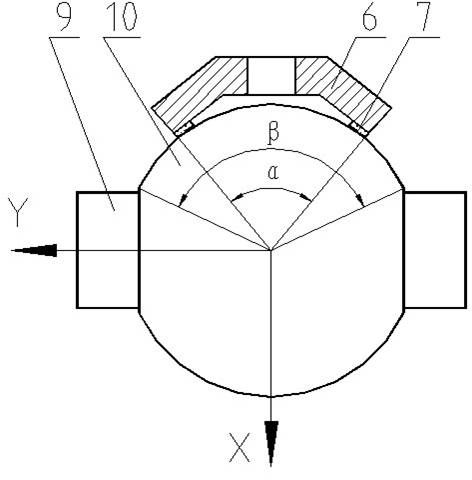

[0032] Such as figure 1 Shown is the structural representation of the embodiment of the novel spherical grinding machine tool of the present invention, the novel spherical grinding machine tool of the present embodiment comprises a machine tool bed 1, a workbench 11 installed on the machine tool bed 1, and The sliding saddle 3 is provided with a grinding wheel frame 5 on the sliding saddle 3. The grinding wheel frame 5 is provided with a sand disc 6 facing the front of the workbench. The rear of the grinding wheel frame 5 is provided with a motor 4 for driving the sand disc 6 to rotate. There are many sand strips 7 inlaid evenly on the top. The two ends of the workbench 11 are oppositely provided with a headstock 8 and a tailstock, and a mandrel 9 which is installed on the headstock 8 and the tailstock and is used to fix the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com