Plasma etching method for eliminating organic substance using sulfur dioxide mixture gas

A technology of sulfur dioxide and mixed gas, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve problems affecting circuit performance and structural differences, and achieve the effects of eliminating time delays of resistors and capacitors, improving impacts, and increasing yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

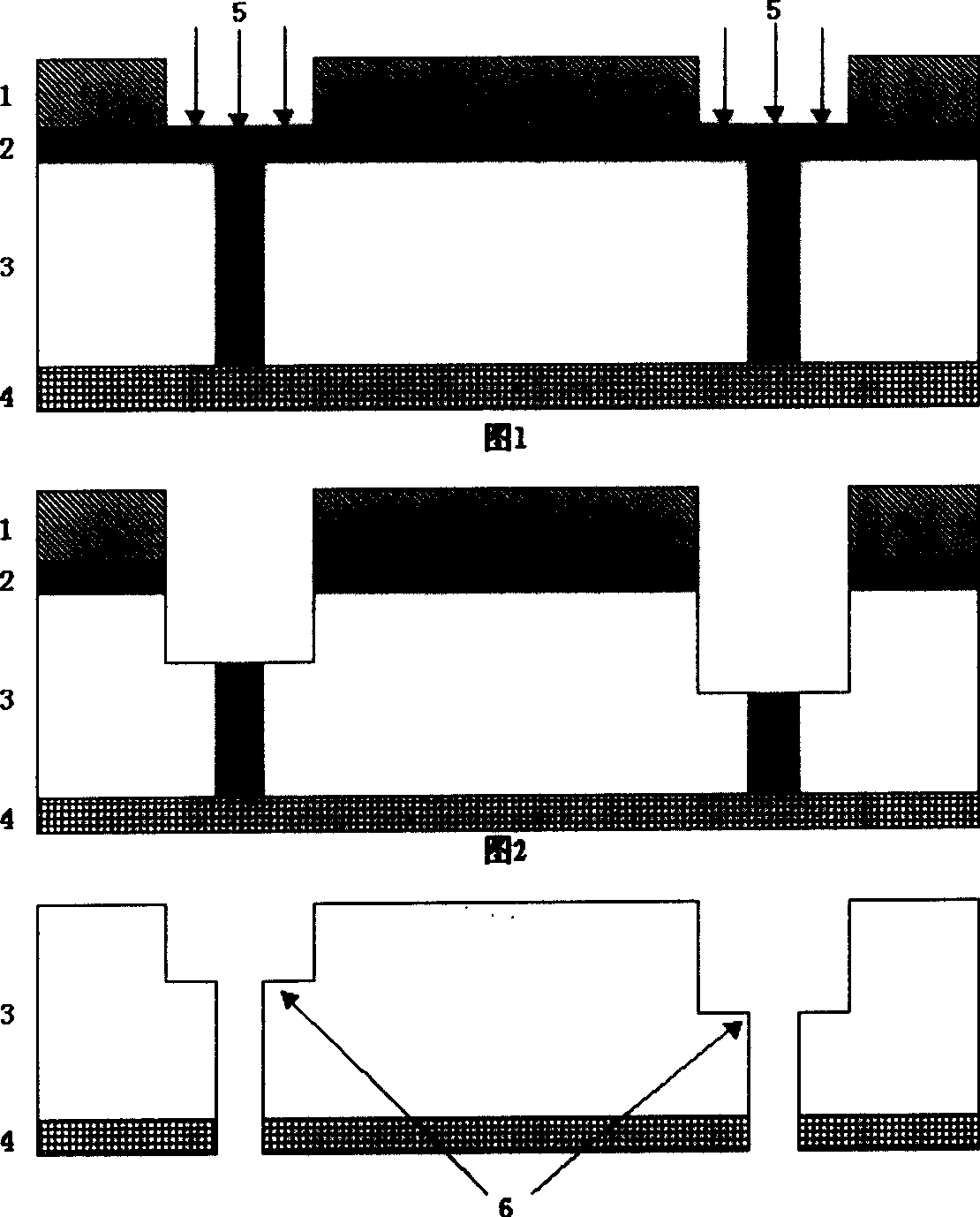

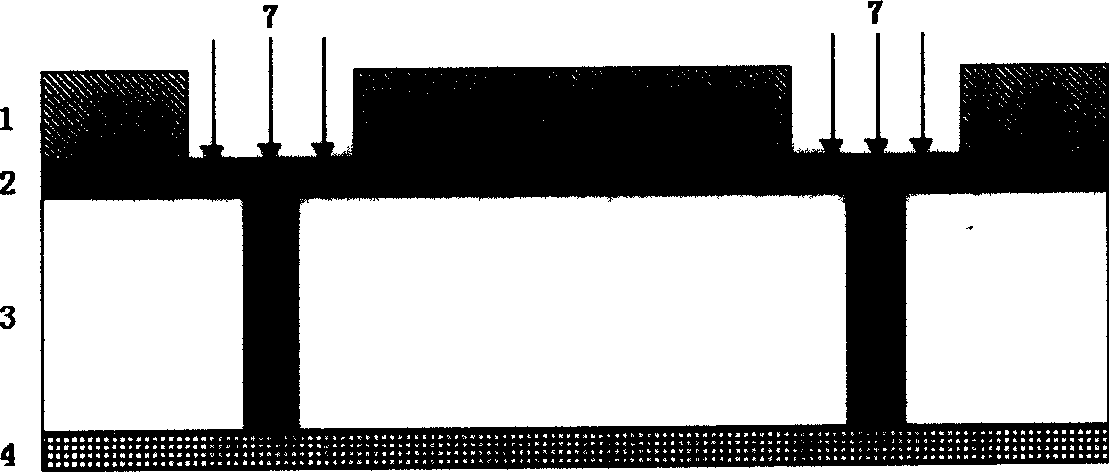

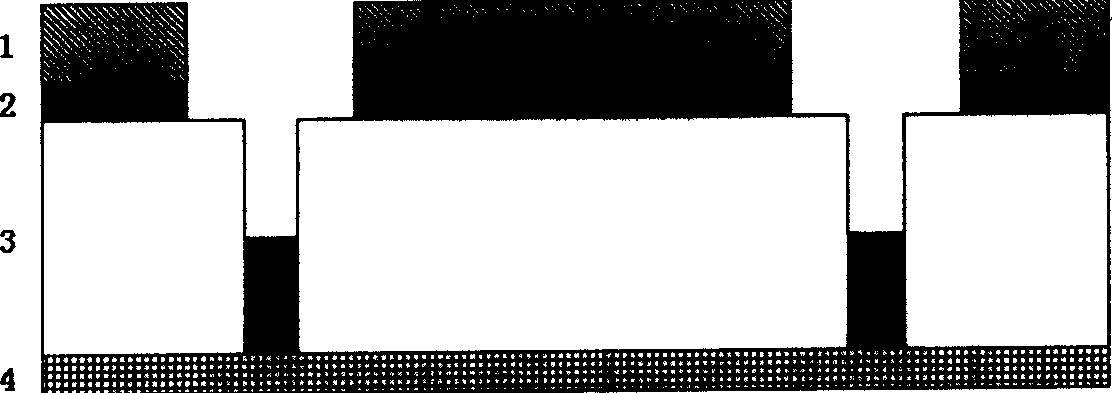

[0015] Implementation steps of the present invention are as follows:

[0016] 1. Deposit the etching barrier material by enhanced plasma chemical vapor deposition: silicon carbide;

[0017] 2. Deposit insulating dielectric material by enhanced plasma chemical vapor deposition method: silicon dioxide:

[0018] 3. Carry out the first photolithography step to expose the pattern of the through hole on the silicon wafer;

[0019] 4. Etching the through hole, removing the photoresist, and cleaning the silicon wafer;

[0020] 5. Filling and coating of organic matter in the anti-reflection layer;

[0021] 6. Carry out the second photolithography step to expose the pattern of the metal groove on the silicon wafer;

[0022] 7. Use sulfur dioxide mixed gas, the mixed gas can be oxygen, hydrogen, nitrogen, argon, carbon monoxide, carbon dioxide or fluorocarbon gas, the volume ratio of sulfur dioxide to mixed gas is 0.5:1 or 1.25:1 or 3:1, for The organic filling layer is etched;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com