A 180-200mm thick alloy structural steel 27simn and its production process

A technology of alloy structural steel and production process, which is applied in the field of iron and steel smelting, can solve the problems of inapplicability, unprovided steel smelting and rolling process, etc., and achieve the effects of improved production process, excellent comprehensive performance and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

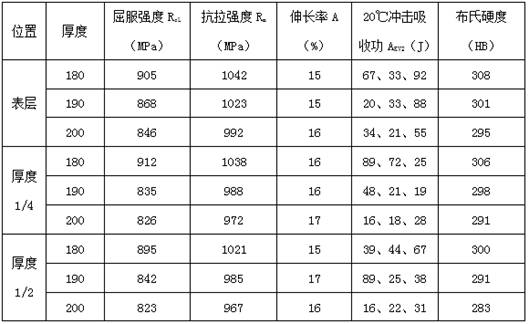

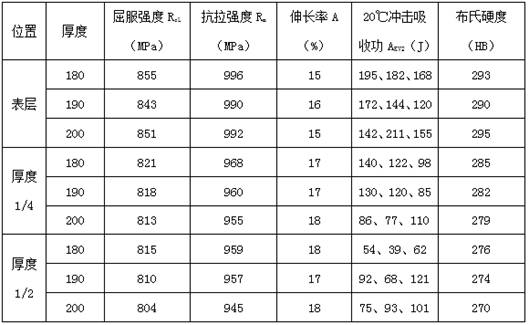

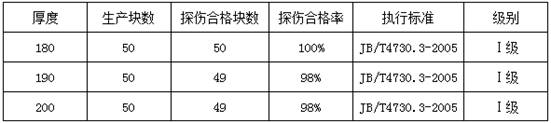

Examples

Embodiment

[0036] C: 0.28, Si: 1.3, Mn: 1.25, P: 0.015, S≤0.005, B: 0.0009, Ti: 0.025, and the rest are Fe and residual elements.

[0037] The carbon equivalent of the chemical composition is (0.49)%. (Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15).

[0038] a. Converter smelting: The temperature of molten iron entering the furnace is 1320°C, and the Si content of molten iron is 0.3%.

[0039] b. LF refining: 1. Heating time 9 minutes, add 400m long Al wire; 2. Heating time 13 minutes, 3. Heating time 8 minutes, add 120m long Ca wire during slagging process to ensure slagging effect;

[0040] c.VD vacuum treatment: vacuum degree 67Pa, vacuum time 18min;

[0041] d. Mold casting: Before casting, the flow rate of argon blowing is 28NL / min, the time is controlled at 15min, and the casting temperature is controlled at 1555°C. After the casting is completed, heat generating agent is added to the riser, and at the same time, the mold slag and carbonized rice husk are evenly covered;

[0042] e. Heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com