A kind of 6mm thick nuclear power containment steel and its manufacturing method

A manufacturing method and containment technology, applied in the direction of metal rolling, etc., can solve the problems of large temperature difference between the head and tail of the rolling piece, large performance fluctuation, easy to exceed the upper limit, etc., to achieve stable yield strength control and optimize the length of the gauge. , to avoid the effect of large temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

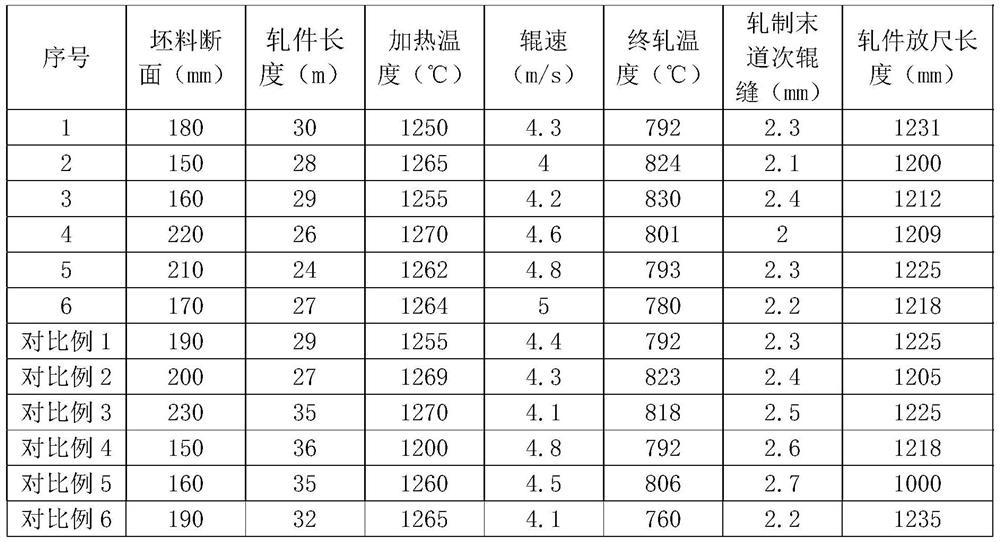

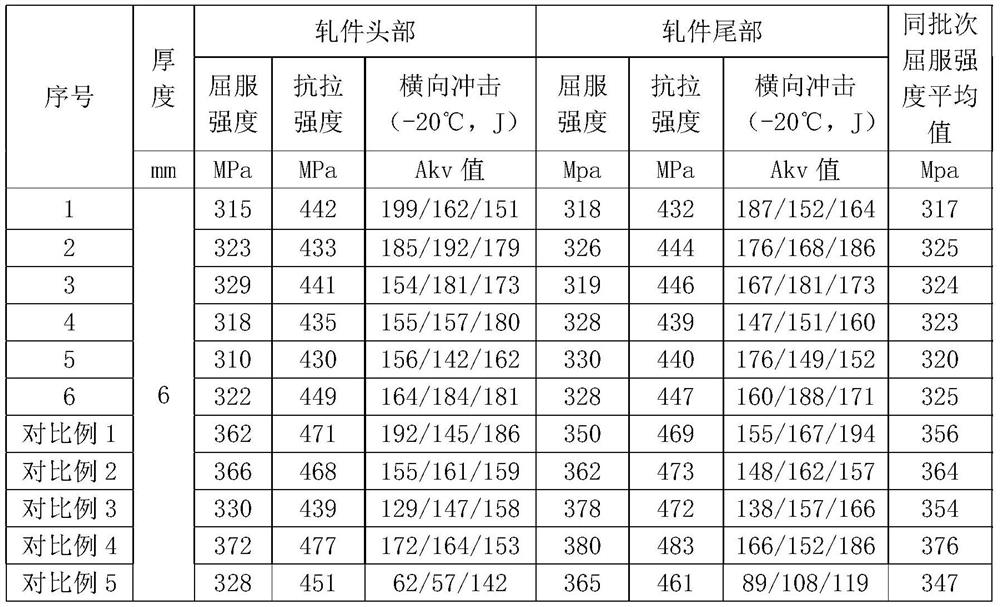

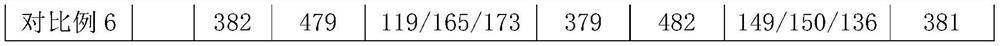

[0023] The following provides 6 sets of examples and 6 sets of comparative examples to describe the steel for nuclear power containment with a thickness of 6mm of the present invention in detail. The chemical composition of steel in each case is shown in Table 1:

[0024] Table 1 Chemical composition of steel (the balance is Fe and impurities)

[0025] serial number C mn P S Si 1 0.14 0.8 0.018 0.008 0.3 2 0.1 0.6 0.019 0.006 0.2 3 0.12 0.7 0.02 0.009 0.4 4 0.11 0.9 0.016 0.007 0.35 5 0.13 1 0.018 0.008 0.5 6 0.09 0.8 0.017 0.01 0.29 Comparative example 1 0.15 0.9 0.018 0.009 0.42 Comparative example 2 0.14 1.2 0.017 0.008 0.35 Comparative example 3 0.1 0.8 0.02 0.006 0.28 Comparative example 4 0.13 0.9 0.018 0.008 0.31 Comparative example 5 0.12 0.7 0.015 0.007 0.46 Comparative example 6 0.13 0.8 0.019 0.008 0.38

[0026] Among them, the compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com