Welding device of piston rod sub-assembly of telescopic shock absorber

A welding device and piston rod technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of shock absorber failure, shock absorber oil leakage, piston rod burn, etc., to reduce waste, improve product quality, The effect of short changeover time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

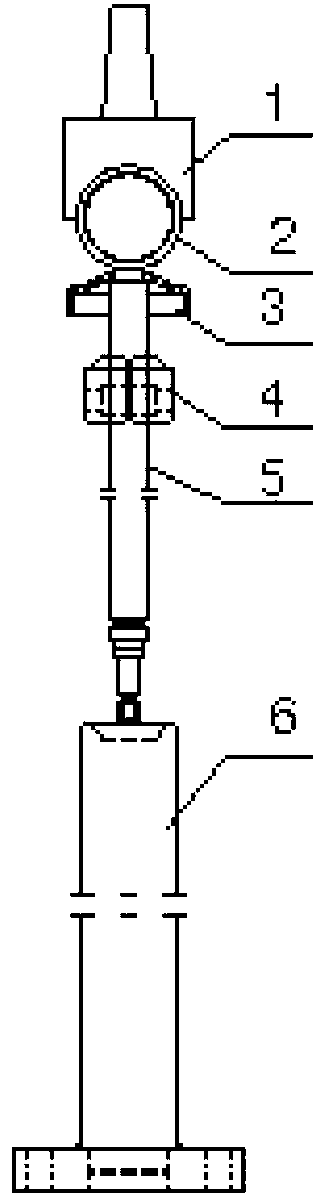

[0009] attached by figure 1 It can be seen that the present invention includes a piston rod 5, the upper end of the piston rod 5 is provided with a dust cover 3 and an upper suspension ring 2 in turn, the bottom of the piston rod 5 is provided with a lower positioning seat 6 for supporting the piston rod 5, and the upper end of the upper suspension ring 2 is provided with a For the upper electrode 1 , a clamping block 4 is provided between the lower positioning seat 6 and the upper electrode 1 . The clamping block 4 is made of pure copper and is used for clamping and fixing the piston rod 5 to avoid damage to the piston rod 5 when it is fixed.

[0010] When in use, first place the piston rod 4 vertically on the lower positioning seat 6, start the clamping block 4 to clamp the piston rod 5, put the dust cover 3 on the piston rod 5, put the upper ring 2 on the upper electrode 1 bottom, and then the upper electrode 1 together with the upper ring 2 presses the piston rod 5 to sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com