Clamp with one surface and two pins and manufacture method thereof

A manufacturing method and pin positioning technology, applied in positioning devices, manufacturing tools, clamping and other directions, can solve the problems of long replacement cycle, inflexible replacement, and high replacement cost, and achieve short replacement time and flexible replacement. , the effect of small replacement investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

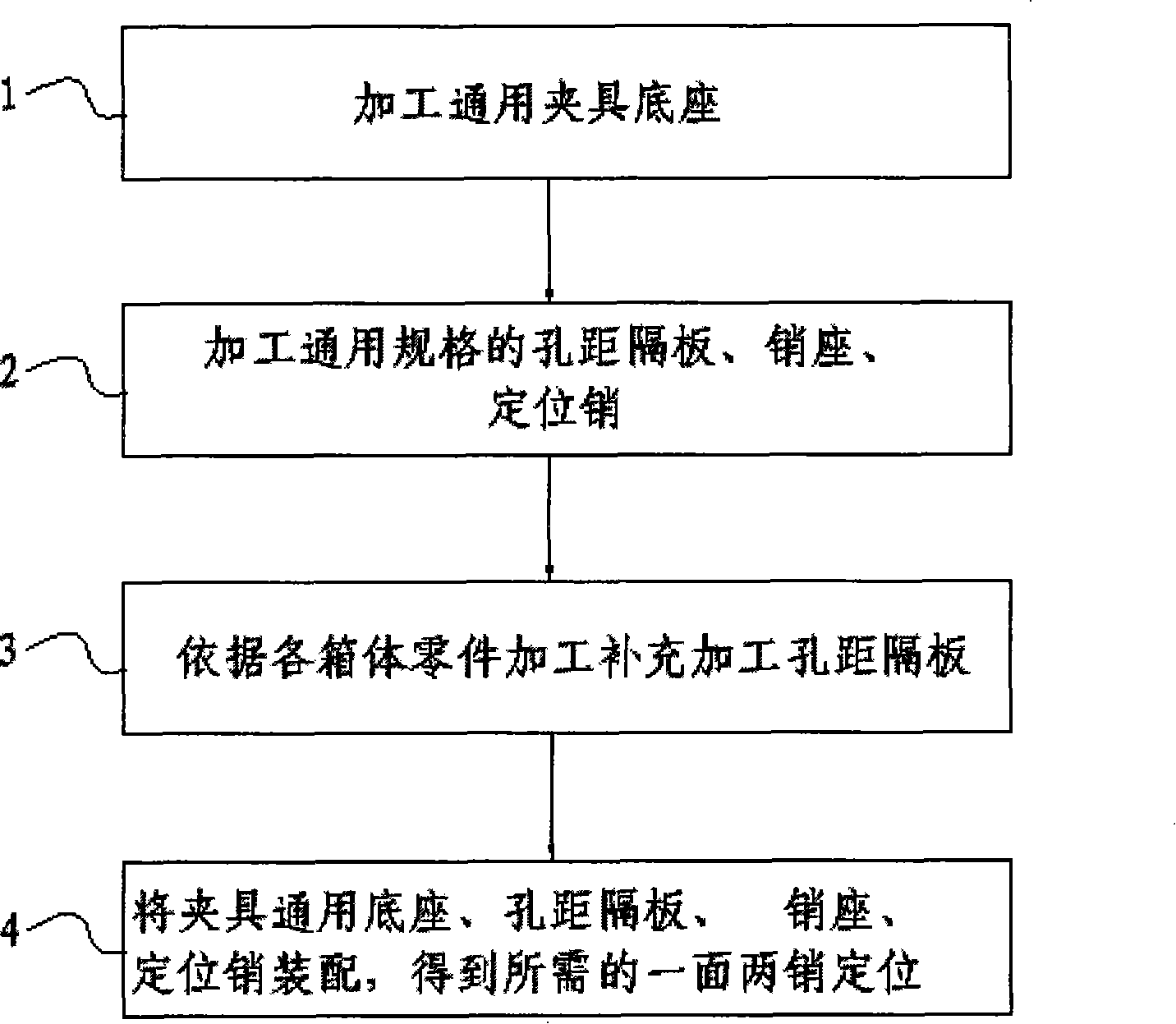

[0041] figure 1 It is a flow chart of the manufacturing method of one side two-pin positioning fixture of the present invention, comprising steps:

[0042] Step 1. Process the universal fixture base;

[0043] Step 2. Process hole spacing partitions, pin hole seats, and positioning pins of general specifications;

[0044] Step 3. According to the size of the hole distance of each box body part, the hole distance partition is shortened to the corresponding length;

[0045] Step 4. Assemble the common base of the fixture, the hole distance partition, the pin hole seat, and the positioning pin to obtain the required positioning of two pins on one side.

[0046] Among them, step 1 is specifically:

[0047] Step 11, casting the universal fixture base;

[0048] Step 12. Process the base of the universal fixture, and process the mounting grooves for the partition and the mounting screw holes.

[0049] Among them, step 2 is specifically:

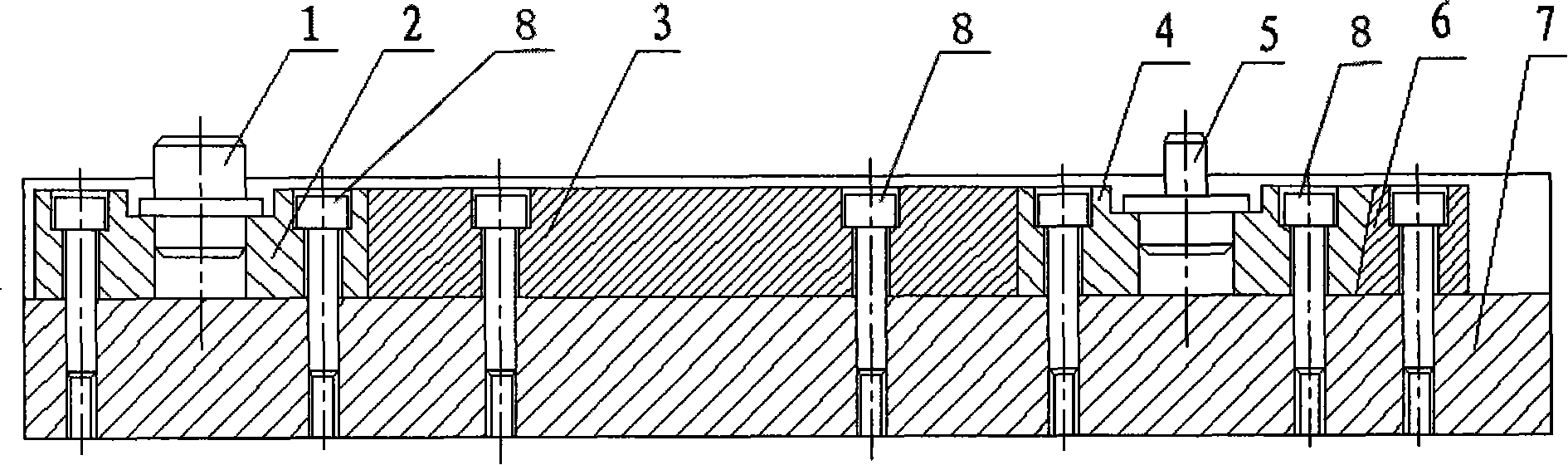

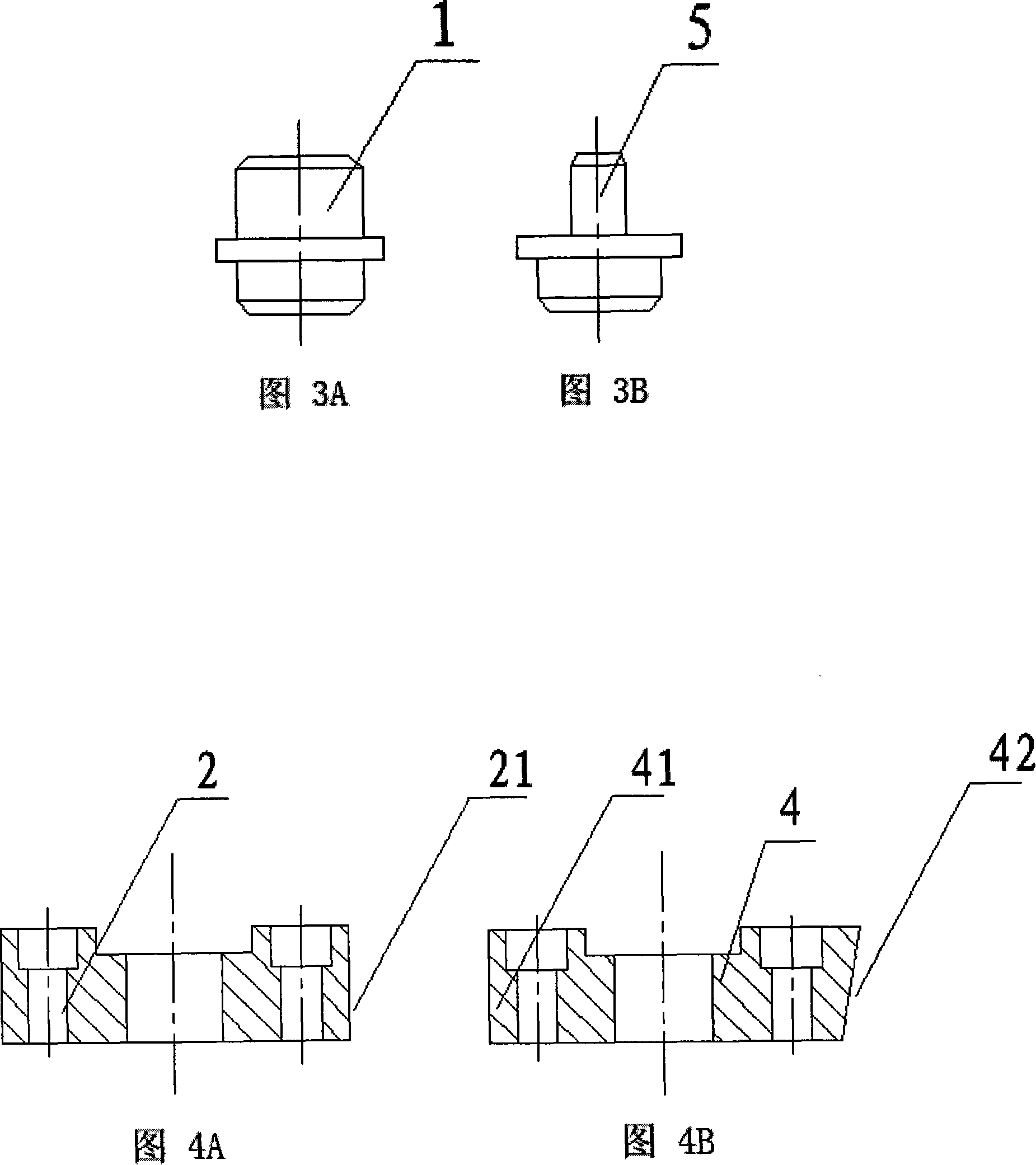

[0050] Step 21, processing the hole-dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com