Method for manufacturing hot protruding transfer hot stamping plate capable of being quickly assembled and disassembled

A production method and hot stamping plate technology, applied in the field of hot stamping printing, can solve the problems of long installation and disassembly time, high manufacturing cost, long plate changing time, etc., and achieve low manufacturing cost, improve production efficiency, and short plate changing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

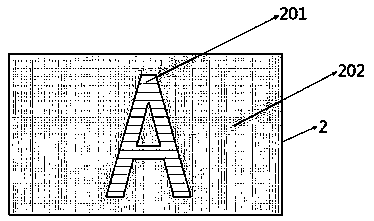

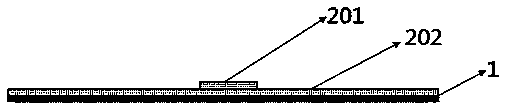

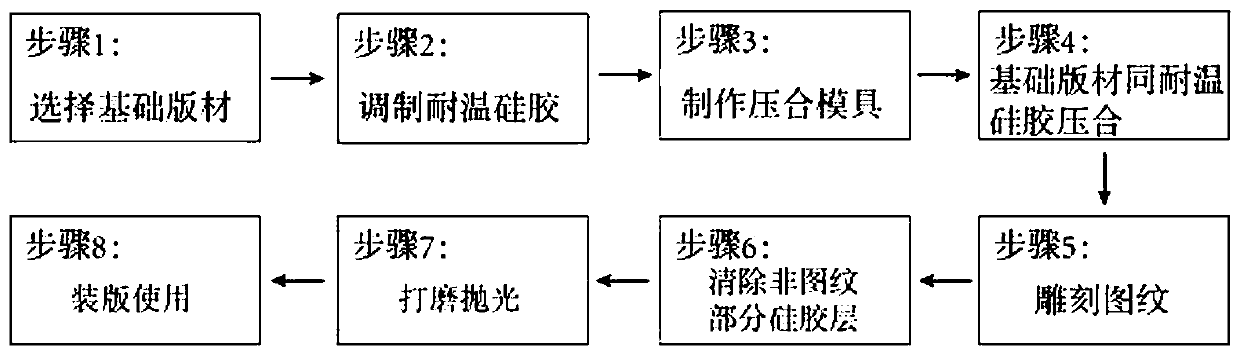

[0036] Such as Figure 1-4 As shown, a method for making a thermal emboss transfer hot stamping plate that can be quickly assembled and disassembled comprises the following steps:

[0037] 1) Select the basic plate material 1. The basic plate material 1 is made of a metal or non-metallic plate material with good thermal conductivity. In this embodiment, an aluminum alloy plate with a metal with good thermal conductivity is preferred. The basic plate material 1 The thickness is 0.1mm.

[0038] 2) Prepare heat-resistant silica gel 2:

[0039] A. Put fluorosilicone rubber, iron oxide, diphenylsilanediol, bis-2,5*, and white carbon black into a container to fully disperse and mix evenly. Silicone fluorogel: iron oxide: diphenylsilanediol: bis 2, 5*: The mixing mass ratio of white carbon black is 80:1:1:1:20; after mixing this mass ratio, silica gel with a hardness of 65 Shore can be obtained.

[0040] B. Put the uniformly mixed material into a high-pressure extruder for high-pr...

Embodiment 2

[0053] Such as Figure 1-4 As shown, a method for making a thermal emboss transfer hot stamping plate that can be quickly assembled and disassembled comprises the following steps:

[0054] 1) Select the basic plate material 1. The basic plate material 1 is made of a metal or non-metallic plate material with better thermal conductivity. In this embodiment, a non-metal thermal conductive resin plate with better thermal conductivity is invented and optimized. 1 Thickness is 1mm.

[0055] 2) Prepare heat-resistant silica gel 2:

[0056] A. Put fluorosilicone rubber, iron oxide, diphenylsilanediol, bis-2,5*, and white carbon black into a container to fully disperse and mix evenly. Silicone fluorogel: iron oxide: diphenylsilanediol: bis 2, 5*: The mixing mass ratio of white carbon black is 85:2:2.5:4:30; after mixing this mass ratio, silica gel with a hardness of 70 Shore can be obtained.

[0057] B. Put the uniformly mixed material into a high-pressure extruder for high-pressure...

Embodiment 3

[0070] Such as Figure 1-4 As shown, a method for making a thermal emboss transfer hot stamping plate that can be quickly assembled and disassembled comprises the following steps:

[0071] 1) Select the basic plate material 1. The basic plate material 1 is made of a metal or non-metallic plate material with good thermal conductivity. In this embodiment, a metal copper plate with a metal with good thermal conductivity is preferred. The thickness of the basic plate material 1 is 3mm.

[0072] 2) Prepare heat-resistant silica gel 2:

[0073] A. Put fluorosilicone rubber, iron oxide, diphenylsilanediol, bis-2,5*, and white carbon black into a container to fully disperse and mix evenly. Silicone fluorogel: iron oxide: diphenylsilanediol: bis 2, 5*: The mixing mass ratio of white carbon black is 90:3:3.5:4:40; after mixing this mass ratio, silica gel with a hardness of 75 Shore can be obtained.

[0074] B. Put the uniformly mixed material into a high-pressure extruder for high-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com