Universal forming terminal fixture for measurement

A fixture and terminal technology, which is applied in the field of general-purpose fixtures for molded terminals, can solve the problems of wasting a lot of time, long time for changing wires, and high investment costs, and achieve the effects of short wire changing time, high work efficiency, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

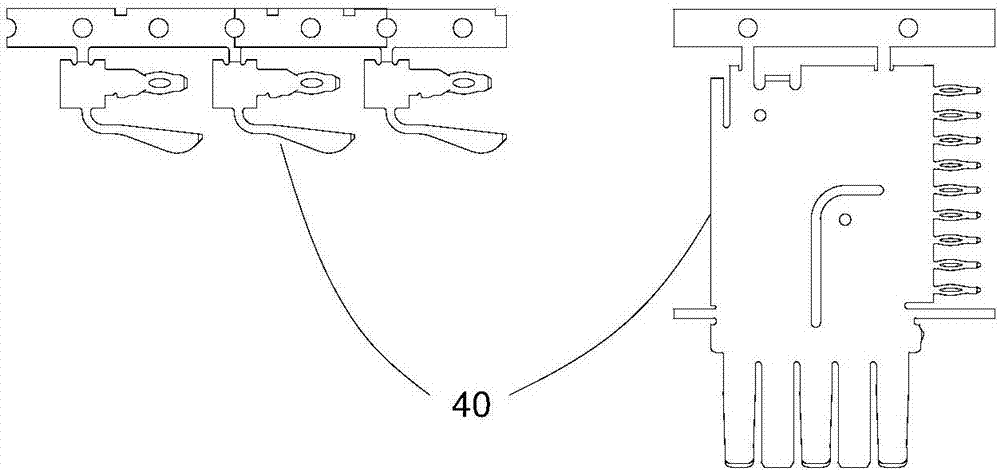

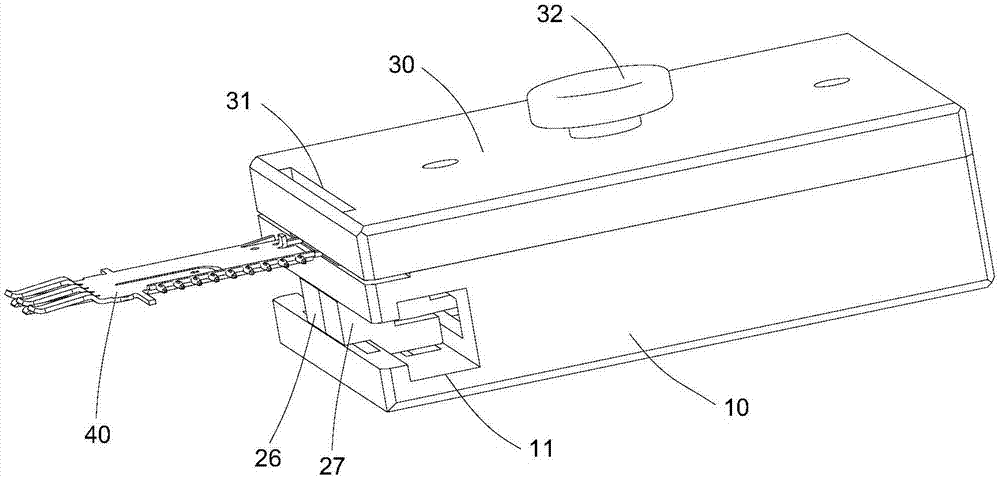

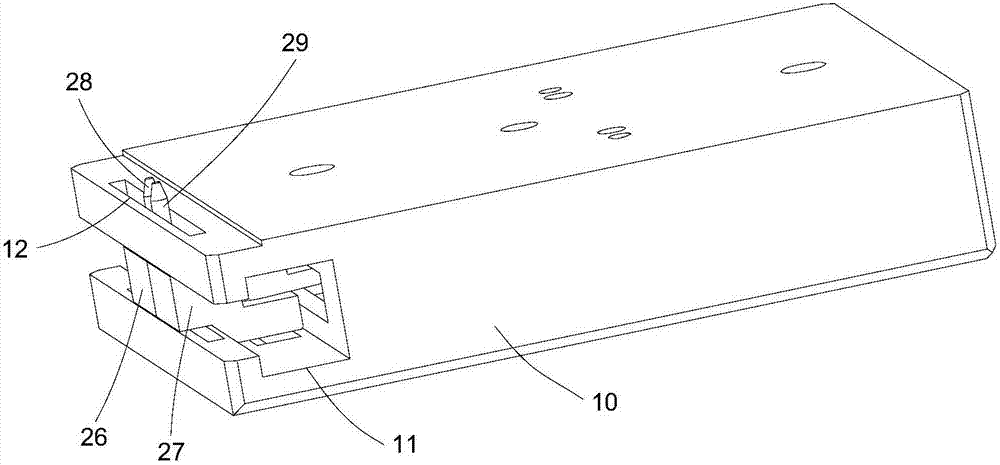

[0027] refer to Figure 1 to Figure 6 .

[0028] The embodiment of the present invention discloses a universal fixture for forming terminals for measurement, which includes a clamping seat 10, a cavity is provided in the clamping seat 10, and a clamping mechanism 20 is provided in the cavity; the clamping mechanism 20 includes a guide seat 21, A connecting block 22 is slidably connected in the guide seat 21, and one end of the connecting block 22 is fixedly connected with a drive portion 23, and the other end of the connecting block 22 is respectively hinged with one end of the first connecting rod 24 and one end of the second connecting rod 25, and the first The other end of connecting rod 24 is hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com