Hydraulic quick-change mechanism for accessory

A technology of hydraulic and locking mechanism, which is applied to mechanically driven excavators/dredgers, etc., can solve the problems of laborious replacement and low efficiency of attachment types, and achieve the effects of short replacement action time, long service life and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

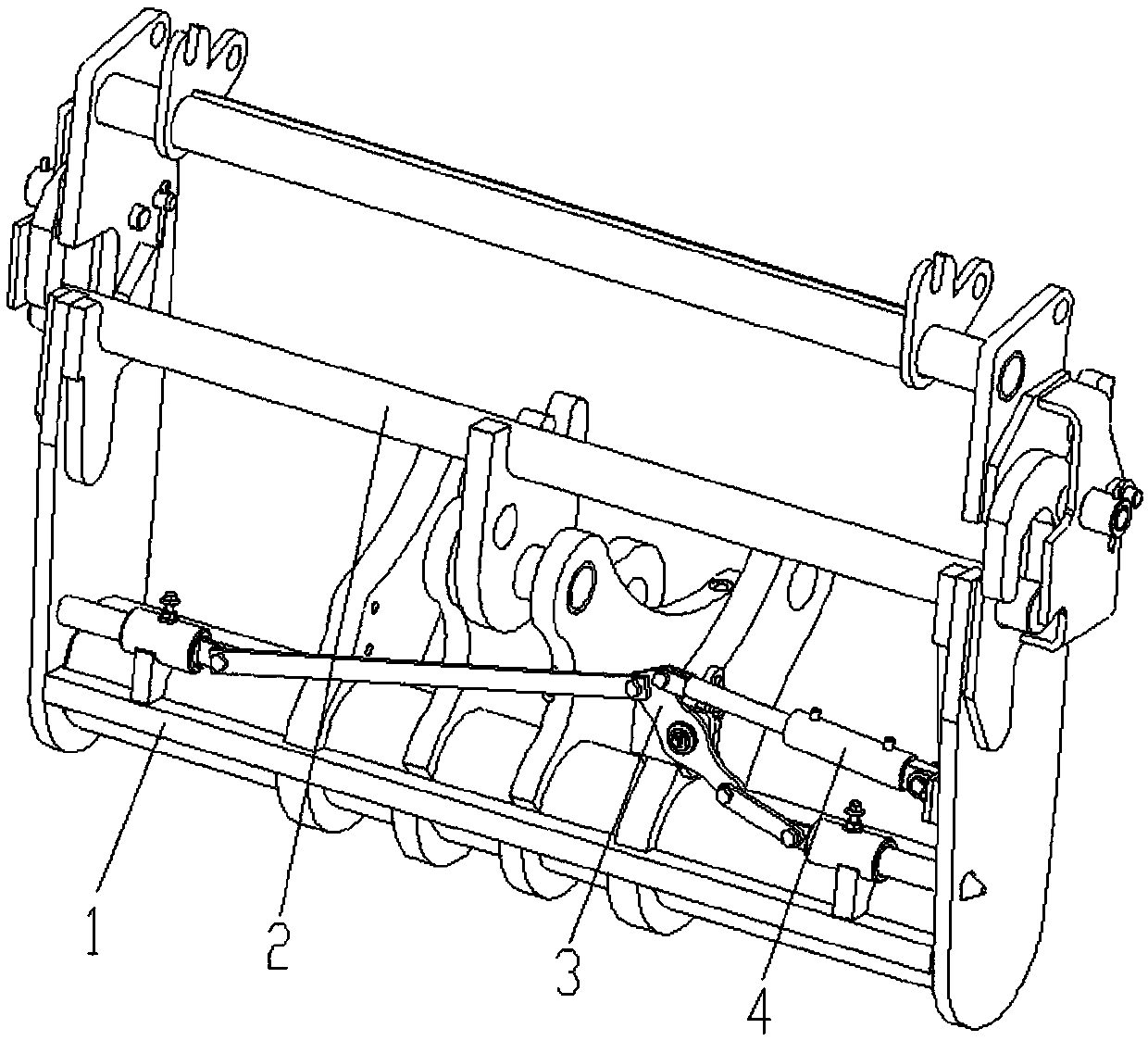

[0026] The hydraulic quick-change mechanism for attachments of the present invention includes an attachment connecting frame 1, a long shaft 2, a long shaft locking mechanism 112, a quick-change connecting rod mechanism 3, and a quick-change oil cylinder 4.

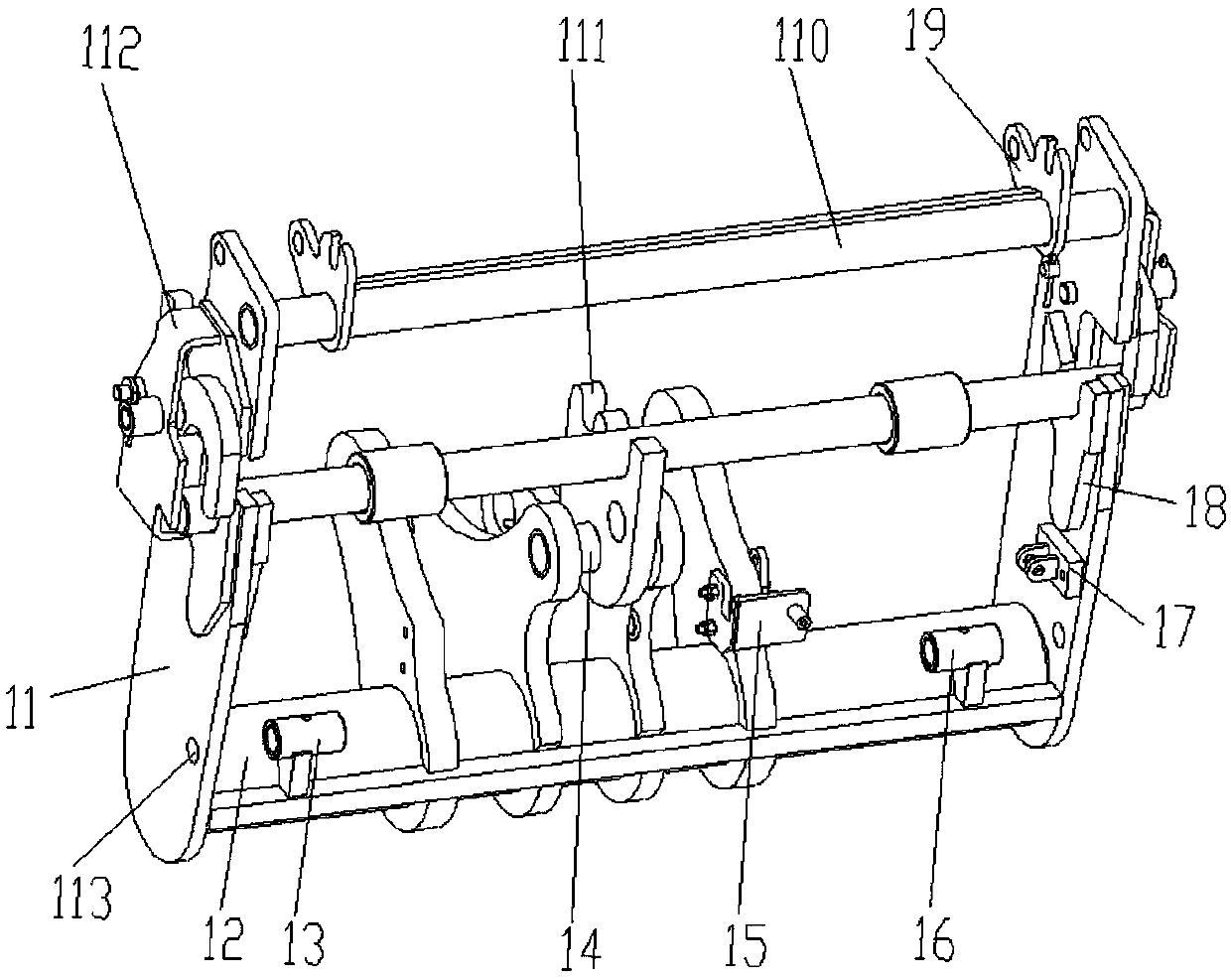

[0027] The attachment frame 1 is composed of a side plate 11, a lower support shaft 12, a left guide shaft sleeve 13, a hinge frame 14, a mounting support 15, a right guide shaft sleeve 16, a cylinder base 17, a side plate reinforcement plate 18, and a lifting lug 19. , The upper supporting shaft 110 and the connecting plate 111 are composed. Among them, the upper support shaft 110 and the lower support shaft 12 are arranged in parallel. The upper support shaft 110 and the lower support shaft 12 are provided with side plates 11 at both ends, and the upper part of each side plate 11 is provided with a long shaft 2 or a connector. With grooves. A long shaft locking mechanism 112 is provided outside the side plate 11 at the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com