Flexible feeding system for assembling connector

A connector and flexible technology, which is applied in the flexible feeding system for assembling connectors and the field of flexible feeding systems, can solve the problems of TEEP and low output per unit area, low utilization rate of automatic equipment, and unusable equipment, etc., to achieve guaranteed Stability and continuity, convenient line change, and short line change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

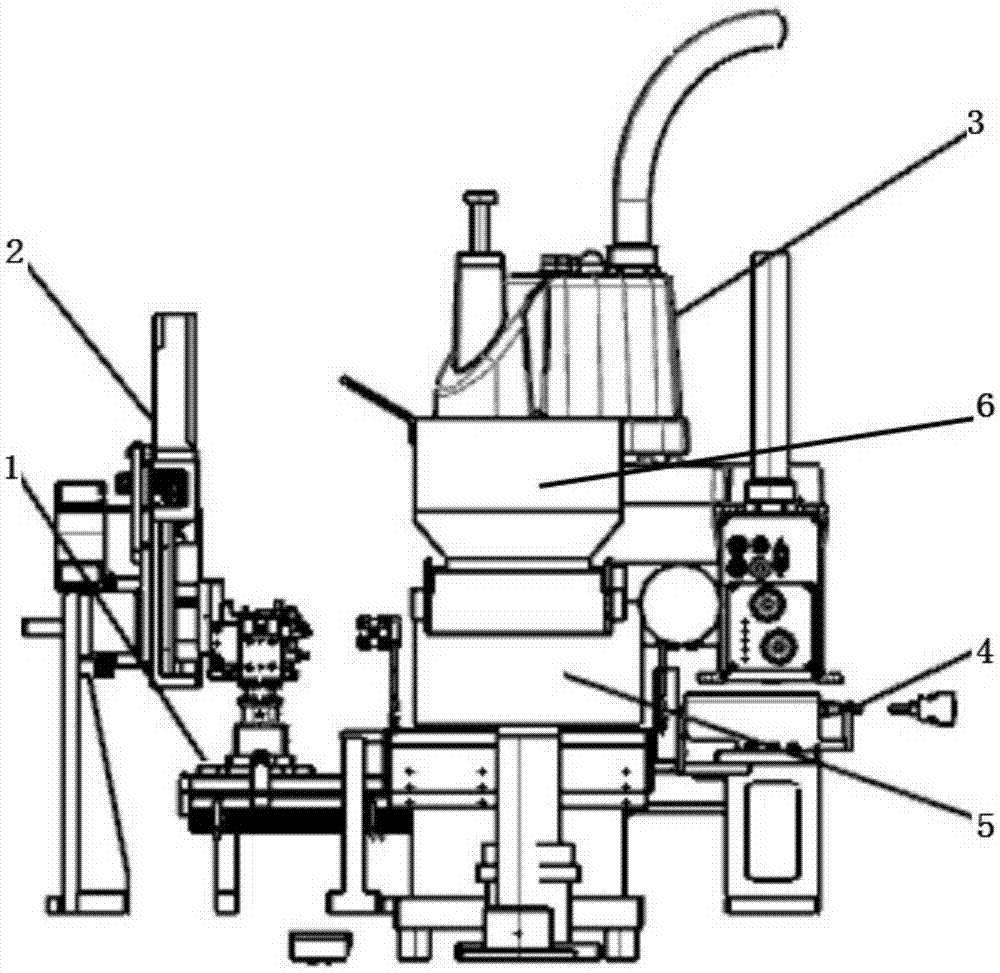

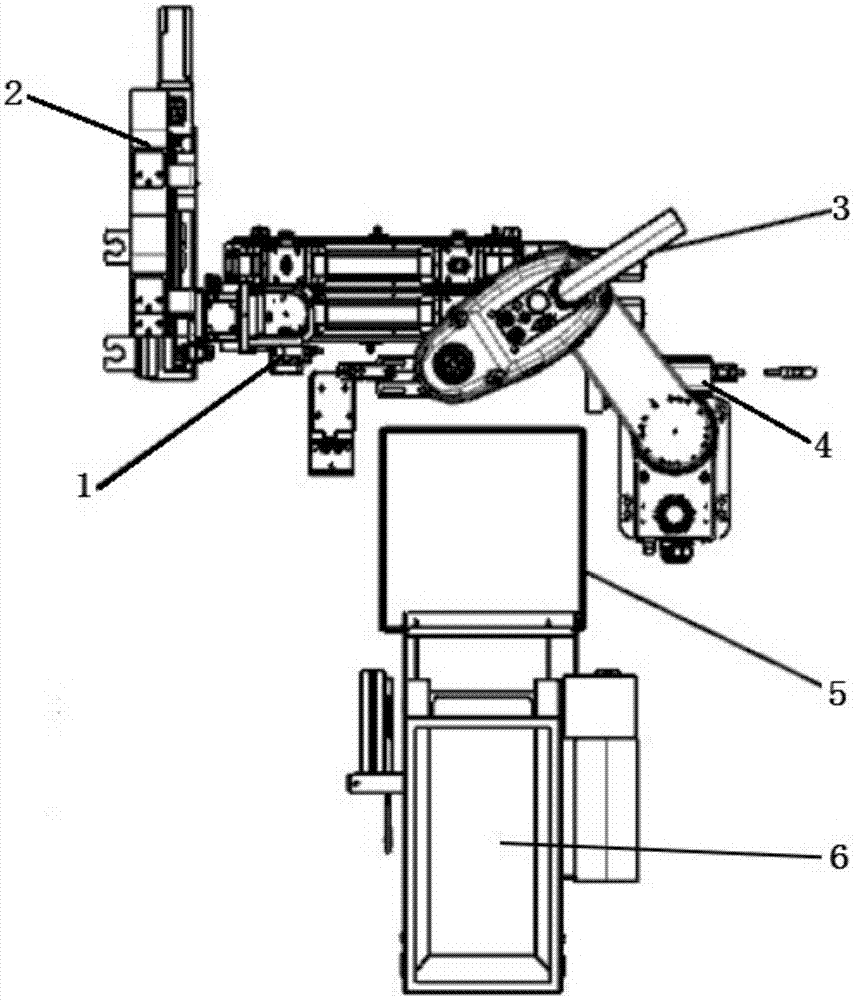

[0026] Such as Figure 1-2 As shown, a flexible feeding system for assembling connectors, the system includes a feeding hoist 6, a feeding vibration unit 5 arranged on one side of the feeding hoist 6, and a feeding vibration unit 5 used in conjunction with The visual image unit 4 and the grabbing manipulator 3, the feeding transfer unit 1 arranged under the grabbing manipulator 3, the assembly robot 2 used in conjunction with the feeding transfer unit 1, and the feeding hoist 6 and the feeding vibration unit 5 respectively , the visual image unit 4, the grasping manipulator 3, the feeding transfer unit 1 and the electrical control box electrically connected to the assembly robot 2.

[0027] Wherein, the feeding vibrating unit 5 includes a linear vibrator and a flat vibrating plate arranged on the linear vibrator, and the linear vibrator is electrically connected to the electric control box through a circuit. The visual image unit 4 is a camera arranged on one side of the flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com