Automatic anti-glare inner rear-view mirror

An interior rearview mirror and anti-glare technology, which is applied in the field of rearview mirrors, can solve problems such as complex control circuit structure and complex production process of color-changing lenses, and achieve good functional effects, short changing time, and guaranteed driving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

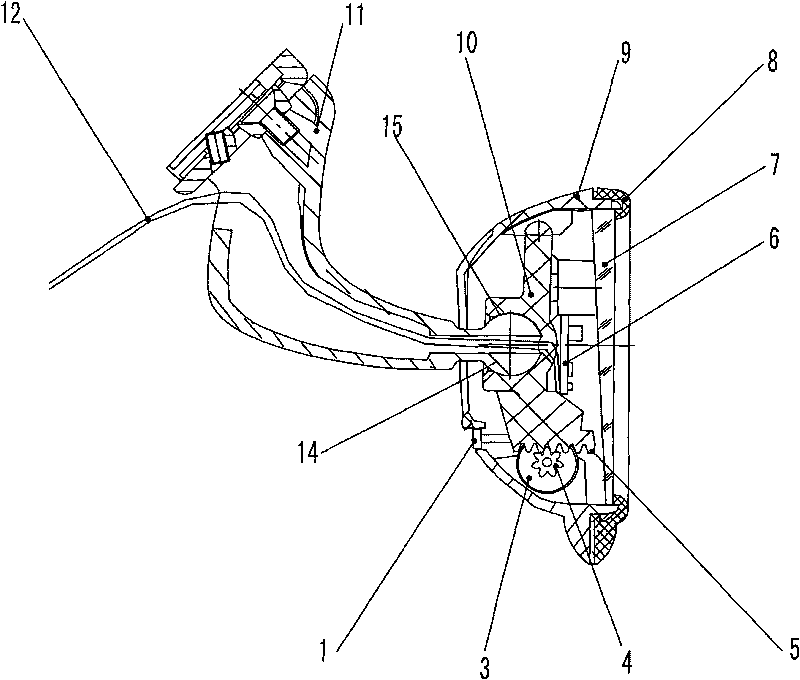

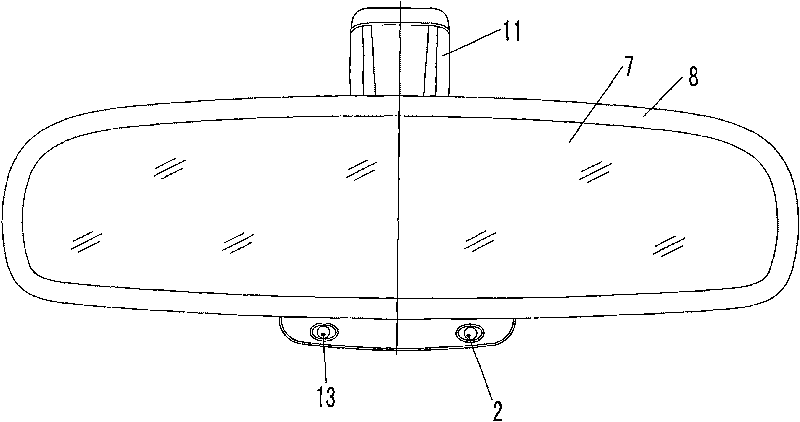

[0039] See figure 1 , Automatic anti-glare inner rearview mirror, including a support 11, the support 11 is fixed on the center of the windshield of the car, a ball head 14 is provided on the support 11, a center hole is opened on the ball head 12, and the support 11 A cavity is also provided inside to facilitate the passage of the wire 12. A concave ball hole 15 is provided in the center of the back of the rotating plate 10, and the ball head 14 of the support 11 is installed in the concave ball hole 15 in the center of the center of the back of the rotating plate 10; the rotating plate 10 is installed on the support 11. In other words, there is a relatively large friction force between the concave ball hole 15 and the ball head 14, that is, the rotating plate 10 needs to apply a relatively large torque to make the rotating plate 10 rotate around the ball head 14, so that the driver After adjusting the position of the inner rear-view mirror, the inner rear-view mirror will not...

Embodiment 2

[0048] See Figure 5 The automatic anti-glare inner rearview mirror of this embodiment is the same as that of Embodiment 1 except that the transmission mechanism is different from that of Embodiment 1. The transmission mechanism of this embodiment includes a rotating sleeve 20 arranged at the bottom of the rotating plate 10 The worm 21 and the worm wheel 22 arranged on the output shaft of the DC motor 3; the worm 21 meshes with the worm wheel 22. When the DC motor 3 is working, the worm wheel 22 and the worm 21 drive the mirror housing 9 to flip relative to the rotating plate 10, In turn, the lens ring 8 drives the anti-glare lens 7 to turn over.

Embodiment 3

[0050] See Image 6 with Figure 7 The automatic anti-glare inner rearview mirror of this embodiment is the same as the first embodiment except that the transmission mechanism is different from that of the first embodiment. The transmission mechanism of this embodiment includes a worm gear transmission mechanism, a large gear 23, and an adjusting rod 24. The worm 25 in the worm gear transmission mechanism is provided on the output shaft of the DC motor 3, and the worm wheel 26 and the large gear 23 are provided on the shaft On the mirror housing 9, the worm 25 meshes with the worm wheel 26, and the worm wheel 26 meshes with the large gear 23; the adjusting rod 24 axially penetrates through the rod holes 29 on the two ribs 27 and 28 in the mirror housing 9, so that there are 24 adjusting rods It can be slid in the axial direction, and the normal direction cannot act alone, and can only be flipped relative to the rotating plate 10 together with the mirror housing 9. A rack 30 mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com